VivaldiCopyright2012©V1.0 2

Table of contents

INTRODUCTION............................................................................................................................................. 3

VIVALDI PUMPS - TECHNICAL FEATURES................................................................................................ 4

CONCERTORANGESERIESV4

Explodedviewofallmodels..................................................................................................................................5

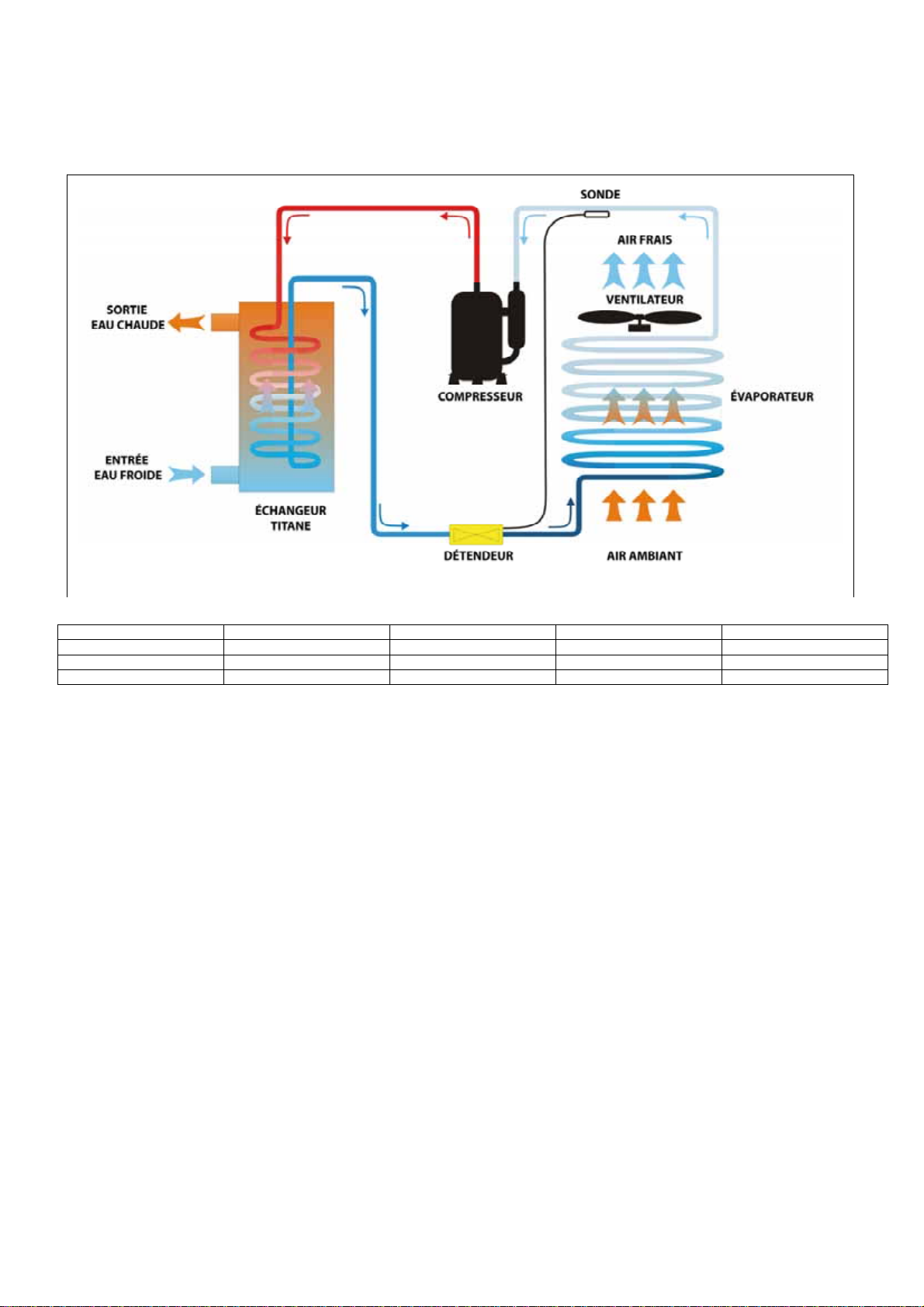

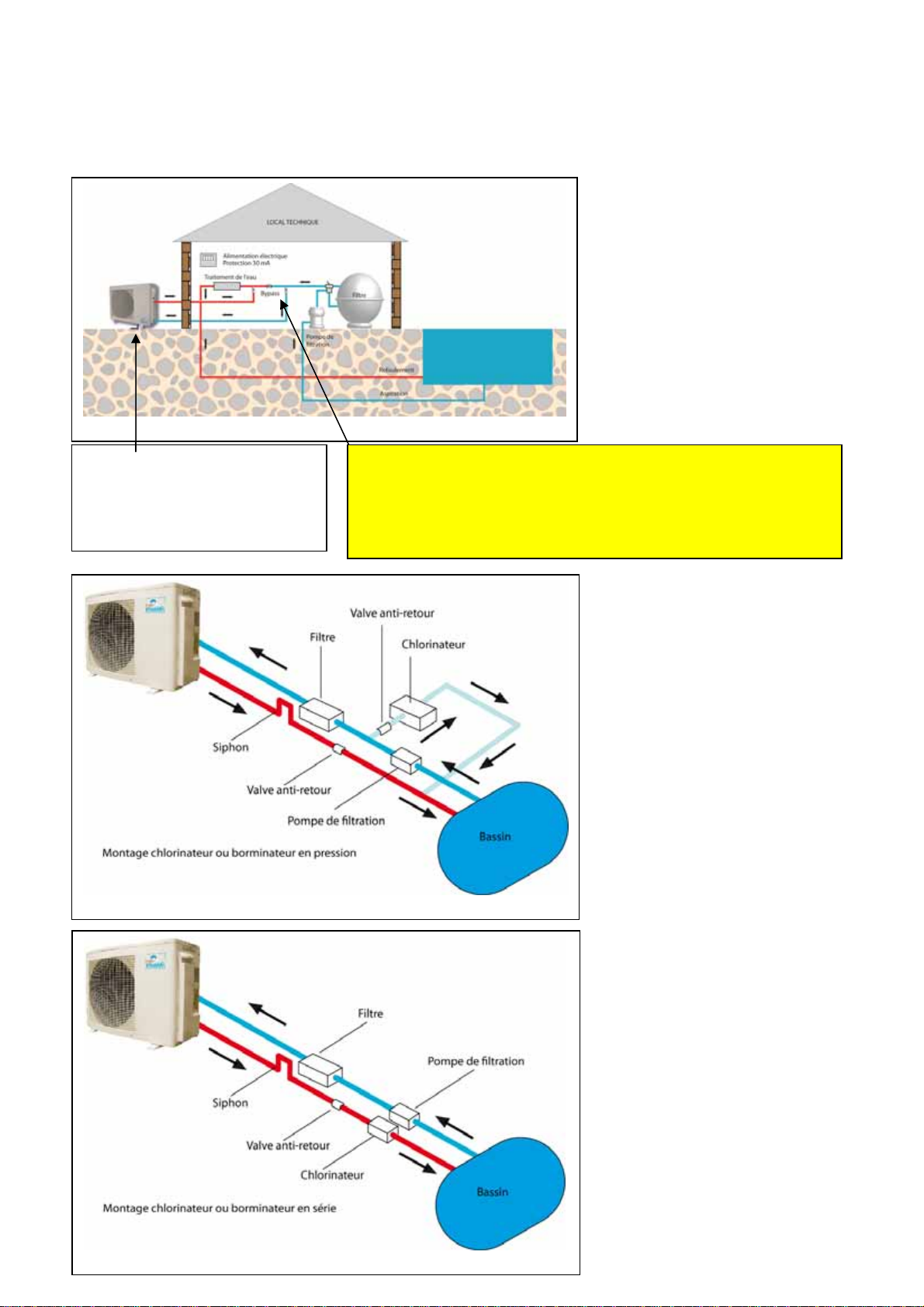

GENERAL DIAGRAM OF THE HEATING AND COOLING CIRCUIT........................................................... 6

Heatingmode .......................................................................................................................................................6

Coolingmode ........................................................................................................................................................6

CONTROL AND SAFETY SYSTEM............................................................................................................... 7

3controldevices ...................................................................................................................................................7

4safetysystems....................................................................................................................................................7

