Vivendi ELGA PURELAB Ultra User manual

PURELAB Ultra

PURELAB Ultra

OPERATOR MANUAL

OPERATOR MANUAL

VERSION 1 UK –05/02

REF: MANU37248

VERSION 1 UK –05/02

REF: MANU37248

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page i

Copyright Note

ELGA®and PURELAB®are registered trademarks of Vivendi Water

Systems Ltd.

The information contained in this document is the property of ELGA

LabWater, a division of Vivendi Water Systems Ltd. and is supplied

without liability for errors or omissions.

No part of this document may be reproduced or used except as

authorized by contract or other written permission from Vivendi Water

Systems Ltd. The copyright and all restrictions on reproduction and

use apply to all media in which this information may be placed.

Vivendi Water Systems Ltd. pursue a policy of continual product

improvement and reserve the right to alter without notice the

specification, design, price or conditions of supply of any product or

service.

© Vivendi Water Systems Ltd. 2002

All rights reserved.

Publication ref: MANU37248

Version 1 - 05/02

ELGA is a trading name of Vivendi Water Systems and USFilter

(USA).

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page iii

TABLE OF CONTENTS

1. INTRODUCTION ............................................................1

1.1 Product Range ......................................................1

1.2 Use of this Manual ................................................1

1.3 Customer Support .................................................1

2. HEALTH AND SAFETY NOTES....................................2

2.1 Electricity...............................................................2

2.2 Ultraviolet Light .....................................................2

2.3 Sanitization Chemicals..........................................2

2.4 Control of Substances Hazardous to Health

(COSHH) ...............................................................2

3. PRODUCT AND PROCESS DESCRIPTION .................3

3.1 Product Description...............................................3

3.2 Process Description ..............................................4

3.3 Technical Specification .........................................9

4. CONTROLS .................................................................12

5. INSTALLATION INSTRUCTIONS ...............................13

5.1 Unpacking the PURELAB Ultra..........................13

5.2 Positioning the PURELAB Ultra .........................13

5.3 Connecting the PURELAB Ultra.........................15

5.4 Initial Controller Set-Up .......................................17

5.5 Setting Up Password / Resetting Replacement

Timers .................................................................22

5.6 Initial Start Up......................................................24

5.7 POU Filter Installation (LC134) - Optional

Accessory............................................................26

6. OPERATION ................................................................27

6.1 Intermittent or Continuous Recirculation .............27

6.2 Manual Dispense ................................................28

6.3 Volumetric Dispense ...........................................29

6.4 Automatic Calibration ..........................................30

6.5 Water Supply Flush.............................................30

7. MAINTENANCE ...........................................................31

7.1 Replacing the Purification Packs.........................31

7.2 Replacing the Ultra-Microfilter (LC109)...............33

7.3 Replacing the Ultrafilter (LC151).........................35

7.4 Replacing the Ultraviolet Lamp

(LC105 and LC118).............................................37

7.5 Replacing the Point-Of-Use Filter (LC134)..........38

7.6 Cleaning the Inlet Strainer (External) ..................39

TABLE OF CONTENTS - CONT'D

PURELAB Ultra Operator Manual ELGA

Page iv PURELAB Ultra Version 1 - 05/02

8. SANITIZATION PROCEDURES.................................. 40

8.1 CT1 Sanitization Tablet - Safety Information ...... 42

9. TROUBLE SHOOTING................................................ 43

10. CONSUMABLES AND ACCESSORIES ..................... 44

11. KEY TO CONTROL PANEL........................................ 45

11.1 Icons ................................................................... 45

11.2 Alarm Conditions................................................. 46

11.3 Replacement Timers........................................... 46

11.4 Quality Alarms..................................................... 47

12. WARRANTY/CONDITIONS OF SALE ........................ 48

13. USEFUL ADDRESSES ............................................... 50

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 1

1. INTRODUCTION

1.1 Product Range

This operator manual has been prepared for the PURELAB Ultra

product models:

PURELAB Ultra Scientific

PURELAB Ultra Bioscience

PURELAB Ultra Genetic

PURELAB Ultra Ionic

PURELAB Ultra Analytic

1.2 Use of this Manual

This manual contains full details on installation, commissioning and

operation of the PURELAB Ultra unit. If the instructions in this

handbook are not followed then the performance of this product

and/or the safety of the user may be compromised.

1.3 Customer Support

Service support and consumable items are available from your local

supplier or distributor. Refer to customer service contact details

shown at the end of this publication.

