WACKER Group EH 23/110/22 User manual

www.wackergroup.com

Operator´s Manual

ELECTRIC-HAMMER

EH 23/110/22

0200145en - 04.2002

0007815 100

T00778GB 1

FOREWORD

Foreword

For your own safety and protection from bodily injuries, carefully read, understand and follow the safety instruc-

tions in this manual.

Please operate and maintain your Wacker machine in accordance with the instructions in this manual.

Defective machine parts are to be replaced as soon as possible.

All rights, especially the right for copying and distribution are reserved.

Copyright by Wacker Construction Equipment AG.

No part of this publication may be reproduced in any form or by any means, electronic or mechanical, including

photocopying, without express permission in writing from Wacker Construction Equipment AG.

Any type of reproduction, distribution or saving on data carriers of any type or method not authorized by Wacker

represents an infringement of valid copyrights and will be prosecuted.

We expressly reserve the right to technical modifications- even without express due notice - which aim at im-

proving our machines or their safety standards.

0200145en_001IVZ.fm 2

FOREWORD 1

SAFETY INSTRUCTIONS 3

General instructions 3

Operation 3

Safety checks 4

Maintenance 4

Transport 4

Maintenance checks 4

TECHNICAL DATA 5

DESCRIPTION 6

Field of application 6

Dimensions 6

Functional description 6

TRANSPORT TO WORK SITE 7

OPERATION 8

Attaching the tool 8

Connection 8

Notes on correct handling 8

MAINTENANCE 9

Maintenance schedule 9

Carbon brushes 10

Lubrication of the motor and transmission 10

Lubrication of the percussion system 10

Lubrication of the tool holder, tolerances 10

ELECTRIC WIRING DIAGRAM 11

DIAGRAM 12

TOOLS 13

REFORGING OF TOOLS 14

FAULTS 15

Carbon brushes 15

Power supply cable 15

Electronics 15

DECAL 16

EC - CONFORMITY-CERTIFICATE 17

SV00011GB 3

SAFETY INSTRUCTIONS

SAFETY INSTRUCTIONS FOR THE USE OF DRILLING AND

BREAKING HAMMERS WITH ELECTRIC DRIVE

General instructions

1. Drilling and breaking hammers may only be operated by persons who

* are at least 18 years of age,

* are physically and mentally fit for this job

* have been instructed in operating drilling and breaking hammers and proven their ability for the job

to the employer

* may be expected to carry out the job they are charged with carefully.

The persons must be assigned the job of operating drilling and breaking hammers by the employer.

2. Drilling and breaking hammers are to be applied for their proper use. Both the manufacturer’s operating

instructions and these safety instructions have to be observed.

3. The persons charged with the operation of these hammers have to be made familiar with the necessary

safety measures relating to the machine. In case of extraordinary uses, the employer shall give the

necessary additional instructions.

4. It is possible that these drilling and breaking hammers exceed the admissible sound level of 89 dB (A).

According to the rules for the prevention of accidents regarding emission of noise, the employees have

to wear ear protection if the sound level reaches 89 dB (A) or more.

Operation

1. The function of operation levers or elements is not to be influenced or rendered ineffective.

2. Make sure that the machine is connected only to voltage and frequency as indicated on its name plate.

Choosecorrectcrosssectionforextensioncord.Seecalculationexampleanddiagramincludedinthismanual.

3. The operator has to switch off drilling and breaking hammers, to disconnect them from the electric mains

and to store them in such a manner that they do not turn over be fore leaving the machines or going on

breaks.

4. Wear safety goggles in order to avoid injuries to the eyes.

5. We recommend wearing suitable working gloves.

6. Wear safety shoes while working with drilling and breaking hammers.

7. Drilling and breaking hammers are always to be operated with both hands on the handles provided for

this purpose.

8. When working with drilling and breaking hammers, especially when carrying out drilling jobs, the opera-

tor has to have a firm stand, particularly when working on scaffolding and ladders.

9. Drilling and breaking hammers are to be guided such that hand injuries caused by solid objects are

avoided. When carrying out demolition jobs at elevated places, special care is required to prevent the

machine or the operator from falling.

