Document No. 17476-C © ViVitro Labs Inc. 2018 Page 4 of 22

SuperPump AR System User Manual

Contents

1Cautions and Warnings.................................................................................................. 5

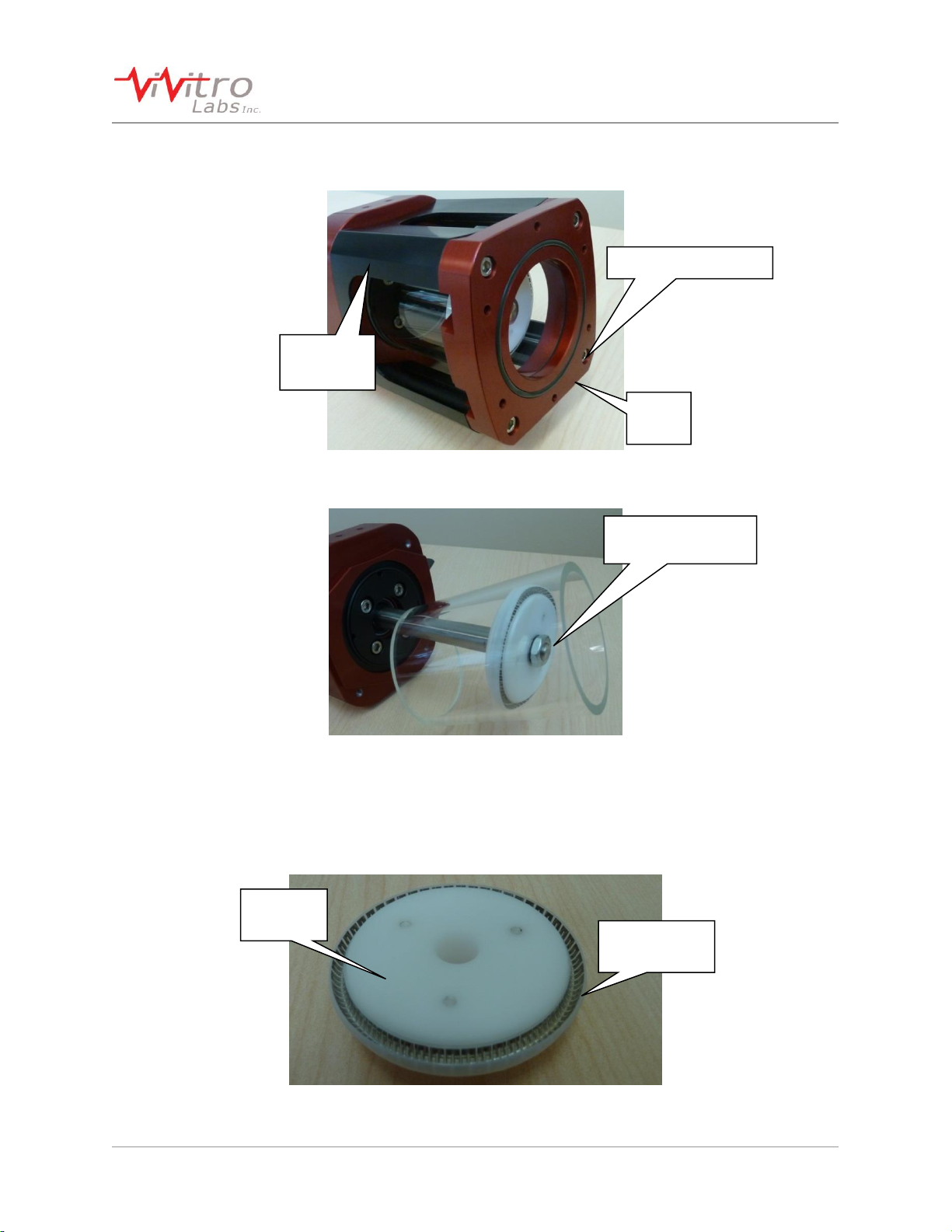

2About the SuperPump AR.............................................................................................. 6

2.1 Overview ................................................................................................................. 6

2.2 Features.................................................................................................................. 6

3Installation....................................................................................................................... 7