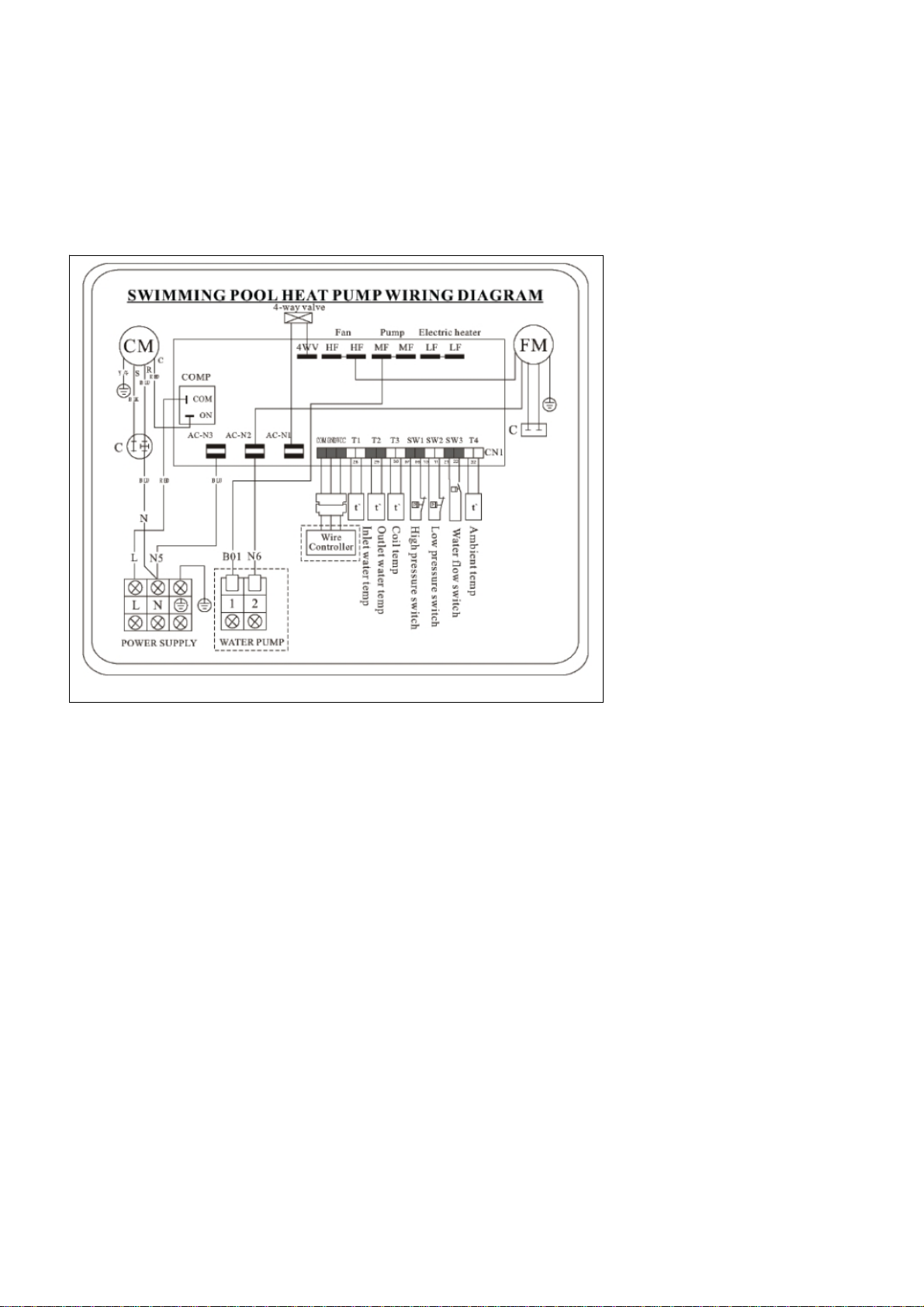

DIAGRAMS OF THE ELECTRONIC CARDS ................................................................................................ 8

Concertorange–V30,V40,V50,V60,V70 ......................................................................................................8

HEAT PUMP INSTALLATION RULES.......................................................................................................... 9

Minimumdistancefromobstacles:.......................................................................................................................9

Distancerequiredfromthepool ...........................................................................................................................9

Otherinstallationprecautions ............................................................................................................................10

ElectricalstandardC15‐100section702.............................................................................................................10