PURELAB Ultra

PURELAB Ultra Operator Manual ELGA

Page 2 PURELAB Ultra Version 1 - 05/02

2. HEALTH AND SAFETY NOTES

PURELAB Ultra products have been designed to be safe, however, it

is important that personnel working on these units understand any

potential dangers. All safety information detailed in this handbook is

highlighted as WARNING and CAUTION instructions. These are used

as follows:

WARNING! WARNINGS ARE GIVEN WHERE FAILING

TO OBSERVE THE INSTRUCTION COULD

RESULT IN INJURY OR DEATH TO

PERSONS.

CAUTION! Cautions are given where failure to

observe the instruction could result in

damage to the equipment, associated

equipment and processes.

2.1 Electricity

It is essential that the electrical supply to the PURELAB Ultra is

isolated before any items are changed or maintenance work

performed.

The ON/OFF switch is located at the left-hand side of the unit. The

mains power lead is located just behind the ON /OFF switch.

WARNING! THIS APPLIANCE MUST BE EARTHED.

The main water supply should be isolated and residual pressure

released prior to removal of any Purification Packs or carrying out

work on the unit.

Switching off the electrical supply will isolate the source of mains

water pressure.

2.2 Ultraviolet Light

WARNING! UNDER NO CIRCUMSTANCES SHOULD

THE LAMP BE CONNECTED AND

ACTIVATED WHEN OUTSIDE THE

HOUSING.

The Genetic, Analytic and Ionic units are fitted with an ultraviolet lamp.

The UV lamp is enclosed in a stainless steel chamber ensuring that

the operator will not be exposed to UV light.

2.3 Sanitization Chemicals

During the sanitization cycle a CT1 sanitization tablet is used and

relevant safety information is included in this handbook. A safety data

sheet conforming to COSHH regulations is also provided with the

tablets and should be read before a tablet is used.

2.4 Control of Substances Hazardous to Health (COSHH)

Material safety data sheets covering the various replaceable

Purification Packs are available upon request. Contact your local

supplier or distributor.

Fuse

ON/OFF

switch

Mains

p

ower lead

Mains power socket

Mains Power Supply

UV Lamp

Ultra with UV Lamp

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 3

3. PRODUCT AND PROCESS

DESCRIPTION

3.1 Product Description

The PURELAB Ultra water purification unit has been specifically

designed to provide a supply of ultrapure water with very low levels

of impurities for laboratory, medical and industrial applications.

The PURELAB Ultra can be bench, underbench or wall mounted with

an optional wall mounting kit. A range of accessories is available to

complement the unit (see Section 10. - Consumables and

Accessories, for detail).

Control Panel Dispense Nozzle Dispense Controller

Door

PURELAB Ultra

The PURELAB Ultra range of water purification units has been

designed to provide the ultimate in high purity water for laboratory

applications. The products need to be fed with pre-treated water,

typically from a reverse osmosis supply. They can be operated directly

from a ringmain feed as point of use polishers, with or without local

buffer storage, using a Docking Vessel or suitable reservoir.

Alternatively, they can be supplied from a local pre-treatment/storage

system, for example a PURELAB Prima and Docking Vessel

combination.

PURELAB Ultra Operator Manual ELGA

Page 4 PURELAB Ultra Version 1 - 05/02

3.2 Process Description

Scientific

Pre-treated water enters via an inlet solenoid, passes

through a flow sensor and is pumped through the primary

purification pack, an intermediate water quality sensor, a

polishing purification pack and final temperature and water

quality sensors before being dispensed or recirculated

through a non-return valve back to the pump inlet.

The first purification pack removes most of the impurities

from the water and the intermediate water quality sensor then

measures the resistivity of the water from the first pack to

check when it needs to be replaced.

Any remaining ionic and organic impurities are removed by

the second polishing purification pack. Product water

resistivity and temperature are measured before dispense.

Solenoid

Valve

NRV

Feedwater Inlet

(Pre-purified Water) Flow

Sensor Pump

Solenoid Valve

Drain

Purified Water

Outlet

Primary

Purification

Pack

Polishing

Purification

Pack

0.2µm Point-of-use Filter

(Optional)

Dispense Controller

Outlet Water

Quality Sensor

Temperature

Sensor

Intermediate

Water

Quality Sensor

Solenoid Valve

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 5

Bioscience

Pre-treated water enters via an inlet solenoid, passes

through a flow sensor and is pumped through the primary

purification pack, an intermediate water quality sensor, a

polishing purification pack, an ultrafilter and final temperature

and water quality sensors before being dispensed or

recirculated through a non-return valve back to the pump

inlet.

