EXPANSION VALVE -*

The expansion valve furnished with your refrigerator has been sized for maximum

coil efficiency. To adjust superheat, place a thermocouple under the expansion

valve bulb. Read the suction line pressure as near coil as possible. (If, at

the condensing unit, estimate suction line loss at 2 PSIG). Convert coil suction

pressure to temperature. The difference between coil temperature and the

thermocouple temperature is superheat. (Use average superheat when expansion

valve is hunting). Do not set superheat until cases have pulled down to operating

temperature and never open or close valve over l/Z turn between adjustments and

allow 10 minutes or more between adjustments. Superheat should be set to 6-8OF.

REFRIGERATION LINES

Refrigerant connections (suction & liquid) are stubbed underneath the case.

Cases multiplexed together must be field connected by running refrigerant

lines in the space under the case. The field installed suction lines must be

insulated to prevent condensation accumulation on the floor. See the section

on "Recommended Piping Practices" for additonal details on piping practices.

IMPORTANT A SEAL AROUND LINES AFTERCONNECTIONS ARE'MADE. KEEP DIRECT FLAME

FROM BOTTOM OF REFRIGERATOR, AS HEAT WILL DISINTEGRATE THE BOTTOM AND INSULATION.

USE A HEAT SHIELD WHEN WELDING NEAR THE BOTTOM OF THE CASES.

REFRIGERANT

R-12 expansion valves are standard. If other refrigerant is used, the order

must specify the expansion valve to be supplied.

*,HEAT EXCHANGER (S3J

only)

Heat exchangers are standard in these refrigerators. They aid to increase

operating efficiency and reduce frosting and flood-'back to compressor.

OPERATION

On single condensing unit systems, a thermostat should be used to control

temperatures. The thermostat bulb is mo[lnted on the rear baffle on S3.modeld and

'.in the discharge air on the S3J, On parallel units, temperature control can be .

