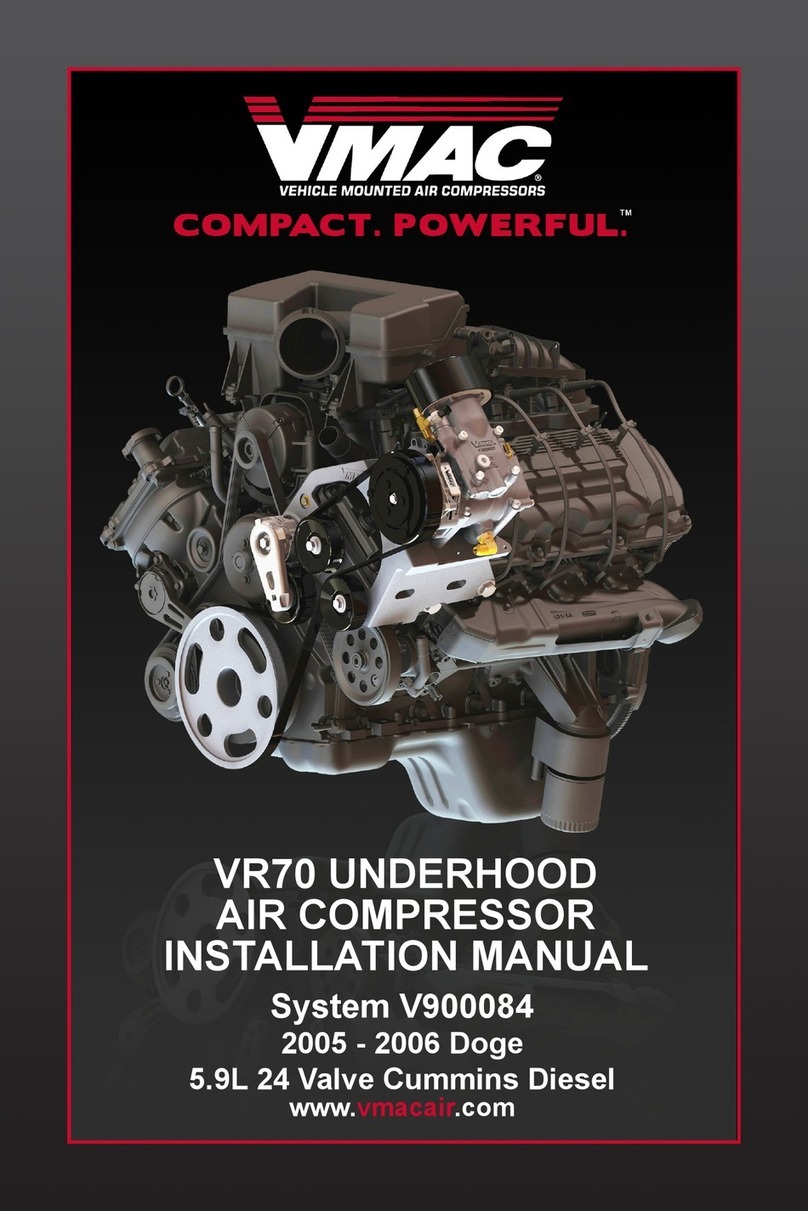

Vmac VR70 User manual

Other manuals for VR70

24

Table of contents

Other Vmac Air Compressor manuals

Vmac

Vmac VR70 User manual

Vmac

Vmac V900104 User manual

Vmac

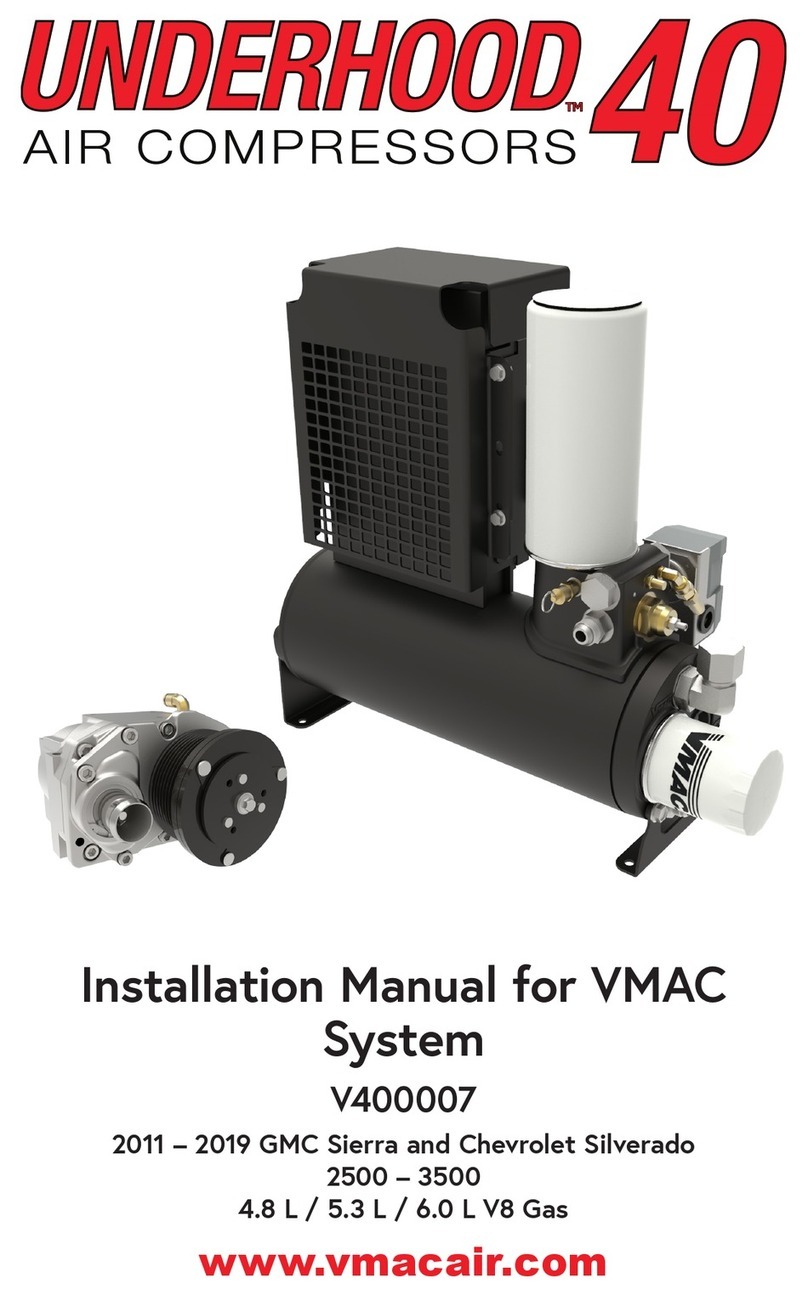

Vmac V400007 User manual

Vmac

Vmac UNDERHOOD 40 Series User manual

Vmac

Vmac Underhood 70 User manual

Vmac

Vmac DM00021 User manual

Vmac

Vmac V400011 User manual

Vmac

Vmac H600013 Installation instructions

