Waterco Hydroxzone Ozone Generator User manual

www.waterco.com

Australian Approval number: 13041001/00

HYDROXZONE

OZONE GENERATOR

Owner’s Manual

GENERAL SAFETY RULES

1. The equipment mentioned in this manual is specially designed for the sanitizing of water in

swimming pools.

2. It is designed to work with clean water at a temperature not exceeding 60°C (140°F).

3. The installation should be carried out in accordance to the safety instructions of swimming

pools especially Standard HD 384.7.702 and the specic instructions for each facility.

4. The rules enforced on accident prevention should be carefully followed.

5. Any modication of the system requires the prior consent of the manufacturer.

6. Original replacement parts and accessories authorized by the manufacturer ensure a high

level of safety.

7. The manufacturer accepts no liability for the damage and injuries caused by unauthorized

replacement parts and accessories.

8. During operation, some parts of the components are subject to dangerous electric voltage.

Work may only be performed on the components or on the equipment connected to it after

disconnecting them and the starting device from the mains power.

9. The user should make sure that assembly and maintenance tasks are carried out by

qualied authorized persons and that these persons have rst carefully read the Service

and Installation Instructions.

10. The operating safety of the components of the system is only guaranteed if the Installation

and Service instructions are correctly followed.

11. The limit values stated in the Technical Specications should not be exceeded under any

circumstance.

12. In the event of defective operation or fault, contact the manufacturer’s Technical Support

Department or its nearest Authorized Agent.

13. If any of the supply cord is damaged, it must be replaced by the manufacturer or its service

agent or a similarly qualied person.

14. This appliance is not intended for use by persons (including children) with reduced

physical, sensory or mental capabilities, or lack of experience and knowledge, unless they

have been given supervision or instruction concerning use of the appliance by a person

responsible for their safety

IMPORTANT SAFETY INSTRUCTIONS

Read and Follow All Safety Instructions

Read and be familiar with this manual before installing or operating your new Hydroxzone

ozone generator.

• Voltage must be determined before unit is installed.

• Do not bury cord.

• Connect only to a properly grounded, grounding type receptacle.

• If the supply cord is damaged, it must be replaced by the manufacturer, its service agent or

similarly qualied persons in order to avoid a hazard.

• This appliance is to be supplied through a residual current device (RCD) having a rated

residual operating current not exceeding 30 mA.

• The equipment must be installed outdoor, but must be undercover to avoid exposure to rain

• The mounting position - The unit must be mounted in a horizontal position. See installation

guide for photo of position (Figure 2.1)

• Install at least 1.5m from the inside wall of the pool using non-metallic plumbing. The ozone

generator is to be located 600mm above the maximum water level to prevent water from

contacting electrical equipment. Install to provide drainage of compartment for electrical

components.

• Wear safety glasses when drilling and tapping holes for installation of unit.

SAVE THESE INSTRUCTIONS

• Short term inhalation of high concentrations of ozone and long term inhalation

of low concentrations of ozone can cause serious harmful physiological

effects.

• Do not inhale ozone gas produced by this device.

• Disconnect all power to pool equipment prior to installation, maintenance, or

removal of the Hydroxzone ozone Generator.

• To avoid risk of electric shock, re, or injury, service should only be performed

by a qualied pool service professional.

• Installation must be performed in accordance with the National Electric Code

and any applicable local or state installation codes.

NOTE: The instructions in this document provide general installation guides.

Consult your dealer for specic installation instructions. Check system for any

visible shipping damage. If damage has occurred, contact the delivery company

and your dealer immediately. Before beginning installation, please verify that all

listed parts are on hand.

i

WHAT IN THE BOX

• 1 Hydroxzone ozone generator • 1 Venturi Injector

• 1 Installation kit

Table of

1. HYDROXZONE OZONE GENERATOR ---------------------------- 01

2. INSTALLATION ----------------------------------------------------- 03

3. HYDROXZONE MAINTENANCE/HOURS ------------------------ 09

4. TROUBLESHOOTING GUIDE ------------------------------------- 09

5. TECHNICAL SPECIFICATIONS ----------------------------------- 10

6. SPARE PARTS LIST ------------------------------------------------ 10

7. WARRANTY -------------------------------------------------------- 10

1. HYDROXZONE OZONE GENERATOR

1.1 INTRODUCTION TO OZONE

The Hydroxzone ozone generator system produces ozone when air is drawn across a special

high-energy vacuum ultraviolet (VUV) lamp, converting some air to ozone and hydroxyl radicals.

