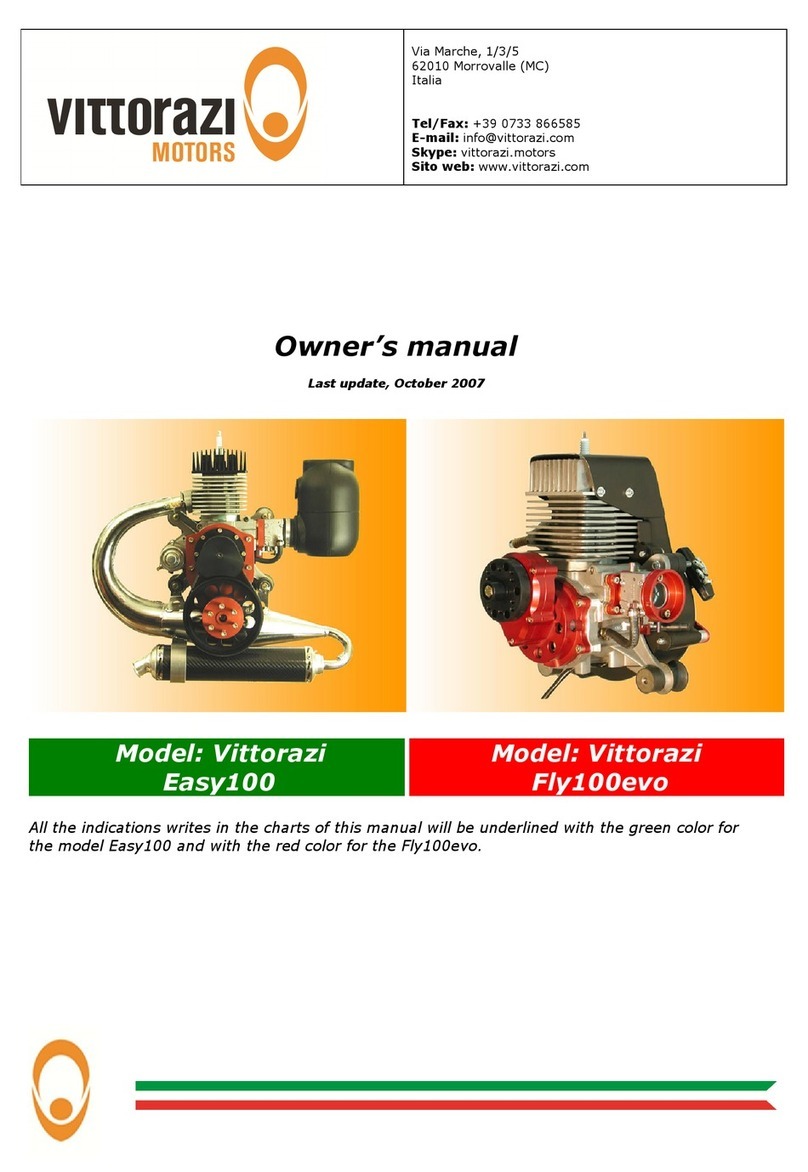

Vittorazi Motors MOSTER 185 EFI User manual

MOSTER 185 EFI

Installation manual

Release V1/2024.

Valid for MY24 version.

Moster 185 EFI - Installation manual –V1/2024 2

Moster 185 EFI - Installation manual –V1/2024 3

Contents

1Introduction 4

2Be careful! Read it completely 6

3Installation 8

3.1 Preparing for installation 9

3.2 Supports to the frame 12

3.3 Electrical system 14

3.4 Battery 24

3.5 Display 31

3.6 Fuel system 35

3.7 Throttle bowden cable 43

3.8 Propeller assembling 46

3.9 Final checks 51

Moster 185 EFI - Installation manual –V1/2024 4

1Introduction

Congratulations and thanks for being a Vittorazi qualified professional.

This manual is intended as a reference point for aircraft manufactures, dealers and professional

people dealing with Vittorazi Motors. Please study this professional manual carefully before

starting the installation activity. The purpose of this manual is to provide all the necessary

information to the professional in order to allow a proper installation of the engine, carried out

autonomously and in total security. The professional manual includes: technical descriptions of

the installation phase and reference values.

All the components of Vittorazi Motors are checked and tested in a process of industrial quality

control before the assembling. Then by sampling the complete motors are checked to assure the

functionality of all the parts through a complete test of twenty minutes on the bench. Note that

the reliability, performance and durability of the engine also strongly depend on the correct

installation of which you are in charge.

In case you need further explanations, you can contact directly the headquarters of Vittorazi

Motors. Please include in the request, the six-digit serial number that identifies the motor (read

3.1 “Preparing for installation”) and a photo of the item in question.