10. Avoid body contact with earthed components. When breaking connecting passages, make sure that

there are no electric wires or gas pipes. No one may stay in the room to which the passage is broken

through, as there is danger of injuries because of falling stones or tools.

11. During operation the tool holder must be closed. Tools and tool holder must be checked for wear in order

to guarantee proper functioning of holder.

12. The operation of this machine may cause broken - off pieces to be flung away. Therefore, during oper-

ation, no one except the operator is to come near this machine.

13. Drilling and breaking hammers have to be disconnected from the electric mains before changing tools.

14. The tools always have to be in perfect conditions.

15. Do not operate these machine in areas where explosions may occur.

SV00011GB 4

SAFETY INSTRUCTIONS

16. Do not misuse the electric cable to pull or lift up the unit or to pull the plug out of the socket. Protect cable

from heat, oil and sharp edges.

17. Electric equipment and material may only be used if they comply with the operational and local safety

requirements. They must be in proper condition and this condition is to be maintained.

18. Do not expose electric tools to rain. Do not use electric tools in damp or wet surroundings.

Safety checks

1. Drilling and breaking hammers may only be operated with all safety devices installed.

2. Before starting operation, the operator has to check that all control and safety devices function properly.

3. Before starting operation, the overload clutch of drilling hammers has to be checked for proper function-

ing.

4. Regularly check cable for damage.

5. In case of defects of the safety devices or other defects reducing the operational safety of the drilling and

breaking hammers, the supervisor has to be informed immediately.

6. In case of defects jeopardizing the operational safety of the hammers, the machine has to be

switched immediately.

Maintenance

1. Only use original spare parts. Modifications to this machine, including the adjustment of the maximum

engine speed set by the manufacturer, are subject to the express approval of Wacker. In case of non-

observance all liabilities shall be refused.

2. Disconnect the drilling and breaking hammer from the electric mains before carrying out maintenance

and repair jobs.

3. Work on the electric parts of the machines may only be carried out by skilled technicians.

4. The green and yellow ground wire of the connecting cable of machines without protective insulation has

to be longer than the other wires so that it is no ripped out first in case the strain relief fails. A break in

this wire would entail grave danger. Check ground wire for passage after repairs.

5. As soon as maintenance and repair jobs have been completed, all safety devices have to be reinstalled

properly.

Transport

When being transported on vehicles, precautions have to be taken that these hammers do not slip or turn over.

Maintenance checks

According to the conditions and frequency of use, drilling and breaking hammers have to be checked for safe

operation at least once every 6 months by skilled technicians, such as those found at Wacker-service depots

and have to be repaired if necessary.

Please also observe the corresponding rules and regulations valid in your country.

TD00359GB 5

TECHNICAL DATA

EH 23/110/22

Machine No. 0007815 ...

Operating weight (mass) kg: 22,4

without tool

Voltage V: 110 ~

Power input kW: 2,2

Current consumption A: 22

Frequency Hz: 50/60

Percussion rate min-1: 1320

Special lubricating grease grease Unirex N2

Shaft for SW 28x160

breaking tools

Drive motor Totally insulatedt universal motor

Single stroke impact J(mkp):

(at tool tip) 40 (4)

Sound pressure level at operators station LPA: 97 dB(A)

The weighted effective acceleration value,

determined according to ISO 8662, Part 1 m/s2: is 7,8

T00526GB 6

DESCRIPTION

Field of application

For breaking concrete and asphalt as well as rubble-laden ground, for demolishing concrete, masonry and sim-

ilar building materials (undisturbed and frozen ground) etc., for ripping up roads and concrete, asphalt, tar as

well as wood-block and stone paving, for cutting off clay, loam, turf and salts, for breaking compacted or

tamped ground, for ramming in posts and earth rods.

☛CAUTION! Always use the proper pin driving tool with the machine when ramming posts or ground rods.

Damage will occur to the percussion system if posts and/or rods are directly inserted into the

toolholder. This will eliminate any responsibility for warranty claims and prevent unnecessary

customer complaints.