3.1 Unpacking the SuperPump...................................................................................... 7

3.2 Installing the SuperPump......................................................................................... 7

3.3 Electrical Requirements........................................................................................... 8

3.4 Fuses....................................................................................................................... 8

4Operating the SuperPump.............................................................................................. 9

4.1 Powering On the System......................................................................................... 9

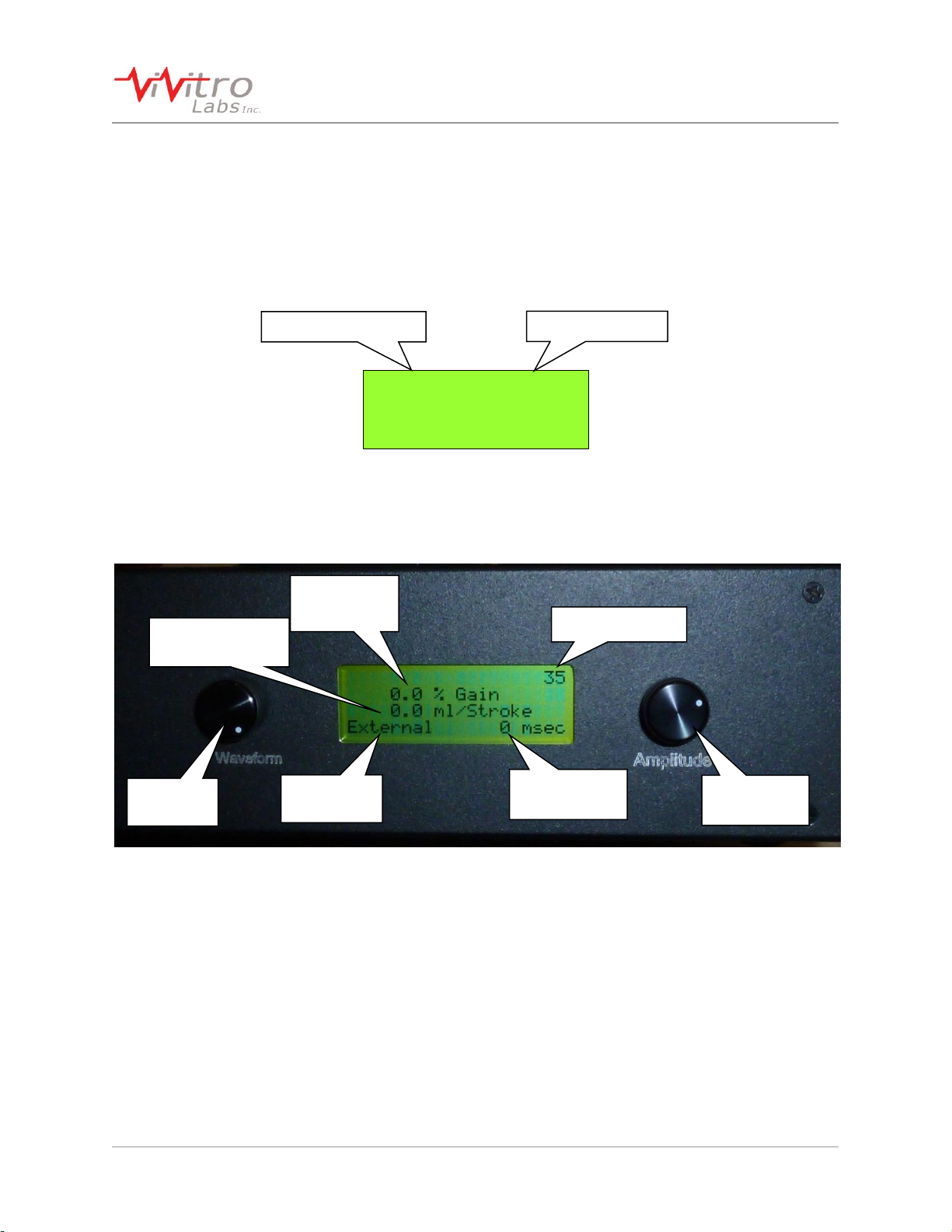

4.2 Front Panel.............................................................................................................10

4.3 Rear Panel..............................................................................................................10

4.4 Select Waveform ....................................................................................................11

4.5 Sync Pulse Delay....................................................................................................11

