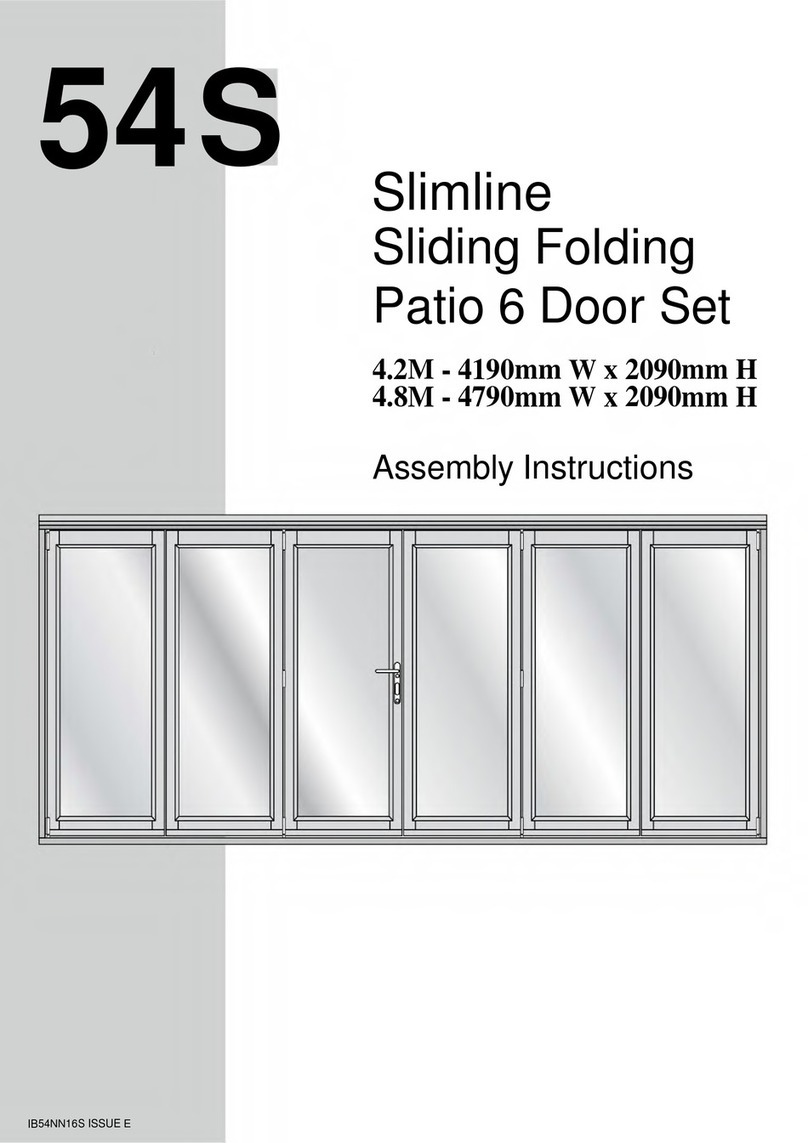

2 Sliding Folding Patio 6 Door Set

About your patio door set

Important information

• We recommend that a competent tradesperson install this product.

• A single person must never carry out the installation, as some

components are very heavy.