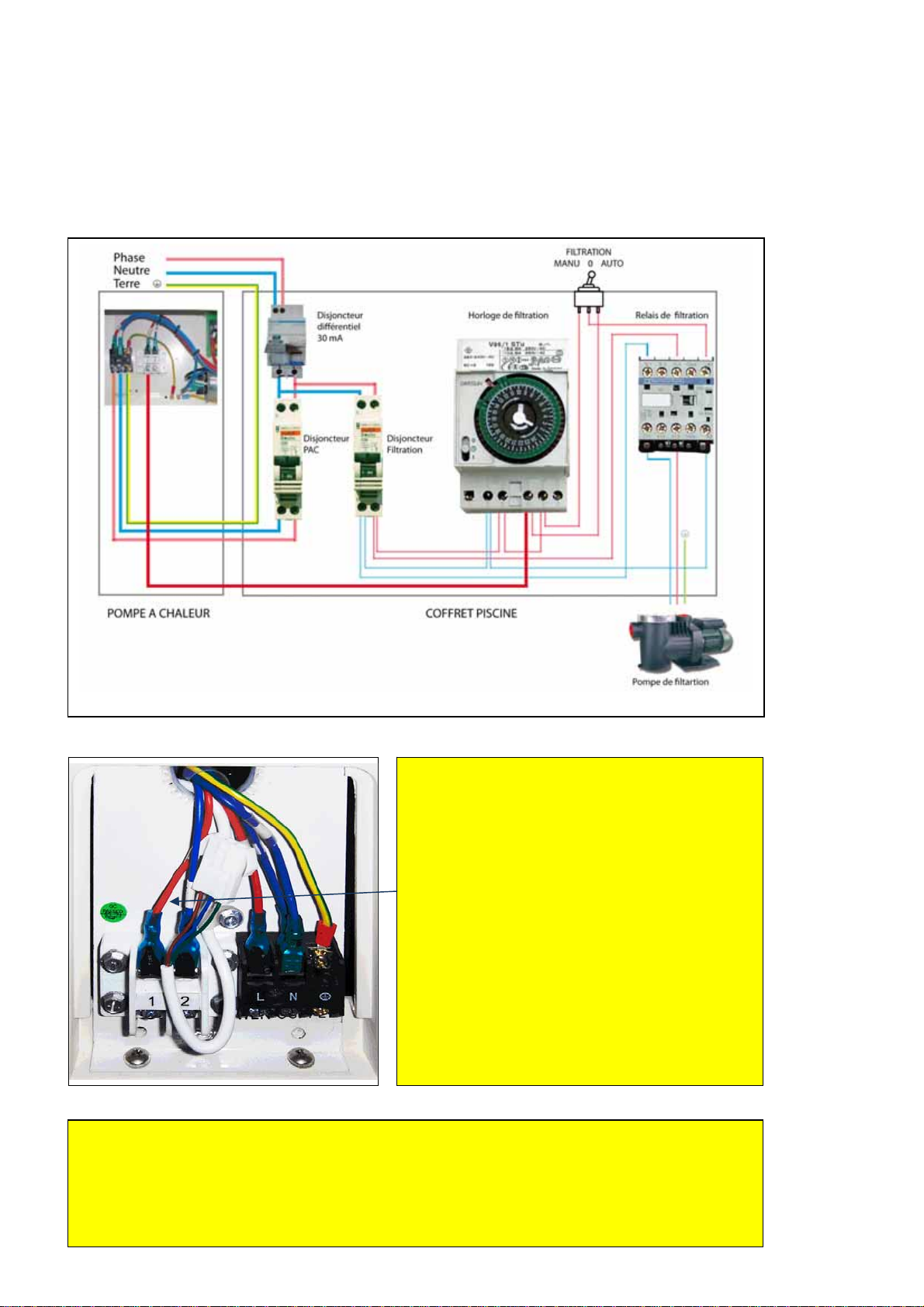

ELECTRICAL INSTALLATION ....................................................................................................................11

Filterpumpservocontrol ....................................................................................................................................12