Also take into account the availability of Illustrated Parts Catalogue (IPC), manual updates, service

bulletins, FAQs, other documents in our official website. The video tutorials are available on the

Vittorazi Motors official YouTube channel. Below the links.

IPC, manuals, bulletins, newsletter, warranties, FAQ

https://www.vittorazi.com/en/services/

Vittorazi Official YouTube channel: video and free tutorials available

https://www.youtube.com/user/VITTORAZIMOTORS

Moster 185 EFI - Installation manual –V1/2024 5

Reading tips:

Attention, warning, danger, risk

Any situation or condition which may result in a serious danger

Recommendation, caution, important advice

Moster 185 EFI - Installation manual –V1/2024 6

2Be careful! Read it completely

To fly in total safety, you must read the following recommendations:

•This engine is not certified. This engine does not fulfil airworthiness regulations. The

products are dedicated to non-certified aircraft and flying as a recreational or sporting

activity.

•Final-user must be aware that the engine can stop, break or shut down at any time.

Such an event may require an immediate and forced landing in inadequate,

congested or impervious areas, with the possibility in the end of causing the death of

the pilot or other persons involved.

•The aircraft equipped with this engine must be conducted in full compliance with

rules and regulations in force relating to the activity of leisure and sport aviation, with

regard to the country in which the operations are carried out.

•Vittorazi Motors and its distributors decline any direct or indirect responsibility related

to this kind of activity. By using a new engine, the owner agrees that these terms and

conditions have been accepted at the time of purchase of the product.

•The engine is not covered by any liability insurance. The use of the engine

automatically determines the assumption of all risks and personal liability for personal

injury or damage to third parties resulting from the activity.

•Improper use of the products or improper technical service (in relation to the

specifications contained in the user, installation and maintenance manual) will held

harmless the company from any liability for any damage due to the malfunctioning

and immediately void the warranty of the product. So, do not use the motor if it has

not been properly maintained or if it has not been used correctly over time.

•Vittorazi does not assume any responsibility for those engines that are used with parts

that are not original, not approved, modified or that have suffered an improper use.

Use of spare parts not original and not recognized by Vittorazi, can make the engine

dangerous and will void the warranty.

•Unauthorized modifications to the motor, to the reduction, to the propeller can

invalidate the warranty of the motor and can compromise the reliability of the aircraft

and its safety. In case it is necessary to intervene, we invite you to contact an authorized

dealer Vittorazi.

•Some geographical areas, due to particular weather conditions such as pressure,

temperature and humidity can affect the performance of the engine. Before taking

off, test the engine on the ground and make sure it does not behave abnormally.

Moster 185 EFI - Installation manual –V1/2024 7

•Always start the engine on a flat and clean surface, without stones or sand. During all

phases in which the engine is kept running near the ground (such as heating, take off,

landing) it is necessary to maintain a safe distance from the engine. A good safety

distance is 100 meters in every direction.

The following engine speed limits must be respected to avoid engine failures, to keep

the warranty valid and to have a correct maintenance scheduling according to the

Vittorazi program:

•Do not keep the engine at full revs for more than 60 seconds.

•Do not keep revs higher than 7.000 RPM during long cruising flights or long climbs.

The average power delivered by the engine during a flight should remain below the

indicated threshold. Contact the aircraft manufacturer for further clarification.

The temperature limit of CHT is 208° Celsius. Do not persist above this temperature

threshold, engine overheating and irreversible damage could occur.

When the CHT exceeds 208°C, the ECU system generates a small engine speed reductions

that last a fraction of a second, without compromising the flight dynamics, just to call the

pilot's attention. This safety function disappears when the speed is reduced below 7400 rpm.

Exceeding the EGT limit is shown on the display with the word "Temp" flashing in the top

right corner. Proceed at reduced power and once on the ground contact your dealer.

LiPo batteries are high-tech products but potentially dangerous to property, animals or

people, especially if used improperly or without experience.

Moster 185 EFI - Installation manual –V1/2024 8

3Installation

This section refers to mechanical and electrical installation, so it is reserved for the aircraft

manufacturer (paramotor, hang glider, ultralight and others) who has qualified personnel in the

mechanical, electrical and aeronautical fields. By following the instructions, it will be possible to

assemble the engine correctly.

Please refer further to the aircraft manual for operation, installation, maintenance. A correct and

safe operation of the same engine, cannot be guaranteed in other applications, than those

approved by the aircraft manufacturer.