The first purification pack removes most of the impurities

from the water and the intermediate water quality sensor then

measures the resistivity of the water from the first pack to

check when it needs to be replaced.

Any remaining ionic and organic impurities are removed by

the second polishing purification pack; the ultrafilter removes

pyrogens, bacteria and other microbial impurities as well as

particles. Product water resistivity and temperature are

measured before dispense.

0.2µm Point-of-use Filter

(Optional)

Purified Water

Outlet

Solenoid Valve

Flow

Sensor

Feedwater Inlet

(Pre-purified Water)

Intermediate

Water

Quality Sensor

Temperature

Sensor

Outlet Water

Quality Sensor

Solenoid Valve

Drain Drain

Primary

Purification

Pack

Polishing

Purification

Pack

Pump

NRV

Dispense Controller

Flush

Solenoid

Valve

Ultrafiltration

Membrane

Solenoid

Valve

PURELAB Ultra Operator Manual ELGA

Page 6 PURELAB Ultra Version 1 - 05/02

Genetic

Pre-treated water enters via an inlet solenoid, passes

through a flow sensor and is pumped through the primary

purification pack and an intermediate water quality sensor.

The water then flows through a UV chamber, further

resistivity and temperature sensors, a polishing purification

pack, an ultrafilter and final temperature and water quality

sensors before being dispensed or recirculated through a

non-return valve back to the pump inlet.

The first purification pack removes most of the impurities

from the water and the intermediate water quality sensor then

measures the resistivity of the water from the first pack to

check when it needs to be replaced.

Purified water flows directly through the UV chamber where it

is exposed to intense UV radiation at wavelengths of 254nm

and 185nm to provide continuous bacterial control and the

photo-oxidation of residual organic impurities. The second

temperature compensated water quality sensor provides data

for TOC monitoring.

Any remaining ionic and organic impurities are removed by

the second polishing purification pack; the ultrafilter removes

pyrogens, bacteria and other microbial impurities as well as

particles. Final water resistivity and temperature are

measured before dispense.

Solenoid Valve

Outlet Water

Quality Sensor

Intermediate

Water

Quality

Sensor

Primary

Purification

Pack

Polishing

Purification

Pack

Dispense

Controller

Drain

Solenoid

Valve

Pump

NRV

Temperature

Sensor

UV Lamp

Drain

Feedwater Inlet

(Pre-purified Water) Flow

Sensor

Solenoid Valve 0.2µm Point-of-use Filter

(Optional)

Purified Water

Outlet

Ultrafiltration

Membrane

Post UV

Quality

Sensor

Temperature

Sensor

Flush

Solenoid

Valve

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 7

Ionic

Pre-treated water enters via an inlet solenoid, passes

through a flow sensor and is pumped through the primary

purification pack and an intermediate water quality sensor.

The water then flows through a UV chamber, a further

resistivity and temperature sensor, a polishing purification

pack, an ultra microfilter and final temperature and water

quality sensors before being dispensed or recirculated

through a non-return valve back to the pump inlet.

The first purification pack removes most of the impurities

from the water and the intermediate water quality sensor then

measures the resistivity of the water from the first pack to

check when it needs to be replaced.

Purified water flows directly through the UV chamber where it

is exposed to intense UV radiation at a wavelength of 254nm

to provide continuous bacterial control.

Any remaining ionic and organic impurities are removed by

the second polishing purification pack; the ultra microfilter

removes bacterial impurities and particles. Product water

resistivity and temperature are measured before dispense.

Feedwater Inlet

(Pre-purified Water)

Solenoid

Valve

Pump

Flow

Sensor

NRV

Solenoid Valve

Drain

Primary

Purification

Pack

Polishing

Purification

Pack

UV Lamp

UMF

Intermediate

Water Quality

Sensor Outlet Water

Quality

Sensor

Temperature

Sensor

Solenoid Valve

Dispense Controller

0.2µm Point-of-use Filter

(Optional)

Purified Water

Outlet

PURELAB Ultra Operator Manual ELGA

Page 8 PURELAB Ultra Version 1 - 05/02

Analytic

Pre-treated water enters via an inlet solenoid, passes

through a flow sensor and is pumped through the primary

purification pack and an intermediate water quality sensor.

The water then flows through a UV chamber, further

resistivity and temperature sensors, a polishing purification

pack, an ultra microfilter and final temperature and water

quality sensors before being dispensed or recirculated

through a non-return valve back to the pump inlet.

The first purification pack removes most of the impurities

from the water and the intermediate water quality sensor then

measures the resistivity of the water from the first pack to

check when it needs to be replaced.