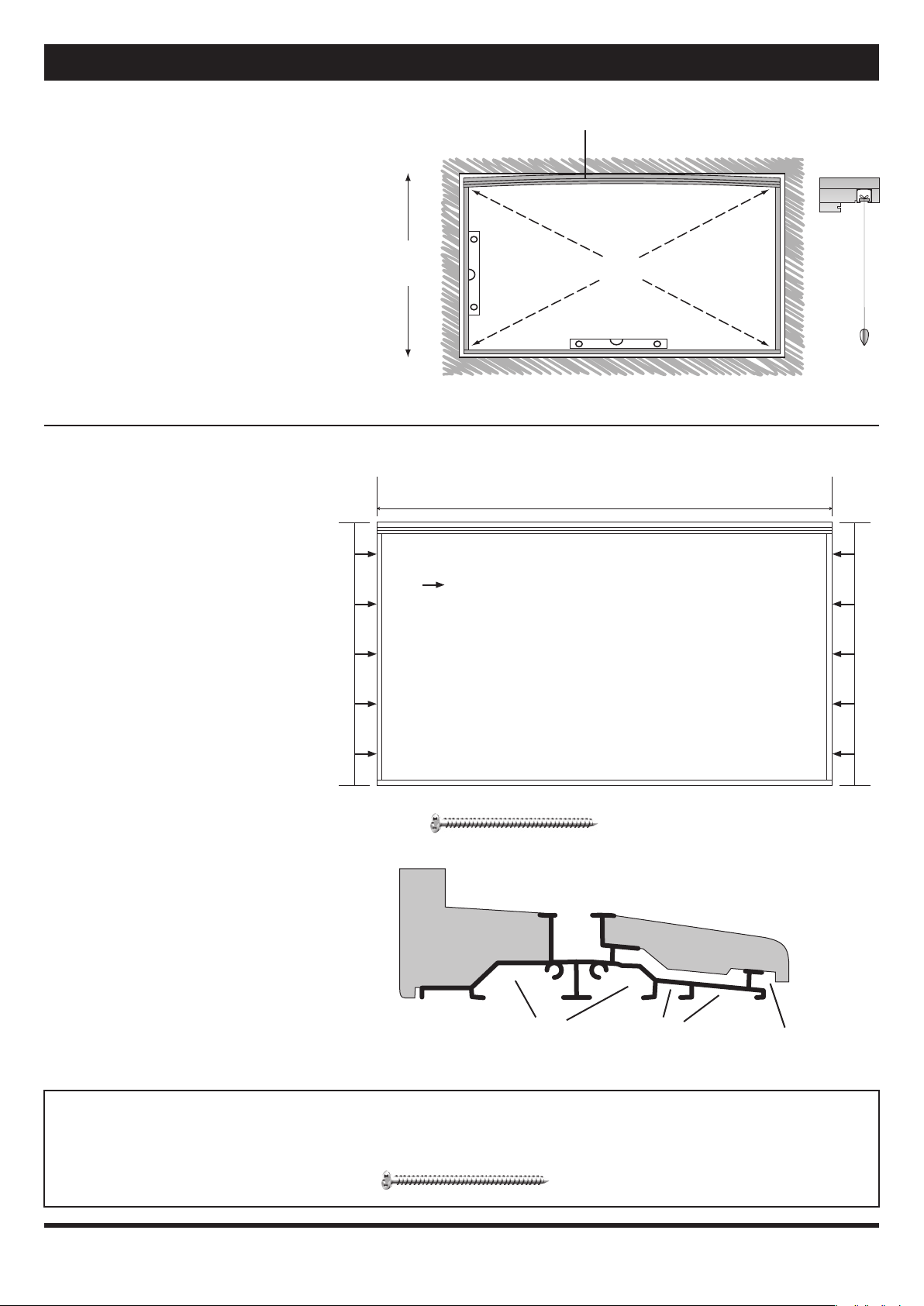

• The Outer-Frame Head requires fixing to the building RSJ over the

opening. The RSJ must be capable of carrying the load of the doors in all

conditions. If in doubt consult a structural engineer.

Automatic Closures and Operators

• The hardware systems are designed for manual operation. Poorly

adjusted automatic operator closers can import significant destructive

forces to tracks, bearings and stops. Such hardware used in installations

is expressly excluded from warranty terms.

Care of aluminium clad timber doors and frames on site

• Please check doors, frame and sill at time of delivery to ensure that

they are acceptable and in good condition. If you find a component

missing or damaged please inform your supplier immediately. We keep

replacement components of most set parts and these can be sent out

to you quickly. This will save you having to re-package and return the

whole set, and allows you to continue with the project. (See separate

parts list for component reference number).

