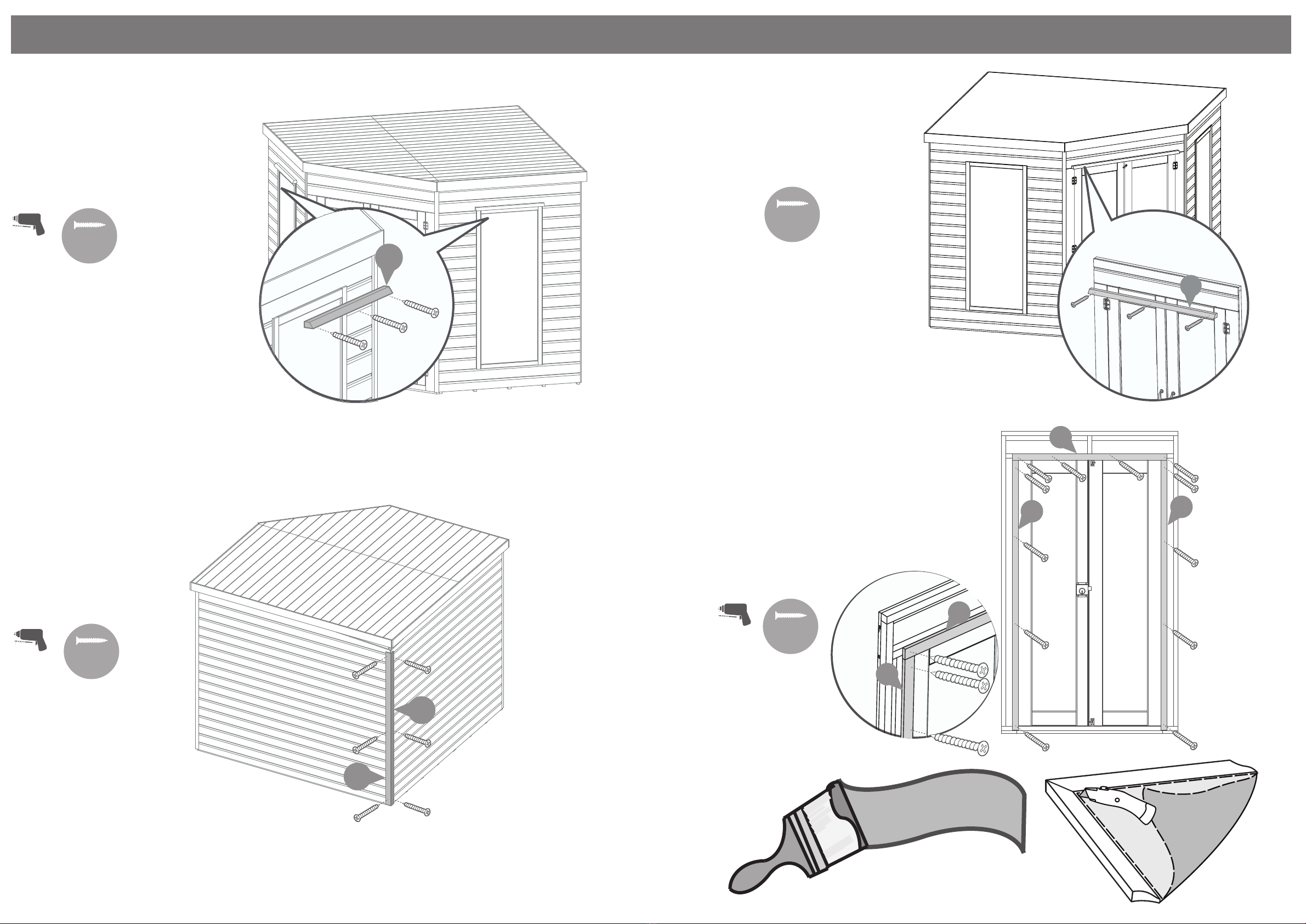

2

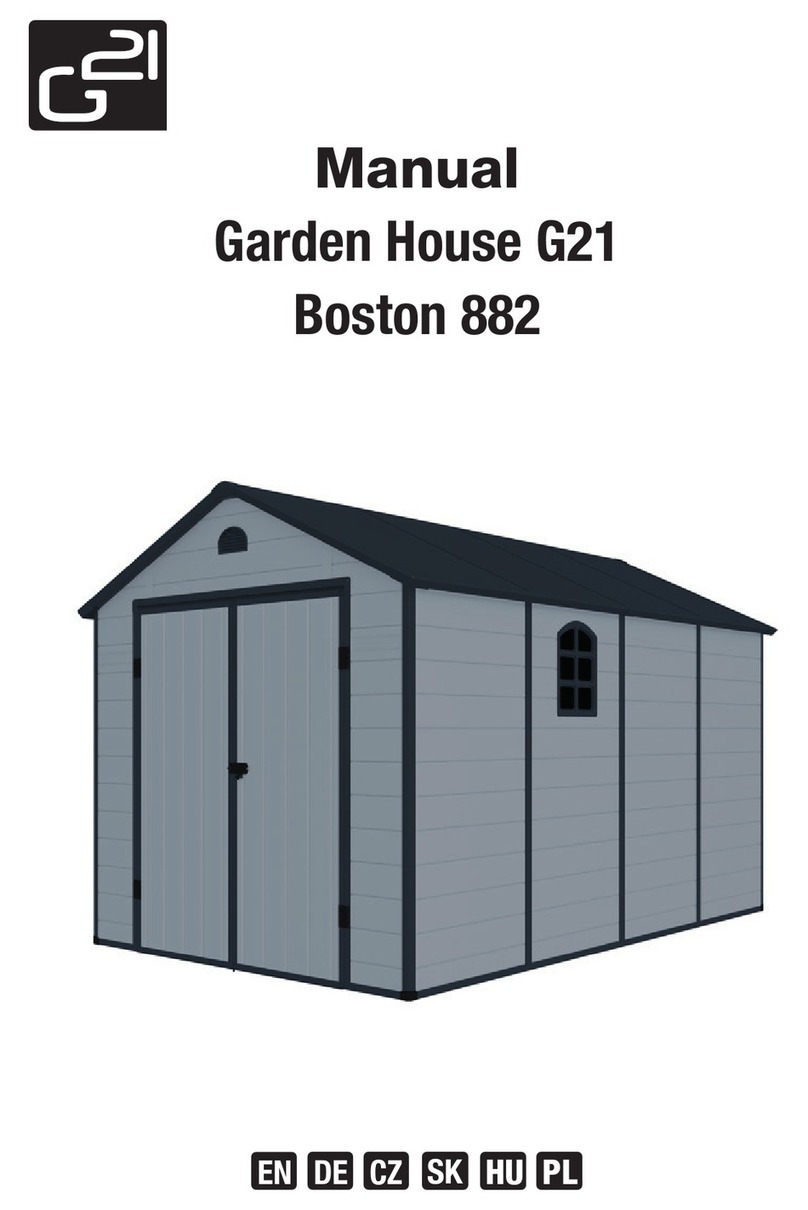