Purified water flows directly through the UV chamber where it

is exposed to intense UV radiation at wavelengths of 254nm

and 185nm to provide continuous bacterial control and the

photo-oxidation of residual organic impurities. The second

temperature compensated water quality sensor provides data

for TOC monitoring.

Any remaining ionic and organic impurities are removed by

the second polishing purification pack; the ultra microfilter

removes bacterial impurities and particles. Product water

resistivity and temperature are measured before dispense.

Feedwater Inlet

(Pre-purified Water)

Solenoid

Valve

Flow

Sensor

Solenoid Valve

Pump

Primary

Purification

Pack

UV Lamp Polishing

Purification

Pack

UMF

0.2µm Point-of-use Filter

(Optional)

Purified Water

Outlet

Solenoid Valve

Intermediate

Water

Quality

Sensor

Temperature

Sensor

Outlet Water

Quality

Sensor

Drain

NRV

Dispense Controller

Post UV

Quality

Sensor

Temperature

Sensor

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 9

3.3 Technical Specification

The Technical Specifications for the PURELAB Ultra are as follows:

Feedwater*

Parameter Limits

Source - Originally from potable supply, then

pre-treated

Preferably reverse osmosis (RO) or filtered service deionisation (SDI) or distilled.

Note: mixed bed or twin bed deionised supplies should be cation limited at exhaustion.

Fouling Index (max) 1 for all models. A 0.2 micron membrane prefilter is recommended for all non-RO feeds.

Service Deionisation (SDI) - MΩ-cm 1 MΩ-cm minimum resistivity at exhaustion.

Reverse Osmosis (RO) - µS/cm Ideally < 30 µS/cm

Free Chlorine 0.05ppm max.

TOC 50ppb max.

Carbon Dioxide 30ppm max.

Silica 2ppm max.

Particulates Filtration down to 0.2 micron advisable to protect internal and/or point of use filters

Temperature 1-40°C - Recommended 10-15°C

Flowrate (maximum requirement) 130 l/hr

Drain requirements (gravity fall with air gap).

Maximum during service

Up to 2 l/min

Feedwater Pressure 0.7bar (10psi), maximum, 0.07bar (1psi) minimum

* Contact technical support for advice on feedwaters outside the range listed.

Note: Different system configurations are available for different feedwater sources. See system set

up.

Dimensions

Height 490mm (19.3")

Width 410mm (16.2")

Depth 365mm (14.4")

Weight

Scientific 14.0kg (30.8 lb.)

Bioscience 14.5kg (32.0 lb.)

Ionic 14.5kg (32.0lb.)

Analytic 15.0kg (33.1lb.)

Genetic 15.0kg (33.1lb.)

Connections

Inlet-quick connect 8mm (5/16") OD

Drain 8mm (5/16") OD

Flush - Bioscience/ Genetic 8mm (5/16") OD

Positioning Wall, bench or under bench mounted.

Environment Clean dry indoor. Temp 5-40°C.

Humidity max 80% non-condensing.

PURELAB Ultra Operator Manual ELGA

Page 10 PURELAB Ultra Version 1 - 05/02

Electrical Requirements

Mains input 100 -240V ac, 50-60Hz all models

System voltage 24V dc

Power consumption during recirculation 60VA

Power consumption during dispense 75VA

Fuses 2 x T6.3 Amp

Reservoir level connection Jack Plug 3.5mm

Noise level during recirculation <40dBA

User Interface

Display Continuous graphical quality display

Graphical flow schematic on screen with mimic display

Backlit display with Intuitive Icons

Adjustable settings Volumetric dispense Selectable dispense volumes (0.1 – 60.0 liters)

Recirculation mode Intermittent or continuous

Feed water type Selectable (RO/DI/SDI)

Display viewing angle Adjustable electronically

Water quality units Selectable (MΩ-cm or µS/cm)

Water quality alarm Selectable alarm setpoints

Date / time Adjustable

Auto restart after power failure Selectable (On/Off)

Audible alarm Selectable (On/Off)

Temperature control Selectable alarm setpoints

Night service Selectable (On/Off)

