WINNCARE

- 7 -

PREVENTIVE MAINTENANCE

SERVICING FREQUENCY:

It is recommended to service the compressors and mattresses at least every 2 years of

use for the following product lines:

-AXTAIR ONE PLUS®

-AXTAIR AUTOMORPHO AUTO PLUS®

-AXTAIR AUTOMORPHO AXENSOR®

-AXTAIR XXL®

-

The period during which spare parts essential to the use of AXTAIR line products will be

available is 7 years from the product invoice date.

MATTRESS:

Top cover: visually inspect for damage and stains on the stitch side (white). If damage

or stains are found, the cover must be replaced.

AXTAIR line mattresses do not contain any wear parts. A simple check of leak-tightness

is recommended at the time of servicing.

Steps for checking mattress leak-tightness:

1. Inflate the mattress to a pressure between 85mBar and 100mBar.

2. Wait for the pressure to stabilize for approximately 30 seconds

3. Record the exact pressure of the mattress (P0)

4. Wait 1 minute and record the new pressure (P1)

5. The mattress is deemed to be compliant with the leak-tightness test if the

difference between P0 and P1 (P0-P1) is less than or equal to 5 mBar.

In the event of non-conformity, it is necessary to identify the failing components (cells,

connection, CPR valve etc.) and to replace them with components provided by the

manufacturer. After replacement a further leak-tightness test should be performed.

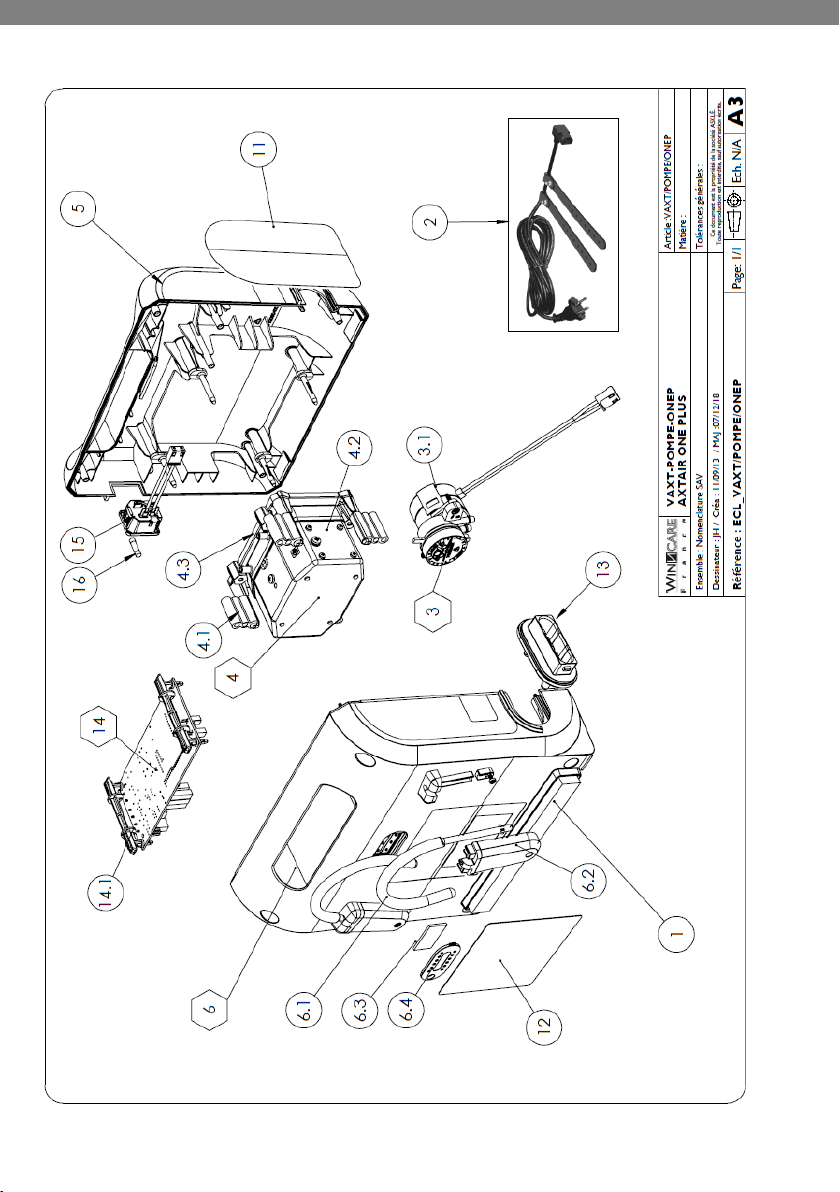

COMPRESSOR:

The filter of the compressor must be replaced once per year or more frequently

depending on environmental conditions (dust, smoke, etc.).

This filter is on the back of the compressor behind a transparent card which shows its

level of fouling. (The original filters are white)

AXTAIR line compressors contain wear parts and sensors which must be checked,

replaced or re-calibrated.

AIRCARE SOLUTION

The Aircare solution was developed for the preventive and curative maintenance of

these systems. Access to the solution requires:

•Following a specific one-day training session. Training module: WS/FORM/05.

The detailed programme and dates for this training are available on

winncare.fr on the training tab. This training is also available as e-learning.

•Downloading specific software running in a Windows environment.