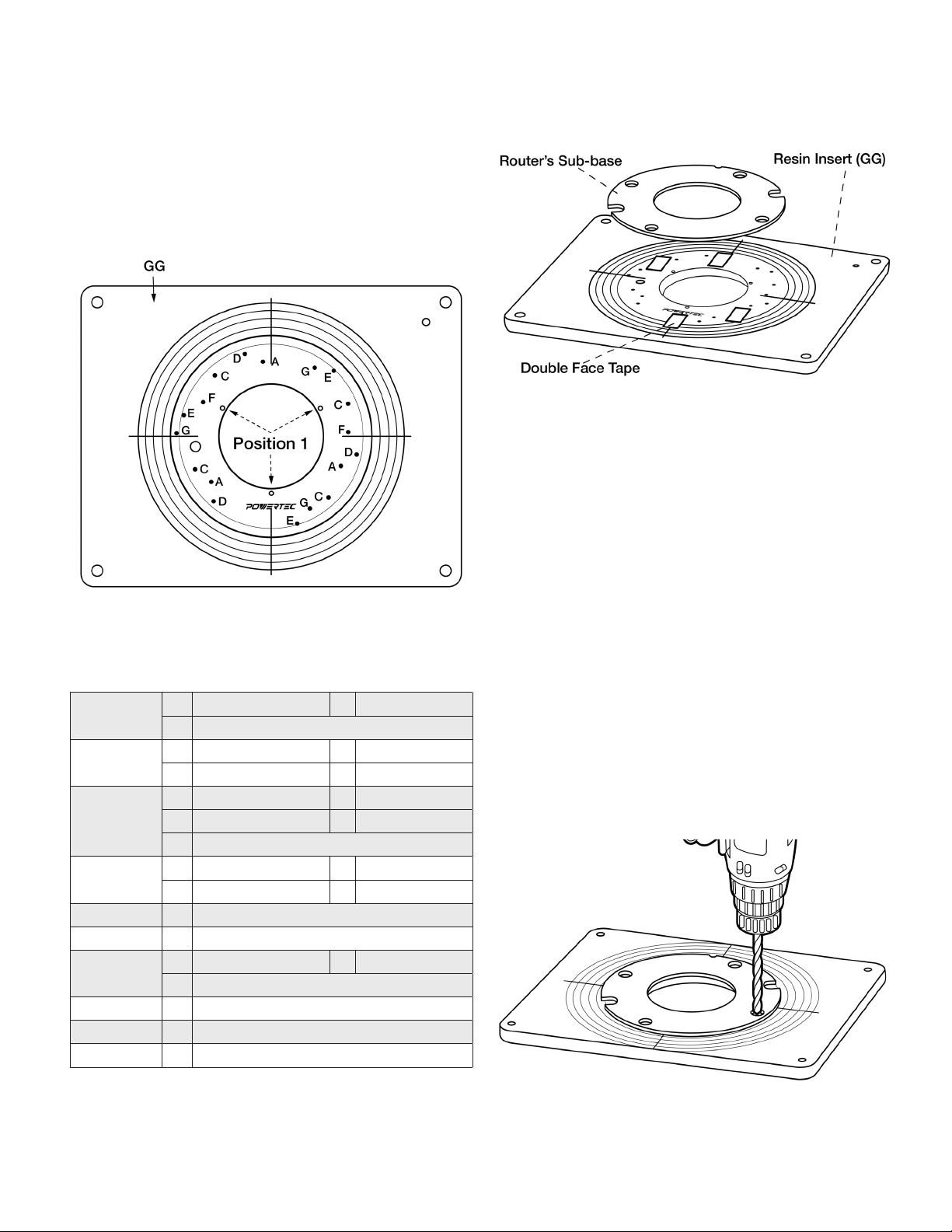

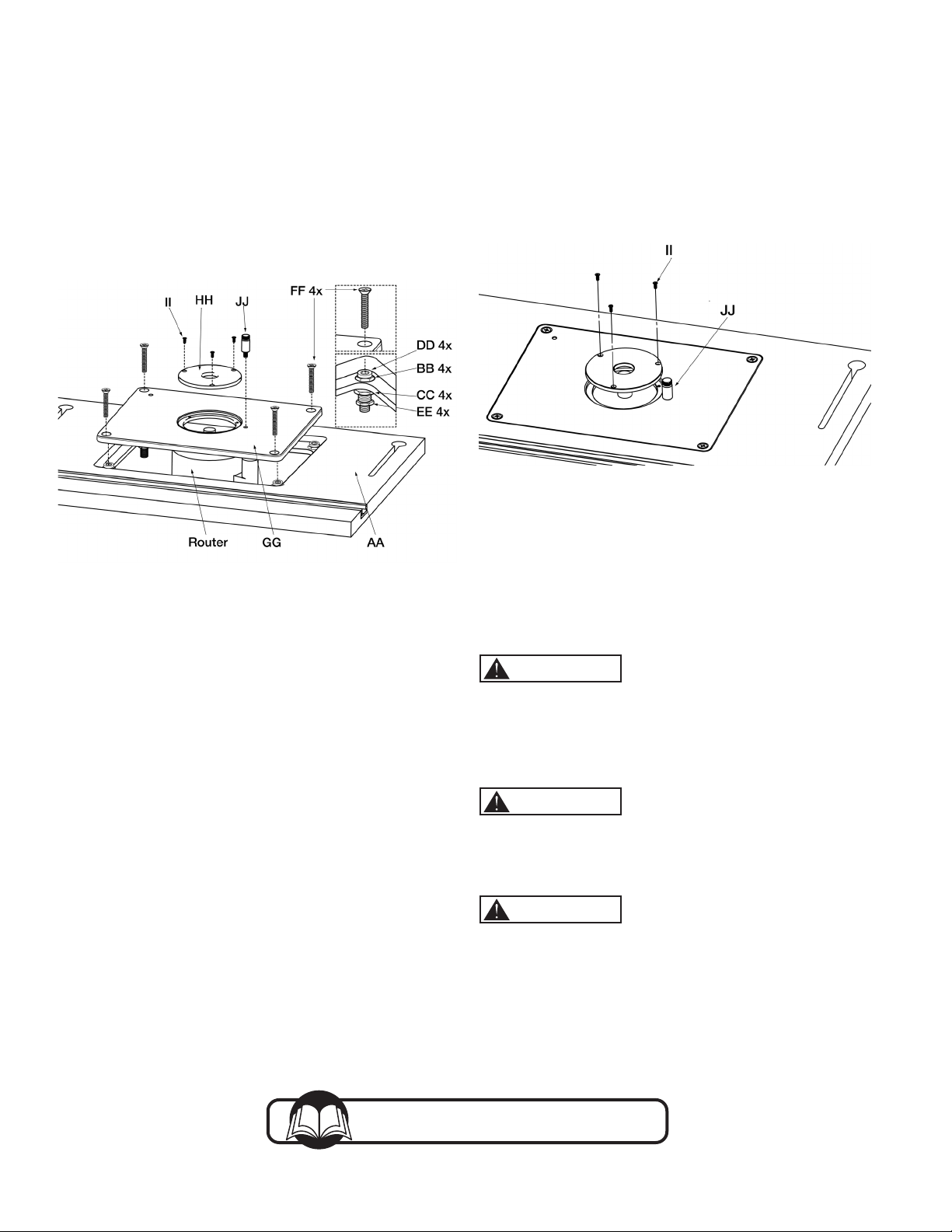

REDUCING RINGS

See Figure 8. There are three reducing rings for exibility in

matching the size of the insert opening to the diameter of the

router bit in use; a solid insert, to be bored for any custom size,

an insert with a 1" opening, and an insert with a 2‑5/8" opening.

To install a reducing ring, simply drop it into the insert‑plate

opening and attach using the three M3 set screws (II) with the

3mm Screwdriver (MM) provided.