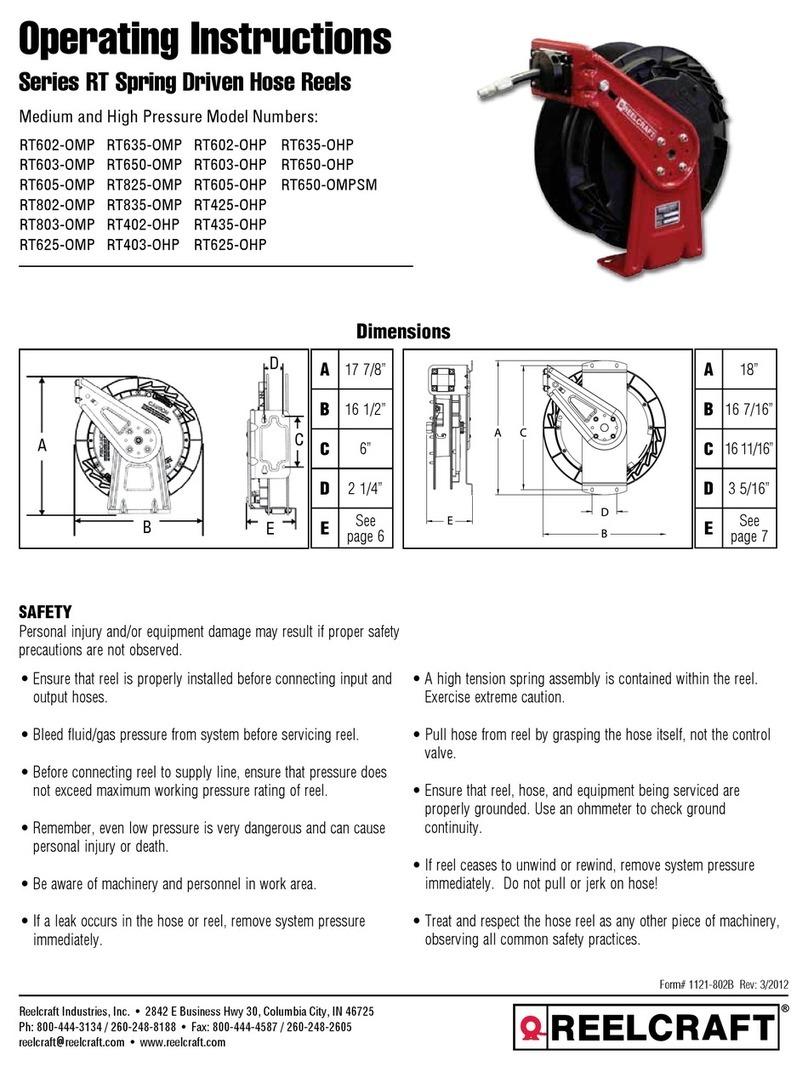

Dimensions

ABCDE

EH 23/110/22 EE 28x160 655 529 210 148 756

Functional description

On activation of the switch lever (1), and electric motor (2) drives the crank mechanism (3) through a transmis-

sion (4).

The rotary motion of the crankshaft journal is converted by means of a con-rod (5)and a guide piston (6) into a

linear motion and transmitted through an air cushion (“pneumatic spring”) to the percussion piston (7).

The percussion piston (7) then strikes the tool directly (without any intermediate piston).

A built-in electronic control (8) ensures a low starting current and constant speed off the drive motor when idling

and under load.

T00143GB 7

TRANSPORT TO WORK SITE

Transport to work site

Conditions:

- Only use suitable lifting equipment with a minimum lifting capacity of 30 kg for the transport of the electric

hammer.

- Always switch off engine during transport!

- Tie down the electric hammer securely during transport on the loading surface of a vehicle.

Note: Also refer to the specifications in safety instructions.

T00527GB 8

OPERATION

Attaching the tool

1. Swivel catch (9) on tool holder (11) outwards.

2. Clean shaft (10) and grease slightly.

3. Insert tool right in.

4. Press catch (9) on tool holder (11) right back.

Only use sharp tools!

Only use tools with perfect shaft (10) to avoid recoil!

Connection

Check before connecting:

1. The mains voltage must be the same as that indicated on the nameplate (12).

2. The electric breaker is operated with 110 V AC (light current).

3. Check whether the necessary fuse is available in the mains supply.

EH 23/110/22 EE 28x160 -A 22

4. The electric breaker is fully insulated and there is therefore no green/yellow PE conductor in the power sup-

ply cable .

