This manual explains the proper installation and use of your appliance, please read it

carefully before using even if you are familiar with the product. The manual should be kept

in a safe place for future reference. In case of failure, only the Authorized Technical

Service may repair this hob. Otherwise the guarantee will be null and void.

Warning

General safety

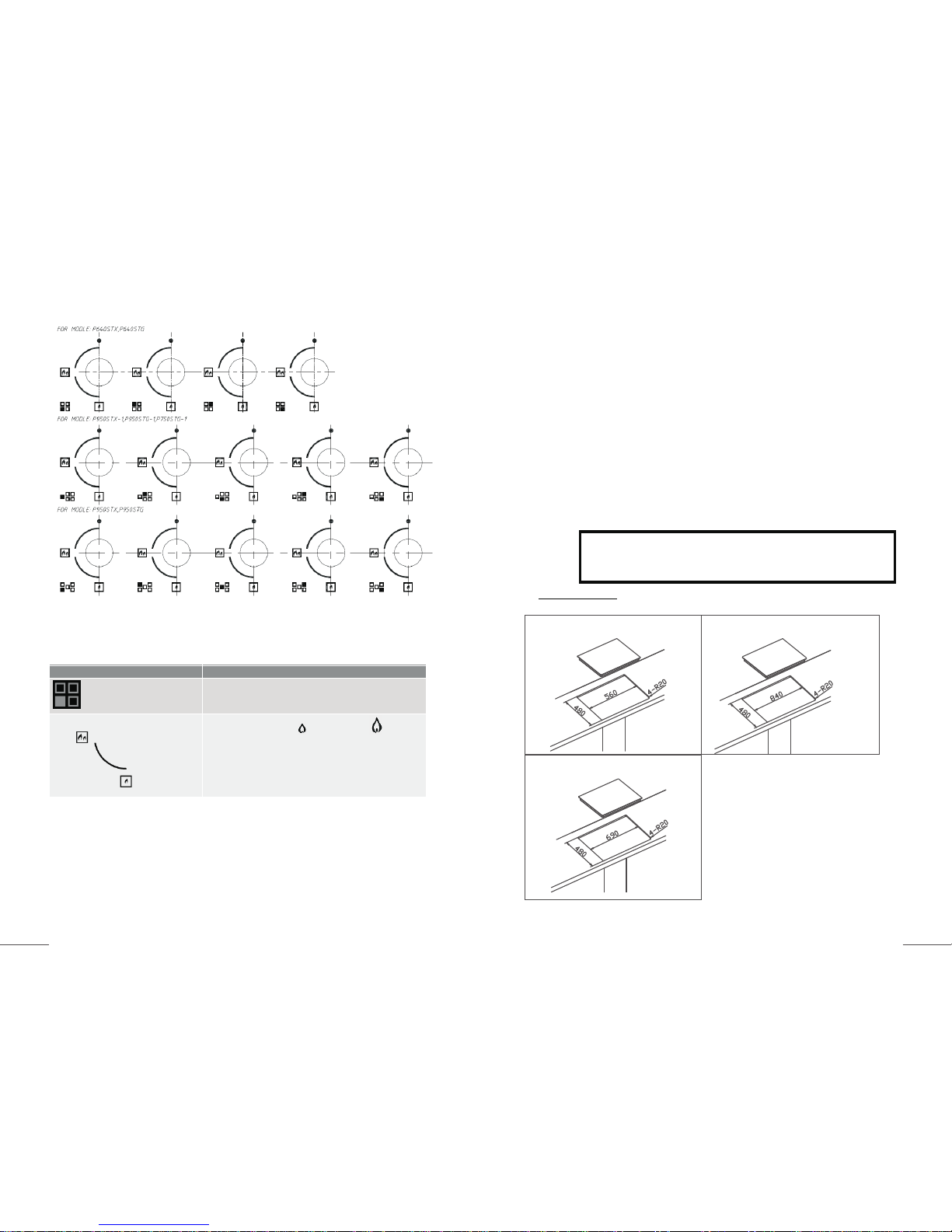

l The appliance may only be installed and connected

by trained, Authorised persons.

