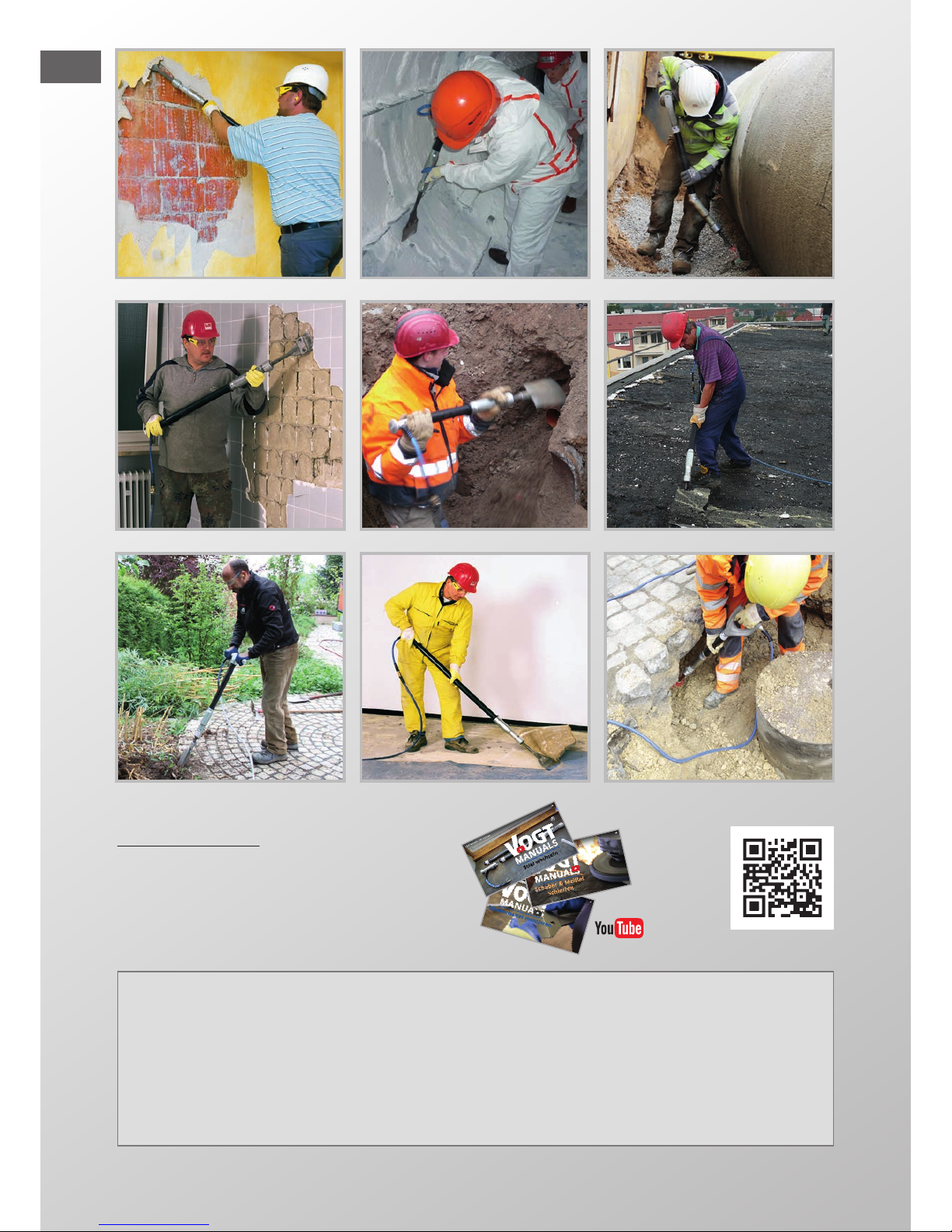

Mounting

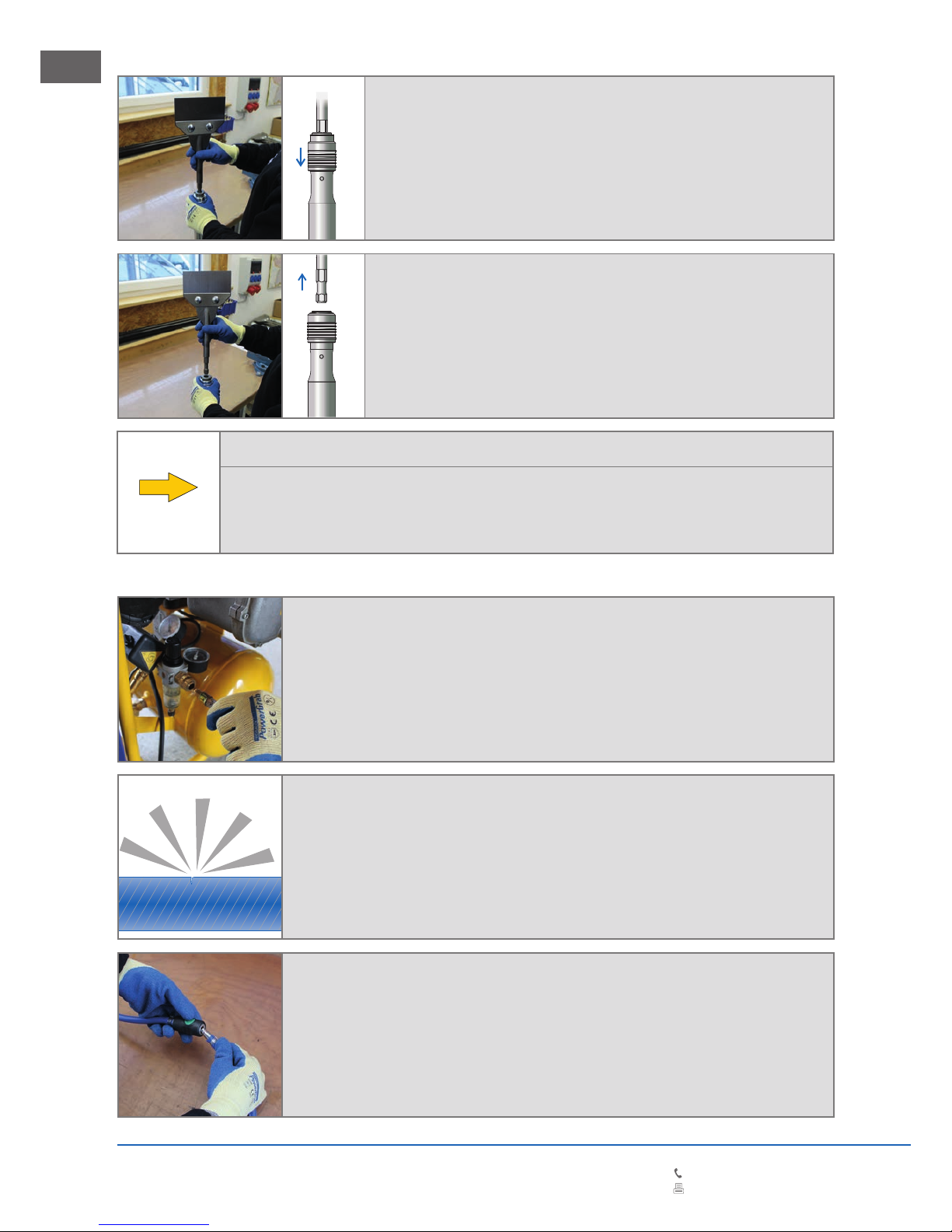

Engage the precision line lubricator in the last compressed air hose upstream of the

VOGT Hammer or VOGT TurboSpade. The distance to the equipment should not exceed

10 meters. Ensure that the lubricator is attached at the same height or level as the equipment.

Lubrication

If the tool is slightly moistened or black with oil at the shank end (hexagon) after

operation, the lubricator is set up correctly.

If the tool has a metallic gleam at the shank end, the oil quantity is set too low.

If oil leaks at the actuator body valve or runs along the chisel, the oil quantity is

set too high.

Setting the oil quantity and topping up oil

Caution: Only carry out work with the compressed air line disconnected.

Open the sealing plug. The quantity of oil supplied can be set using the adjusting screw

underneath. The quantity of oil supplied is reduced by turning the adjusting screw in a

clockwise direction and increased by turning it anticlockwise. The oil can be topped up

by opening the sealing plug. An oil lling should be used up after 2-3 working days.

If the recommended consumption diers considerably, turn the adjusting screw 1/8th

in the corresponding direction and continue to monitor the oil consumption.

Oil types

Use VOGT Special Oil Z 500 or other types of pneumatic oil. Important: Only use resin-free oil!

Lay the compressed air hose between the compressed air source

and the place of use. But do not connect the hose yet!

(See Section 3.2 for connecting the hose)

If distances exceed 30 m, use a hose with a larger cross-section!

Compressed air hoses with a claw coupling must be equipped with