Notes on correct handling

Place the electric breaker with tool on the material in question and switch on by pressing the switch lever.

After a few seconds the electric breaker reaches its full percussion rate.

Exploit the weitht of the electric breaker when working.

Applying great force against the surface being worked does not improve the performance of the tool.

In order to avoid no-load strokes and to ensure easy handling, it is necessary to apply a certain amount of pres-

sure on the handles.

Positionthechiselinsuchawaythatthematerial to be worked can be split. This prevents the tool from jamming

and the demolition perfomance is increased.

T00145GB 9

MAINTENANCE

Maintenance schedule

Check all external screw connections for tight fit appox. 8 hours after first operation.

Component Maintenance work Maintenance interval

Feed cable Check for perfect condition, change if daily

defective.

Protective hood Ventilations slits free of dirt, clean if necessary.

Tools Check the shaft and cutting edges and, if necessary,

sharpen, reforge or replace.

Motor head Regrease via grease nipple (see technicla data) 20 hours

Carbon brushes Check for wear - if remaining length less than12 mm 80 hours

in spite of cut - out facility - replace.

Motor head Check all screws tight fit - if necessary,

retighten.

Percussion system Dismantle, clean, regrease.

Tool holder Check for wear.

Electric breaker Maintenance - WACKER service station. 300 hours

T00145GB 10

MAINTENANCE

Carbon brushes

- Check carbon brushes:

1.Replace carbon brushes (16) if the surface has been worn down unevenly.

2.Replace carbon brushes (16) if the are less than 12 mm long.

- If shut-down device has triggered replace carbon brushes (16).

Lubrication of the motor and transmission

The sealed motor armature bearing and the transmission mean that additional lubrication with in the mainte-

nace interval of 300 hours is unnecessary.

Lubrication of the percussion system

1.The percussion system (17) is to be moderately greased with special grease (see technicla data) via the

grease nipple (19) located on the crankcase (accessible via the lubrication bore on the hood) roughly every 20

hours of operation or at the latest if the tool shaft (10) runs dry.

2.After about 80 hours the percussion system (17) is to be dismantled, cleanded and regreased. Slightly grease

the percussion piston (7) and guide piston (6) on the running surfaces only. The percussion rate deteriorates

if too much grease is applied to the percussion piston bottom and guide piston end face. The needle sleeve in

the con-rod is to be washed out and regreased using special grease (see technicla data).

Lubrication of the tool holder, tolerances

1.Only insert tools (18) with a cleaned and slightly greased shaft (10) into the tool holder (11).

2.The tool guidance system is to be regularly checked for wear. A new tool (18) must be 400 mm from the collar

of the shaft (10) and have a play of max. 10 mm. Replace severely worn tool holders (11) in order to avoid

breakdowns in operation and damage.