Any procedure of installation, maintenance and/or repair of the products must be carried out

exclusively with the original Vittorazi parts and tools specified by Vittorazi, in compliance with the

specifications contained in the user, installation and/or maintenance manual of the products; to

ensure maximum safety and performance of the products, the above-mentioned procedures will

be carried out by mechanics with proven experience in the Ultralight aviation or general aviation

or with experience gained by Vittorazi professional training courses. Failure to do so, will hold

harmless the company from any liability for any damage due to the malfunctioning and

immediately void the warranty of the product.

Vittorazi shall not be liable for any damages deriving from the installation of its motors onto

aircraft and/or equipment that require airworthiness certifications.

Frame design must give strong consideration to the following sections: 3.2 Supports to the frame,

3.3 Electrical system, 3.4 Battery, 3.6 Fuel system. It is also recommended to carry out the checks

described in the relevant paragraph (3.9 Final checks) before starting the engine.

Moster 185 EFI - Installation manual –V1/2024 9

3.1 Preparing for installation

On delivery of the engine:

•Check that the six-digit engine serial number on the engine casing matches the number

on the packaging box.

Check that there is no damage of any kind related to the transport of the engine.

Engine openings are closed by special plugs to prevent the entry of foreign substances and

moisture. These should only be removed when necessary for installation.

Moster 185 EFI - Installation manual –V1/2024 10

Moster 185 EFI - Installation manual –V1/2024 11

Moster 185 EFI - Installation manual –V1/2024 12

3.2 Supports to the frame

The engine is fixed to the aircraft frame through the 4 spacers (1) that are connected to the 4

dampers (2). Do not replace the dampers (2), as they are designed and approved for this engine.

Use M8 screws for fixing, taking care not to rotate and damage the rubber part. The vibration

dampers reduce the vibrations transmitted from the engine to the frame. For safety reasons,

straps are fitted around the vibration dampers.

The components to be installed, in particular the fuel tank, fuel hoses and the battery, must

have a certain distance from the exhaust system as high temperatures are reached during

engine operation.

Moster 185 EFI - Installation manual –V1/2024 13

For safety reasons, the engine has the airbox already fitted. It can be removed if necessary,

during installation. When reinstalling it, check that the airbox has been fitted correctly, and

in particular that the fixing clamp (1) on the sleeve and the safety strap (2) have been securely

fastened.

Moster 185 EFI - Installation manual –V1/2024 14

3.3 Electrical system

3.3.1 Signal wiring

The signal wiring is composed by the injector signal cable (1), the air rotary valve signal cable

(2), the ground cable (3), the start/stop button cable (4) and the spark coil signal cable (5).

The signal wires are clamped with an M6 F8 rubberized cable clamp (6) and an M6 F8 rubberized

cable clamp (7) that fix the signal cable, an M5 F5 rubberized cable clamp (8) that fix the start/stop

button cable (4) and the coil signal cable (5), an M4x12 screw (9) that fix the ground cable (3) and

an M5 F6 rubberized cable clamp (10) that fix the spark coil signal cable (5).

Signal wiring scheme:

Air rotary valve

Injector

Spark coil

Ground

Stick

Moster 185 EFI - Installation manual –V1/2024 15

Clamp the start/stop button cable to the throttle bowden cable to block the movement of

the start/stop button cable, due to airflow or vibration, that could lead to stress at the

connector root or loss of connection.

Clamp the throttle bowden cable to the frame to block the movement of the throttle

bowden cable, due to the movement of the throttle, airflow or vibration, that could generate

stress on the bowden cable fixing and the root of the start/stop button cable.

Position the fastening point at least 20 cm away from the throttle bowden fixing support.

Throttle

bowden

cable

Start/Stop

button cable

Frame

Throttle

bowden

cable

Moster 185 EFI - Installation manual –V1/2024 16

3.3.2 Power supply wirings

The power supply wiring is composed by the ECU supply cable (1), the EGT and CHT probes

cable (2), the starter relay power cable (3).

The power supply wires are clamped with an M5 F6 rubberized cable clamp (4) that fix the ECU

supply cable (1) and the EGT and CHT probes cable (2), a plastic cable clamp (5) that fix the EGT

and CHT probes cable (2) and two plastic cable clamps (6, 7) that fix the starter relay power cable

(3).

Power supply wiring scheme:

Starter relay

EGT sensor

CHT sensor

ECU supply

Moster 185 EFI - Installation manual –V1/2024 17

3.3.3 Electric starter wiring

The Electric starter wires are clamped with three M6 F8 rubberized cable clamps (1, 2, 3) and a 26-

92 mm plastic cable tie (4).

Electric starter wiring scheme:

Moster 185 EFI - Installation manual –V1/2024 18

When the battery XT60 connector is connected, the starter wiring is powered, take care not

to cut the cables or create a short circuit.