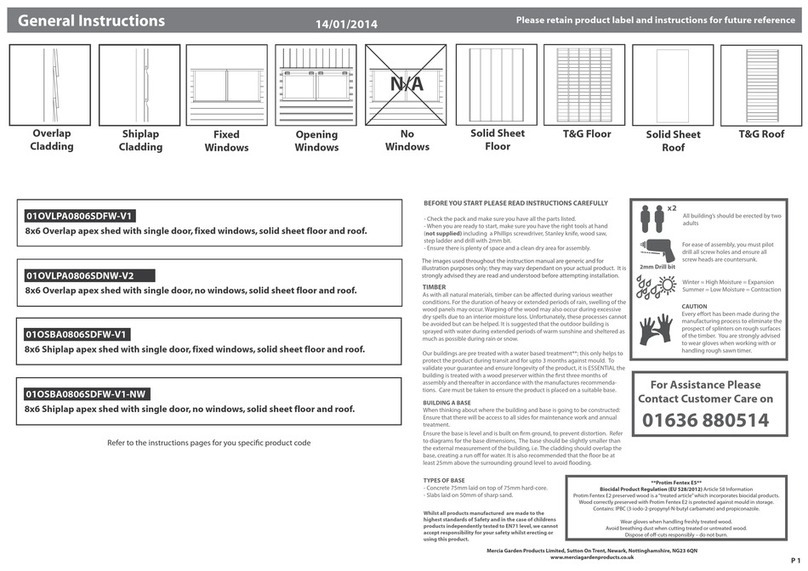