SK00108GB 11

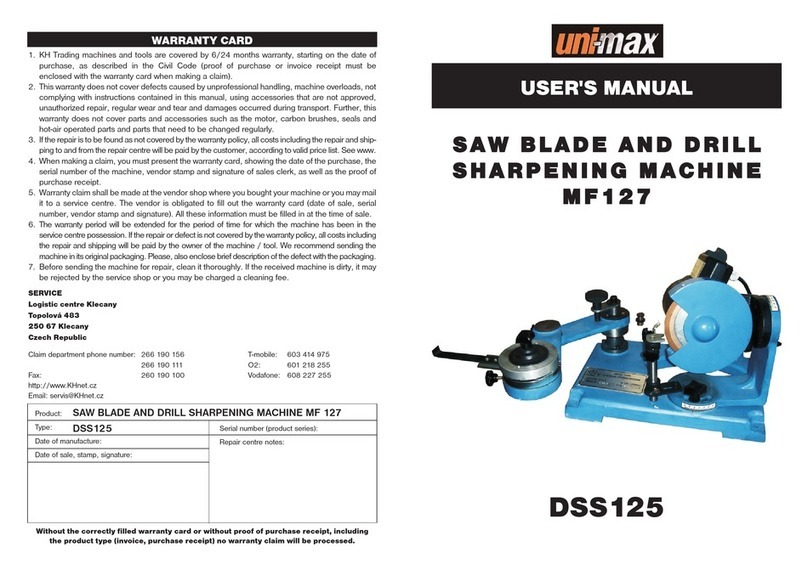

ELECTRIC WIRING DIAGRAM

EH 23/110/22

1. Motor

2. Electronics with suppression capacitor

3. Connection without electronics (electronics bypassed)

4. Switch

5. Plug

SK00001GB 12

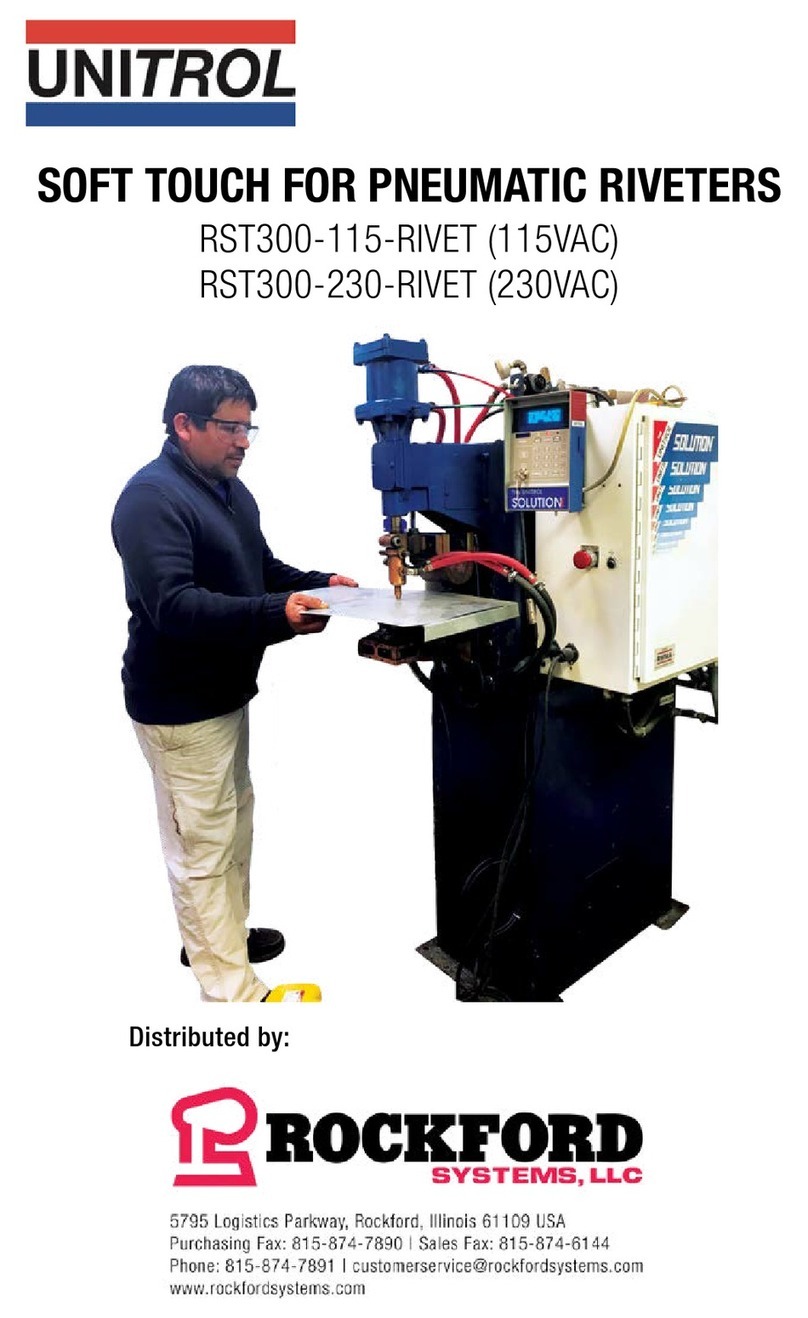

DIAGRAM

Selection of required cross section for extension of cables and power lines

This procedure takes into consideration:

1. The ohmic and inductive resistance of the line with an admissible loss of voltage of 5% and cos phi =

0,8 as per voltage-frequency-curves.

2. The admissible warming-up of the lines as per VDE standard (table of required minimum cross section).

☛ATTENTION! The larger one of both cross sections has to be chosen.