Vmac

Vmac H400005 Installation instructions

Vmac

Vmac PREDATAIR User manual

Popular Air Compressor manuals by other brands

Villager

Villager VAT VE 50 L Original instruction manual

Bostitch

Bostitch BTFP02028 instruction manual

Full Boar

Full Boar V-TWIN FBACVT-5030U Original instructions

Winncare

Winncare Axtair One Plus Technical manual

Bushranger

Bushranger Max Air III 55x23 owner's manual

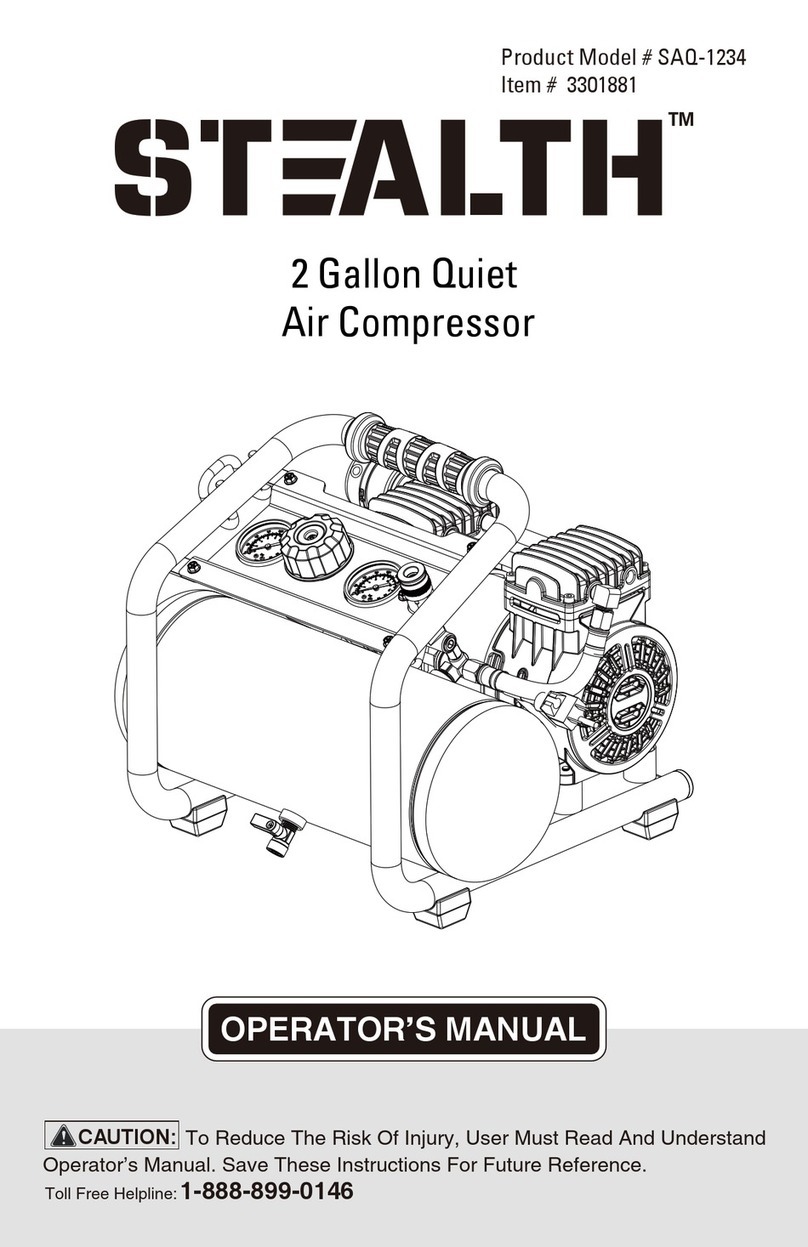

Stealth