A Dynamic Venturi is inserted on the return line, by-passing through a venturi, which creates

suction that draws the ozone/hydroxyl radicals into the water ow, mixing the bubbles as the

water returns to the pool.

It is operated automatically by connecting the Hydroxzone ozone generator system directly

to the circulation pump or plugging into a timer. A check valve is employed to prevent water

owing up to the ozone generator, in the event of system failure.

Although ozone is mainly thought of as a sanitiser, it acts primarily as an oxidiser in the pool

environment. In a typical chlorinated pool, up to 90 percent of the pool’s chlorine may be used

up in reactions unrelated to disinfection. The by-products of these reactions are combined

chlorines. Combined chlorine is the cause of eye irritation, odour and the other unpleasant side

effects of chlorination. When the ozone/hydroxyl radical is used, they oxidize a large portion of

the contaminants, which results in the formation of combined chlorine. The result is that more

chlorine is available for disinfection and less chlorine is required to maintain the pool. Ozone

provides some disinfection, but ozone residual cannot be established, so the use of bromine

primary sanitiser [chlorine, bromine, hydrogen peroxide] is always recommended.

I pg 01

Hydroxzone Ozone Generator

NOTE: Hydroxzone must be used in combination with an approved/registered

sanitiser.

i

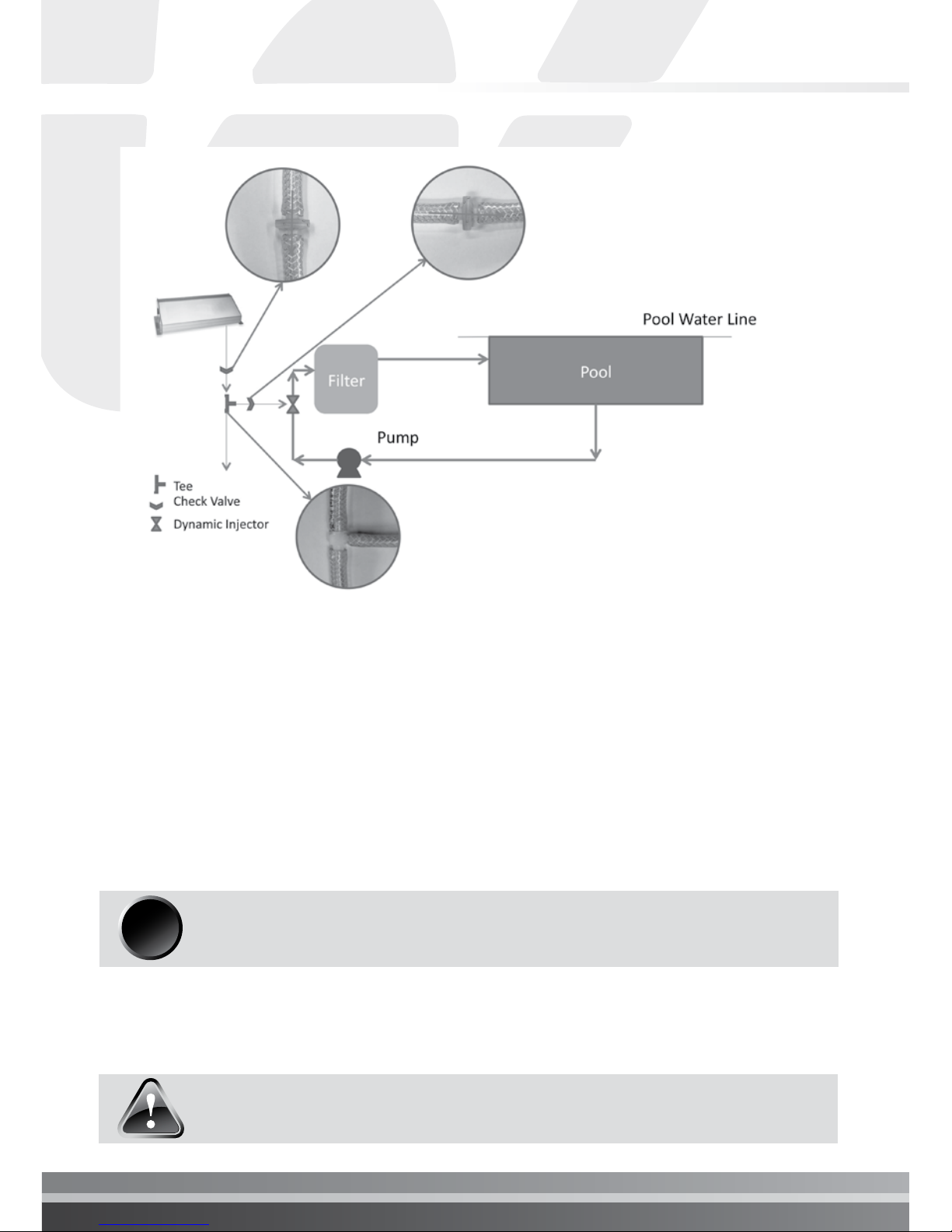

1.1 Typical Installation of Hydroxzone

¾”

Hose

¼”

Hose

¾”

Ball Valve

(If using a DE lter)

¼”

