12

TROUBLESHOOTING

1) Poor heat output

A) Stove too small for a room.

Seek advise from a Qualified Heating Engineer as to (KW) output required for room

size as a guideline the volume of the room in cubic feet divided by 500 i.e. room

15’x15’x8’ would require 3.6kw approx.

B) Chimney and/or flue pipe restricted, room ventilation restricted.

On installation these will have been checked but regular maintenance is necessary

as conditions can change i.e. soot build up, birds nesting, masonry fall, dust build up

or furniture blocking vents.

C) Poor quality fuel.

Only burn dry seasoned timber, soft woods have a lower heat output then hard

woods per hour. Solid fuels vary in heat value check with your coal merchant as to

suitability.

2) Dirty Glass Panel

A) Generally caused by poor fuel quality, see (1c)

B) Use secondary air slide (Airwash) for glass panel

C) Fire burning to low, open air vents on stove create hot fire this may ‘burn’ glass

clean.

D) If glass requires cleaning use glass cleaner recommended by your supplier, only

use glass cleaner or cold glass. DO NOT USE any abrazifs or scrapers these will

scratch glass causing tar build up harder to remove.

3) Unburnt Fuel In Firebox

Insufficient air reaching fuel. Open primary air slide, this will supply combustion air to

burn fuel fully (unless it has reached a ‘point of return’)

Check ash pan is full, empty if required, grate may be blocked de-ash with riddler,

check for jammed clinker or nails in grate when fires out and cold.

4) Smoke And Fumes Entering Room

These are very dangerous and must NOT be tolerated. Open window and allow fire to

burn out, seek expert advice immediately. DO NOT USE stove until the problem is

solved. A list of Qualified Engineers is available from

UK Solid Fuel Association

7 Swanwick Court, Alfreton

Derbyshire DE557AS

Tel- 0845-601-4406

R.o.I.

Irish National Fireplace Organisation

162 Chapel Street, Dublin

Tel-01-801-5959

5) Chimney Fire

Identified by loud roaring sounds, dense smoke and sparks exiting chimney. Shut

down air supply to stove by closing air vents, close stove door fully, call fire brigade

immediately. Regular chimney maintenance will prevent chimney fires. Seek advice

from a Qualified Chimney Sweep. Chimneys must be checked annually more often

when bitumas coal and poor quality smoky fuels are used.

7

CO ALARMS

Building regulations require that whenever a new or replacement fixed solid fuel or wood/biomass

appliance is installed in a dwelling a carbon monoxide alarm must be fitted in the same room as

the appliance. Further guidance on the installation of the

carbon monoxide alarm is available in BS EN 50292:2002 and from the alarm

manufacturer’s instructions. Provision of an alarm must not be considered a substitute for either

installing the appliance correctly or ensuring regular servicing and

maintenance of the appliance and chimney system.

OPERATING INSTRUCTIONS

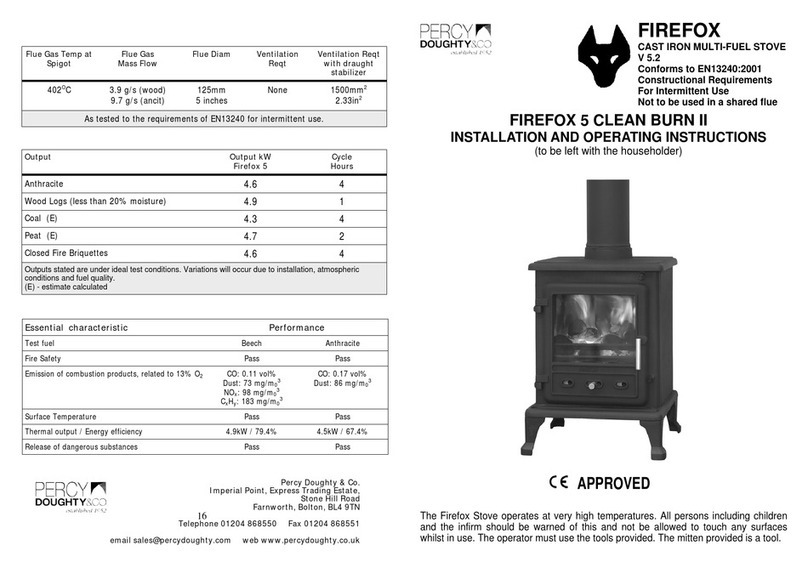

Primary Air

Primary air is controlled via the sliding vents in the bottom of the door; this provides a convention-

al air draught to the bed of the fire. (+) indicates more air, (-) indicates less air. To adjust, slightly

turn the knob anti-clockwise to loosen, then move sideways. When in the desired position, turn the

knob clockwise until tight.

Secondary Air

Secondary air is controlled via the sliding vent above the door, it is this ‘airwash’ that keeps a

clean and uninterrupted view of the fire, also aiding in good secondary combustion of fuel and

reducing emissions into the chimney and environment. To adjust the secondary air intake, simply

move the slider left (-) for less air or right (+) for more air.

The stove has a pre-determined amount of fixed air supply on the primary and secondary air slid-

ers. This is factory set and should not be adjusted or altered as it

facilitates the clean burn function. Because of the pre-set air supply it is important that the flue

draught requirements are adhered to, i.e. minimum = 12 pascals, maximum = 15 pascals. If the

flue draught exceeds the maximum requirements then over firing can occur and suitable

measures to control draught must be adopted.

Note: Over firing due to fixed air supply will not be dangerously high but efficiency may be com-

promised.

Damper Assembly (optional)

When burning wood only, a flue damper assembly may be fitted. When the damper is set in the

open position the chimney draws at full draught, increasing the volume of air flow through the

stove and flue. Shutting the damper restricts the flow, slowing the rate of burning. This is an after

market product and will be of the type with positive open and closed indication to prevent misun-

derstanding.

De-Ashing

It is important that the riddler is used to remove the ash to ensure an airflow through the firebed

and allow the fire to burn over the entire area of the grate. Insert peg on operating tool into hole in

riddling rod, draw tool forwards and backwards with a slow positive action. Set rod in back position

after de-ashing.

Notes On Wood Burning

Wood burns best on a bed of ash and it is therefore only necessary to remove surplus ash from

the grate occasionally. Burn only dry, well seasoned wood, which should have been cut , split and

stacked for at least 12 months, with free air movement around the sides of the stack to enable it to

dry out. Burning wet or unseasoned wood will create tar deposits in the stove and chimney and

will not produce a satisfactory heat output.