VS Security Products LTD ZZ001234, ZZ001235 Page 10 of 15

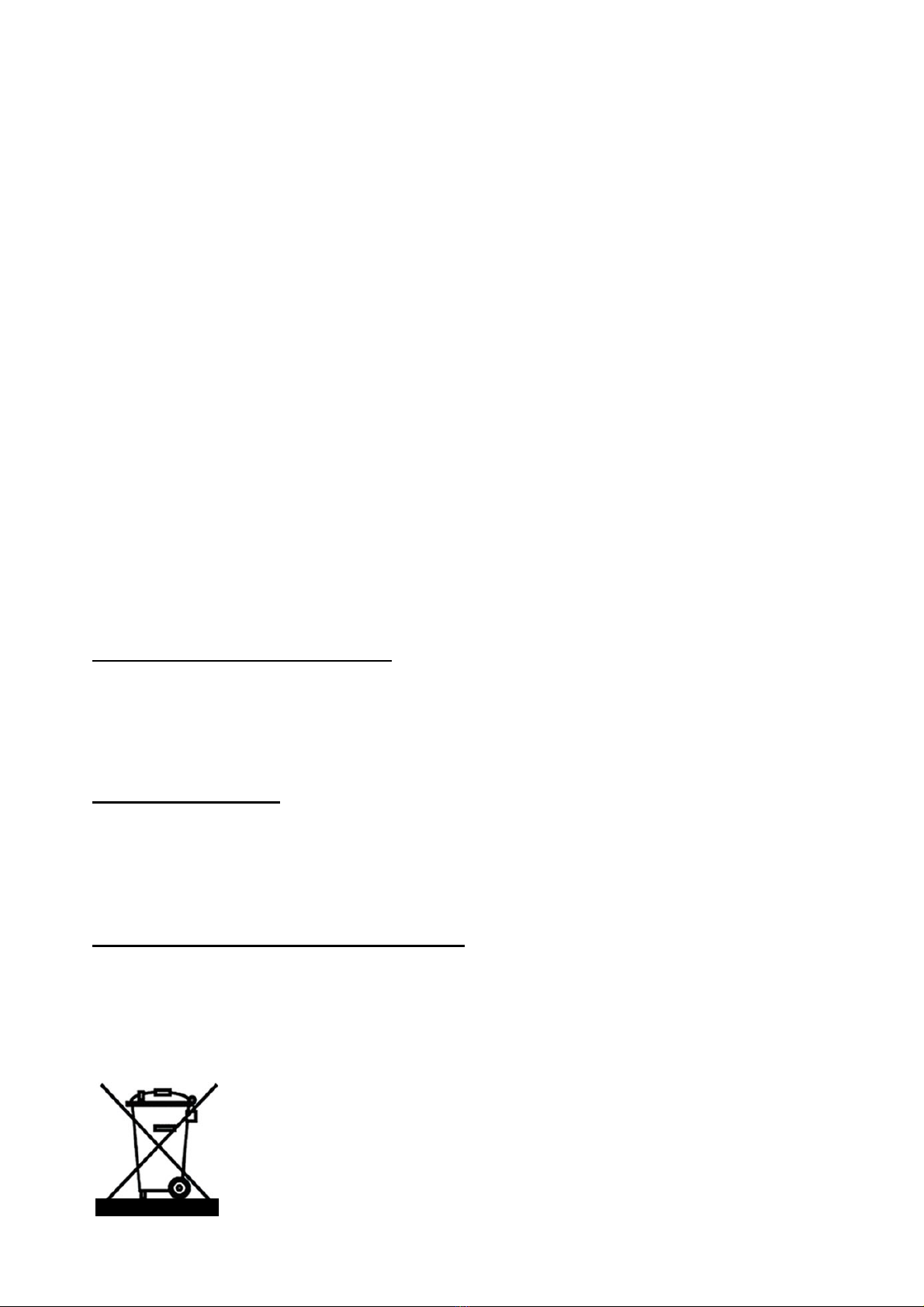

1. Press to destroy – Starts the shredding process.

2. Fine Cut, Course Cut – Selects size of shredded partials. Defaults to Standard Cut.

3. Beep on Key Press – Machine beeps when screen button pressed, touch to switch off.

1. Lid Open Please Close Lid – Lid over media feed slot is open, close to proceed with shredding.

2. Destroying Press to stop – Shredding is underway, unit can be stopped in an emergency.

3. Destruction Complete – Shredding is complete.

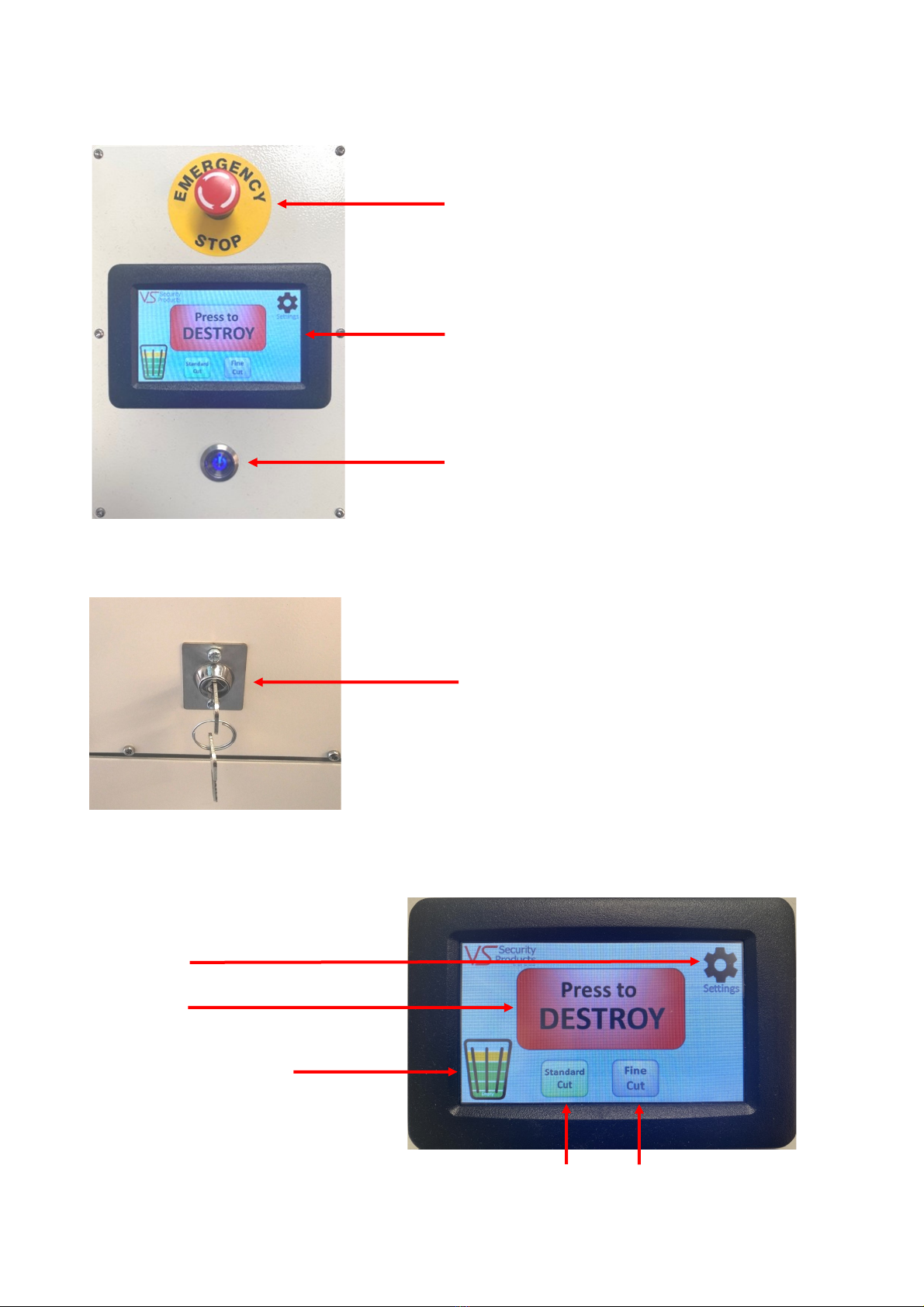

4. Machine Locked please use the key – use the key to switch on to proceed with shredding.

5. Machine opened during crush cycle – shredding cycle aborted as the Lid over media feed slot has been opened

during the shred cycle. Close lid press OK and restart.

6. Desktop Model only—Drawer Opened During Crush Cycle – Shredding cycle aborted as drawer has been

opened. Close drawer press OK and restart.

7. Desktop Model only—Warning Drawer Not Detected - Shredding cycle aborted as no drawer detected. Check

drawer present and press OK and restart.

8. Floor Standing Model only—Trolley Door Opened During Crush Cycle - Shredding cycle aborted as trolley door

has been opened. Close door press OK and restart.