Hose

Hydroxzone

Pump

HeaterFilter

Bypass

Exit Pool

Check Valve

Bypass

Entrance

Venturi Injector

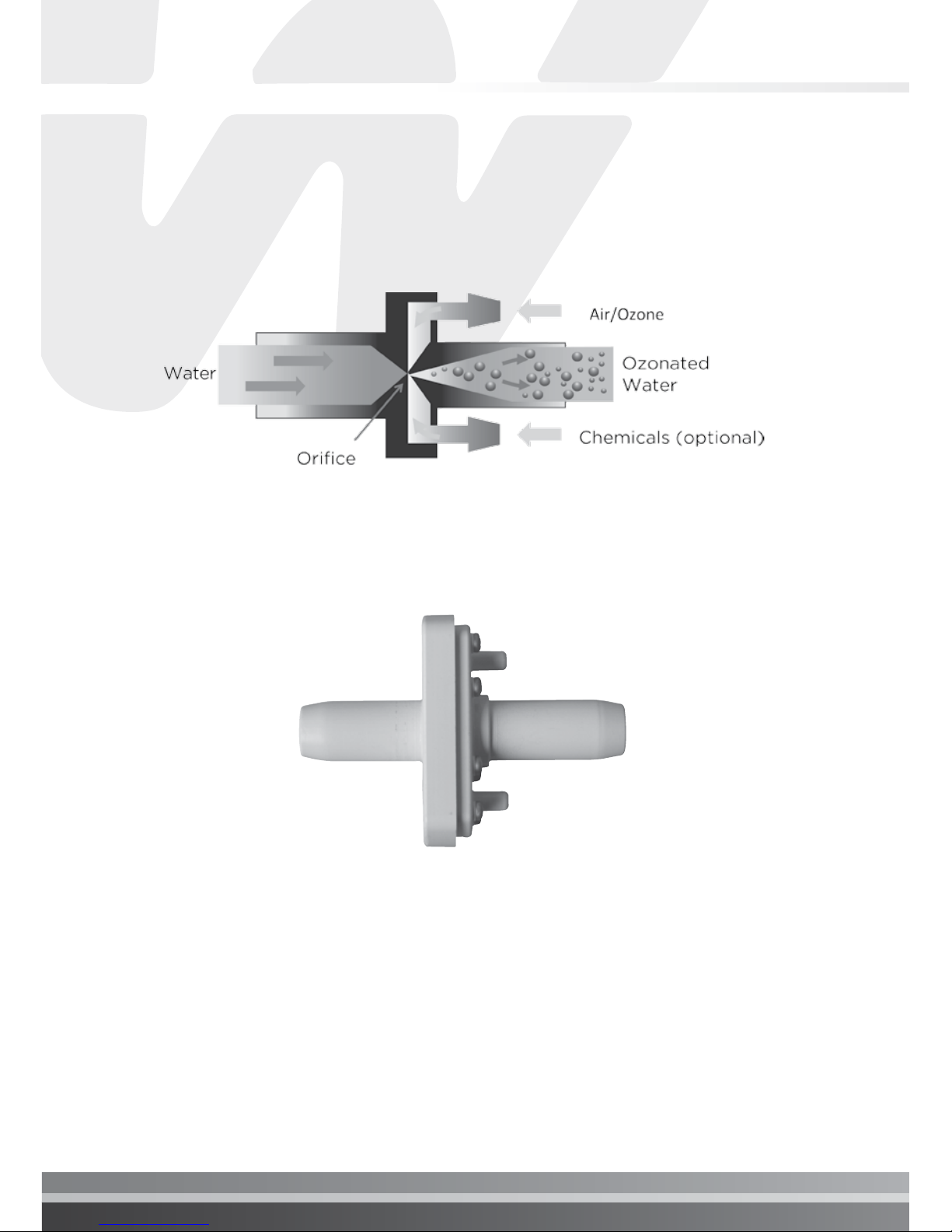

1.2 THE DYNAMIC VENTURI INJECTOR (DVI) ASSEMBLY

Hydroxzone ozone generator uses a Dynamic Venturi Injector that enhances the transfer of

ozone to the water. The injector is specially designed to minimise the pressure drop across the

system.

Figure 1.2 How the injector works

Figure 1.3 Venturi Injector

I pg 03

Hydroxzone Ozone Generator

2. INSTALLATION

2.1 PREPARING FOR INSTALLATION

I. Check for and correct all leaks in plumbing.

II. Balance the pool Water

III. Backwash the lter on retrot installation.

IV. Shock the pool. Hydroxzone must be used in combination with and approved/registered

sanitiser

V. Turn pump OFF.

VI. Locate section of plumbing where the Venturi Injector needs to be located.

VII. Venturi Injector must be installed after the lter and any other additional equipment installed

in line (e.g. heater or solar)

VIII. The unit must be mounted out of direct contact with the weather.

IX. Hydroxzone must be mounted on a wall in a horizontal orientation as shown below.

Figure 2.1 Hydroxzone Mounting Position

NOTE: The minimum recommended vacuum at the inlet of the Venturi injector is 2 L/min.

The vacuum can be measure by using a vacuum meter (Waterco’s P/N 72522813). It may

be necessary to install a Ball Valve (not included) in the main line between the Entrance and

Exit of the bypass. The Ball Valve will need to be adjusted to ensure adequate ow through

the bypass.

Multispeed pumps can alter the water ow rate through the pool system. Adjusting the

speed of a Multispeed pump will affect the water ow and the vacuum through the Venturi

Injector.

When making any adjustments to the speed of the Multispeed pump, make sure there is a

minimum vacuum of 2L/min through the venturi injector.

All pools are different. Depending on the hydraulic resistance in the pool system, running a

Multispeed pump on low speed may not create enough vacuum. If this is the case, the pump

speed will need to be increased until the minimum required vacuum is reached.