4.6 Cycle Count - Totalizer ...........................................................................................12

4.7 Pump Operation .....................................................................................................12

5Waveforms.....................................................................................................................13

5.1 Internal Waveforms.................................................................................................13

5.2 External Waveforms ...............................................................................................13

6Faults and Alarms..........................................................................................................14

6.1 Limit Switches.........................................................................................................14

6.2 Pump Error.............................................................................................................14

7Maintenance and Cleaning............................................................................................15

7.1 Cleaning .................................................................................................................15

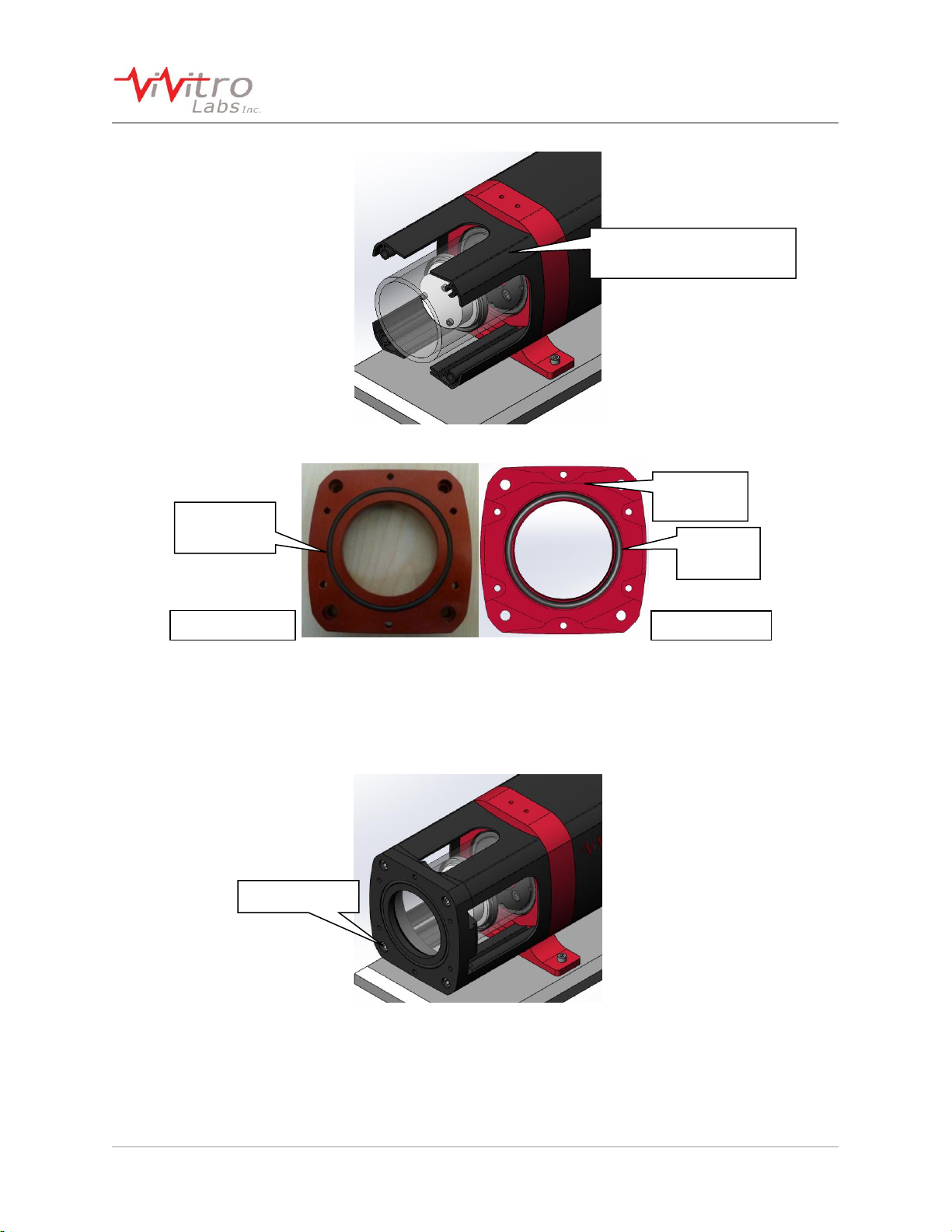

7.2 Piston Seal Leakage...............................................................................................15

7.3 Piston Seal Replacement........................................................................................15

8Specifications ................................................................................................................19