Indicators Product water quality Resistivity or conductivity

Intermediate water quality Resistivity or conductivity

Temperature Degrees Centigrade or Fahrenheit

Total Organic Carbon (TOC)* ppb C

Purification pack Replacement date

UV lamp* Replacement date

Filter* Replacement date

Alarms-Audiovisual Purified water purity Above set point alarm

Temperature**** Above set point alarm

UV lamp operation* Imminent lamp failure or failure to start

Calibration Calibration alarm – calibration required

Purification pack Change reminder

UV lamp* Change reminder

Filter* Change reminder

Reservoir**** Low level / level control disconnect alarm

Outputs RS232 printer connection

RS232 remote display connection

Volt free contact-internal

Remote dispense

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 11

Safety Features

Power fail safe

Water temperature alarm

Water quality alarm

Purification pack interlock

UV current monitoring

Timeout of manual dispense

Low operating voltage 24V

Dry contact alarm connection

Visual alarms

Audible alarms

Operational Features

Low noise levels – minimum intrusion

Continuous calibration to traceable standards

Drop dispense

Multistage monitoring

Restart on power interrupt

Volumetric dispense

Optional printer kit for record of operating parameters

Optional remote display

Purified Water Specification

Scientific Ionic Analytic Bioscience Genetic

Flowrate 2.0 l/min max.

Inorganic Resistivity 18.2 MΩ-cm (0.055µs/cm)

TOC **<15ppb **<5ppb **<2ppb **<10ppb **<3ppb

Bacteria ***<1cfu/ml <1cfu/ml

Pyrogens - <0.03Eu/ml <0.001Eu/ml

pH Effectively neutral

Particles ***0.2µm0.05µmUltrafiltration

RNase / DNase - Free

Capacity

(LC147)

56,000 liters >18MΩ-cm per single purification pack

µS/cm at pH7.0

Conforms to ASTM, CAP, NCCLS – TYPE 1 and BS3978 Grade 1 Specification.

* On some models only.

** Dependant on feedwater - recommended feed <50ppb TOC

*** With POU filter fitted.

**** Switches process off.

Purification Packs

Standard pack LC147 recommended for most applications. Refer to Section 10 for alternative cartridges.

As part of our policy of continual improvement we reserve the right to

alter the specifications given in this document.

PURELAB Ultra Operator Manual ELGA

Page 12 PURELAB Ultra Version 1 - 05/02

4. CONTROLS

The PURELAB Ultra operates with a tactile membrane control panel,

which has a graphics display window and four multi-purpose control

buttons.

Details of how to use the controls will be given in the appropriate

sections.

The PURELAB Ultra control panel has a range of control icons as

follows:

Button Icon Function

PROCESS Turns the process

on/off

ESCAPE from any

feature

Menu

Scroll

(0.10)* Preset dispense

volume

LEFT

Reset

Accept

Volumetric dispense

CENTRE

(0.50)* Preset dispense

volume

Mute Alarm

Printer

RIGHT

(1.00)* Preset dispense

volume

Intermittent

recirculation

* Example only - Ref. to Section 6.3 Step 3.

Process button

Left hand Centre Right hand

Control button Control button Control button

Control Panel

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 13

5. INSTALLATION INSTRUCTIONS

5.1 Unpacking the PURELAB Ultra

The following items are supplied with your PURELAB Ultra.

1. PURELAB Ultra unit.

2. Sanitization by-pass blocks LA638

(2 off, fitted in unit).

3. 6 metres of 8mm (5/16") O/D tube.

4. 1 off Pack of CT1 tablets.

5. 1 off Strainer Assembly.

6. Operator Manual in English.

7. Multilingual Operator Manual on CD.

8. Mains Lead.

9. Reservoir Level Connecting Lead.

10. Icon Directory, fitted on inside of door.

5.2 Positioning the PURELAB Ultra

Before installation and operation of the PURELAB Ultra unit, please

read and observe the following points.

Environment

The unit should be installed on a flat, level surface, in a

clean, dry environment. The unit can also be wall mounted

against a vertical wall capable of supporting the weight (for

this we recommend the use of the wall mounting kit Part No.

LA610 on substantial brick/concrete walls or LA622 for stud

partition walls).

WARNING! IF THE UNIT IS TO BE WALL MOUNTED,

ENSURE IT IS MOUNTED USING THE

CORRECT WALL MOUNTING KIT AND

THAT THE WALL IS CAPABLE OF

SUPPORTING THE OPERATING WEIGHT

OF THE SYSTEM. ALWAYS CAREFULLY

FOLLOW THE INSTRUCTIONS INCLUDED

IN THE KIT.

Note: Refer to Specifications for unit weights

(Section 3.4 - Technical Specification).

The unit is designed to operate safely under the following conditions:

•Indoor Use

•Altitude up to 2000m

•Temperature Range 5 - 40°C

•Maximum Relative Humidity 80% @ 31°C decreasing

linearly to 50% @ 40°C, non-condensating

The unit is in Installation Category II, Pollution Degree 2, as per

IEC1010-1.