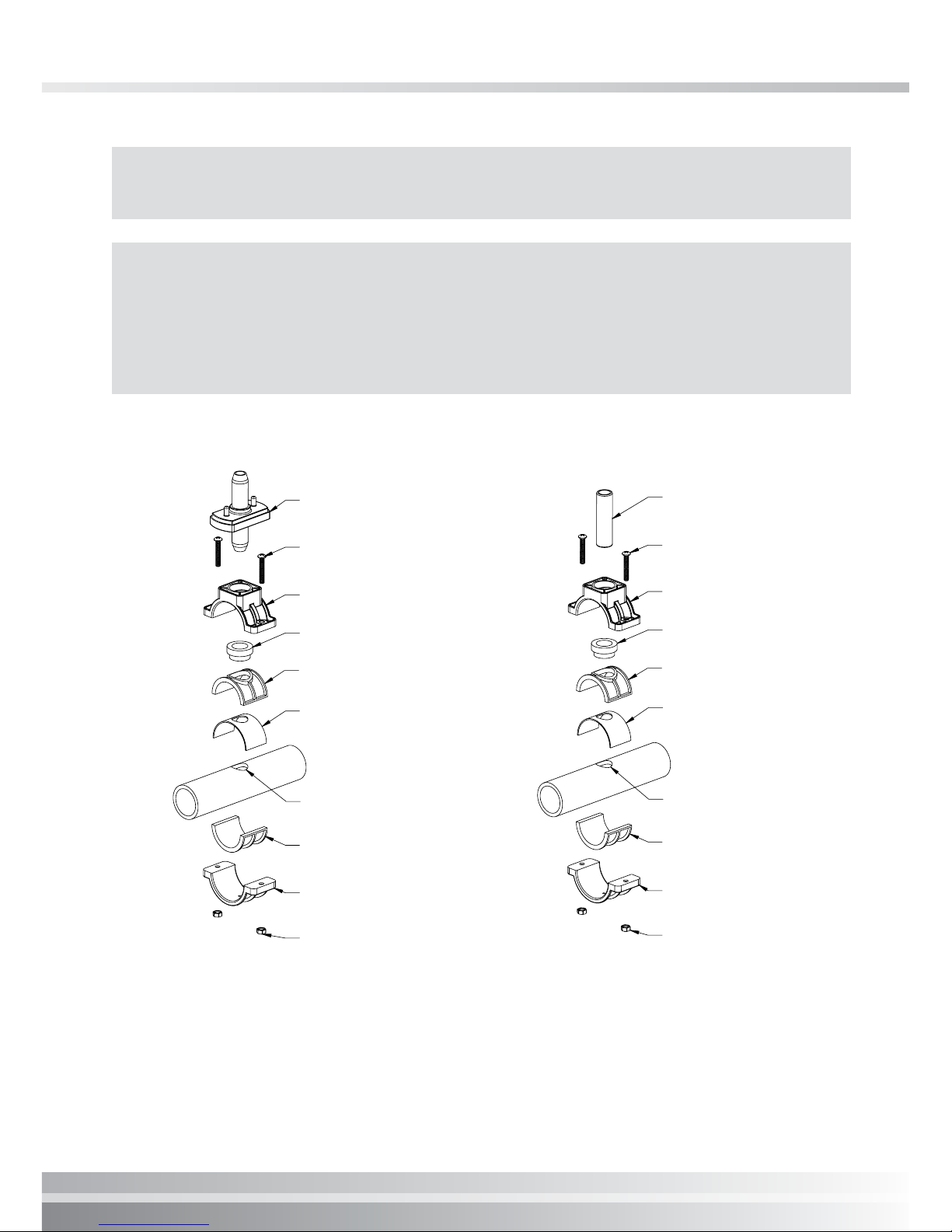

2.3 INSTALL THE SADDLE CLAMPS (BYPASS)

1. Turn pump OFF.

2. Locate section of existing plumbing in which you choose to install the ENTRANCE leg of

the bypass. Location should be in any accessible area after the pump, but before the lter

(Please refer to Figure 1.1).

3. Install Saddle Clamp Top & Bottom, (and adapters if needed), without bushing, (this will be

used as a guide for your installation hole).

4. Drill a 7/8”/22mm hole through one wall of the pipe, using power drill, being careful not to

drill too deep to avoid penetrating the opposite side of the plumbing.

5. Locate section of existing plumbing in which you choose to install the EXIT leg of the

bypass (Please refer to Figure 1.1). Location should be in any accessible area after the lter,

and heater (if equipped).

6. Repeat steps 3 & 4.

7. Remove both Saddle Clamp Assemblies.

8. Using components listed, mount one Saddle Clamp Assembly on Entrance bypass location

with the INLET side of the Venturi Injector mounted in the Saddle Clamp Bushing, (ozone

ports should be facing upward). Tighten both screws. (refer to Figure 2.2)

9. Using components listed, mount the other Saddle Clamp Assembly on Exit bypass location

with the 15mm x 75mm length (½” x 3”) PVC pipe mounted in the Saddle Clamp Bushing.

Tighten both screws. (refer to Figure 2.3)

10. Attach one end of 20mm (¾”) clear hose to Venturi Injector and secure with a metal clamp.

Attach other end of 20mm( ¾”) clear hose to 15mm x 75mm Length (½” x 3”) PVC pipe and

secure with a metal clamp.

11. Mount the Hydroxzone Ozone Generator on a wall or surface at least above maximum

water level to prevent water from contacting the electrical equipment. Unit orientation will

not affect performance.

2.2 RECOMMENDED WATER CHEMISTRY

(WATER BALANCE)

Consult the local pool professional for the correct water balance according to the swimming

pool type.

PARAMETER SUGESTED VALUE

pH 7.2-7.6

Total Alkalinity 60-200 ppm

Calcium Hardness 100 -500 ppm

Stabiliser (Sunscreen) 60-60 ppm

Phosphates <0.2 ppm

I pg 05

Hydroxzone Ozone Generator

NOTE: For 50mm pipe, do not use 40 mm adapters and gasket and turn bushings so small

end points toward Injector (for Entrance) or PVC Pipe (for Exit).

