Vmac A800185 User manual

1

www.vmacair.com

Owner’s Manual

A800185

VMAC Eliminator After-Cooler

2

Contents

VMAC Document Revisions……………………………………………………………………………………………………………………..1

Equipment Specifications and Accessories................................................................................................... 2

Safety ............................................................................................................................................................ 3

Installation .................................................................................................................................................... 5

Calibration/Testing ....................................................................................................................................... 7

Operation...................................................................................................................................................... 9

Drawings and Components.........................................................................................................................10

Warranty .....................................................................................................................................................11

VMAC Document Revisions

Document # 1930225

Version

Revision Details

Revised by/date

Checked by/date

Approved

by/date

Date

Implemented

A

Engineering release

MH 10 Dec 2014

MP 06 Feb 2015

RD 04 Feb 2015

03 Mar 2015

1

3

Equipment Specifications and Accessories

Air Requirements: 80CFM-185CFM

Electrical Requirements: 12V DC

Connections: 1” NPT Intake & Discharge

Accessories:

Optional mounting bracket kit: A700143

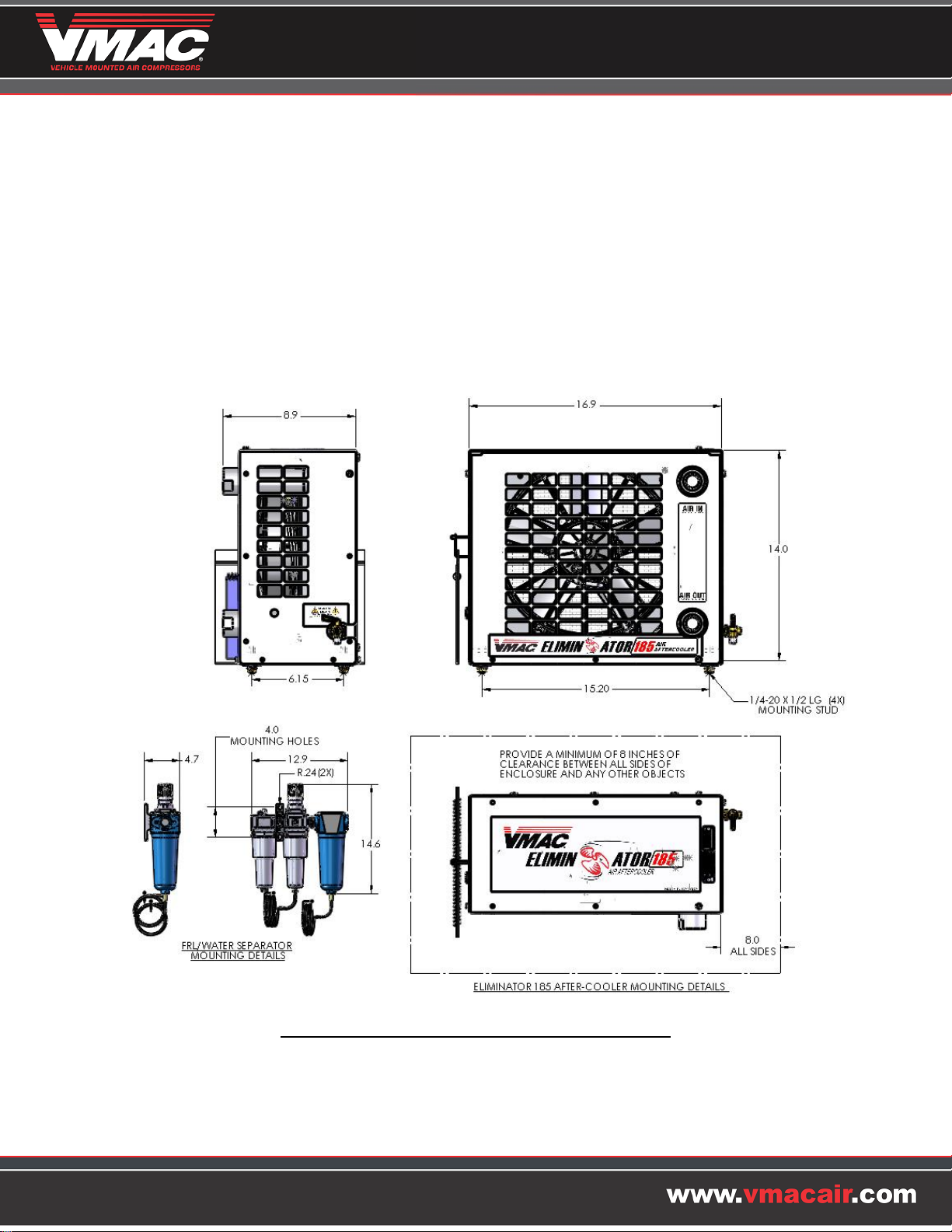

After-Cooler and FRL/Water Separator Mounting Details

2

4

Safety

Important Safety Notice

The information contained within this manual is based on sound engineering principles, research,