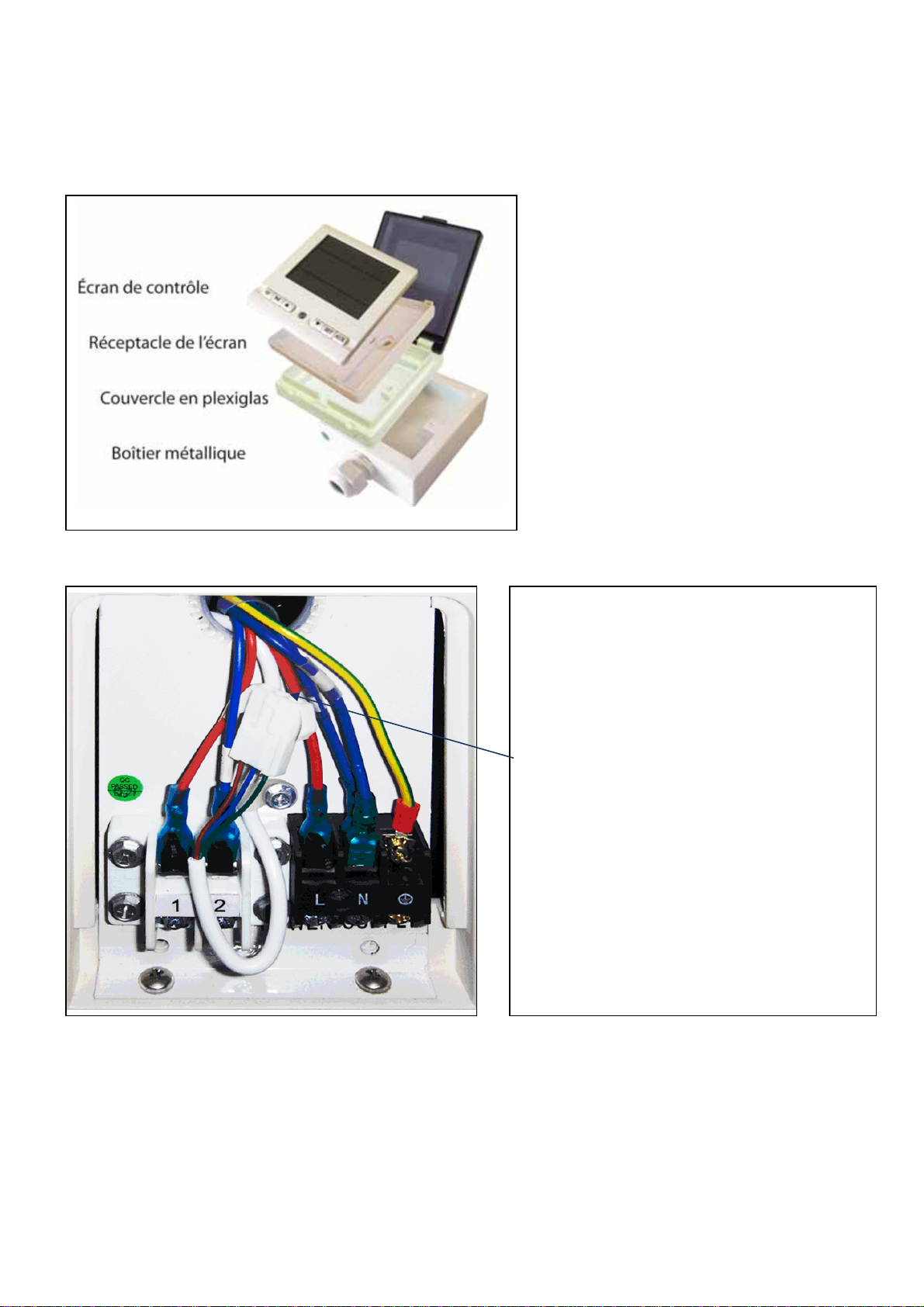

Assemblyandinstallationofthecontrolbox......................................................................................................13