Figure 2.2

Saddle Clamp Assembly

at Bypass Entrance

Figure 2.3

Saddle Clamp Assembly

at Bypass Exit

Venturi Injector

Screw (2)

Saddle Clamp Top

Bushina

Top Adapter

Gasket

22mm (7/8”) Dia. Hole

Bottom Adapter

Saddle Clamp Bottom

1/4-20 Nut (2)

PVC Pipe

Screw (2)

Saddle Clamp Top

Bushing

Top Adapter

Gasket

22mm (7/8”) Dia. Hole

Bottom Adapter

Saddle Clamp Bottom

1/4-20 Nut (2)

NOTE: If your ltration system uses a Diatemateous Earth (DE) or cartridge lter, install a

20mm (¾”) Ball Valve (not included) in the 20mm (¾”) Hose on the output side of the Venturi

Injector as shown in Figure 1.1. This allows the bypass to be closed when back ushing or

adding DE. It may be necessary to install a Ball Valve (not included) in the main line between

the Entrance and Exit of the bypass. The Ball Valve will need to be adjusted to ensure

adequate ow through the bypass.

2.5 INSTALL HYDROXZONE SUPPLY TUBE

2.5.1. The Hydroxzone unit is supplied with sufcient braided supply tube which may be

cut to length. Ensure sufcient slack in the supply tube. Do not extend the length of

the braided supply tube.

2.5.2. For installations where the Hydroxzone unit is installed 400mm above the highest

point of the lter system, cut the polybraided line to a minimum of 600mm from

the Hydroxzone unit and install the check valve with the concave shape facing the

direction of the Venturi Injector, (Make sure you can blow air through the Check

Valve towards the Injector port). See Figures 2.4.

2.5.3. Cut a 150mm length of ¼” polybraided hose and connect one end to the open

ozone suction point (As shown in illustration 2.5) on the Venturi Injector and the

other end to the OUTLET side of the Check Valve.

