Page 12 of 34 Page 13 of 34Doc: Transducer Installation

Version: 2.6 May 2021

Doc: Transducer Installation

Version: 2.6 May 2021

wassp.com wassp.com

TRANSDUCER INSTALLATION MANUALTRANSDUCER INSTALLATION MANUAL

4 HULL MOUNTING CONSIDERATIONS

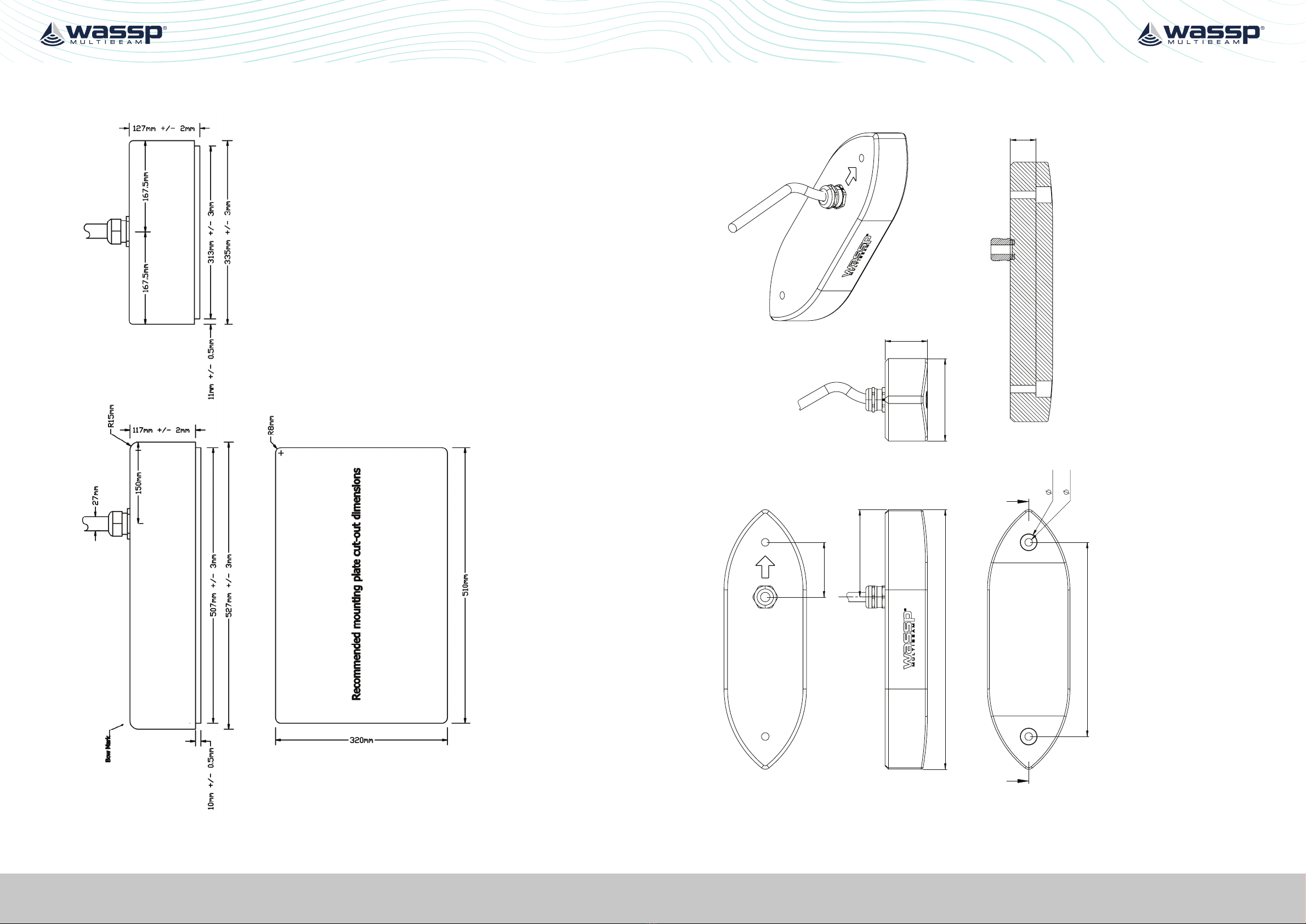

The transducer is mounted on the hull below the water line, normally using a permanent

sea chest. The transducer must be mounted so that it is aligned with the fore-aft axis of

the vessel. It must also be mounted so that the flat underside of the transducer is as close

to horizontal as possible.