l Built-in appliances may only be used af ter they have

built in to suitable built-in units and work surfaces

that meet standards.

l In the event of faults with the appliance or damage

to the glass toughened (cracks, scratches or splits),

the appliance must be switched off and

disconnected from the electrical supply, to prevent

the possibility of an electric shock.

l Repairs to the appliance must only be carried out by

trained Authorised persons.

l The technical and identification data for the hob

figure on the reference plate fixed to the appliance.

l This reference plate must be consulted before

making the electrical connections.

l The electrical connections must be made by

specialist aware to the legal and regulatory,

requirements in each country.

l If the cable is damaged in any way it must be

replaced by the manufacturer or after sale service

or by authorized technical staff, to avoid hazard.

Correct use

l People (including children) who, because of their

physical, sensory or mental capabilities or their

inexperience or ignorance are not able to use the

device safely, should not use this device without

supervision or instruction by a responsible person.

l This appliance should be used only for normal

domestic cooking and frying of food.

l The appliance must not be used as a work surface

or as a storage surface.

l Additions or modifications to the appliance are not

permitted.

l Do not place or store flammable liquids, highly

inflammable materials or fusible objects (e.g. plastic

film, plastic, aluminum) on or near the appliance.

l Do not heat an empty pan on the appliance.

Children’s safety

l The cooking zones will become hot when you

cook. Therefore, always keep small children

away from the appliance.

l The appliance is not intended for use by

young children or infirm persons without

supervision.

l Young children should be supervised to

ensure that they do not play with the

appliance.

Safety during use

l Remove stickers and film from the glass

ceramic.

l There is the risk of burns from the appliance if

used carelessly.

l Cables from electrical appliances must not

touch the hot surface of the appliance or hot

cookware.

l Overheated fats and oils can ignite very

quickly. Warning! Fire hazard!

l Switch the cooking zones off after each use.

l Users with implanted pacemakers should

keep their upper body at least 30 cm from

cooking zones that are switched on.

l Risk of burns! Do not place objects made of

metal, such as knives, forks, spoons and

saucepan lids on the cooking surface, as they

can get hot.

