Your Humidity Source humidifier

is

a precision-built

instrument that, given proper care, will provide years

of

dependable service. All that is required is periodic cleaning

during the humidifying season when your humidifier is most

used. Depending on local water conditions, mineral solids and

other matter may accumulate

in

various parts

of

the unit.

These accumulations must be removed so that water flows

freely for efficient operation

of

the humidifier. A reverse

osmosis water treatment system will remove minerals and

greatly reduce the need to clean the humidifier.

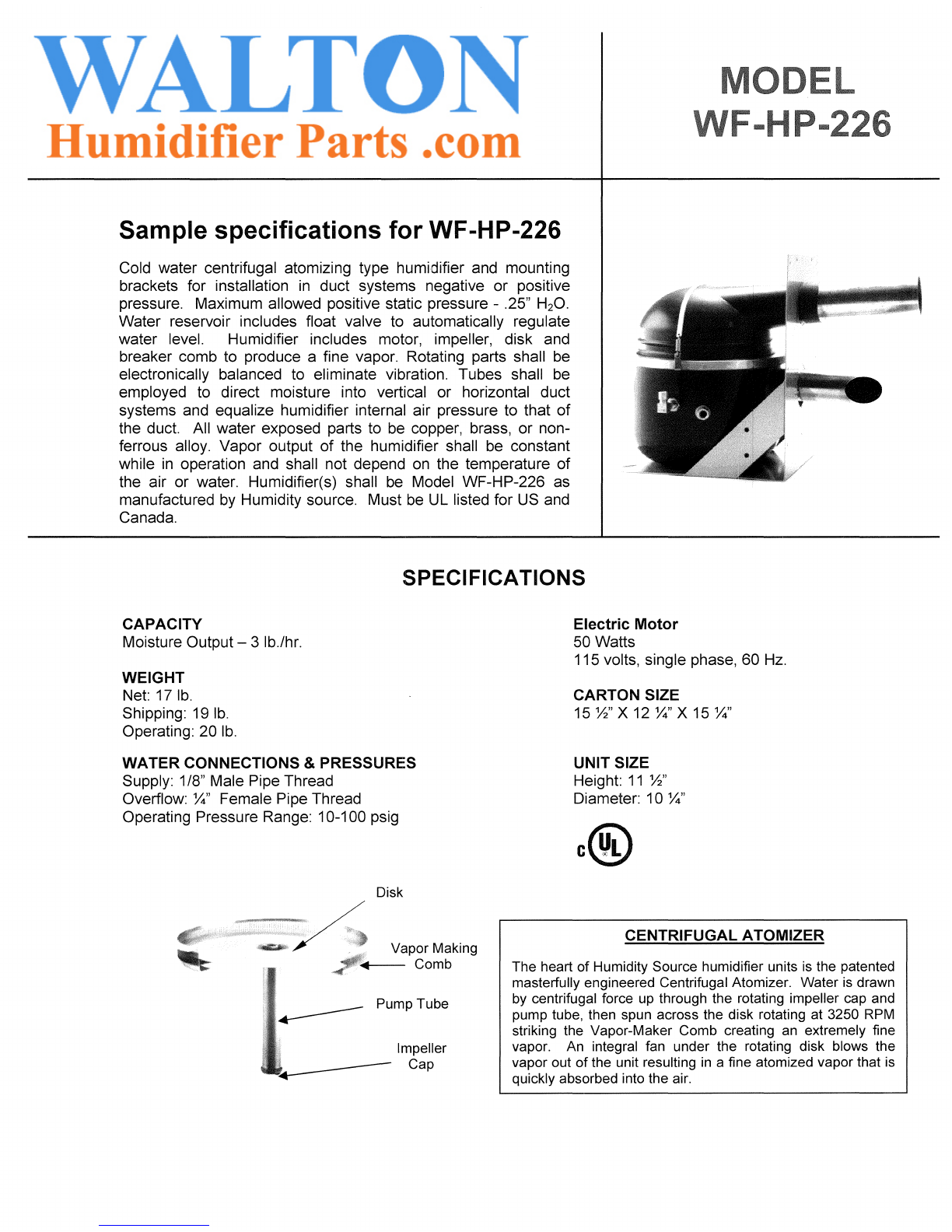

Dome

Atomizing

Unit

Pump

Tube oo

..