Example: Nominal voltage 3 ~ 400 V, 50 Hz

Rated current 15 A Line length 100 m

15 A x 100 m = 1500 A x m

Cross section as per diagramm: 2,5 mm2

Cross section as per table: 15 A : 1 mm2

Chosen cross section: 2,5 mm2

Voltage - Frequency - Curves

Cross-section area of cable in mm2Minimum cross-section

area according to VDE

Max. Max.

Cable load fuse

mm2AA

115 10

1,5 18 10/3~16/1~

2,5 26 20

434 25

644 35

10 61 50

16 82 63

25 108 80

Rated current x length of cable A x m

SK00023GB 13

TOOLS

Tools with ø 27x80, EE SW 25x108* shanks Type Ref.-No.

Effective length

Moil point 280mm 4001322

280 mm 0036379 *

Effective length

Flat chisel, width 30 mm 280mm 4001323

280 mm 0036380 *

Effective length

Wedge chisel, width 35 mm 300mm 4002158

Effective length

Wide chisel, width 75 mm 300 mm 4002191

Effective length

Spade, width 120 mm 300mm 4001324

300 mm 0036381 *

650mm 4002161

Effective length

Asphalt cutter, width 75 mm 250mm 4002193

Ramming hood

(w/o ram rod) 150 x 150 mm 0039871

Ram rod Effective length 0039776

130 mm

Driving hood for posts up

to ø 80 mm (w/o ram rod) 0039869

to ø 120 mm (w/o ram rod) 0039870

Driving mandrel (bore ø 12,8 mm) suited for

Dehn rods ø 20 mm 4001360

Driving mandrel (bore ø 16 mm) suited for

Dehn-and Langer-Glienke rods ø 25 mm 4001361

Ramming hood can be provided with bore

or threaded bore up to ø 35 mm 0063990

Ramming hood can be provided with bore from

ø 10 mm up to ø 55 mm 0044138

Blank unhardened for special tools ø 50 mm 4001396

Blank unhardened for special tools ø 70 mm 0038785

Wedge set ø 34 mm 4002354

Tie tamping tool 30 x 80 4001327

Tie tamping tool 30 x 80 (noise-reduced) 0038947

Tie tamping tool 30 x 120 4002192

SK00011GB 14

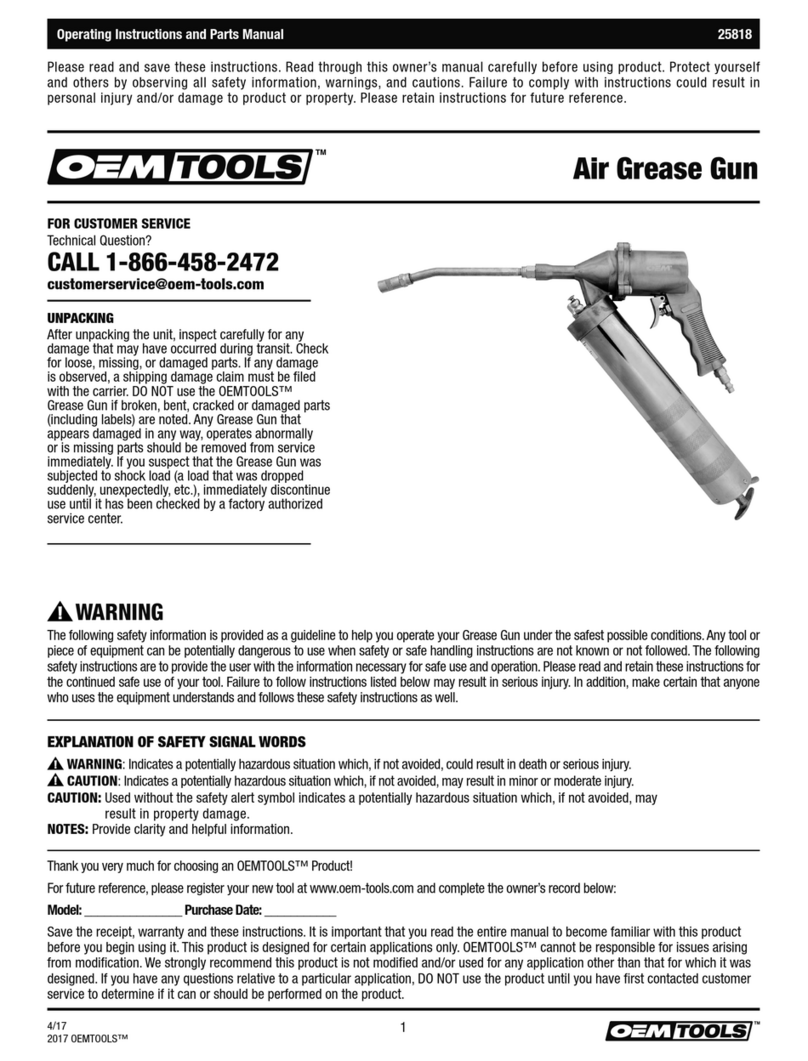

REFORGING OF TOOLS

☛ATTENTION! Use safety glasses when doing this job.

When reforging of the tools becomes necessary, care should be taken that only that part of the tool that needs

reforging is heated. Moreover, it is important that the heat is increased slowly and that it is constantly watched,

otherwise heat cracks are likely to occur on hardened tools.

Forging temperature: 800oto 1000o(1470oto 1830oF) bright cherry - red to yellow

The tool should be forged within these limits and, if necessary, shoud be heated repeatedly. A temperature

below 800oC (1470oF) may cause tension cracks, where as when the temperature exceeds 1000oC (1830o

F) the steel is overheated and spoilt. After forging, the tools should be quenched in an ash or sand box. Do not