Rear Mounting Points

Unit Rear Mounting Points

PURELAB Ultra Operator Manual ELGA

Page 14 PURELAB Ultra Version 1 - 05/02

Electrical

The units can be connected universally to any electrical

supply in the range of 100 - 240V and 50 - 60Hz. The mains

lead is supplied with a molded plug on one end and a molded

connector to the unit on the other. The unit should be

connected to an earth. The unit includes a battery which will

require changing on a periodic basis, typically every 3-5

years. (Contact local Service provider)

WARNING! DANGER OF EXPLOSION IF BATTERY IS

INCORRECTLY REPLACED. REPLACE

ONLY WITH THE SAME OR EQUIVALENT

TYPE RECOMMENDED BY THE

MANUFACTURER (3 VOLTS, LITHIUM

CR2032). DISPOSE OF USED BATTERIES

ACCORDING TO THE MANUFACTURER’S

INSTRUCTIONS.

Drain/Flush

A semi-rigid flexible connection to a sink or suitable drain

capable of at least 2.0l/min is required. The drain point

should have a gravity fall below the level of the unit and any

connections direct to drain should have an air-break device

fitted. On the Genetic & Bioscience units a separate flush line

to drain is required. The drain and flush drain lines should run

individually to a convenient drain point.

Feed Water

The feedwater should be potable water, pre-purified using

reverse osmosis, deionisation, or distillation. If using a supply

other than reverse osmosis treated, it is strongly

recommended that a 0.2 micron membrane filter is installed

prior to remove colloidal impurities. The feedwater should

enter the PURELAB Ultra via an 8mm (5/16") O/D semi rigid

tube, and should be in the temperature range 1 to 40°C (34

to 104°F). To ensure optimum performance it is

recommended that the feedwater temperature be between 10

to 15°C.

CAUTION! Operating with feed water temperatures

outside the range from 1 to 40°C (33.8 to

104°F) will cause damage to the PURELAB

Ultra unit.

For pressurized feeds, the minimum direct inlet pressure is

0.07bar (1.0psi) and maximum inlet pressure is 0.7bar

(10psi). Higher feedwater pressures must be reduced using a

pressure regulator valve (Part No. LA575).

Reservoir feeds to the PURELAB Ultra unit should be

positioned at the same height, or above the unit, to provide a

positive flooded inlet pressure of approximately 0.07bar

(1psi).

Fuse

ON/OFF

switch

Mains

p

ower lead

Mains power socket

Electrical Connections

ELGA PURELAB Ultra Operator Manual

PURELAB Ultra Version 1 - 05/02 Page 15

5.3 Connecting the PURELAB Ultra

Once the PURELAB Ultra unit has been positioned either on a wall or

on a bench, it should be connected as follows:

•Mains water inlet tube

•Drain tube - to drain

•Flush tube (Bioscience and Genetic) - to drain

Step 1 - Remove Transit Plugs

1. PUSH in collet on connector.

2. PULL out transit plug.

3. CUT a clean square end on an 8mm OD semi

rigid drain tube.

4. PUSH tube into connector.

Step 2 - Connect Water Inlet

1. Connect 8mm tube from the PURELAB Ultra

inlet to the inlet strainer.

2. Connect the inlet strainer to the pre-purified

water supply.

Step 3 - Connect Drains

1. Connect 8mm tube from the drain and UF drain

(if fitted) and direct to a suitable drainage point.

CAUTION! The drain and flush lines should allow a

gravity fall to drain with no restrictions.

CAUTION! If the water supply is at a pressure greater

than 0.7bar (10psi) fit a pressure regulator

(LA575).

