9

ENGLISH

The only inuencing factors are the level of insulation and the location of

the pool with regard to wind shelter.

Useful advice: To reduce running costs and speed up the heating process;

Insulate the pool wherever possible. A oating solar cover is an essential

minimum to retain heat.

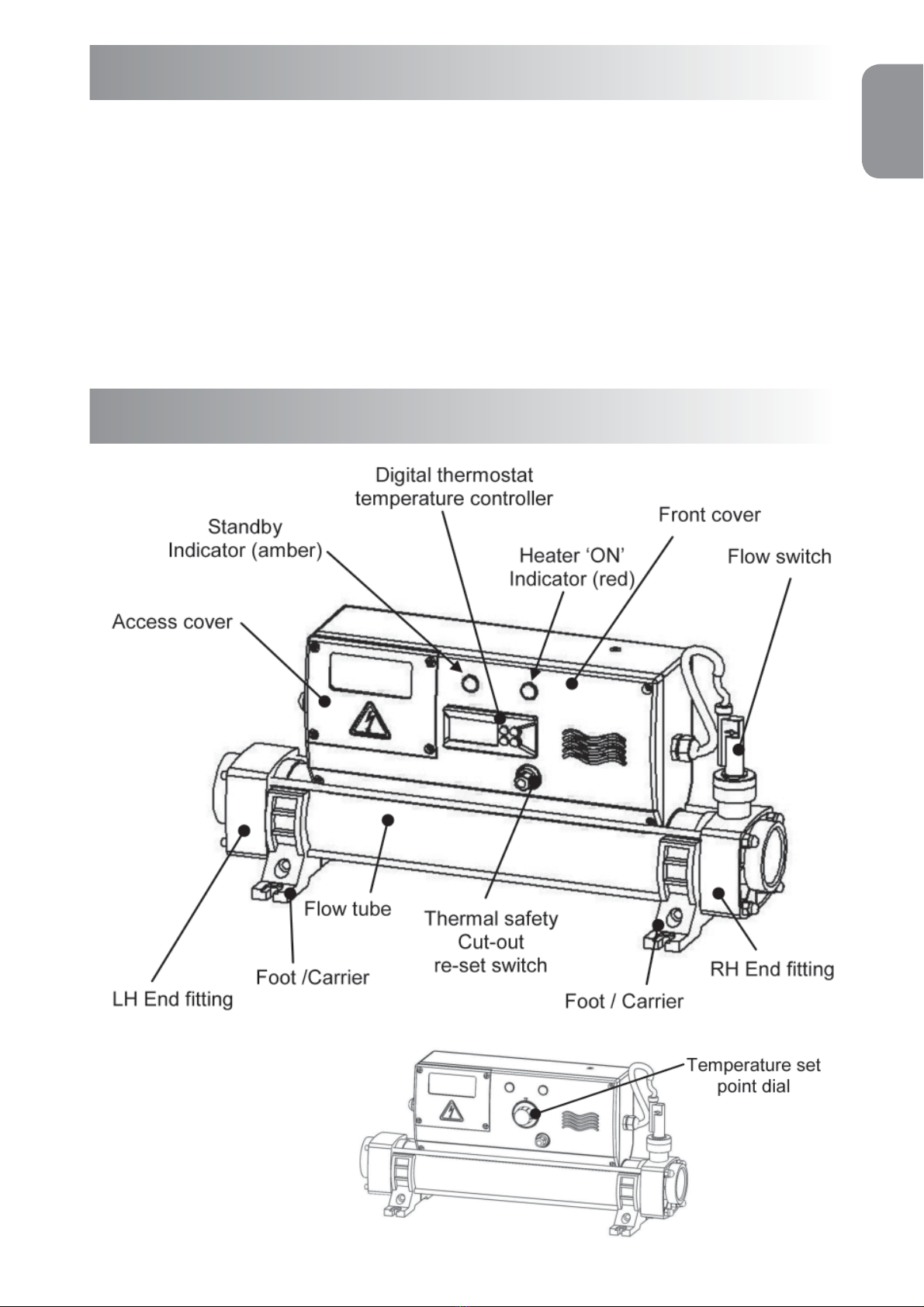

Quick Function Test

Observe the main electricity meter when the heater is on (ie: red light

‘On’) and then observe it again when the heater is in the standby mode

(ie: amber light ‘On’) The test should show that the meter is recording

more electricity being used by the heater when the red light is ‘On’. It is

impossible for an electric heater to waste energy, if it is drawing power

then that power will be turned into heat that will be trans-ferred to the

water.

Accurate Function Test

If a more accurate test is required to conrm that your heater is delivering

the specied heat output, two electricity meter readings will need to be

taken from the properties main electricity meter, with an exact one hour

interval (ie: take one meter reading and then a second reading exactly one

hour later) then by subtracting the rst reading from the second reading

the number of units (kilo watts kW) consumed can be calculated. Note that

your heater is also rated in kW hours.

The pool pump and heater will need to be running continuously during

the test (ie: with the heater red light ’On’) To avoid inaccurate results when

performing this test, it is important to refrain from using other high current

consuming appliances in the property (such as tumble dryer, showers,

cookers etc).

A large domestic pool pump of 1 horsepower will draw less than 1kW in a

one hour period. The conclusion of the test should prove that for example

a 6kW heater and a ½ horsepower pump will draw between

6.3-kW ~ 6.5-kW in one hour. It is impossible for an electric heater to waste

energy, if it is drawing power then that power will be turned into heat that

will be transferred to the water.