If the vessel has a keel, the transducer can be mounted somewhere along the length of

it. If it is mounted on the hull, it should be far enough away from the keel so that the keel

will not be detected within the 120° WASSP beam pattern. Figure 4 on page 10 shows

a sea chest type through-hull mounting designed specifically for a fast moving, alloy hull

crayfish boat.

The performance of the system is directly related to the mounting location of the

transducer, especially for high-speed cruising. The installation should be planned in

advance, keeping in mind the fixed cable length of your transducer (5m / 10m / 20m)

and the following factors:

»Air bubbles and turbulence caused by movement of the vessel seriously degrade the

sounding capability of the transducer. The transducer should be located in a position

with the smoothest water flow.

»The transducer should not be mounted close to propellers because noise from

propellers can adversely aect the performance of the transducer.

»Mount the transducer inboard of lifting strakes as these create acoustic noise.

»The transducer must always remain submerged, even when the boat is rolling,

pitching or planing at high speed.

»A practical choice would be somewhere between a 1/3 and a 1/2 of the boat’s

length from the bow. For planing hulls, a practical location is generally towards the

rear of the vessel, to ensure that the transducer is always submerged, regardless of

the planing angle.

»Do not mount another transducer near the WASSP transducer as it will cause

interference

Planing hulls

On planing hulls the transducer needs to be mounted in or on the aft part of the hull,

which stays in the water when the vessel is on the plane.

The transducer can be mounted either in a streamlined housing or blister on the hull or

inside the hull in a specially prepared coerdam, with the transducer face flush with the

hull and faired to the hull shape.

It is important that the part of the hull in front of the transducer is smooth and has no hull

penetrations or attachments of any kind.

Displacement hulls

A practical choice is somewhere in the area between a ⁄ and a ⁄ of the vessel’s length,

from the bow. The transducer should be mounted in a housing or blister attached to the

hull.

The disturbed aerated water tends to be in a layer against the hull, it’s thickness varies by

vessel’s speed and sea conditions. Therefore the deeper the housing is, i.e. the further

the transducer is away from the hull, the better the equipment will perform. Also on

V-shaped hulls the housing should be mounted against or close to the keel, again to get

deeper and away from aeration and turbulence. The 120 WASSP beam pattern must be

kept in mind when mounting the transducer. No part of the keel or hull should protrude

into this pattern.