extensive field experience and technical information. Information is constantly changing with the

addition of new models, assemblies and service techniques. If a discrepancy is noted in this manual,

contact VMAC prior to initiating or proceeding with service. Current information may clarify the

matter. Any person with knowledge of such discrepancies who performs any work on the system,

service and repair assumes all risks.

Only proven service procedures by qualified personnel are recommended. Anyone who departs from

the specific instructions provided in this manual must first assure that their safety and that of others is

not being compromised and that there will be no adverse effects on the performance or the operational

safety of the equipment.

VMAC will not be held responsible for any liability, injuries, loss or damage to individuals or to

equipment as a result of the failure of any person to properly adhere to the procedures set out in this

manual or standard safety practices. Safety should be your first consideration in performing service

operations. If you have any questions concerning the procedures set out in this manual or require any

more information on details that are not included in this manual, please contact VMAC before beginning

any work. Our local number is 1-250-740-3200, and our toll free number is 1-800-738-8622.

To order parts, contact your VMAC dealer. Your dealer will ask for the VMAC serial number, part

number, description and quantity. To locate you nearest dealer, call 1-888-241-2289, or see our website

at www.vmacair.com and click Find a Dealer.

Safety Messages

This symbol is used to call your attention to instructions concerning your personal

safety. Read the message that follows and be aware of the possibility of injury or

death.

This symbol is used to call your attention to instructions on a specific procedure that if

not followed may damage or reduce the useful life of the compressor.

This symbol is used to call your attention to additional instructions involving fire

hazards.

Note: It is impossible to warn about every conceivable hazard; let good common sense be your guide.

3

5

Safety Precautions

Observe the following general safety rules:

Pay attention to the system during operation; do not leave it unattended

Follow safe work practices and wear appropriate safety equipment when operating air powered

equipment, particularly eye and hearing protection

Follow all safety precautions for mechanical work

Follow safety procedures for the type of work being completed

Avoid all contact with pressurized air; if it penetrates skin, it can enter the bloodstream and cause

serious bodily harm or death

Do not breathe the compressor air. Vaporized oil is a severe respiratory hazard

Avoid contact with drive belts and stay clear of all moving parts when the system is operating

To prevent compressor explosion or fire, make sure that the air entering the compressor is free of

flammable vapors

To prevent compressor explosion or fire, make sure that correct servicing procedures and intervals

are observed

Vaporized oil propelled by high pressure is an explosive mixture

4

6

Installation

Locate the Eliminator After-Cooler in a suitable location that provides good air flow and easy

accessibility. The selected location must have at least eight inches of clearance between all sides of the

Eliminator and any other objects. There should be sufficient space to connect air lines, wiring and access

the manual drain.

Ensure the Eliminator is mounted after the receiver tank if one is being used.

1. Place the Eliminator After-Cooler in position and drill the appropriate mounting holes.

2. Fasten the rubber mount feet securely. If using VMAC optional mount kit A700143, install the After-

Cooler unit to the brackets, then fasten the brackets securely.

3. Connect the supply line from the air source to the “Air In From Compressor” fitting. Support the

fitting on the Eliminator with a wrench to prevent damage.

4. Connect the delivery line to the Water Separator to the “Air Out to Water Separator” fitting. Support

the fitting on the Eliminator with a wrench to prevent damage.

5. Place the Water Separator & FRL combination unit in a position where the filters can be easily

monitored and changed then drill the appropriate mounting holes.

It is important to mount the Water Separator & FRL below the level of the After-Cooler

to improve moisture flow and prevent freeze up in cold climates.