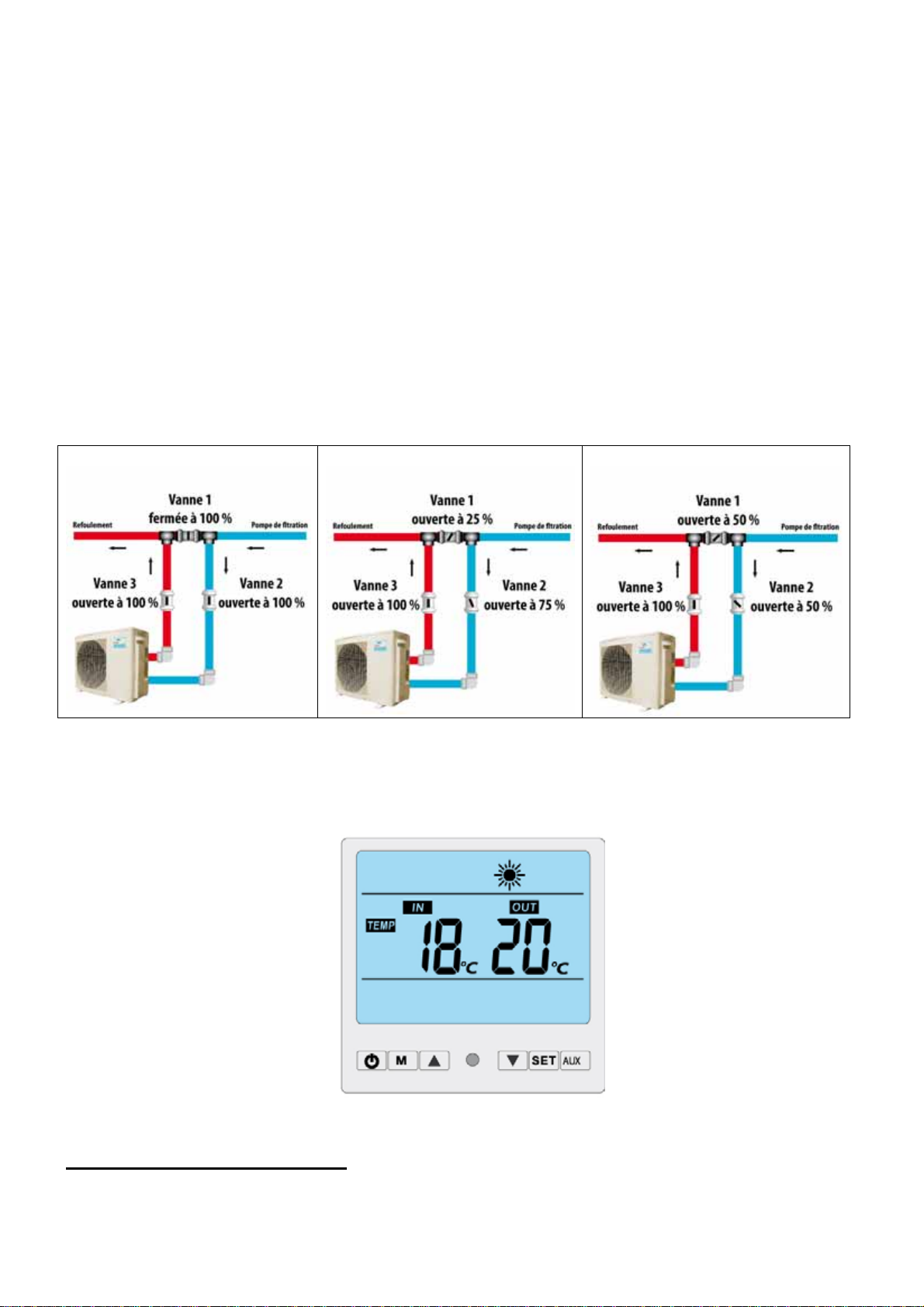

–HYDRAULIC INSTALLATION.................................................................................................................... 13

