4

3 - INSTALLATION

•Priortoallservicingorotheractionsontheequipment,installation,commissioning,operation,ormaintenance,thepersonnel

in charge of these operations shall become familiar with the instructions and recommendations provided in the installation

manual of the unit as well as the elements of the project's technical file.

•The personnel responsible for receiving the unit must conduct a visual inspection in order to identify all damage to which the

unit may have been subjected during transport: refrigerating circuit, electrical cabinet, cassis and cabinet.

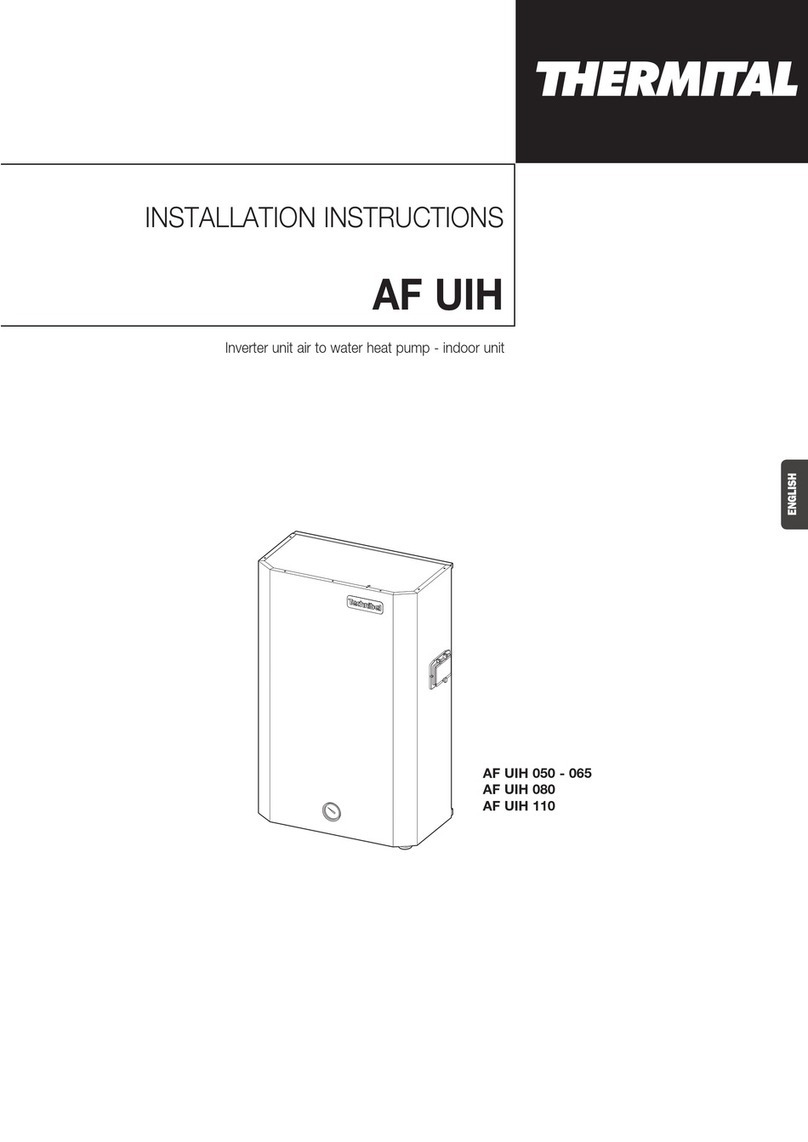

3000

300

1000

300

A

C

learances to be respected

2 lower side panels

must be removed to

gain access to the 2

screws which secure

the unit to the

wooden base.

•The unit must not be installed near the following:

-sources of heat,

-combustible materials,

-return/air intake of an adjacent building.

•The unit must be installed, started, maintained and repaired

by qualified servicing personnel in compliance with the

requirements of all directives, laws and regulations and in

accordance with standard trade practices.

•During installation, troubleshooting and maintenance

operations, the use of pipes as a step: under the stress, the

pipe may rupture and the refrigerant may cause serious

burns.

•The unit is delivered on a wooden pallet and shrink-wrapped.

•PMERV units are secured to the pallet by two screws for

transport. They can be accessed and extracted by removing

the 2 lower side panels.

•Alift truck may be used to remove the unit from its pallet.

•Handle the unit with care.

•Crane installation: once the plastic film has been removed, the machine may be lifted by placing the hoisting hooks into the

four Ø 22.5 holes.

•Spacers or protective pads should be placed between the slings and body to avoid damage.

•The unit's centre of gravity and weight are indicated on the space requirement diagrams and in the table of the technical

documentation.

•Before installation, verify the following points:

-the unit must be installed outside in an appropriate location and in compliance with environmental requirements (sound

level, integration, etc...),

-the unit’s installation location must be perfectly level and strong enough to support the weight of the unit and must have

adequate inundation protection. Attention: the condensates are not connected to a condensate collector.

-sufficient space around the unit should be provided in order to facilitate servicing and maintenance operations (see

drawing above),

-air suction to the coil and fan discharge must not be obstructed,

-install the unit above the region’s average snowfall level,

-vibrations and noise must not be transmitted to adjacent buildings,

-install the machine on anti-vibration pads and fit hoses on piping elements, as required,

-if necessary, consult an acoustics specialist concerning the unit’s optimum location.

•AVOID:

-excessive exposure to sea-air or corrosive gases,

-the proximity of the extractor fan,

-projections of mud (next to a roadway or path, for example),

-areas where there is strong wind blowing against the unit's air exhaust.

•Protection index of the unit:

-IP 44 : for the electrical equipment,

(IPXXB : for the mechanical hazards).

4 - CONNECTIONS

4.1 - HYDRAULIC CONNECTION

•Connect the water pipes to the corresponding connections:

-PMHRV 2044 to 2072 : male 1"1/2 (40 x 49).

•Connect the hydraulic filter onto the water intake. Also provide 2 isolation valves for intake cleaning purposes.

•The pipes must be at a sufficient distance from the removable panels to enable servicing operations to be performed.

•Make the connection with flexible hoses preferably.

•The diameter of the pipes must be calculated according to the installation (take care with high head losses).

AClearance must be 300 mm.