6. Route the drain lines from the water separator and the air filter so water can drain on to the ground.

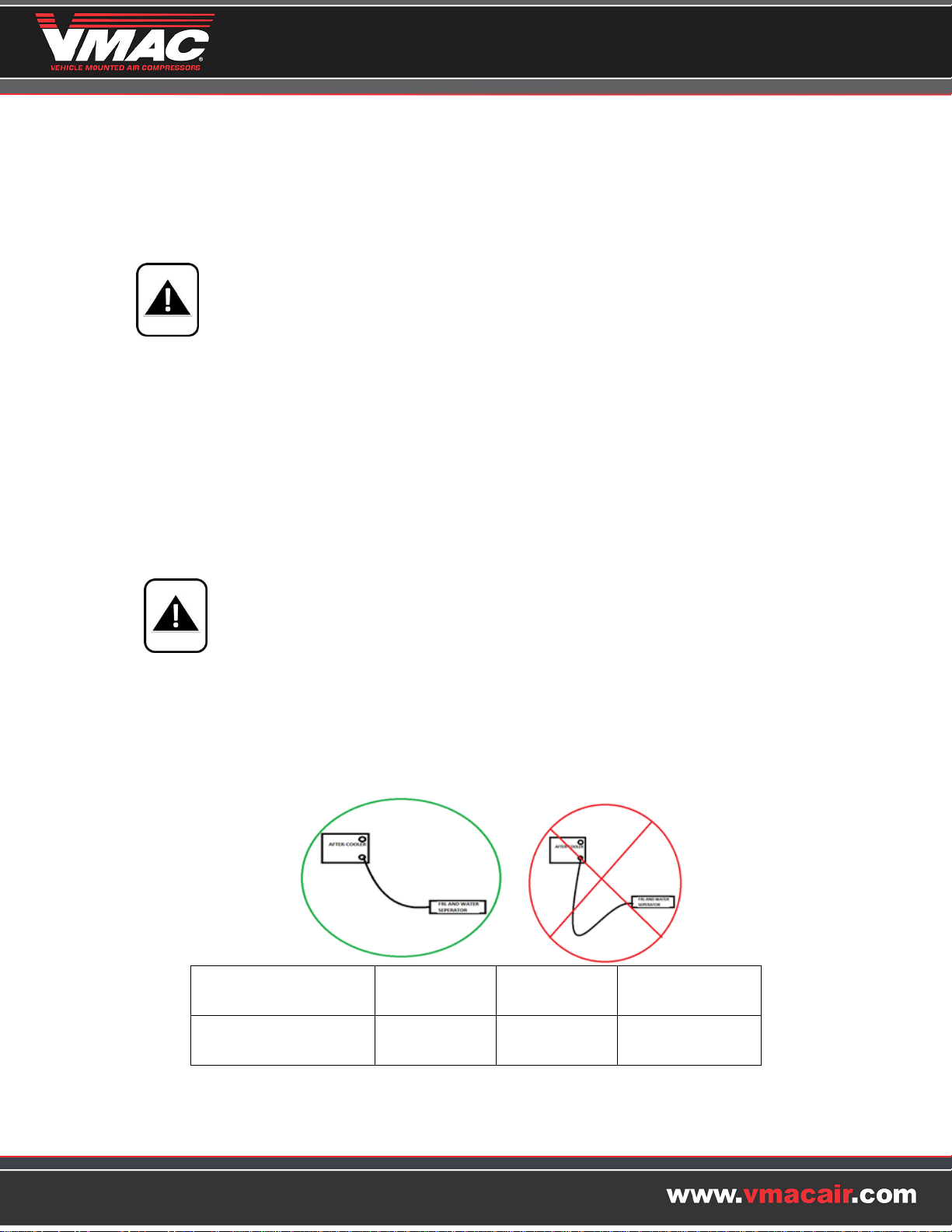

7. Connect the delivery line from the Eliminator to the water separator. Make sure the hose does not

get routed lower than the water separator. Refer to the chart below for the minimum hose diameter

allowed between after cooler and water separator. It is best practice to install the largest hose

available to reduce pressure drops across the system.

5

Compressor CFM

Up to 5 Feet

Up to 10 Feet

Up to 25 Feet

150 CFM - 185 CFM

1”

1 ¼”

1 ½”

7

8. Connect the red wire from the Eliminator After-Cooler to a key- switched 12-volt source through a

20-amp fuse using the wire size recommended in the following table.

9. Connect the green wire to a good body ground using the wire size recommended in the following

table.