harden the tools before they have cooled from the forging.

Hardening: Heat point or blade in direction of tool shank up to a cherry red colour (780o- 810oC) over the

shortest distance possible (approx. 30 - 40 mm), then quench in water with approx. 20oC while constantly

swinging tool around.

Tempering: Heat tool at shaft approx. 10 cm behind tip until point or blade reaches brown-red tempering col-

our: Let tool cool off in air.

Polish one side of the tool‘s point or blade to be able to recognize tempering colour.

Grinding: Sharpen the insert tools on grinding wheels-favourably sandstone-under sufficient cooling water.

The edges should not be allowed to turn blue as the hardness of the tools will be affected. Take care to achieve

the proper cutting edge and pointed angle. The harder the material to be cut, the greater the angle should be.

Point chisel Flat chisel Blank Plaster chisel

Spade Pointed spade Asphalt cutter Gouge, cranked

Carbide-tipped twist drill

Tools with hardmetal bits may

only be sharpened on special

emerywheelmachinesforhard

metal

Tools made out of

tempering steel -

C70W2 - can be

forged, hardened and

ground

T00146GB 15

FAULTS

Carbon brushes

Cause: - Carbon brushes worn.

Remedy: - Replace carbon brushes.

Power supply cable

Cause: - Damage.

Remedy: - Replace completely.

Electronics

Cause: - Failure of the electronics.

Remedy: - The wiring diagram shows how it is possible to continue

to use the machine in the event of an electronic fault by

changing the motor connection.

SK00593GB 16

DECAL

Ref. Part No. Qty. Part

1 0064925 1 Decal - Sound power level

C0002004.GB

EC - CONFORMITY-CERTIFICATE

Wacker Construction Equipment AG , Preußenstraße 41, 80809 München

hereby certify that the construction equipment specified hereunder:

1. Category: Breakinghammer

2. Type: EH 23/110/22

3. Equipment item number:

0007815 ...

4. absolute installed power: 2,2 kW

has been evaluated in conformity with Directive 2000/14/EC:

and has been manufactured in accordance with the following directives:

2000/14/EG

EMV - Richtlinie 89/336/EG

EN 55014

EN 61000-3-2

98/37/EG

HD 400, IEC 745

EN 500-1

EN 500-4

..................................................

Dr. Sick

Board of Directors

File certificate carefully

Conformity

assessment

procedure

At the following notified

body Measured

sound power level Guaranteed

sound power level

Annex VIII VDE Prüf- und

Zertifizierungsinstitut

Zertifizierungsstelle

Merianstraße 28

63069 Offenbach/Main

105 dB(A) 109 dB(A)

18

Table of contents