1. Connect to the mains power using the power lead provided.

2. Press the power button, the touch display lights up and the system initializes.

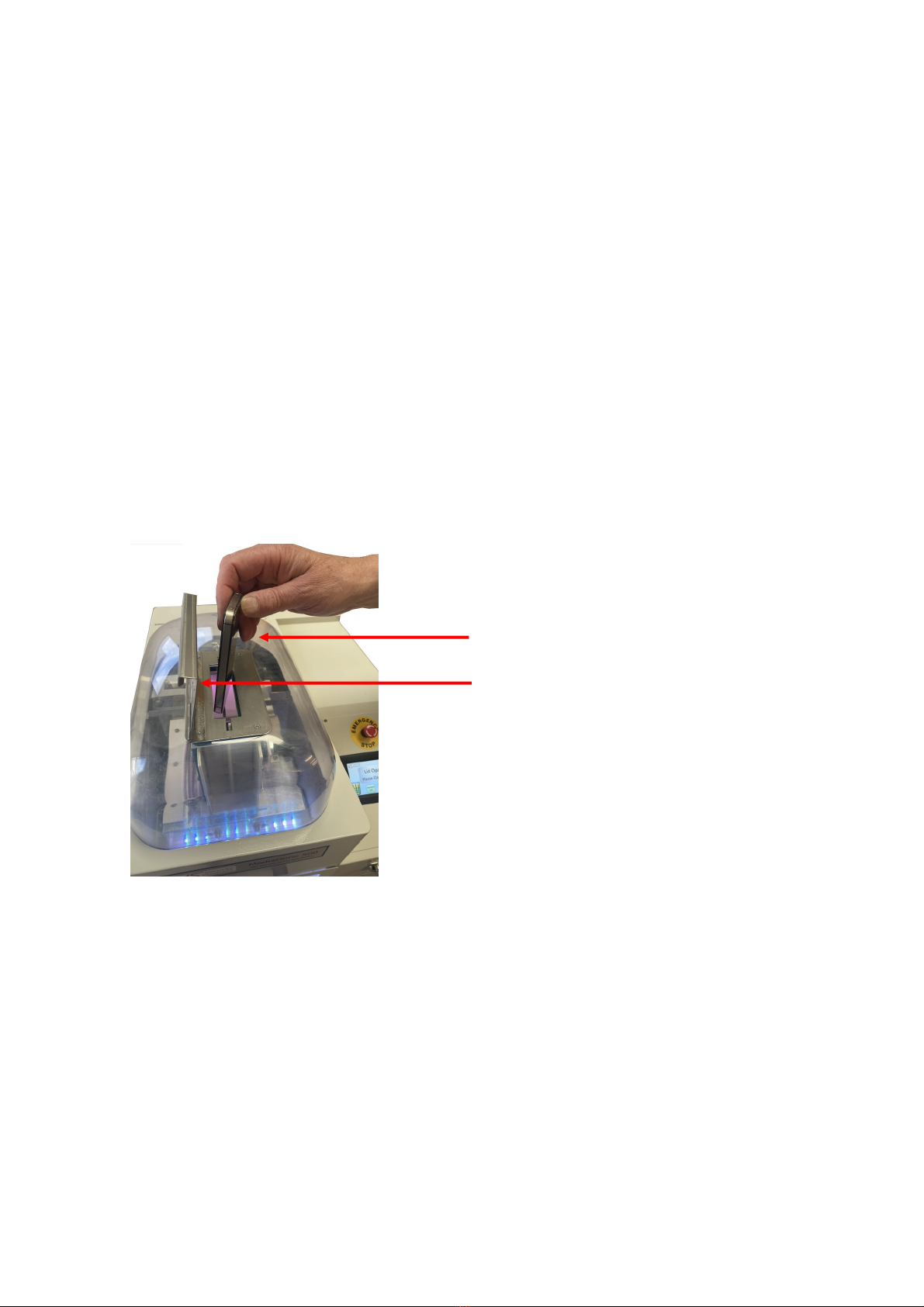

1. Open the Flap and drop the media, like USB sticks, Solid State Drives (SSD’s), flash drives, Smart Phones etc

into the destruction chamber.

2. The media should be shredded individually, one at a time (this ensure the MediaGone 500 gives its best

performance) /

3. Close the Flap and press Destroy on the Display.

1. The MediaGone 500 has 2 shred particle sizes, Course and Fine.

2. Course gives lager partials with a faster throughput.

3. The machine defaults to Course, to select fine press Fine before pressing Destroy.

1. Press the Destroy Button on the Display.

2. The cutters will be energized and shredding will commence.

3. The cutters will rotate backwards and forwards shredding the media.

4. When all the media has been shredded the cutters will stop and ‘Destruction Complete’ will be displayed.

Media

Flap

Figure 13