Figure 8

STARTING PIN

To use the Starting Pin (JJ), begin with your workpiece touching

the pin, but not in contact with the router bit. Slowly pivot

the workpiece into the bit until the workpiece makes contact

with the bit guide bearing. Always feed the workpiece so the

router bit rotates against (not with) the feed direction. With the

workpiece in solid contact with the guide bearing, ease the

workpiece off of the starting pin and feed the workpiece against

the guidebearing.

WARNING

Use the starting pin when routing along curved edges and only

with router bits that have a guide bearing. When routing along

straight edges, always use thefence.

GENERAL MAINTENANCE

WARNING

When servicing, use only identical replacement parts. Use of

any other parts may create a hazard or cause product damage.

To ensure safety and reliability, all repairs should be performed

by a qualied servicetechnician.

WARNING

Keep the Router Table Top dry, clean, and free from oil and

grease. Always use a clean cloth when cleaning. Never use brake

uids, gasoline, petroleum based products or any strong solvent

to clean the Router Table Top. Chemicals can damage, weaken or

destroy plastic which may result in serious personalinjury.

IMPORTANT: Store router sub-base in a convenient place.

It will be needed when removing router from router table and

during handling.

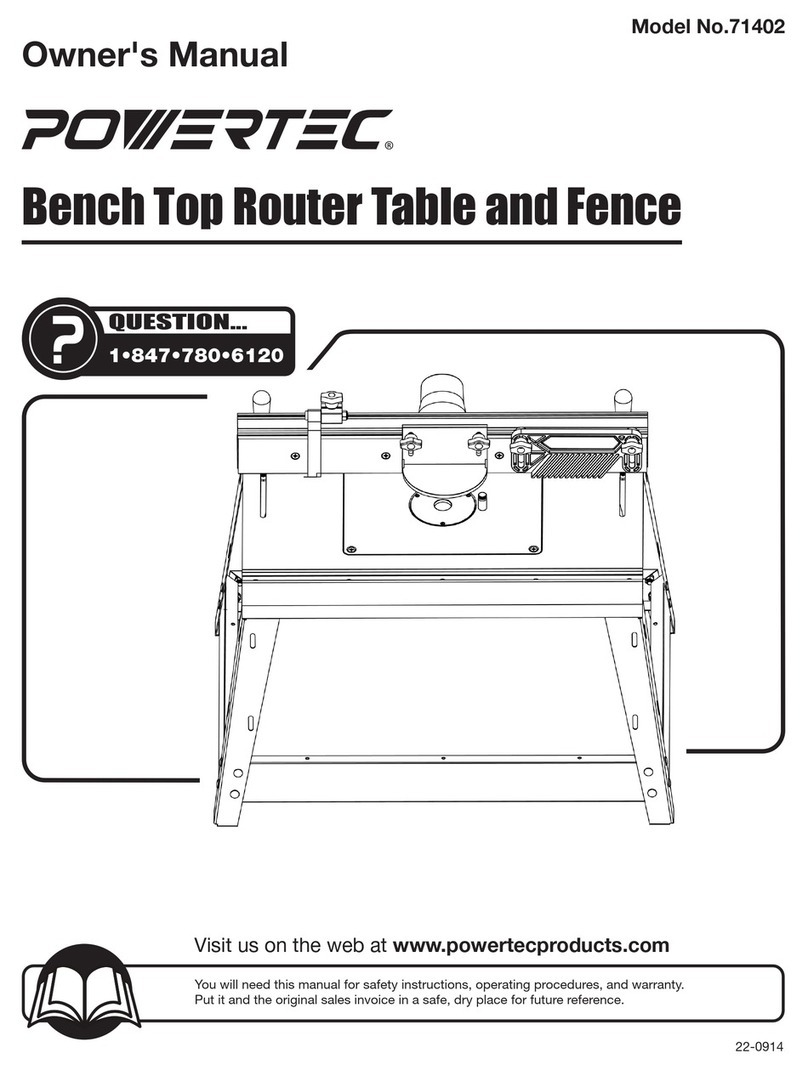

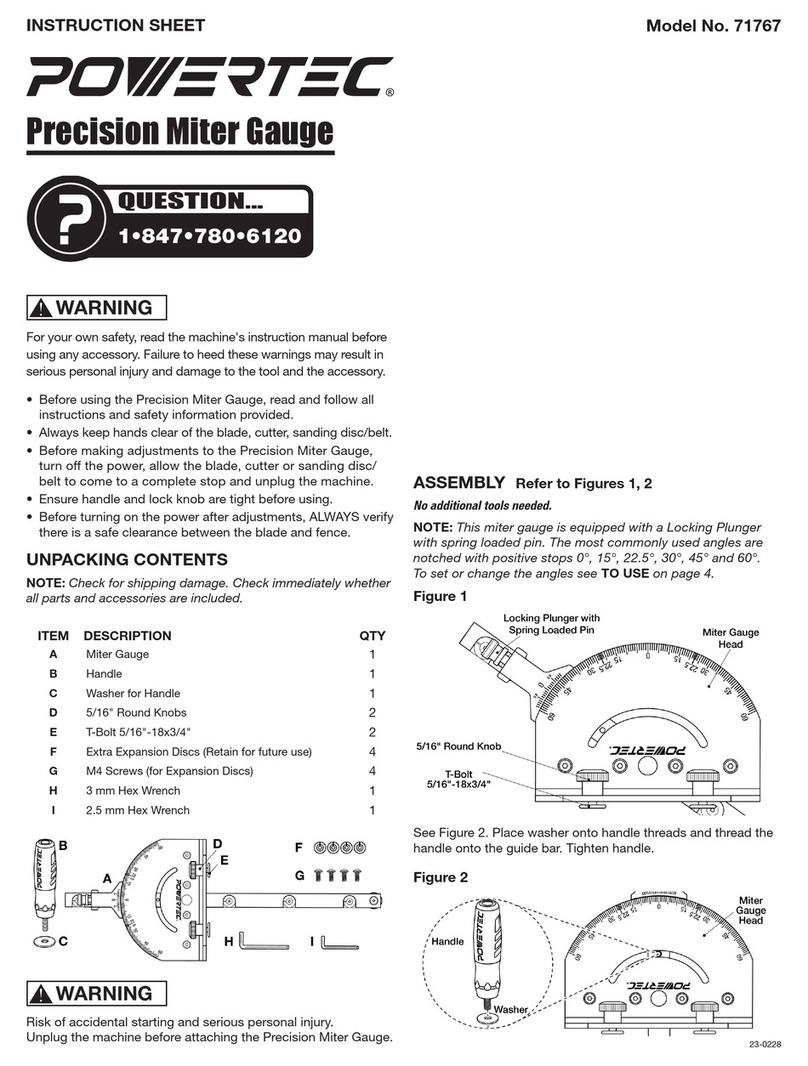

3. See Figure 7. Using the screws for attaching the sub‑base to

the router, attach router base to Resin Insert GG).

NOTE: Depending on the thickness of your router sub-base, it

may be necessary to purchase longer screws. Make certain the

screws are long enough to fully thread into the router base. If

you are mounting a fixed-base router, install the motor unit in the

routerbase.