a claw coupling adapter for VOGT standard coupling (e.g. Z 200

adapter) in a depressurised state at the end where the VOGT

compressed air equipment should be connected.

Basic rule:

The lower the material resistance, the lower the operating pressure. The operating pressure is too

high if the tool “jumps away” from the material. Excessive pressure increases the vibration, reduces

performance and can cause damage e.g. to the equipment. VOGT compressed air equipment must be

continuously lubricated during operation as the equipment can be damaged otherwise.

We recommend using VOGT precision line lubricator Z 300.

You will need a compressed air hose with an inner diameter of at least 9 mm (e.g. VOGT metal hose

drum Z 100, VOGT PU streamline hose Z 110) to connect the VOGT compressed air equipment to the

compressed air source.

Risk of equipment damage if the operating pressure at the equipment exceeds 6 bar.

Check the operating pressure and set the correct value if necessary.

Use a pressure regulator if necessary (item no. Z 400)

NOTE

To ensure air supply to VOGT compressed air equipment, a suciently powerful compressed air source

(e.g. compressor) with an output of 3 to 6 bar and an actual supply amount of at least 190 l/min for VH 25/

VH 30 or 255 l/min for VH 10, VH 50, VH 50.18, VH 60, VH 60.18, VTS 50, VTS 60 is required. This corresponds

to a minimum suction capacity of about 380 - 450 l/min. More powerful compressed air sources may be

used while taking account of the corresponding operating pressures. Please refer to the table in Section 8

for the operating pressures recommended for the respective materials.

If needed, use the VOGT pressure regulator (Z400 S).

EN