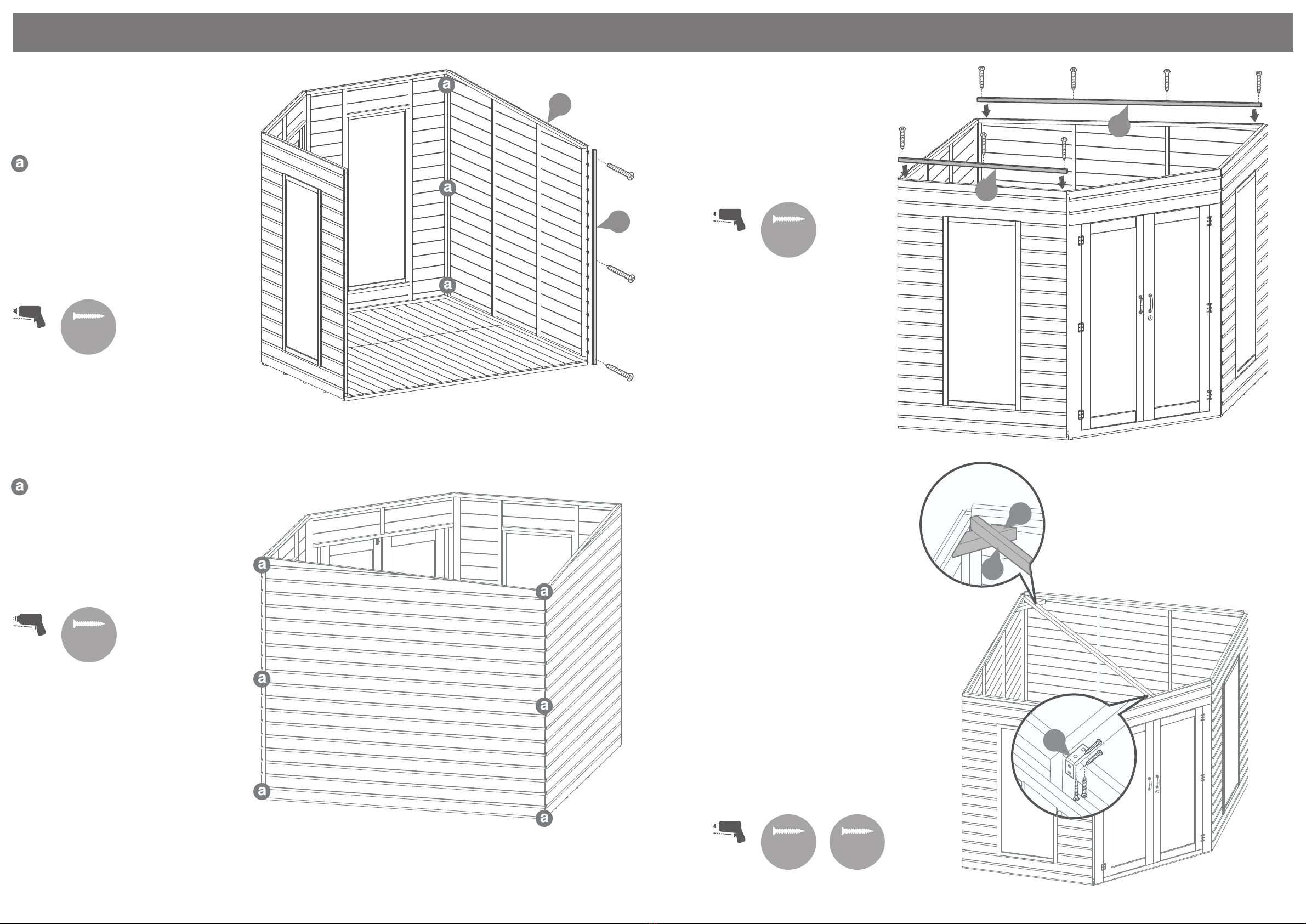

1

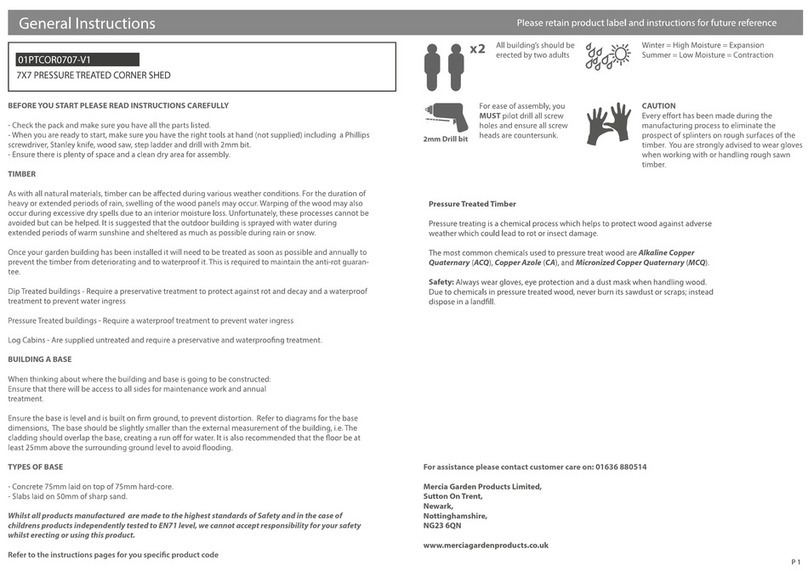