UF Drain

Drain

Inlet

Inlet and Drain Connection

Direction of

water flow

Collar

Mesh filter

Collar

Strainer

Inlet

Feed Water Inlet

Connector Collet

Blanking

transit plug

Pull plug

Depress

collet

Clean square

cut end

Tube 8mm OD

Simply push in tube to attach

Tube in secured position

Fitting tubes

Table of contents

Popular Water System manuals by other brands

Zip

Zip HydroTap CS Commercial Installation and operating instructions

Reclaim

Reclaim REHP-CO2-160GL Owners & installation manual

King Technology

King Technology AQUA SMARTE Plus MINERAL ACTIVATOR Operational instructions

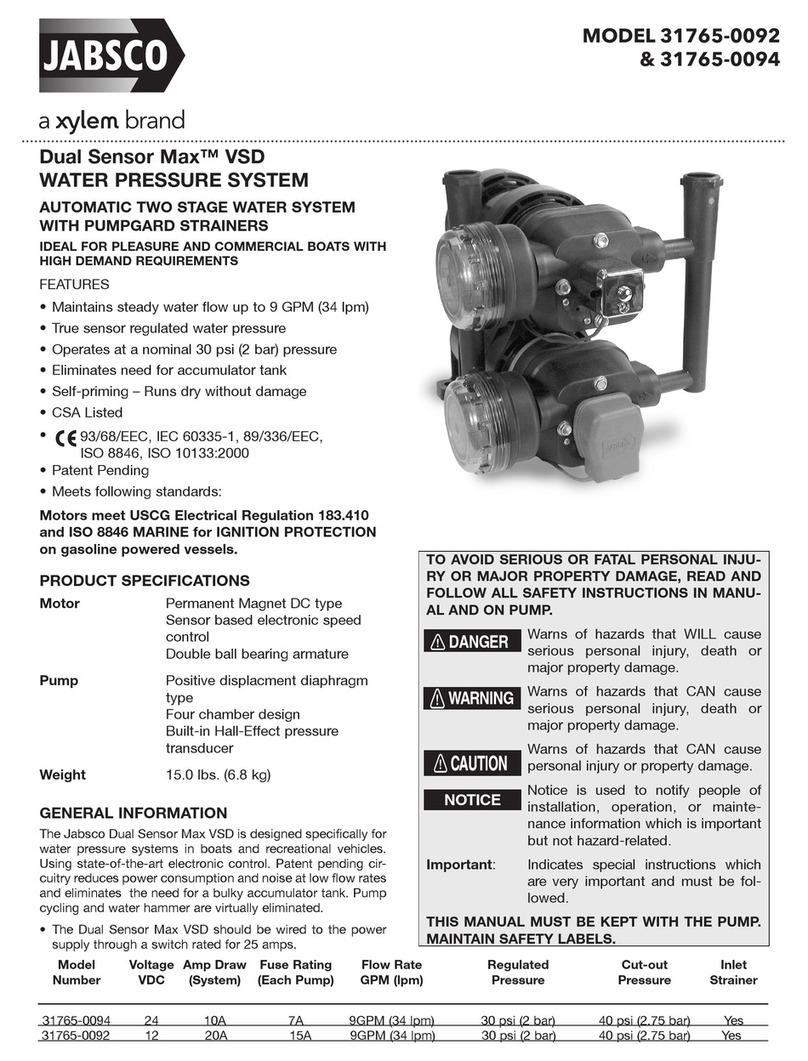

JABSCO

JABSCO 31765-0092 manual

Brita

Brita PROGUARD Coffee manual

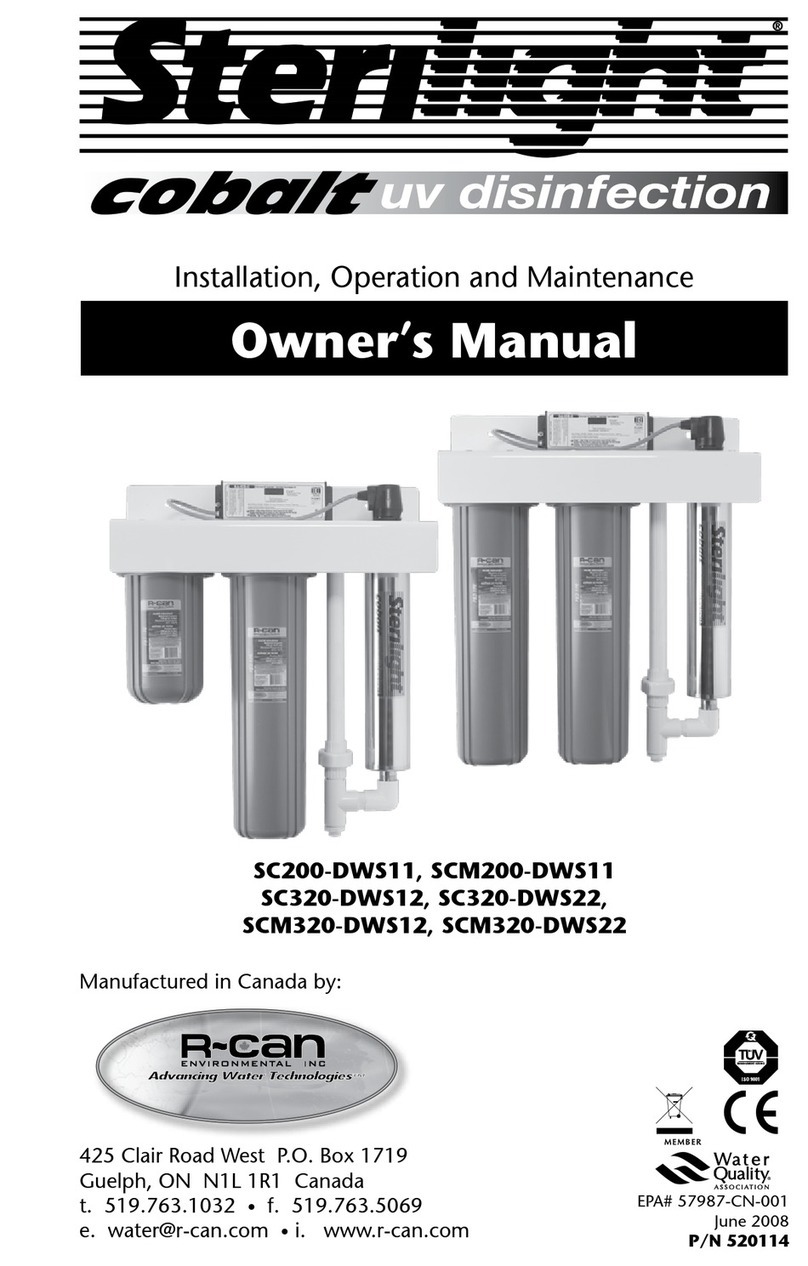

Sterilite

Sterilite Cobalt SC200-DWS11 owner's manual

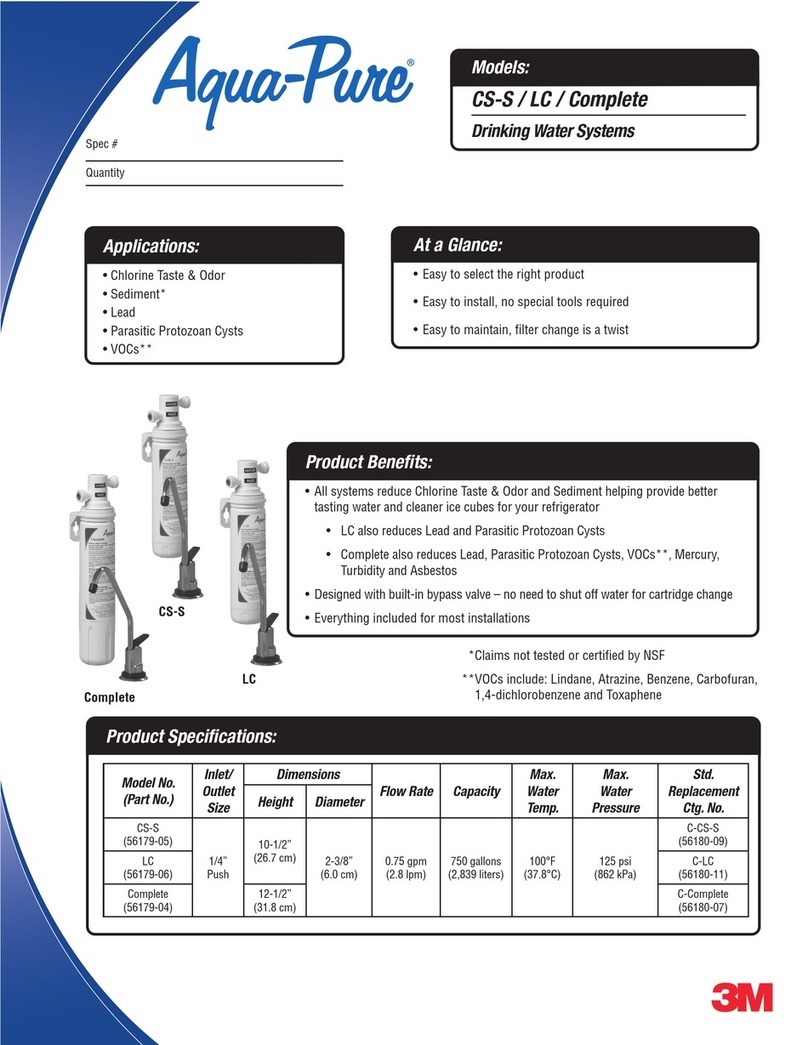

3M

3M Aqua-Pure CS-S quick guide

Kenmore

Kenmore 625.384650 manual

Field Controls

Field Controls CLEARWAVETM WATER CONDITIONER CW-HD-4 installation manual

Zip

Zip HydroTap G4 Installation and operating instructions

OSMOSEA

OSMOSEA NEW12 ES60 Instructions for installation, use and maintenance manual

CEFLA

CEFLA PURE 500 operating manual