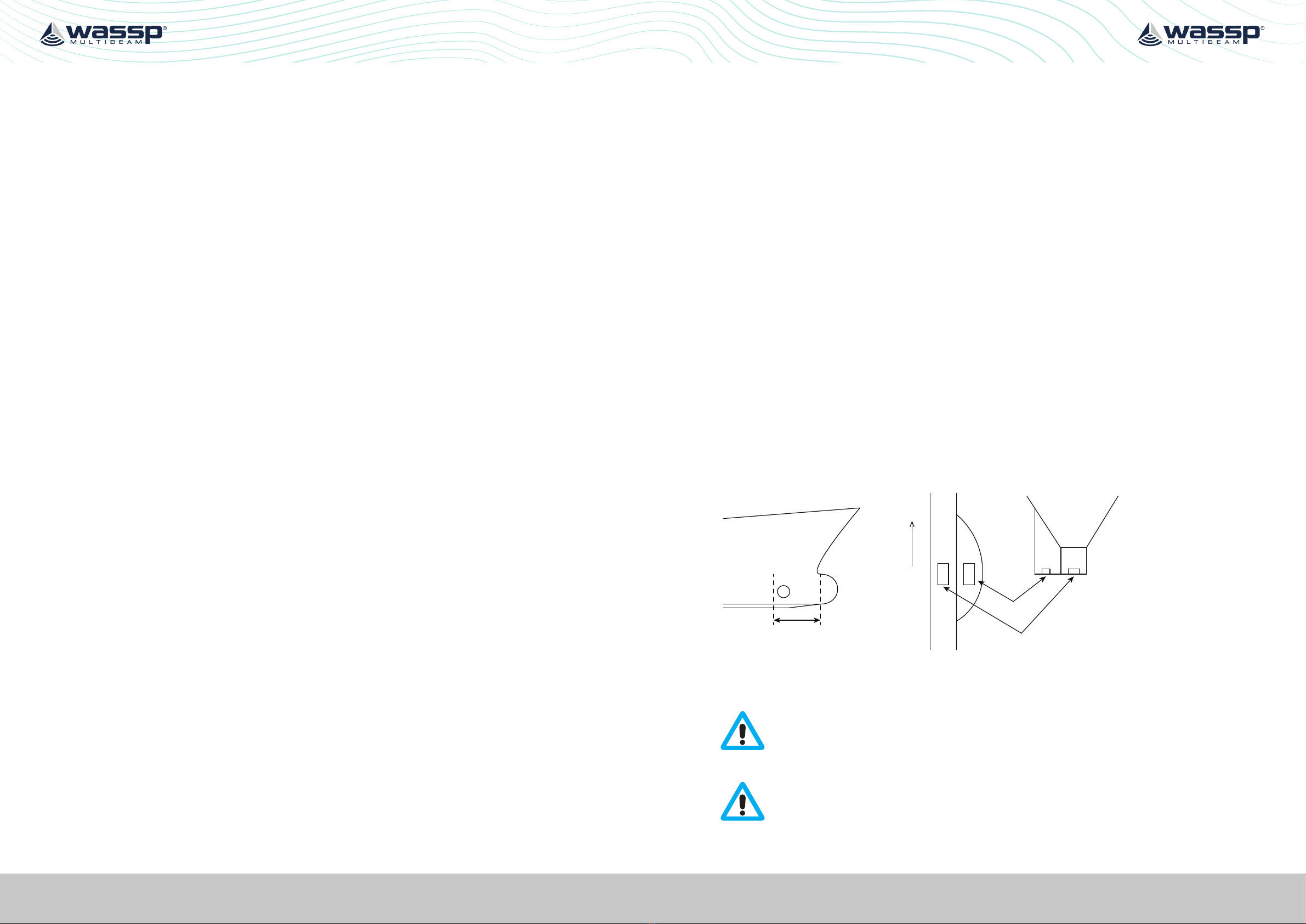

Larger displacement hulls with bow thruster

The best location on these vessels is in or against the keel, forward of a line just aft of the

thruster cavity. Locations further aft are becoming heavily aected by aeration when the

vessel pitches and air exhausts out of the thruster tunnel on the downward movement

of the bow. This air creates havoc with the performance of any transducers further aft on

the hull. "Figure 7. Transducer mounting locations for larger displacement hulls" suggest

mounting locations for these types of vessels.

In these installations, the strength of the mounting becomes very important, as the

transducer can be out of the water when the vessel pitches. Re-entry into the water

exerts large forces on the transducer face and the mounting structure.