~

Of Pump Tube

Showing Apertures

Reservoir

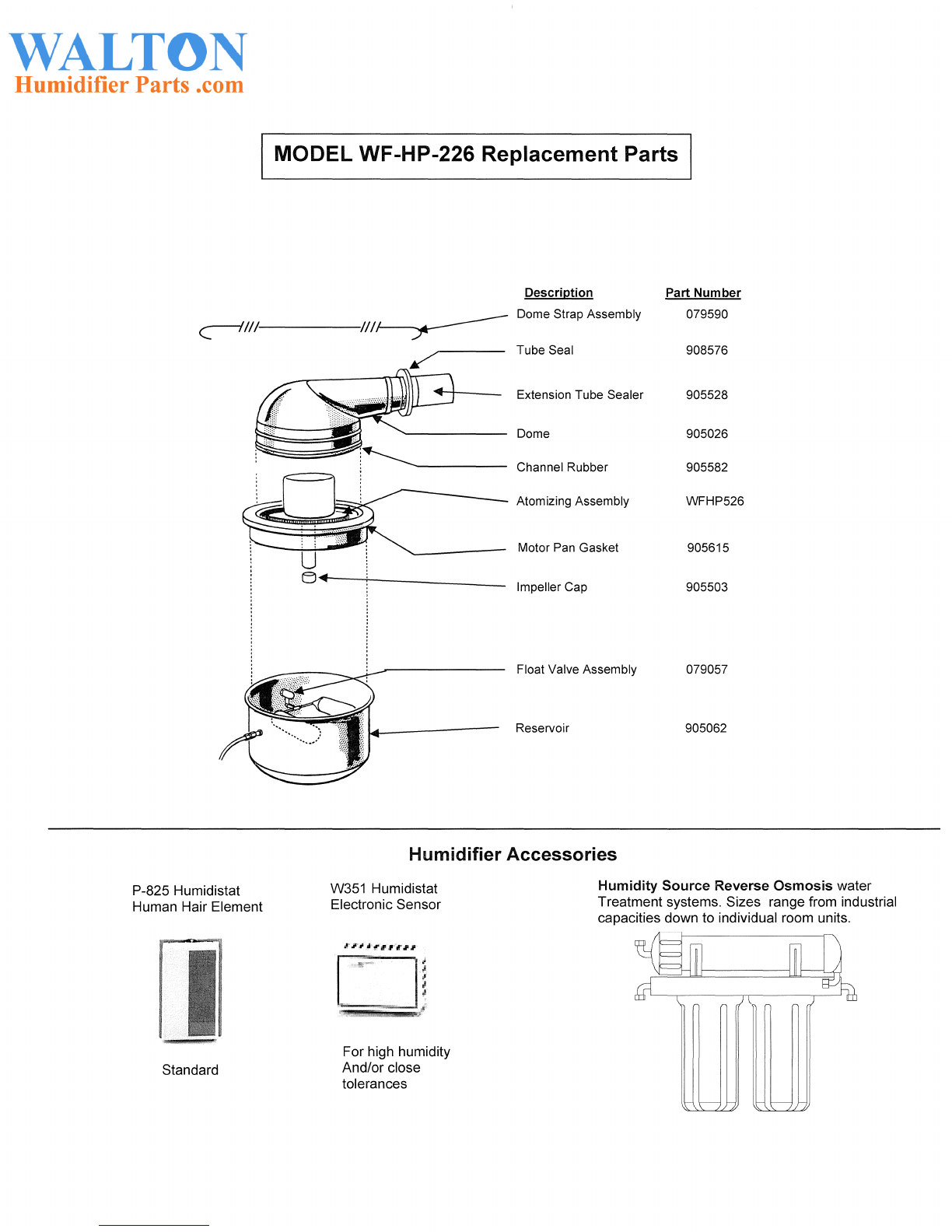

CLEAN YOUR HUMIDIFIER AT END OF THE HEATING

SEASON. LEAVE THE UNIT EMPTY AND DRY

DURING THE SUMMER MONTHS. REFILL AGAIN

IN

THE

FALL. INSPECT AND CLEAN (IF NEEDED) ONCE

OR

TWICE DURING THE HEATING SEASON.

IF

USED ALL

YEAR, INSPECT AND CLEAN AS NECESSARY

QUARTERLY

STEP 1.

DISCONNECT ELECTRICAL PLUG FROM HOUSE LINE.

TURN OFF WATER SUPPLY.