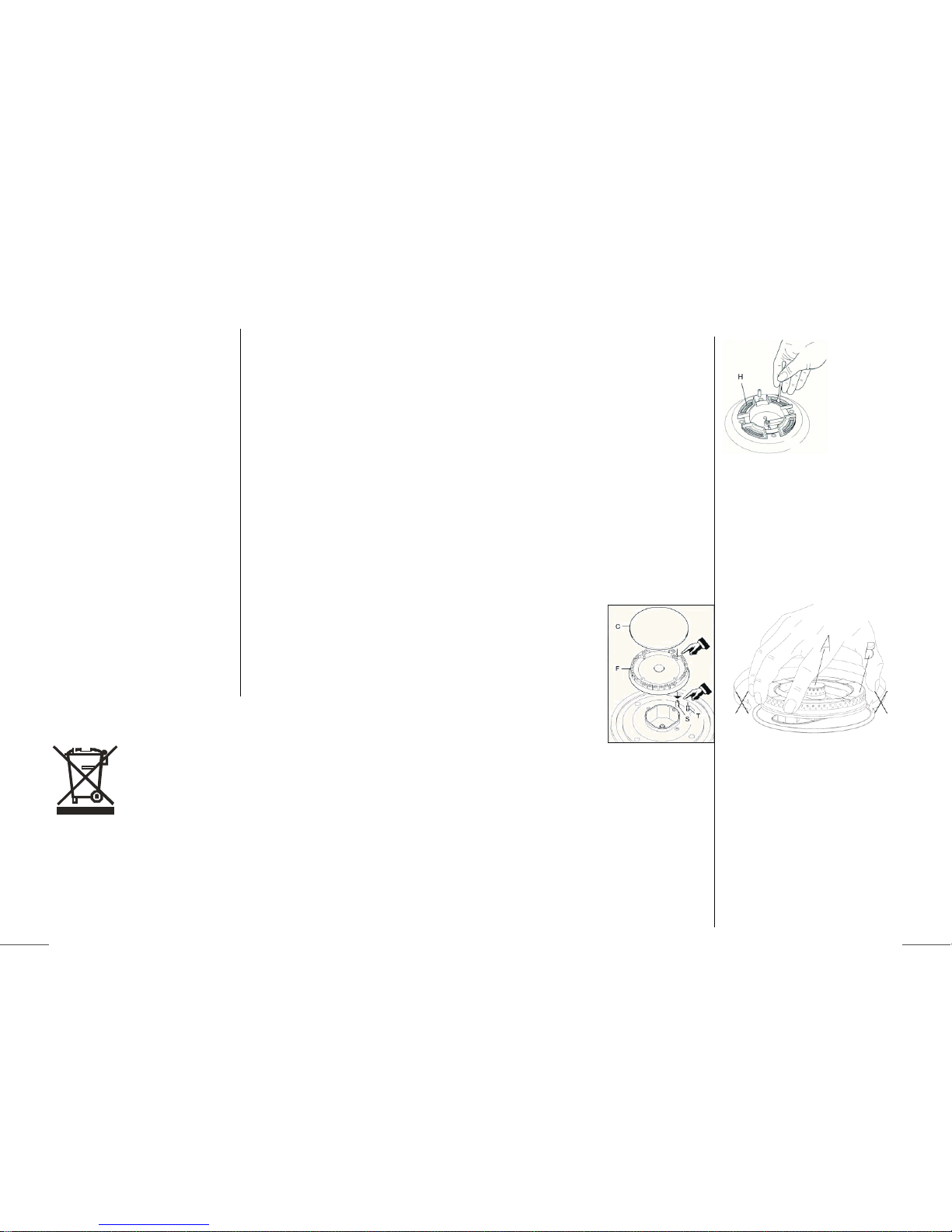

TROUBLESHOOTING

Servicing of the hotplates must only be done by an authorised service representative (see back of this booklet) and the

hotplate must not be modified. Power must be disconnected before any servicing or maintenance is conducted.

l Clean the panel: Suggest each clean after cooking

l Clean ignition needle ,thermocouple , burner and Pan support: Recommended cleaning at least once a month

Abnormal conditions include:

l Excessively yellow or sooting flame type.

l Flame lifting off the burner ports.

l Flame lighting back into the burner (normally associated with a popping sound).

l Objectionable odour of the flames combustion products.

Should a faulty condition develop in the hotplate that is not described above, refer to the following table first for

possible causes and remedies prior to contacting an authorised service representative. Servicing beyond the remedies

listed shall only be undertaken by an authorised service representative.