A 60A fuse (BF1 type) is housed inside the upper battery compartment.

Electric starter:

Moster 185 EFI - Installation manual –V1/2024 19

Fix the ECU and the starter power cables to the frame, in an appropriate position to facilitate

connection with the battery and to block the movement of the cables, due to airflow or

vibration, that could generate stress on the roots of the cables.

Place the fixing point at about 10 cms from the connectors.

Frame

Supply

cables

Connectors

Moster 185 EFI - Installation manual –V1/2024 20

Do not fix the connectors to the frame, this could damage the connectors due to vibration,

creating the risk of short-circuiting and/or engine shutdown during flight.

Table of contents

Other Vittorazi Motors Engine manuals

Vittorazi Motors

Vittorazi Motors Moster 185 Classic User manual

Vittorazi Motors

Vittorazi Motors Easy100 User manual

Vittorazi Motors

Vittorazi Motors Moster 185 Factory R User manual

Vittorazi Motors

Vittorazi Motors COSMOS 300 User manual

Vittorazi Motors

Vittorazi Motors Moster 185 Plus User manual

Vittorazi Motors

Vittorazi Motors Easy100 User manual

Popular Engine manuals by other brands

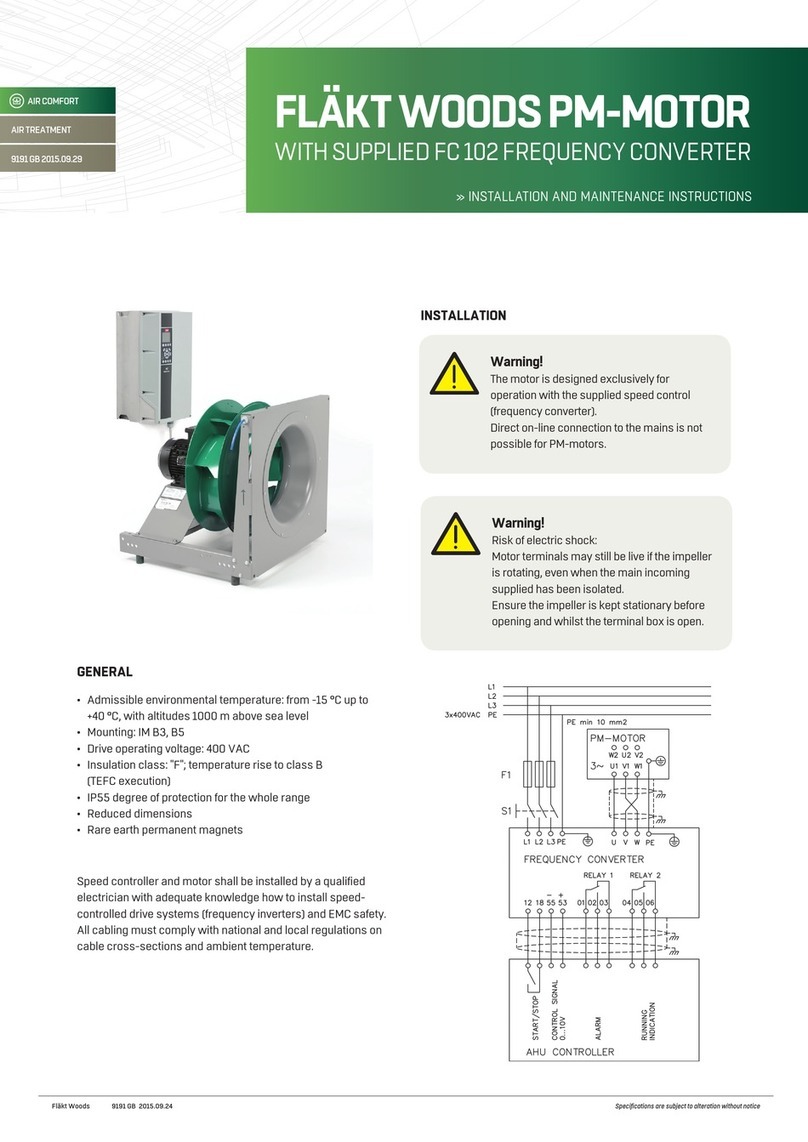

flakt woods

flakt woods PM Installation and maintenance instructions

HunterDouglas

HunterDouglas MOTOLUX TURNILS 802142000 Programming instructions

Oriental motor

Oriental motor 3TK6GN-AUL operating manual

Vanguard

Vanguard 25E300 Repair manual

Man

Man D 2866 E operating instructions

DANA

DANA 4360-34 parts list