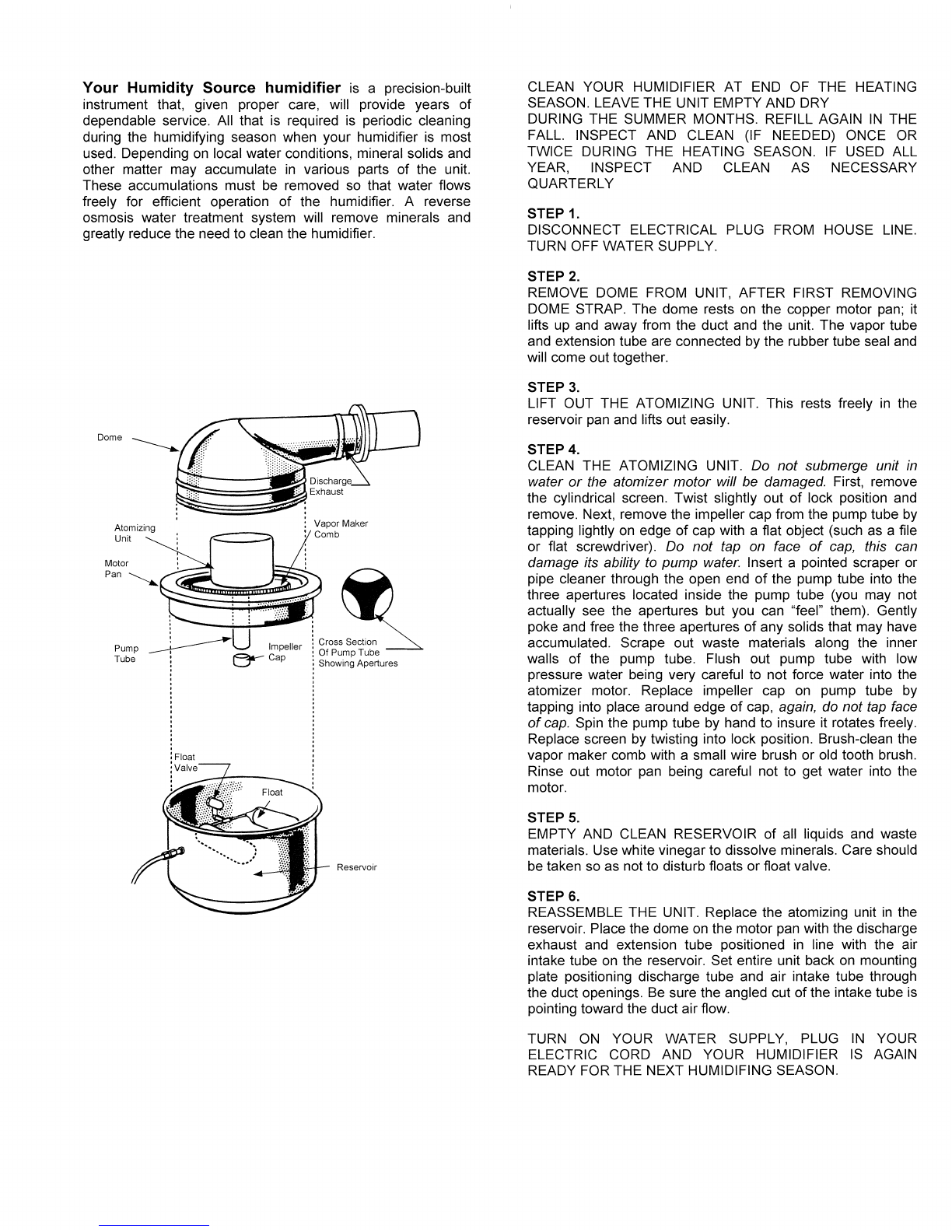

STEP 2.

REMOVE DOME FROM UNIT, AFTER FIRST REMOVING

DOME STRAP. The dome rests on the copper motor pan; it

lifts up and away from the duct and the unit. The vapor tube

and extension tube are connected by the rubber tube seal and

will come out together.

STEP

3.

LIFT OUT THE ATOMIZING UNIT. This rests freely

in

the

reservoir pan and lifts out easily.

STEP 4.

CLEAN THE ATOMIZING UNIT. Do not submerge unit

in

water

or

the atomizer motor will be damaged. First, remove

the cylindrical screen. Twist slightly out

of

lock position and

remove. Next, remove the impeller cap from the pump tube by

tapping lightly on edge

of

cap with a flat object (such as a file

or flat screwdriver). Do not tap

on

face

of

cap,

this can

damage its ability to pump water. Insert a pointed scraper or

pipe cleaner through the open end

of

the pump tube into the

three apertures located inside the pump tube (you may not

actually see the apertures but you can "feel" them). Gently

poke and free the three apertures

of

any solids that may have

accumulated. Scrape out waste materials along the inner

walls

of

the pump tube. Flush out pump tube with low

pressure water being very careful to not force water into the

atomizer motor. Replace impeller cap on pump tube by

tapping into place around edge

of

cap, again, do not tap face

of

cap.

Spin the pump tube by hand to insure it rotates freely.

Replace screen by twisting into lock position. Brush-clean the

vapor maker comb with a small wire brush or old tooth brush.