• When storing prior to installation the doors and frames should be kept

in their packaging, handled with care and stored in a dry, ventilated

building. Doors and frames should be stored flat on a level surface (not

on edge or on end).

• Doors should not be stored or fitted in the building until the wet trades

such as plastering, painting etc. Have been completed and the room is

dried out.

VERY IMPORTANT

• It is vitally important to handle the doors and frames very carefully at all

times to avoid damaging the powder-coated finish on the aluminium.

• All frames and doors should be handled by two people at all times as

they are very heavy.

Trimming

• This Sliding Folding Door Set is not designed to be trimmed on site and

should be fitted as supplied.

Conditions of Sale

• We shall not be held responsible for any incidental work expenses

arising out of or because of any defect in our product, or bad

workmanship to our product. In the event of the goods having

manufacturing defects and requiring replacement, our liability will be

limited to the value of the door or frame component only. These notes

do not affect your statutory rights with the retailer of this product.

Maintenance

Hardware in buildings is subject to deterioration from everyday

use, and also environmental attack due to atmospheric and

other conditions. Maintenance of hardware is even more

important in severe environments such as coastal marine areas,

and some industrial areas. Even stainless steel products require

maintenance to prevent deterioration in some environments.

We require the following minimum maintenance to be followed

otherwise the warranty shall be void.