Figure 7

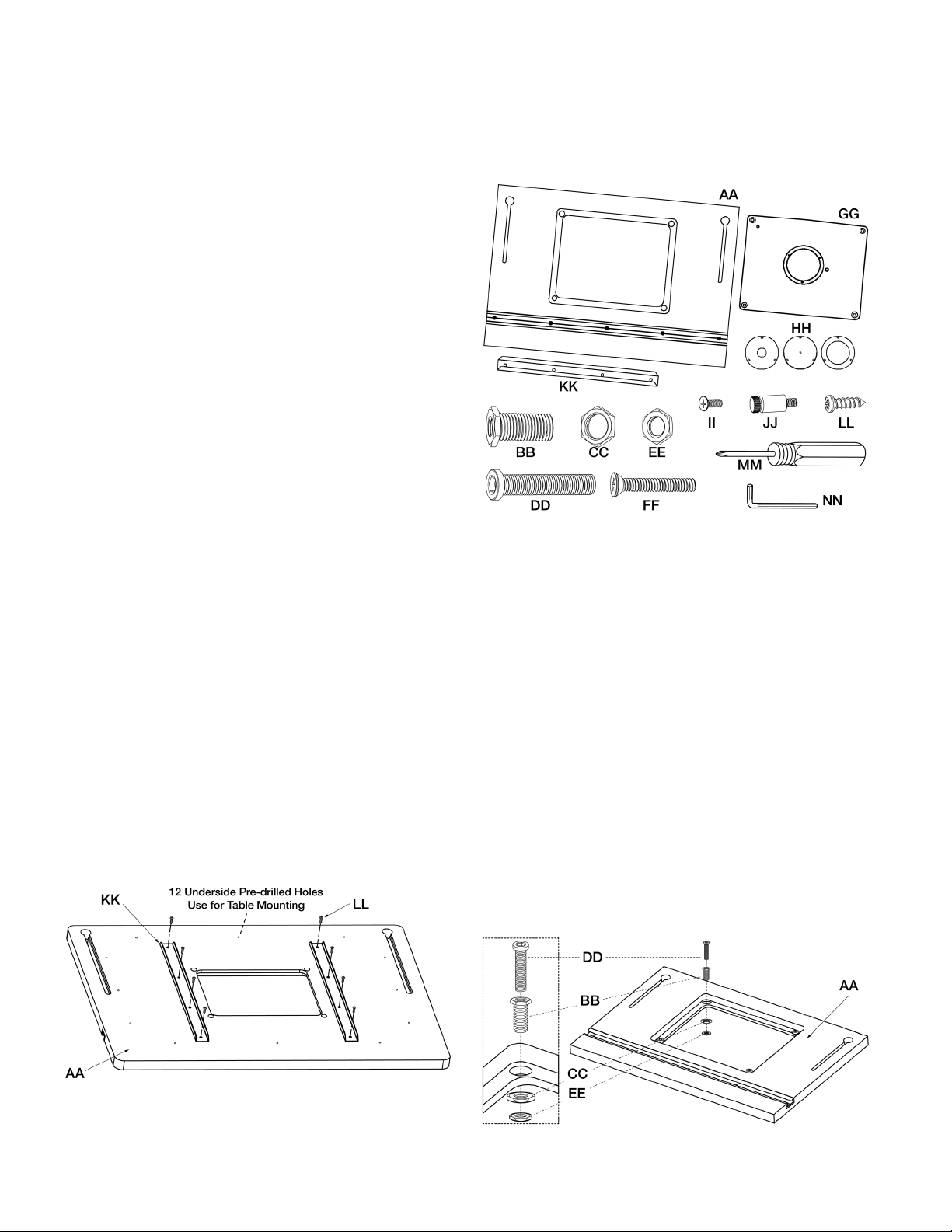

4. Place Resin Insert (GG), with the router attached,

into Router Table Top (AA) opening, resting it on the

Adjustment Screws (DD). Using the M6 Hex Wrench (NN)

provided, adjust the adjustment screws through the holes in

the insert plate. Use a straight edge to verify the insert plate

is ush with the tabletop. Once ush, tighten Hex Nuts (EE).

If not ush, ne‑tune the adjustment screws until the insert

plate is ush with the tabletop.

5. Thread the four Flat‑head Screws (FF) through the

countersunk holes in the insert plate and into the center

hole on each adjustment screws and tighten, locking the

insert plate in place. Some adjustment of the lock down

screws and adjustment screws may be necessary to ne‑

tune the alignment.

6. Choose the reducing ring appropriate for the job and attach

it to the insert plate using the three Set Screws (I I). When

needed, thread the Starting Pin (JJ) into the threaded hole in

the insert plate and tighten.

Southern Technologies, LLC

Chicago, IL 60606

Put these instructions and the original sales invoice

in a safe, dry place for future reference.

Visit us on the web at www.powertecproducts.com