3

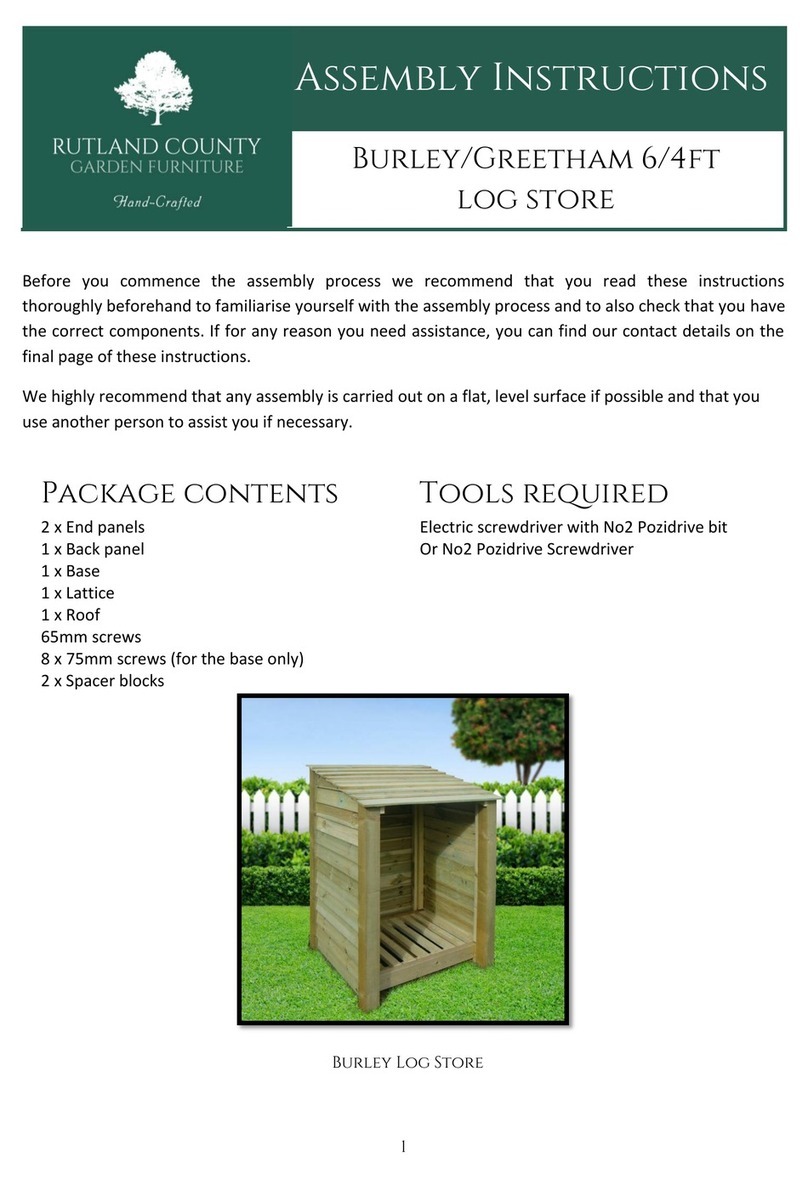