Length of Wire

Recommended Wire Gauge

Less than 5 feet

14 Gauge

5 to 8 feet

12 Gauge

Over 8 feet

10 Gauge

10. Splice the white wire from the Eliminator After-Cooler to the white clutch wire at the VMAC VR

compressor using 18 gauge wire.

11. If the Eliminator After-Cooler is not used in conjunction with a VMAC VR compressor, connect the

white wire to a power source through an on/off switch using 18 gauge wire.

6

E

L

I

M

I

N

A

T

O

R

Green

Red

White

VR compressor clutch wire

20 A

12 V source

8

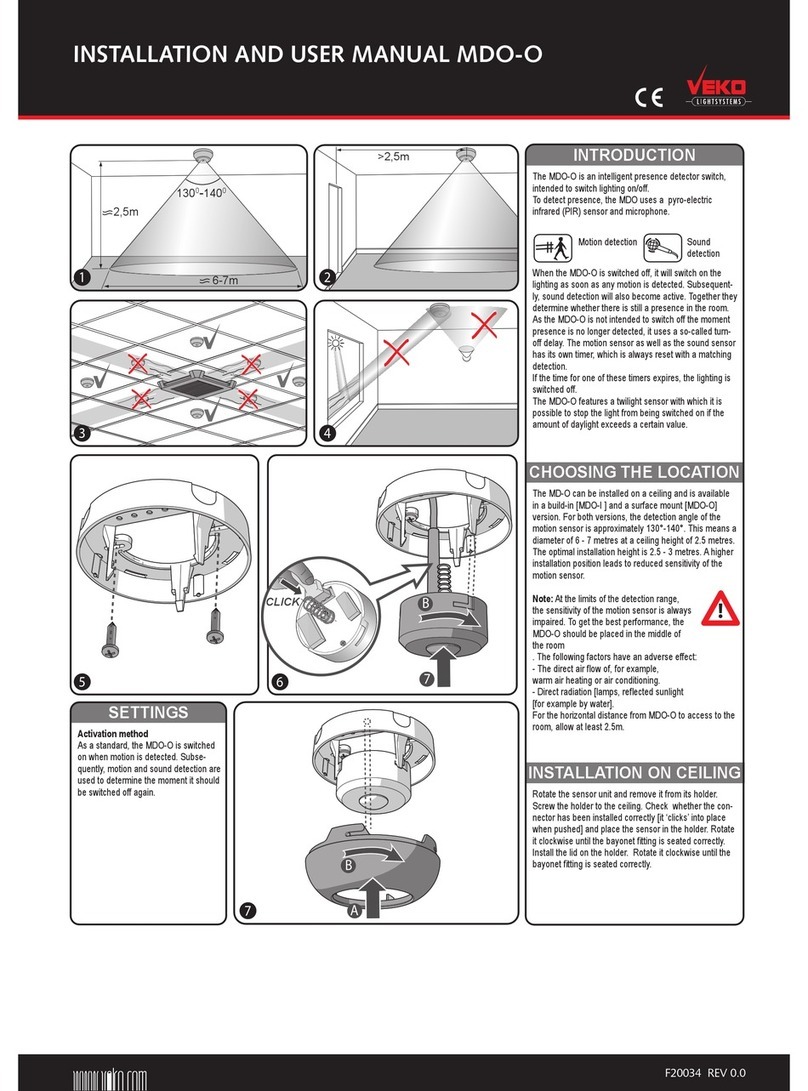

Calibration/Testing

1. If the truck is equipped with a VMAC VR system, place the manual transmission in neutral or the

automatic transmission in park and fully apply the park brake.

2. Start and run the engine long enough to stabilize at base idle and reach normal operating

temperature.

3. Close all compressor air system outlets.

4. Press the “ON” button on the VMAC VR system display box to engage the air compressor.

5. Verify that the fan on the Eliminator After-Cooler is running and that air is blowing out of the grill on

the front of the unit.

The unit has an auto-drain function that will vent water when it reaches a pre-determined level.

There is no operational test for this function, ensure that the system vents water during

operation.

7

9

88

8

AIR IN

FROM COMPRESSOR

AIR OUT

TO

WATER SEPARATOR / FRL

UNIT

FAN AIR FLOW DIRECTION

AIR IN

FROM COOLER

AIR OUT

TO AIR TOOLS

10

Operation

If the Eliminator is correctly wired into the compressors on/off switch there will be no required

manual input to activate or deactivate the Eliminator fan.

