3

TABLE OF CONTENTS

1. DESCRIPTION AND FUNCTIONS .................................................................................................................................................... 6

1.1 Intended purpose ............................................................................................................................................................................... 6

1.2 Technical data ........................................................................................................................................................................................ 7

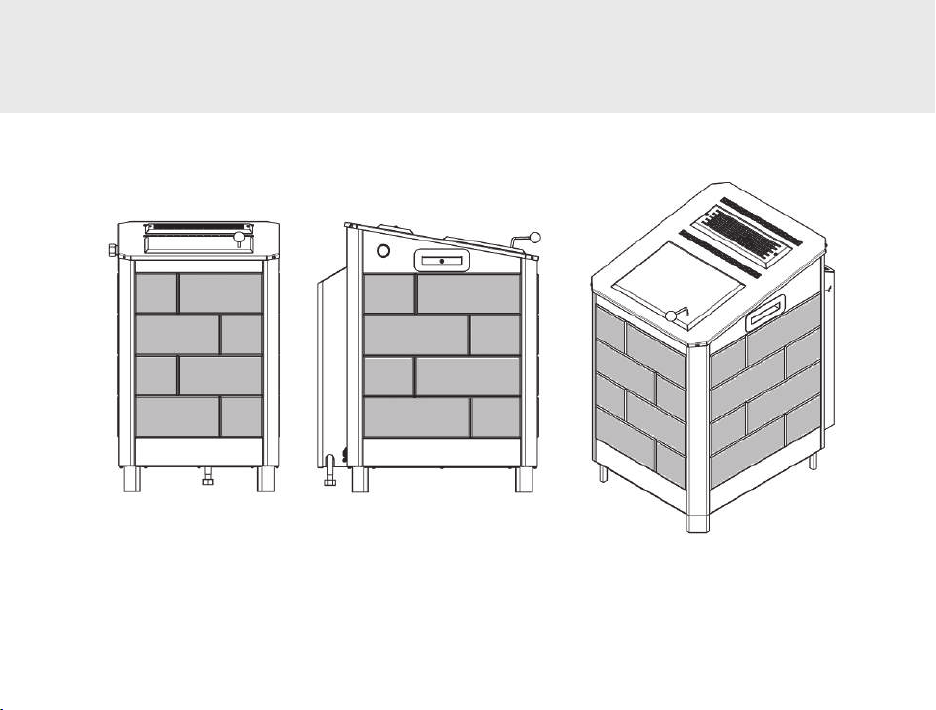

1.3 Components ........................................................................................................................................................................................... 8

1.4 Design and functions ...................................................................................................................................................................... 9

1.5 Instrumentation .............................................................................................................................................................................. 15

1.6 Marking and sealing ..................................................................................................................................................................... 16

1.7 Packing .................................................................................................................................................................................................... 16

2. APPLICATION .................................................................................................................................................................................................. 21

2.1 Preparation for use ....................................................................................................................................................................... 21

2.1.1 Safety precautions ......................................................................................................................................................................... 21

2.1.2 Mains connection and preparation for operation ............................................................................................ 23

2.1.3 Stone facing assembly (for stone-faced heaters only) ................................................................................. 28

2.2 Operation .............................................................................................................................................................................................. 32

2.2.1 Safety precautions ......................................................................................................................................................................... 32

2.2.2 Operation procedure .................................................................................................................................................................. 33

2.2.3 Recommendation for steam generator descaling ........................................................................................... 35

2.2.4 Emergency actions ....................................................................................................................................................................... 37

2.2.5 Possible faults and troubleshooting ............................................................................................................................ 38

3. MAINTENANCE ............................................................................................................................................................................................. 39

4. STORAGE AND TRANSPORTATION .......................................................................................................................................... 39

5. DISPOSAL ........................................................................................................................................................................................................... 40

6. WARRANTY ....................................................................................................................................................................................................... 40

7. WARRANTY CARD ...................................................................................................................................................................................... 42