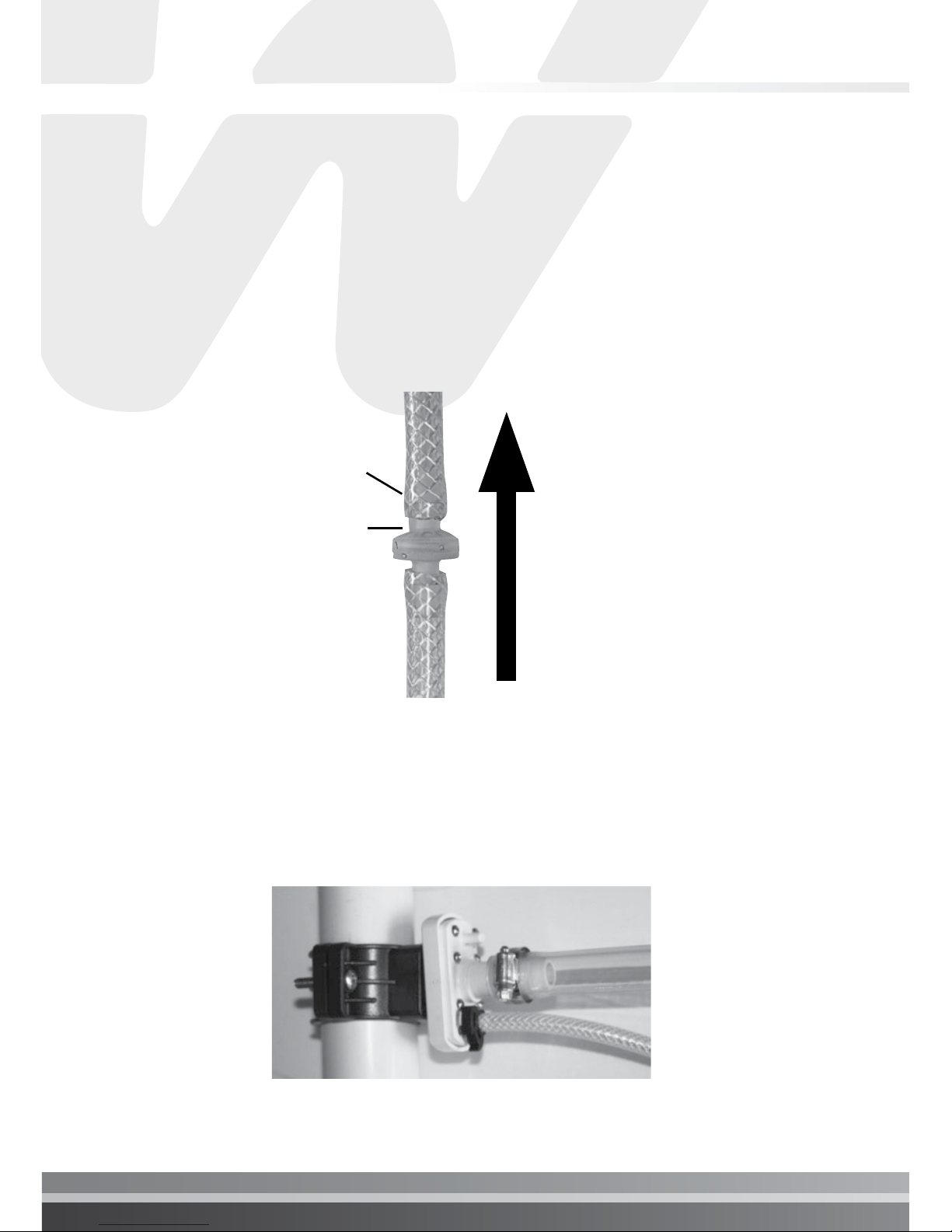

2.4 Check Valve Orientation

Ozone

Flow

Direction

Concave

Shape

2.5 Ozone Inlet point at venturi injector

Outlet

I pg 07

Hydroxzone Ozone Generator

2.5.4. Connect the polybraided hose to the barb on the side of the Hydroxzone Ozone

Generator. (see Figure 2.6).

2.5.5. For ooded installations or where the Hydroxzone is installed below 400mm above

the highest point of the lter system, two (2) check valves and a drain must be

installed as follows: (see Figure 2.7)

I. Cut the braided supply tube a minimum of 600mm from the Hydroxzone unit.

II. Install the supplied ¼” barb Tee between the 2 sections of supplied polybraided

hose, with one end of the Tee vacant and pointing to the ground

III. Cut the polybraided hose supply line approximately 200mm further on the

Venturi Injector side of the ¼” barb Tee piece, and install a check valve with the

concave shape facing the direction of the Dynamic Venturi Injector, ensuring the

ow of air from the Hydroxzone unit to the Dynamic Venturi Injector.

IV. Cut the polybraided hose to length, ensuring a length of 200-300mm of braided

supply hose is available to make a drain off the ¼” barb Tee piece

V. Take the 200-300mm piece of polybraided hose supply and cut it in half

VI. Install the second check valve between the 2 pieces of cut supply hose

VII. Connect the 200-300mm piece of hose with check valve installed, and connect

to the base of the Tee – ensuring that the concave shape is facing toward the

vacant end of tube (Figure 2.7). Ensure this drain tube is pointing to the ground.

This will ensure water is able to drain from the supply tube.