If the Eliminator is installed on a separate compressor and using an auxiliary switch for activation,

this switch should be turned on as soon as the compressor is turned on. The fan should then be

turned off when the compressor is turned off.

At the end of the day or shift, shut the compressor system down, vent the air, then open the manual

drain valve on the side of the cooler to drain the air line of moisture to avoid freeze-up in cold

weather. Leave the valve open until you are ready to start the compressor again.

To avoid freeze up in cold climates it is critical that the system is completely

discharged after each use using the manual drain on side of Eliminator.

This allows the water separator to completely drain out the moisture preventing ice

damage to the internal components.

During daily operating the inlet air fitting can become very hot, never touch the inlet

fitting with your bare hands without allow sufficient cooling down of the unit.

9

11

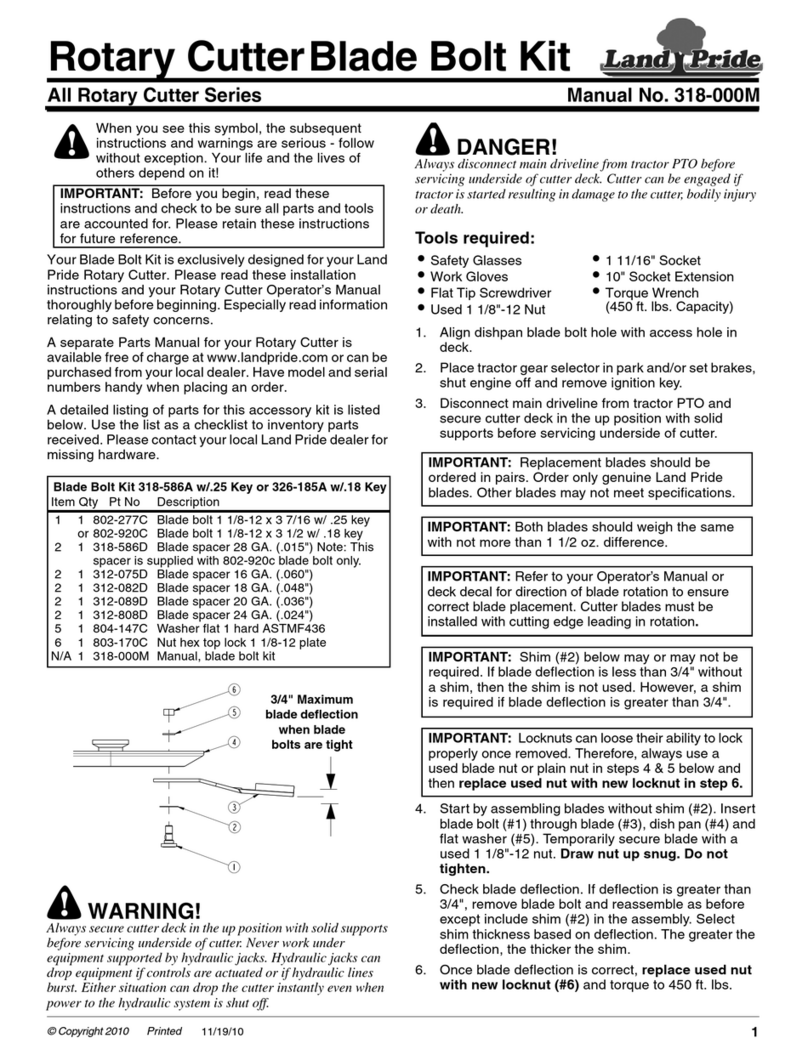

Drawings and Components

10

ITEM.

QTY.

PART#

DESCRIPTION

8

4

1500596

VIBRATION MOUNT,NAT RUBBER, 1/4-20

9

4

1570499

WASHER, FLAT, THICK, SS 1/4

10

4

1550527

NUT, NYLOK, S/S, 1/4-20

11

2

3200446

ADAPTOR, AFTERCOOLER, 185

12

1

6000659

SHROUD, FAN, AIR DRYER

13

6

1500595

RIVET, ALU, STANDARD, BLIND 1/4"

14

2

2200133

CLAMP, INSULATED DOUBLE TUBE, 1/4

15

4

1520627

BOLT, HHCS, FL, PL, M8 X 1.25 X 20

16

1

1500631

SCREW, PHMS, M5 X 8

17

1

5000168

VALVE, MANUAL DRAIN

18

2

5830116

O-RING, VITON, ORB-16

19

1

3550891

HARNESS, FAN, A800185

20

1

3600124

COOLER, #16 ORB PORTS

21

1

3501070

FAN, 11" PUSHER 12V

22

6

1570163

WASHER, FLAT, 3/16

23

6

1550524

NUT, NYLOCK, 10-32

ITEM.