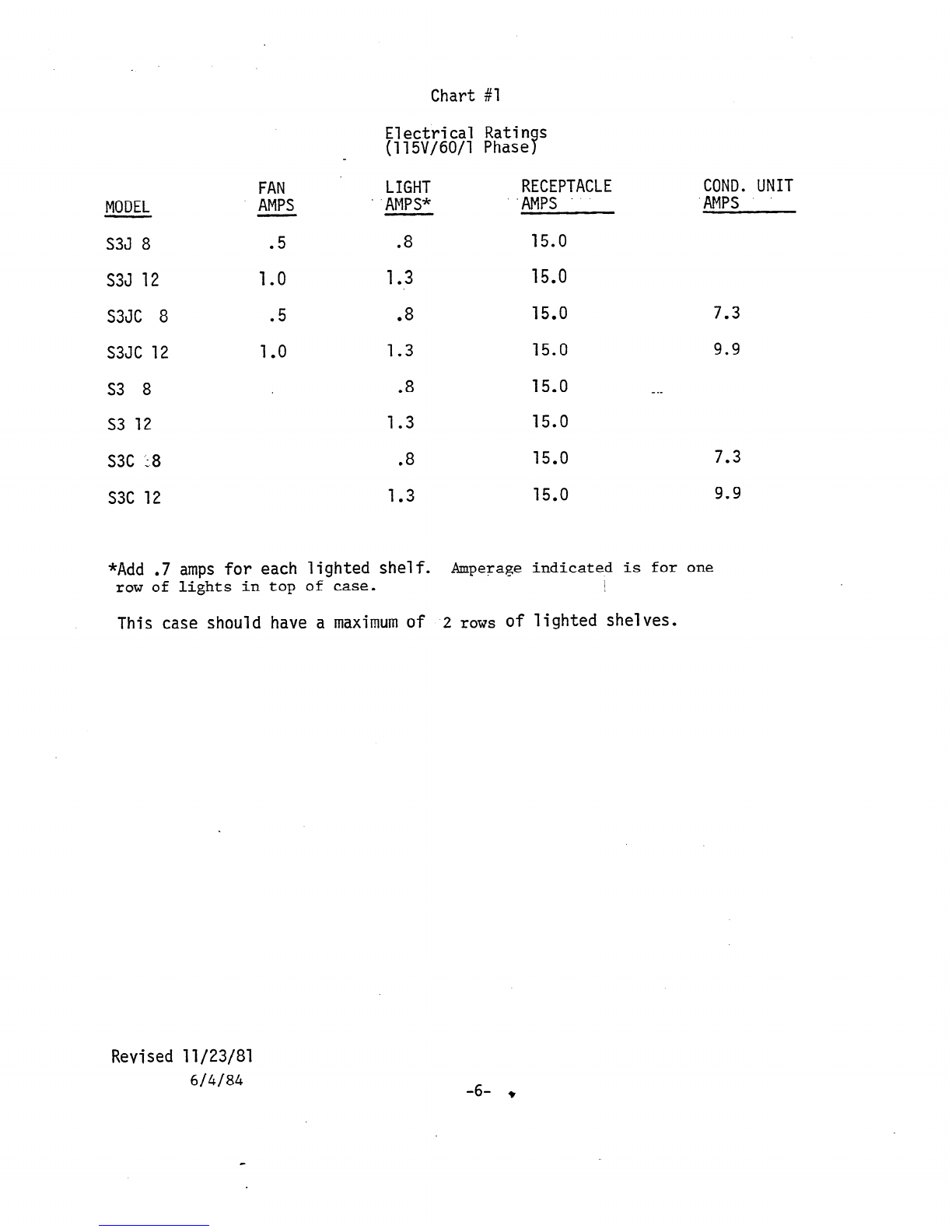

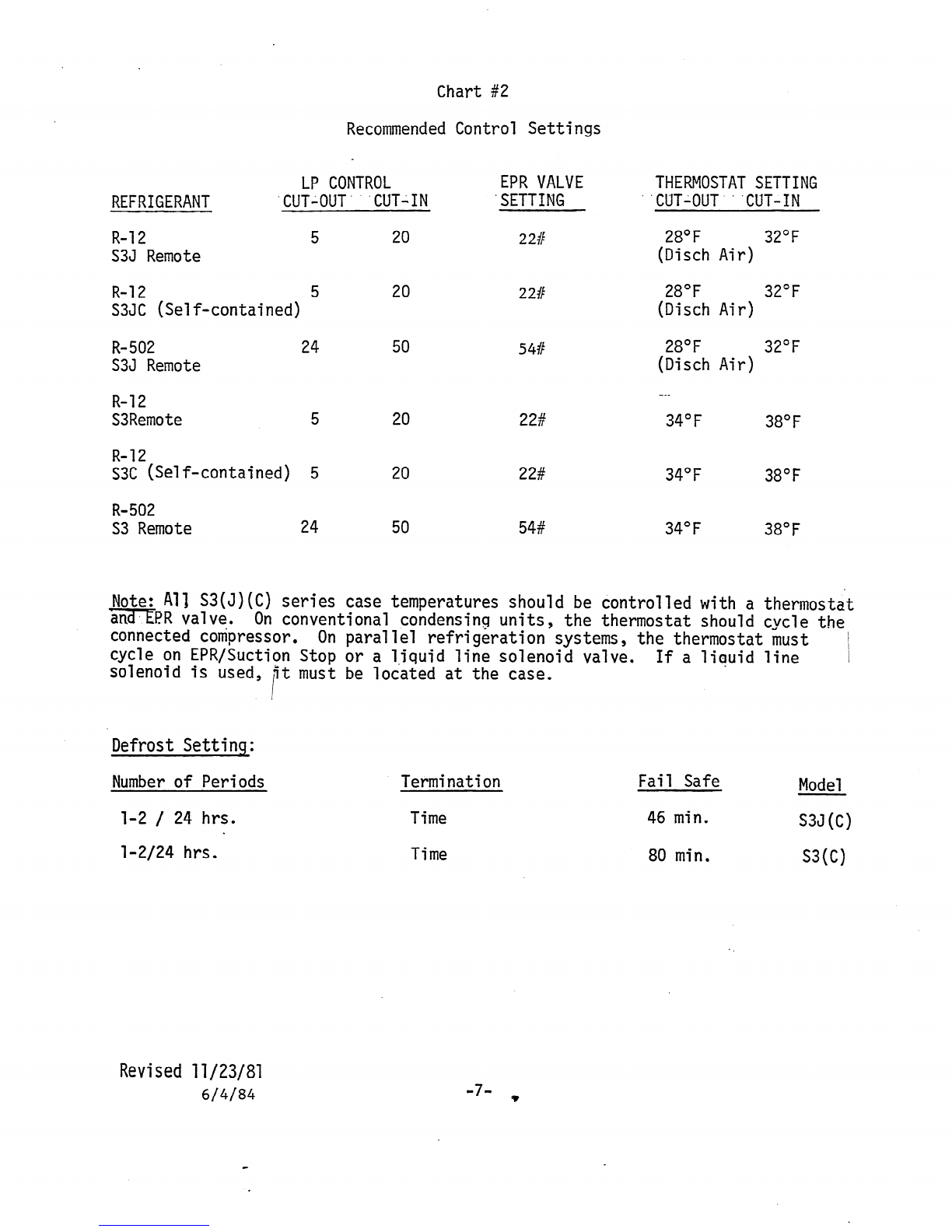

provided by EPR valve and thermostat. Chart #2 shows approximate settings for .

merchandisers. Since many variables are present in each-installation, such as 'i

. store temperature, length of tubing runs, temperature desired in refrigerator, etc.,

'Chart #2 is only a guide for-the installer.

DEHYCRATION OF REFRIGERATION SYSTEMS

Please read'ca~~fully.befd~~'~l~~i~g'~~~t~m intd operation. After laying

. refrigerant lines, they should be blown out before making final connection at

fixture or condensing unit. Use dry nitrogen to prevent any foreign matter

being left in the lines. Keep pressure below 250 pounds. To prevent scaling

due to brazing, dry nitrogen should be allowed to flow through lines while

brazing operations are taking place.

. After the refrigeration system has been pressure-tested and proven leak-free,

it is recommended that the system be dehydrated with a vacuum pump to 100 microns

for the first two evacuations and 500 microns on the third. The triple evacuation

method requires evacuating the system three successive times and breaking each

vacuum with dry refrigerant. Allow the pressure to rise above atmospheric pressure.

Revised 11/23/81

9

4

LI -

WJ)