EXAMPLESOFCONNECTIONS14

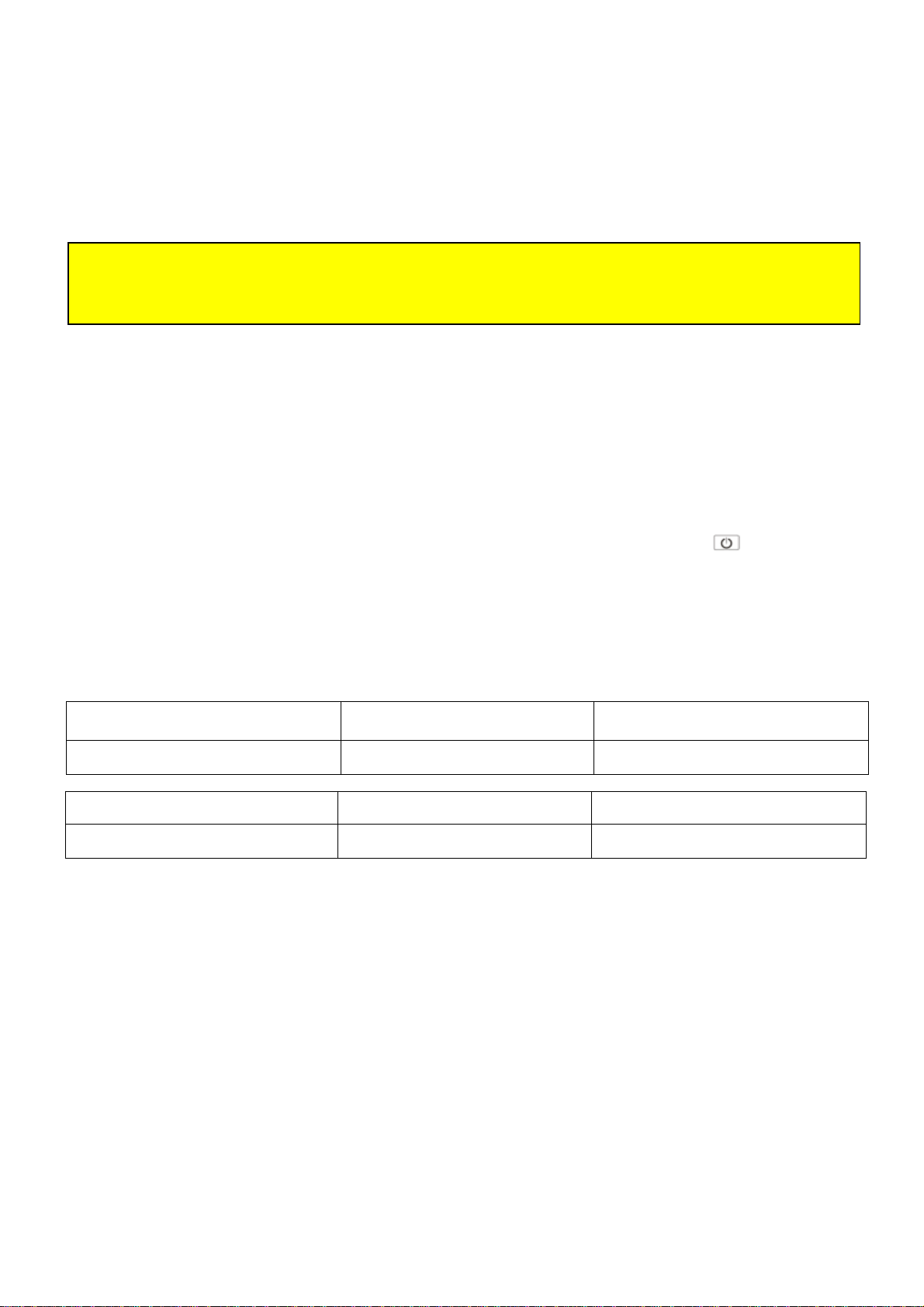

Bypass(divertervalves) ......................................................................................................................................15

INITIAL COMMISSIONING........................................................................................................................... 16

Calculatethetemperatureincreasetime ...........................................................................................................16

Operatingprinciple .............................................................................................................................................17

SafetyInstructions ..............................................................................................................................................17

Recommendedoperatingtemperature ..............................................................................................................17

Operationduringcoldseasons ...........................................................................................................................17

Defrostcycles ......................................................................................................................................................17

Descriptionofthecontrolpanel..........................................................................................................................18

Selectmode.........................................................................................................................................................18

Configurationoftheheatpump .........................................................................................................................19

Errormessages/Errorfixing(1):.........................................................................................................................20

Errormessages/Errorfixing(2):.........................................................................................................................21

Errormessages/Errorfixing(3):.........................................................................................................................22

Tableoferrorcodesandcorrectiveaction..........................................................................................................23

GENERAL MAINTENANCE .........................................................................................................................25

Cleaningthefilterandthebasket.......................................................................................................................25

Adjustmentofthebypassvalves.........................................................................................................................25

Controlofwaterchemistry .................................................................................................................................25

Recommendedwaterchemistryvalues ..............................................................................................................25

Wintering ..............................................................................................................................................................1

Cleaningtheevaporator .....................................................................................................................................25

Removinglimescale ............................................................................................................................................25

GUARANTEE................................................................................................................................................26

Durationandpurposeoftheguarantee .............................................................................................................26

LimitsoftheGuarantee ......................................................................................................................................26

Repairsunderguarantee ....................................................................................................................................26

DECLARATION OF EC CONFORMITY....................................................................................................... 28