QTY.

PART#

DESCRIPTION

1

1

6000456

TRAY, BASE ,AIR DRYER

2

1

6000458

COVER, AIR DRYER

3

2

1500598

RIVET, ALUMINUM, CLOSED END, 1/8"

4

1

6000457

PANEL, REAR ,AIR DRYER

5

34

1500587

SCREW,SL,MC IND HEX 10-32 X 5/8-SS

6

34

1570488

WASHER, NYLON, 3/16

7

1

6000455

PANEL, FRONT ,AIR DRYER

ITEM.

QTY.

PART#

DESCRIPTION

1

1

3600162

FILTER, MOISTURE SEPARATOR, 185

2

1

4900205

NIPPLE, HEX, 1 NPT

3

1

3600161

ASSEMBLY, FRL, 185 CFM

4

36”

1700055

HOSE, BRAKE BLACK, 1/4

5

36”

1700630

HOSE, DRAIN, 1/4" ID

6

1

2200229

CLAMP, SPRING, 5/16 OD

2

3

4

1

7

5 6

8

9

10

11 18

12 13

14

15 16

17

19

20

21

23 22

1

2

3

4

6

5

12

Warranty

GENERAL PROVISIONS AND LIMITATIONS

VMAC, Division of Mangonel Investments Corporation, (hereafter ”VMAC”) warrants to each original retail purchaser (hereafter “Buyer”) of its

new Accessory Product (hereafter “Product(s)”) from VMAC or its authorized Dealers that such Product(s) are, at the time of delivery to the

Buyer, free of manufacturer defects in material and workmanship.

NO WARRANTY IS MADE WITH RESPECT TO

Any Product(s) which have, in VMAC’s judgment, been subject to negligence, accident or improper storage, installation, application, operation

or maintenance, or have been repaired or altered in such a way that affects the Product(s) adversely.

Components or accessories manufactured, warranted and serviced by others.

Damages caused from service and repairs and corrections with minimum action, such as adjustments and inspections, or replacement of items.

Consequential damages caused by Product(s) failure.

Any Product(s) if other than VMAC’s genuine components are used in the Product(s).

Normal wear and tear of Product(s).

WARRANTY PERIOD

The warranty period will commence 30 days from date of shipment from VMAC.

The Product(s) is warranted against manufacturer defects in materials and workmanship for a period of 12 months.

Replacement components of Product(s), shall be warranted for the remainder of the original warranty period.

VMAC OBLIGATIONS

VMAC’s obligation is limited to repairing or, at VMAC’s option, replacing, during normal business hours at an authorized service facility of

VMAC, any component, which in VMAC’s judgment is proven to be defective as warranted.

VMAC’s obligation is limited to Product(s) proven to be warranted. No liability is accepted for any consequential damages, injuries or expenses

directly or indirectly related to Product(s) failure.

BUYER OBLIGATIONS

Buyer shall notify VMAC of the alleged defect within 10 days of initial discovery and return the allegedly defective component(s) within 30 days

of initial discovery.

The Buyer must prepay all costs associated with the warranty claim and submit receipts and/or invoices to VMAC for evaluation.

If required by VMAC, the Buyer must return components claimed under this warranty to a facility designated by VMAC for evaluation, to

establish a claim under this warranty.

DISCLAIMER AND WARRANTY SERVICE

Any labor costs claimed in excess of VMAC’s set rate and/or times are not provided by this warranty. If applicable, any labor costs in excess of

VMAC rate schedules caused by, but not limited to, location or inaccessibility of the equipment, travel time or labor provided by unauthorized

service personnel are not provided by this warranty.

This warranty is in lieu of all other warranties or obligations, express or implied. VMAC expressly disclaims all implied warranties of

merchantability or fitness for a particular purpose.

Warranty claims must be pre-authorized by VMAC, and the components returned via prepaid freight using the designated “Returned

Merchandise Authorization” number and form

11

Other manuals for A800185

1

Table of contents

Other Vmac Accessories manuals