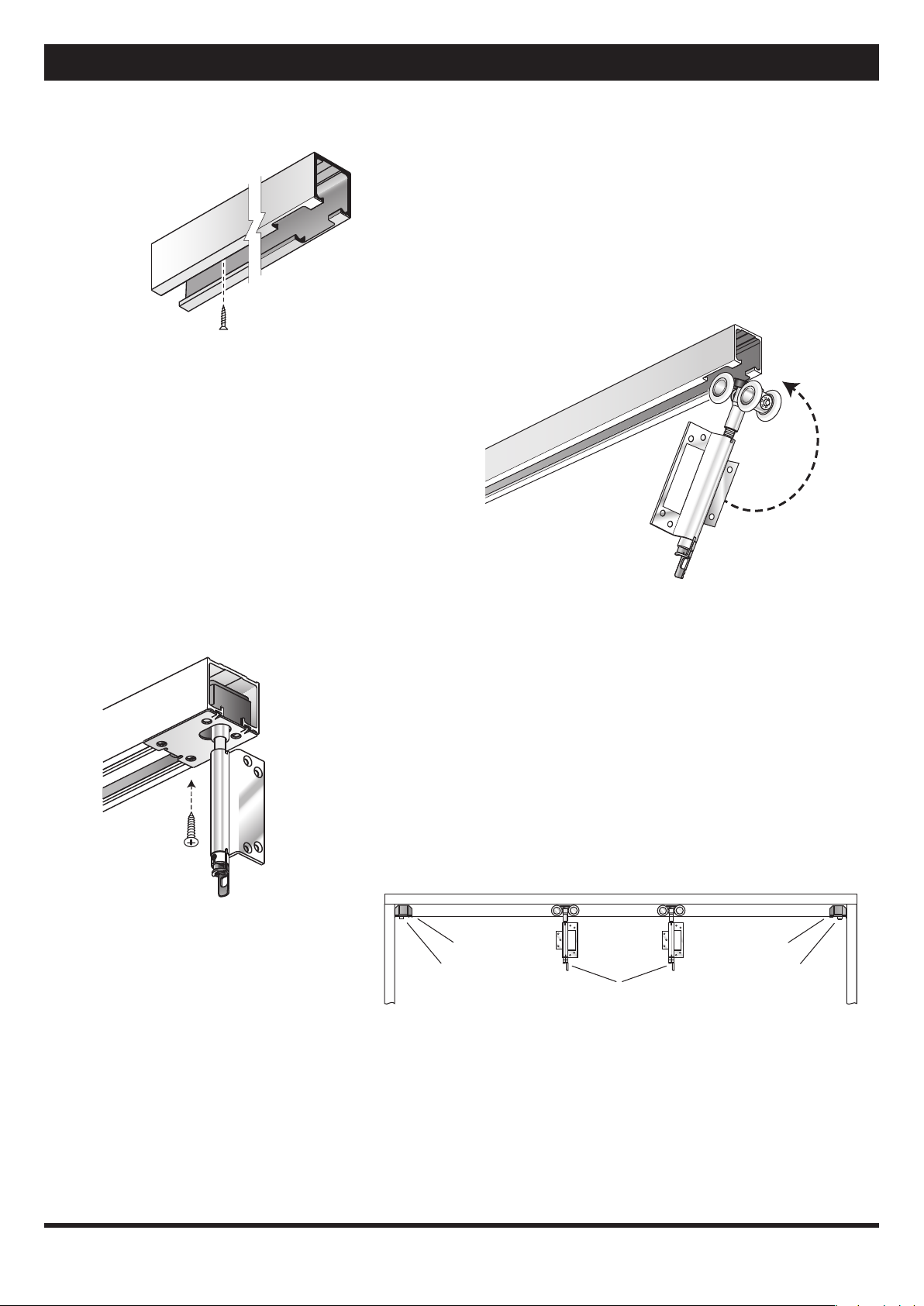

Track and Bearings:

Using a spatula or similar (not your fingers), apply a small amount

(typically a 1/2 teaspoon of white petroleum jelly (Vaseline) or similar

All products must be installed in accordance with accepted good trade practice (and in accordance with supplied

instructions where applicable), and maintained in accordance with these procedures or else the warranty shall be void.

lubricant to the inner lip of each side of the track. Ensure that the wheels

pass through the lubricant and it is distributed evenly along the track. Put

additional lubricant around bearings. Lubricant reduces wear, improves

smoothness and further protects against corrosion or track and bearings.

Remove all surface contaminants by wiping all visible track surfaces

with a damp soft cloth and mild detergent, then wipe clean with a clean

cloth. In severe environments, apply a thin film of corrosion preventative

such as WD40, by wiping with a soft cloth moistened with one of these

products.

Stainless steel bearings are manufactured from hardening-grade stainless

steel and although this material performs considerably better than plated

steels, it is susceptible to corrosion unless maintained as described above.

