FLASHBAKE®/ MICROWAVE OVEN GENERAL

Form 24694 (April 2001)Page 5 of 52

to +60 sec.). Compensation voltage range

is 108 to 132VAC.

Voltage compensation occurs after

approximately 5 seconds of menu cook

operation. The display will show "OPTIMIZING

COOK TIME.”The time will flash and then

display the new adjusted time, based on the

amount of voltage compensation required.

NOTE: Voltage compensation only occurs

during menu cook operation and only occurs

once during the cooking cycle (at the initial

start of the menu cook cycle). When using

menu cook, you are selecting preprogrammed

items from a menu. These items require

compensation for accurate and consistent

cooking results. When cooking with combi

cook, voltage compensation does not occur.

•Thermal Compensation: When cooking food

items consecutively, the temperature inside the

oven cavity can become very hot. The control

automatically compensates for the increased

temperature by adjusting the cooking power

levels of both the upper and lower halogen

lamps. At the start of each new cook operation

(just prior to voltage compensation occurring),

the cavity thermistor reads the cavity

temperature and the control board adjusts

power levels to compensate for heat that

already exists in the oven cavity. It is not

possible to see the adjusted power levels in

the display.

•Thermal Protection: If oven cavity

temperatures reach somewhere between 500

and 600 degrees, or if cook time exceeds 12

minutes of cooking at halogen power levels

greater than 7, all power levels (lamps and

microwave) will be reduced by the control

board to 7 for the remainder of the combi cook

cycle. The consumer will not notice any change

in display readout, however, they may notice

that the halogen lamps are cycling differently

than expected.

In the unlikely event that internal oven cavity

temperature exceeds 600

(

F, combi cook

operation will be terminated. When the control

board terminates the combi cook cycle, it

returns the display to its normal off position

(with time of day clock showing in display).

Since the thermistor in the cavity is constantly

being monitored by the control board, when the

unit cools, the control board returns oven to

normal operation.

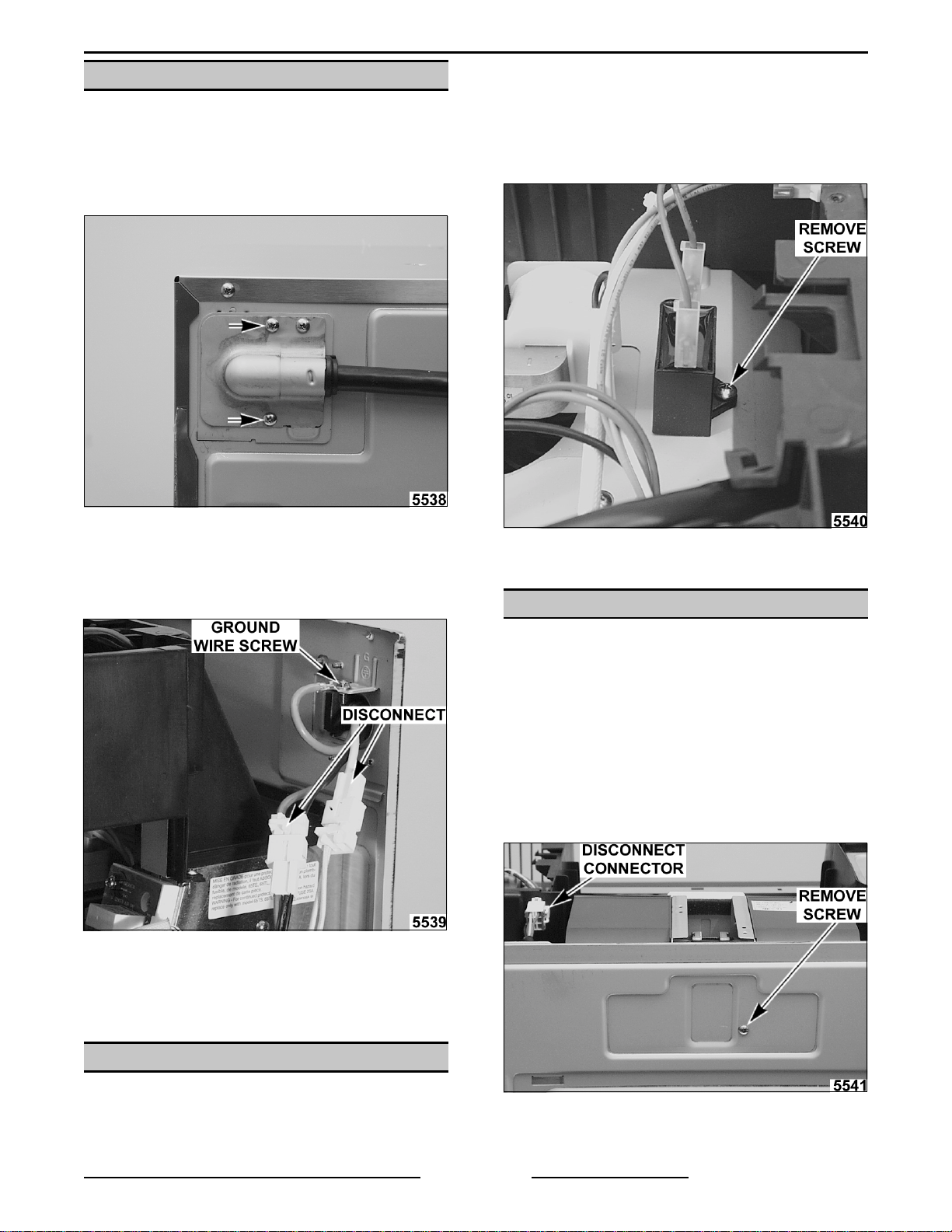

ELECTRICAL SPECIFICATIONS

Model FBMW2 is supplied with a cord and plug.