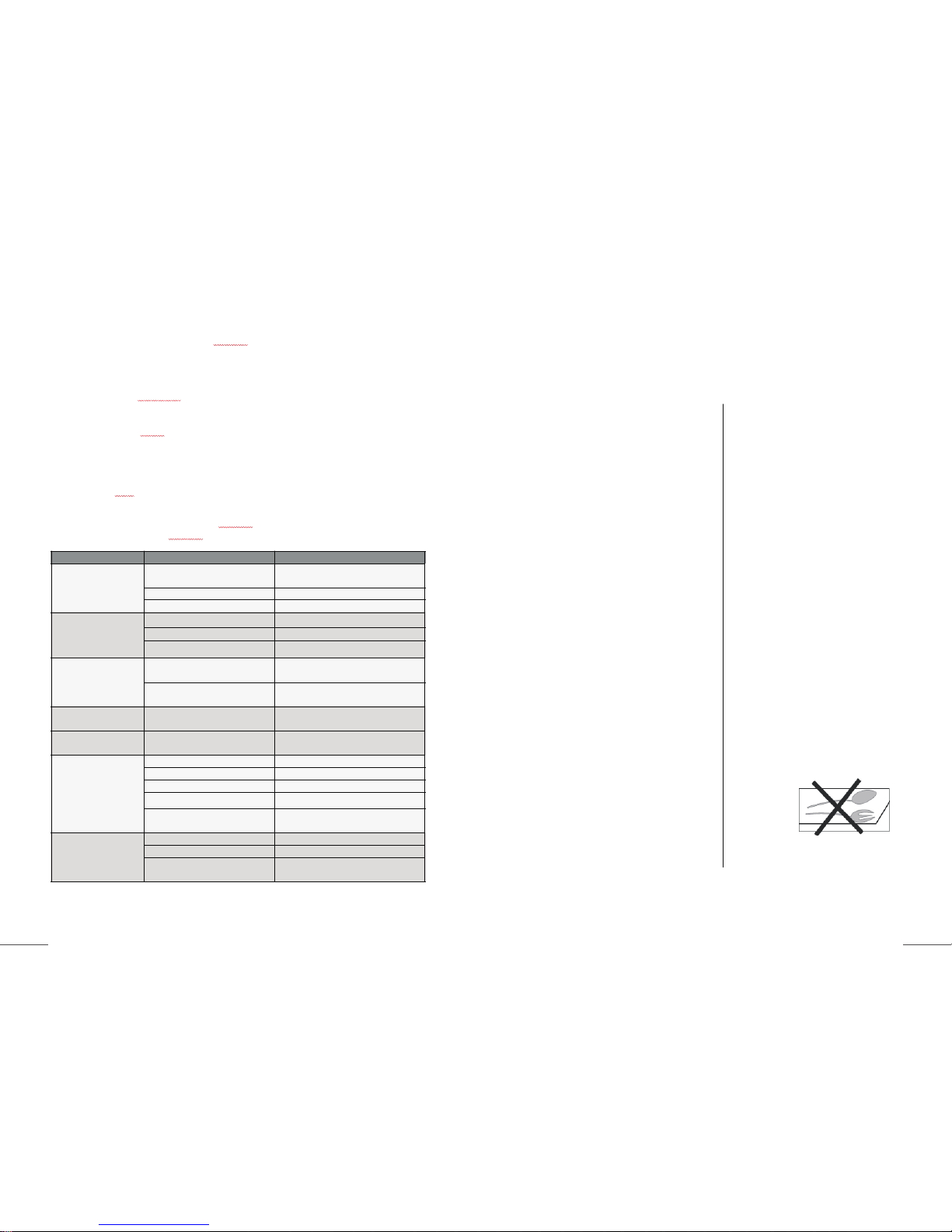

FAULT POSSIBLE CAUSE REMEDY

No spark when gas control

knob depressed.

No power. Check plugged in and switched on.

Check mains circuit breaker.

Loose sparker cable. Call authorised representative.

Burner not aligned properly. Remove and re-fit burner.

Burner not lighting when

spark ignition working.

Gas supply off. Check gas supply valve on.

Burner not aligned properly. Remove and re-fit burner.

Burner ports blocked. Remove, clean and replace burner.

Burner goes out when

control knob released.

Flame safeguard not activated. Re-light, allow more time for flame safeguard

to activate.

Flame safeguard faulty connection or

broken. Call authorised representative.

Uneven flame pattern or

slight flame lifting. Burner ports blocked. Remove, clean and replace burner.

At minimum flame setting

the flame is too high. Turndown control setting incorrect. Call authorised representative.

Small flame on High

setting.

Regulator faulty. Call authorised representative.

Gas supply pressure low. Call authorised representative.

Incorrect injector fitted. Call authorised representative.

Blocked injector or gas supply tube. Call authorised representative.

Incorrect utensil size. Refer to operating instructions utensil

choice.

Flame too high on High

setting.

Regulator faulty. Call authorised representative.

Incorrect injector fitted. Call authorised representative.

Incorrect utensil size. Refer to operating instructions utensil

choice.