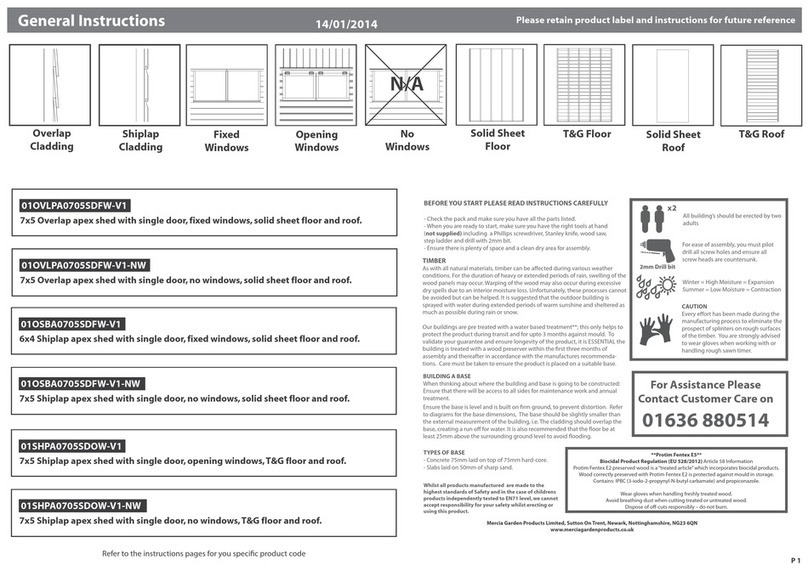

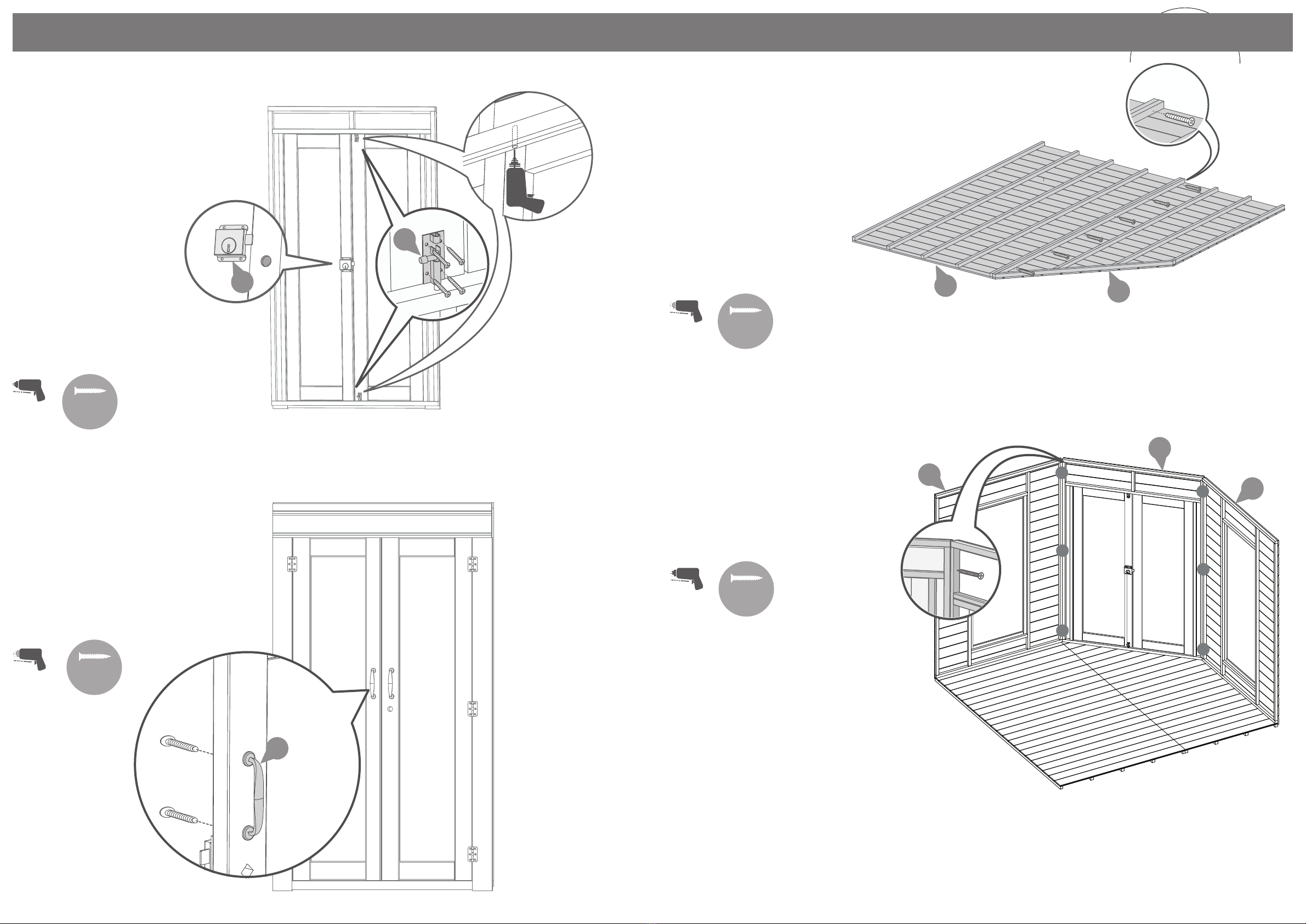

4