Contents

Contents

1 Safety Precautions ..............................................................................................................................5

1.1 Additional safety precautions for gas heated tumble dryer .............................................................7

1.2 General safety information..........................................................................................................7

1.3 Commercial use only..................................................................................................................7

1.4 Copyright ..................................................................................................................................7

1.5 Symbols....................................................................................................................................7

2 Technical data.....................................................................................................................................8

2.1 Drawing ....................................................................................................................................8

2.2 Technical data ...........................................................................................................................9

2.3 Connections ..............................................................................................................................9

3 Setup ...............................................................................................................................................10

3.1 Unpacking...............................................................................................................................10

3.2 Recycling instruction for packaging ........................................................................................... 11

3.3 Siting ......................................................................................................................................12

3.4 Mechanical installation .............................................................................................................12

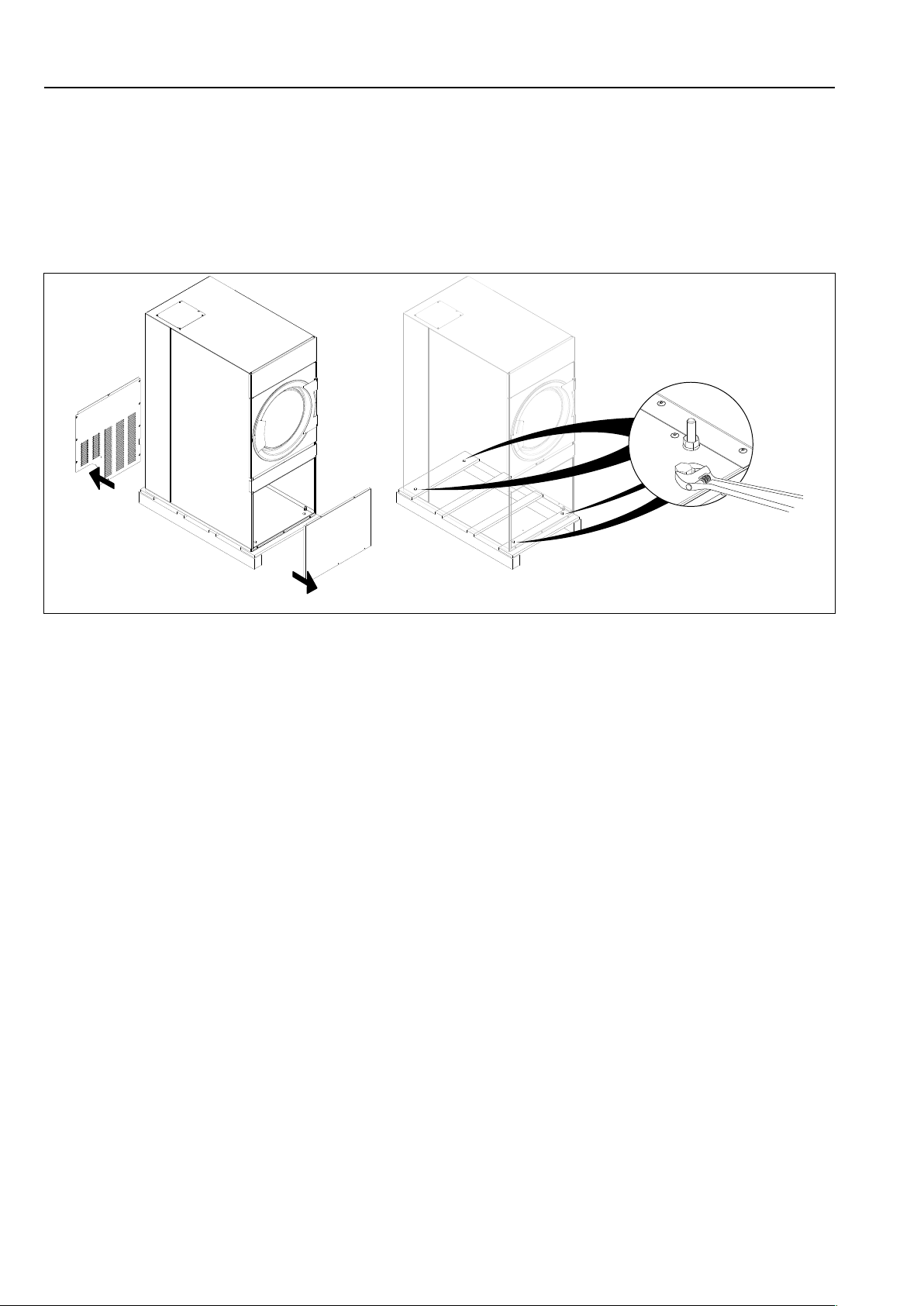

3.4.1 Securing the machine .....................................................................................................13

4 Marine installation .............................................................................................................................14

5 Reversing the door ............................................................................................................................15

6 Evacuation system ............................................................................................................................18

6.1 Air principle .............................................................................................................................18

6.2 Fresh air..................................................................................................................................19

6.3 Exhaust duct ...........................................................................................................................19

6.4 Shared exhaust duct ................................................................................................................20

6.5 Exhaust dimensioning ..............................................................................................................20

6.6 Adjusting the dryer...................................................................................................................21

7 Steam connection .............................................................................................................................23

7.1 Connecting the steam ..............................................................................................................23

7.2 Steam calorifier........................................................................................................................24

8 Gas connection .................................................................................................................................25

8.1 Fasten the label .......................................................................................................................25

8.2 General...................................................................................................................................25

8.3 Gas installation........................................................................................................................26

8.4 Table of pressure and adjustment..............................................................................................27

8.5 Test run...................................................................................................................................28

8.6 Converting instructions.............................................................................................................28

8.7 Data label................................................................................................................................30

9 Electrical connection..........................................................................................................................31

9.1 Electrical installation ................................................................................................................31

9.2 Single-phase connection ..........................................................................................................31

9.3 Three-phase connection...........................................................................................................32

9.4 Electrical connections ..............................................................................................................33

9.5 Functions for I/O-cards.............................................................................................................34

9.5.1 Central payment (2J) ......................................................................................................34

9.5.2 Central payment (2J) ......................................................................................................35

9.5.3 External coin meter/Central payment (2K) ........................................................................36

9.5.4 Price reduction (2K)........................................................................................................37

9.6 Option.....................................................................................................................................37

9.6.1 External connection 100 mA............................................................................................37

10 At first power up ................................................................................................................................38

10.1 Select language.......................................................................................................................38

10.2 Set time and date.....................................................................................................................38

10.3 Activate/Deactivate the service alarm ........................................................................................38

11 Function check..................................................................................................................................39

12 Disposal information..........................................................................................................................41

12.1 Disposal of appliance at end of life ............................................................................................41

12.2 Disposal of packing..................................................................................................................41

The manufacturer reserves the right to make changes to design and component specifications.