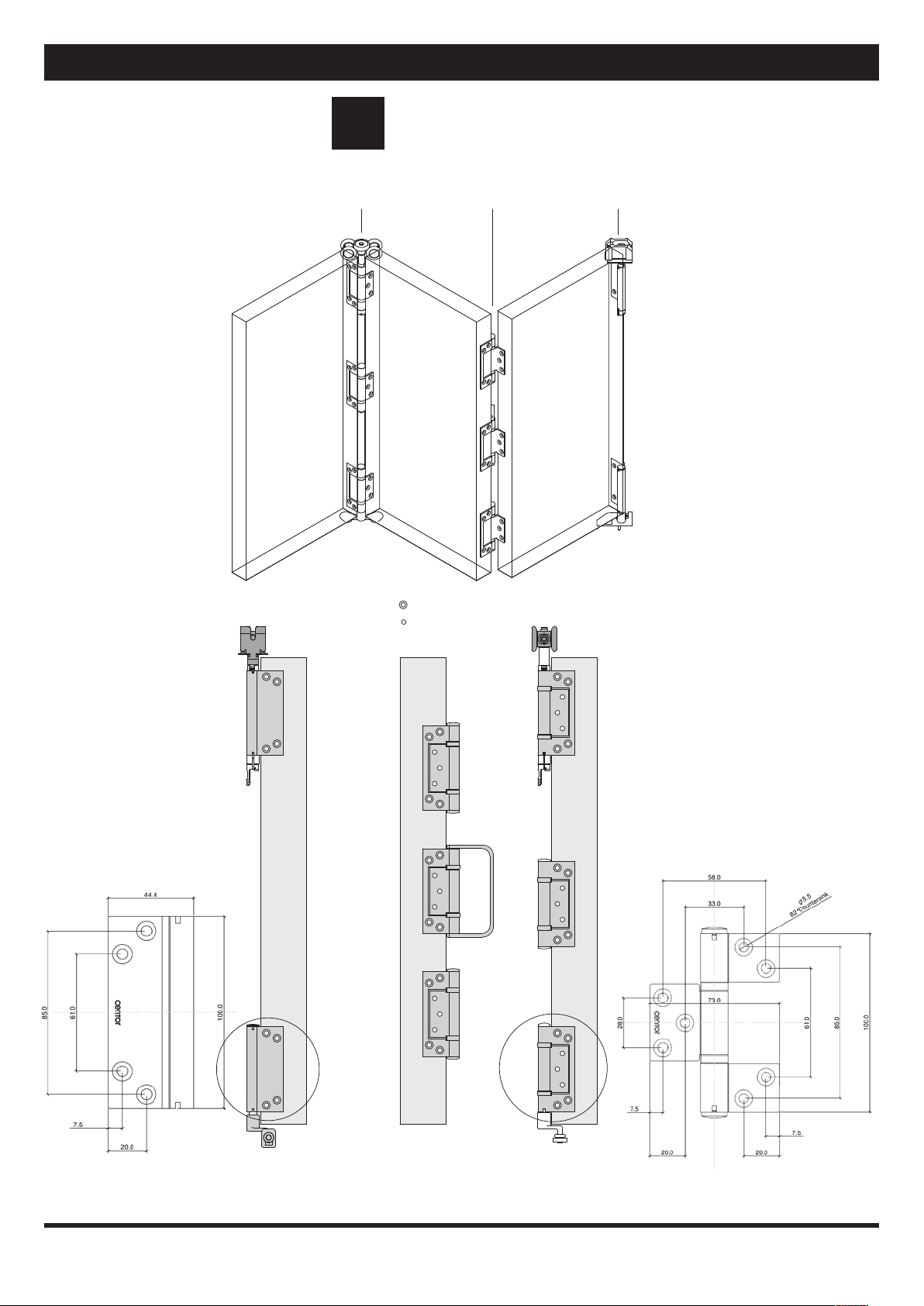

Hangers, Pivots and Brackets:

A light spray application of a corrosion preventative such as WD40,

followed by a light wipe with a dry cloth to remove excess, is

recommended to all hangers, pivots and brackets. Exposed surfaces should

first be wiped with warm soapy water and a soft rag, and then rinsed

clean before applying the corrosion preventative.

Hinges:

Wipe down the visible surfaces with warm soapy water on a soft rag

and then rinse off by wiping with a clean damp rag. Application of a

thin film of light machine oil or WD40 will help to maintain the original

lustre of the metal finish. Be careful not to get these compounds on the

timberwork itself as may cause staining.

Drop bolts:

Spray application of a suitable lubricant such as WD40 to the sliding pin

inside the bolt and to the lock cylinder is recommended. A tube attached

to the nozzle will help to concentrate the spray where you want it to go.

There are access holes or slots on all drop bolt products so that this can

be done without removing the locks from the doors.

Frequency:

The procedures mentioned above need to be carried out as often as is

necessary to prevent deterioration in the installed environment, however

we recommend the following minimum frequency of application:

General environment - 6 monthly

Marine environment - 3 monthly

Please be careful not to get the lubricants or other liquids above on the

Timber components as may cause staining of the timber.

The properties of timber

No two trees produce identical grains or colour of wood and this adds

to the beauty of a natural product. We therefore cannot guarantee that

all doors and frame components will look exactly the same in grain and

colour. Warping of wood is not a defect if it does not exceed 1/4 inch

(6mm) in its installed position.

Maintaining the doors and frame

The outside powder-coated finish on the aluminium should be regularly

washed with warm soapy water, rinsed with clean water and dried off.

The oak timber inside finish is a resilient polyurethane clear varnish

which should last for several years. To maintain, just wipe down with a

damp cloth. When the oak requires re-coating, use a proprietary brand of

clear PU varnish.