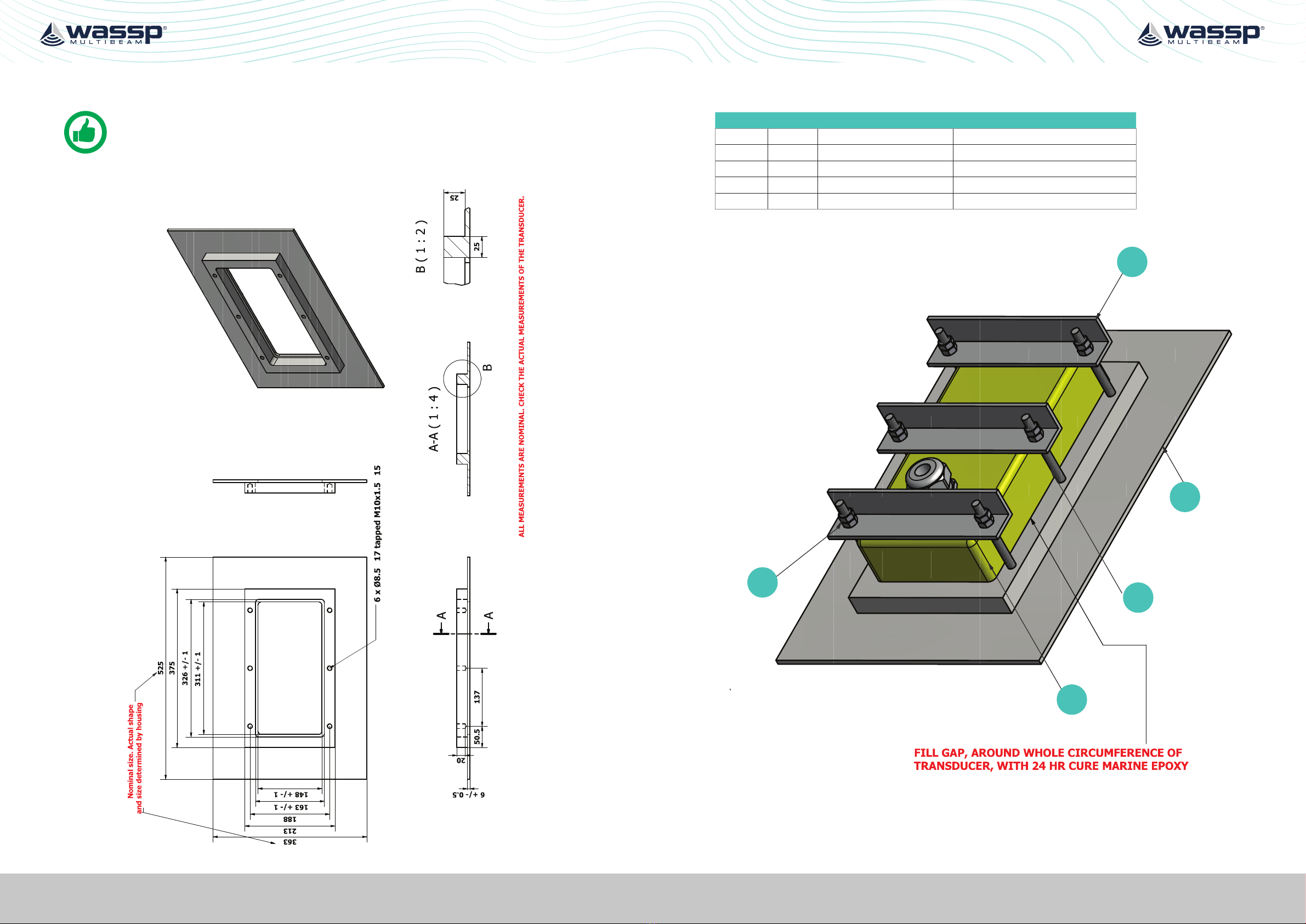

See "5.1. 160kHz Transducer Mounting" on page 14 and "5.2. 80kHz Transducer

Mounting Assembly" on page 16 for mounting diagrams and instructions. These steps

must be carried out accurately and completely.

FW D

Viewfrom above

In housing

In box keel

Mounting area for transducer

on large vessels with thruster

View from the bow

Figure 7. Transducer mounting locations for larger displacement hulls

CAUTION: Please see "5 Mounting Assembly" on page 14. In particular

pay attention to the torque tension of the mounting nuts and the

requirement to fill any gaps that exist between the transducer body and the

retaining with epoxy.

A non-solvent based anti-fouling must be applied to the transducer face