Stealth SAQ-1234 Operator's manual

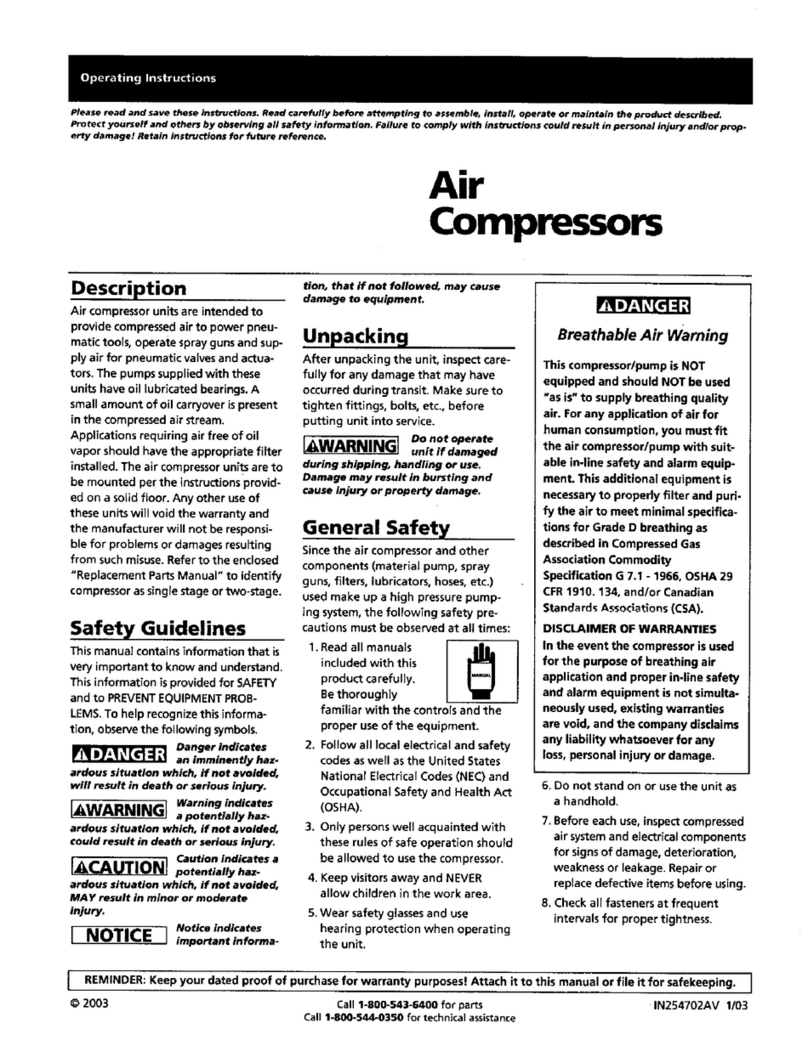

Campbell Hausfeld

Campbell Hausfeld DP4615 operating instructions

Schneider Airsystems

Schneider Airsystems UNM 210-8-25 WXOF operating manual

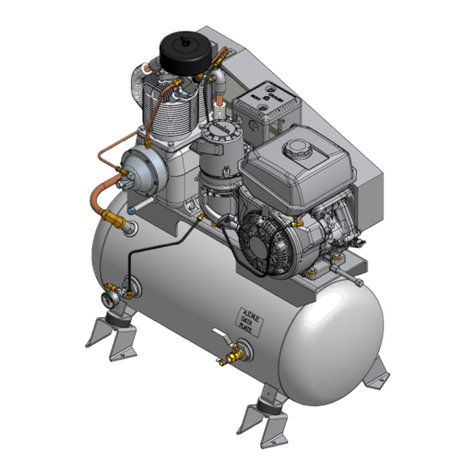

Gardner Denver

Gardner Denver HGR7-3K Operation maintenance manual & parts list

KUSSMAUL

KUSSMAUL AUTO-PUMP 091-9B-4-AD instruction manual

Will Burt

Will Burt 40 instructions

RIDGID

RIDGID IN625301AV Operator's manual