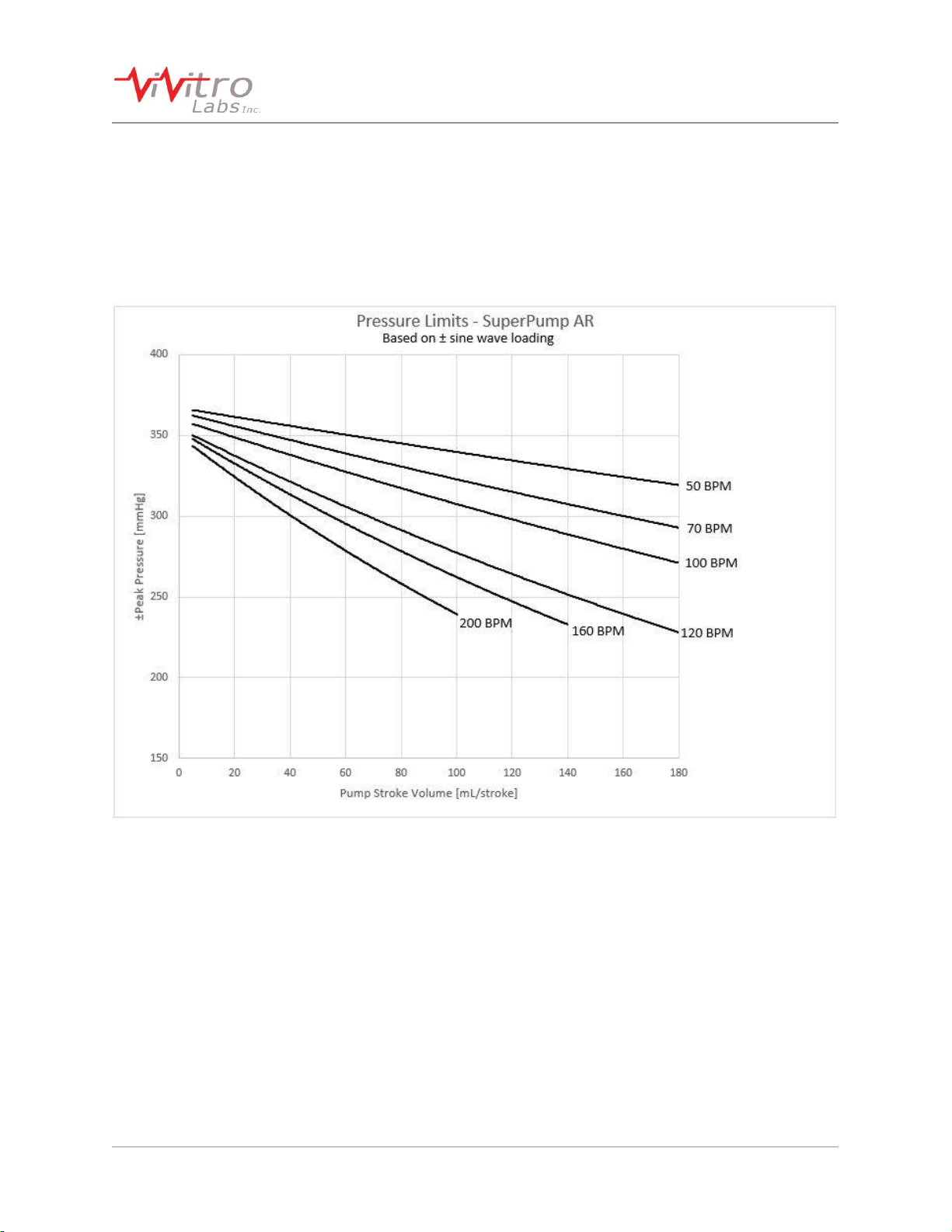

9Pressure Limits..............................................................................................................20

10 Mounting Details............................................................................................................22

10.1 Mounting Feet Bolt Pattern.....................................................................................22

10.2 Pump Cylinder Mounting Face Bolt Pattern ............................................................22