Rinse out motor pan being careful not to get water into the

motor.

STEP

5.

EMPTY AND CLEAN RESERVOIR

of

all liquids and waste

materials. Use white vinegar to dissolve minerals. Care should

be taken so as not to disturb floats

or

float valve.

STEP

6.

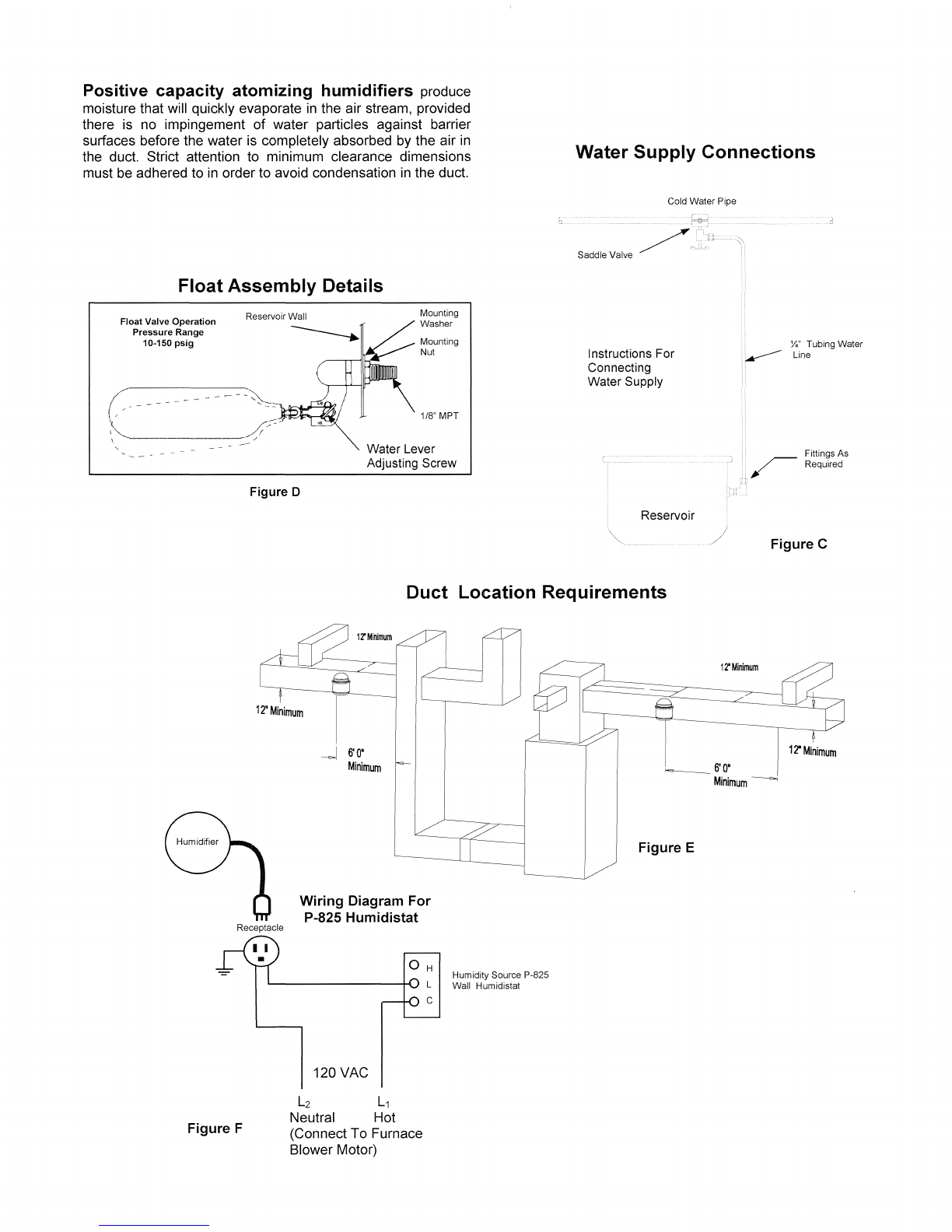

REASSEMBLE THE UNIT. Replace the atomizing unit

in

the

reservoir. Place the dome on the motor pan with the discharge

exhaust and extension tube positioned in line with the air

intake tube on the reservoir. Set entire unit back on mounting

plate positioning discharge tube and air intake tube through

the duct openings.

Be

sure the angled cut

of

the intake tube is

pointing toward the duct air flow.

TURN

ON

YOUR WATER SUPPLY, PLUG

IN

YOUR

ELECTRIC CORD AND YOUR HUMIDIFIER

IS

AGAIN

READY FOR THE NEXT HUMIDIFING SEASON.