356.805.003 3Date: 2019-04-04

Index

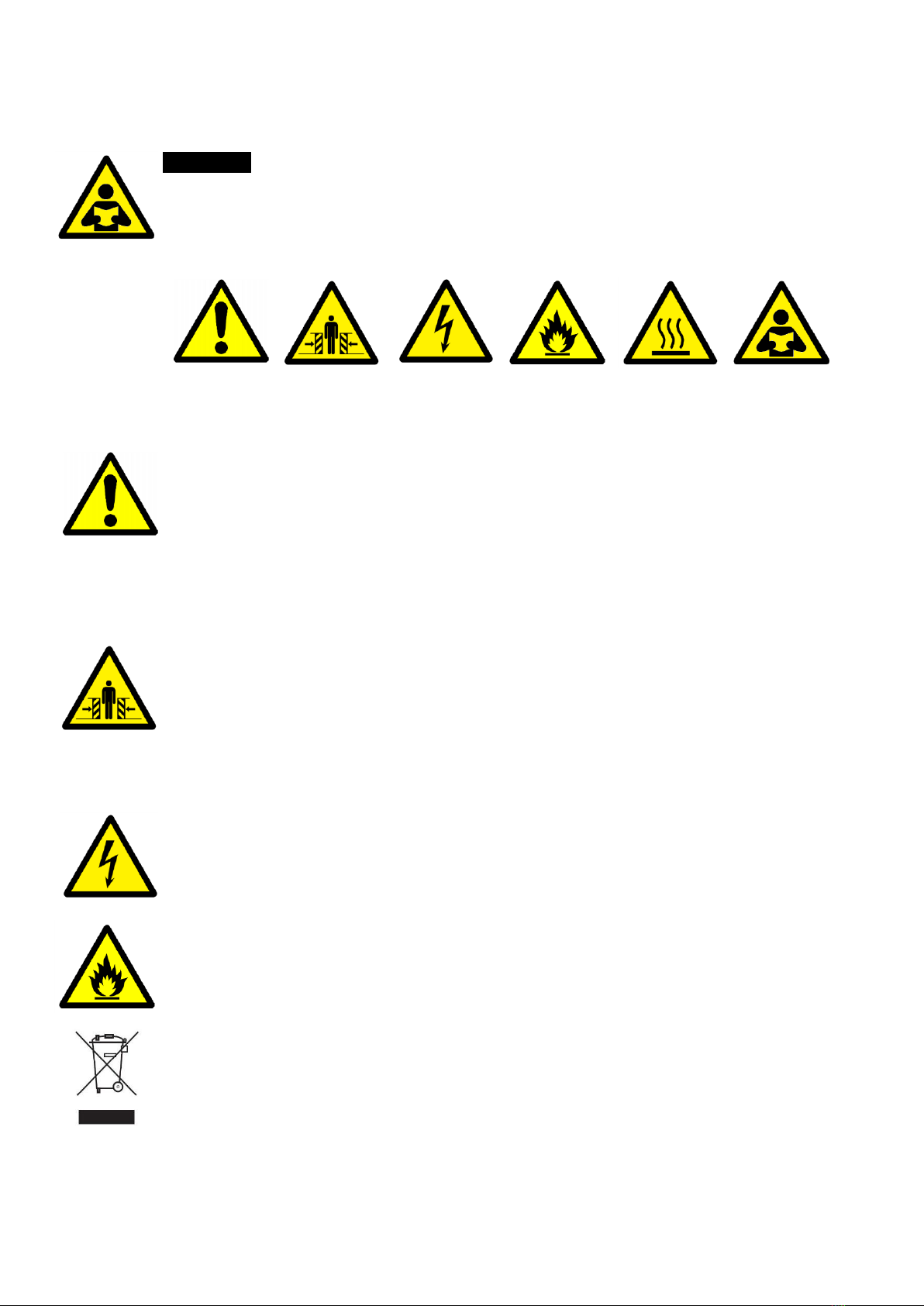

SAFETY INFORMATION 1

INDEX 3

TECHNICAL SPECIFICATIONS 4

DRAWING 5

INTRODUCTION 6

PACKAGE CONTENT ...................................................................................................................................... 6

DESCRIPTION............................................................................................................................................... 6

AREA OF USE............................................................................................................................................... 7

USING FOR THE FIRST TIME ............................................................................................................................ 7

TRANSPORT ................................................................................................................................................ 7

PHYSICAL INSTALLATION 8

FASTENING THE TRACKS TO A SURFACE OR TRUSS............................................................................................... 8

TRACK ASSEMBLY INSTRUCTIONS 9

AC POWER 10

POWER CABLES AND POWER PLUG ................................................................................................................ 10

INSTALLING A POWER INPUT OR OUTPUT CONNECTOR ON A POWER CABLE........................................................... 10

SETUP 11

MOUNTING ON THE TRACK .......................................................................................................................... 11

MOUNTING THE LOAD ................................................................................................................................ 12

DATA LINK 13

RADIO CONTROL 13

TIPS FOR RELIABLE RADIO TRANSMISSION ....................................................................................................... 14

TIPS FOR RELIABLE DATA TRANSMISSION ........................................................................................................ 14

CONNECTING THE DATA LINK........................................................................................................................ 14

CHANGING TRANSMITTER STATION ............................................................................................................... 15

SELECTING WIRELESS MODE (FACTORY DEFAULT) ............................................................................................ 15

MODE SETTING.......................................................................................................................................... 16

DMX ADDRESS SETTING AND CHANNEL OVERVIEW........................................................................................ 16

SETTING THE LOW AND HIGH POSITIONS (DMX OPERATION)............................................................................. 18

POSITIONING............................................................................................................................................. 19

DUTY-CYCLE.............................................................................................................................................. 19

SYNCHRONIZED MOVEMENTS OF MULTIPLE UNITS ........................................................................................... 20

SERVICE AND MAINTENANCE 21

SPARE PARTS............................................................................................................................................. 21

ON-SITE SERVICE........................................................................................................................................ 21

MAINTENANCE PLAN .................................................................................................................................. 21

CHECKLIST ................................................................................................................................................ 22

APPENDIX 1 - DIMENSIONS 23

APPENDIX 2 –POWER CONNECTORS 24

APPENDIX 3 - BLOCK DIAGRAM 26

TRACKRUNNER UPRIGHT –CHEAT SHEET 28