For cord and plug units, an NEMA 14-30R wall

receptacle is required.

Model FBMW3 is a unit intended to be hard wired.

NOTE: Early hard wired models left the factory with

the green and white wires crimped together. On

these units the frame is grounded by connection of

ground lead to neutral white lead. Effective January

1, 1996, the National Electrical Code requires that

new construction use a (4) conductor connection

and will not permit grounding through neutral. If

used in new construction after January 1, 1996, or if

local codes do not permit grounding through neutral

white lead, open the factory crimp connection and

connect neutral white lead to branch circuit neutral

conductor in usual manner.

120/208-240, 60 Hz, single phase, 30 amp power

supply is required.

Working voltage = 208 to 264VAC.

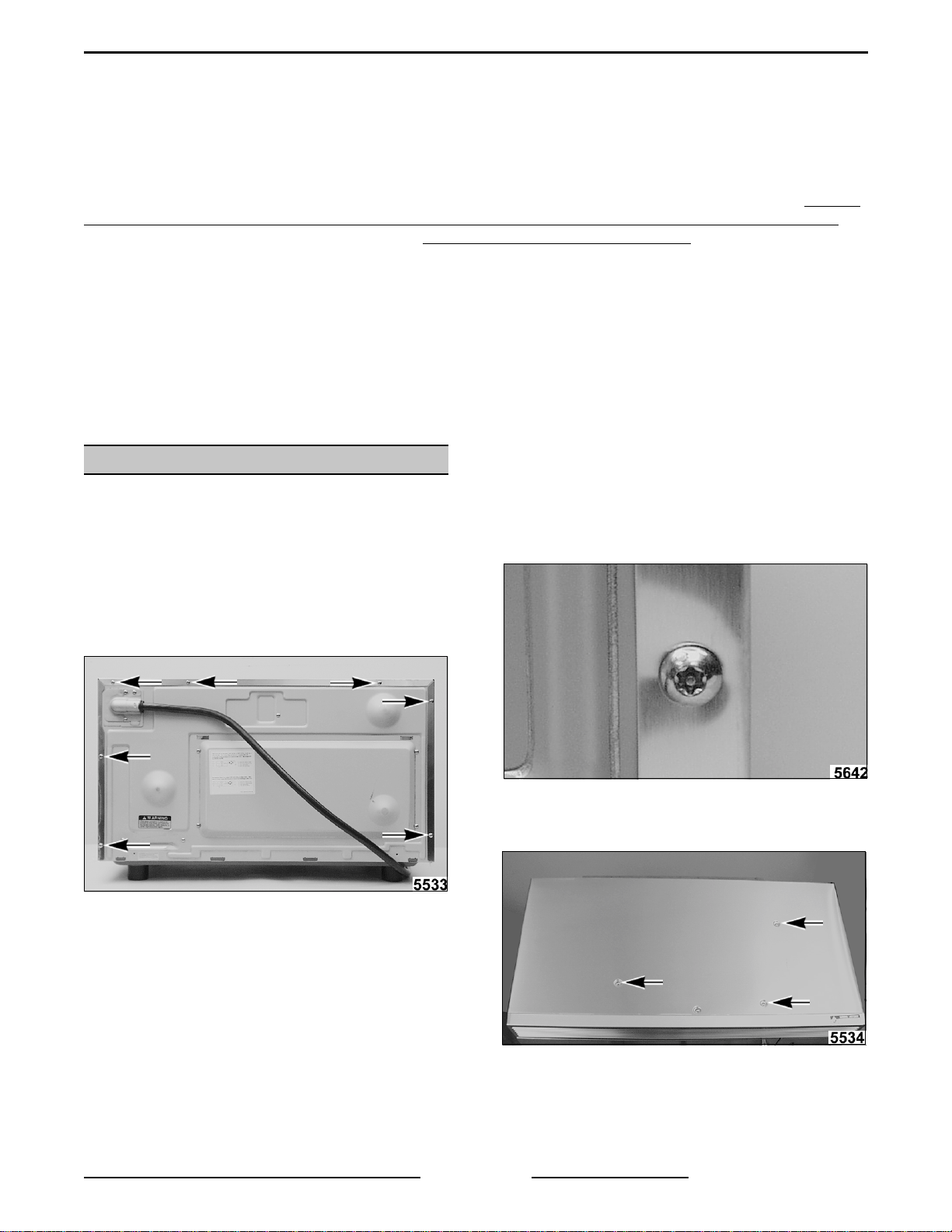

INSTALLATION

Refer to the INSTRUCTIONS manual shipped with

the oven for installation instructions.