VIII. Connect the other end of the braided supply tube to the Dynamic Venturi

Injector’s open nipple. Secure with a black plastic clip.

2.6 Connecting polybraid hose to Hydroxzone

2.6 ELECTRICAL INSTALLATION

Hydroxzone ozone generator is designed to operate on either 120 or 240 VAC, 50/60 HZ.

Connect theHydroxzone ozone generator either to the circulation pump switch or timer.

Hydroxzone ozone generator unit and circulation pump should be started simultaneously. Refer

to national electrical codes or local code grounding and installation procedures for swimming

pool equipment.

Avoid running the ozone unit on short cycles. The useful life of the UV lamp will be reduced if

stop/start operation is performed. Continuous operation of 4 to 8 hour periods per day is highly

recommended.

2-7 Installation on flooded condition

IMPORTANT: Hydroxzone must run when the pump is operational. Damage to

unit may occur if air does not pass through the unit for prolonged periods of

time.

i

CAUTION: Make sure the voltage is the same as prescribed on the side of the

HYDROXZONE ozone generator. Over voltage will void customer warranty.

I pg 09

Hydroxzone Ozone Generator

3. HYDROXZONE MAINTENANCE

The Hydroxzone ozone generator is rated to last 20,000 hours of continuous operation. Start

up and shut down cycles should be kept to a minimum to extend the life of the lamp. The U/V

lamp within the Hydroxzone will provide up to 80% of the maximum output for the system right

up until the lamp stop working.

It is good practice to check the vacuum level on the Dynamic Venturi Injector at regular intervals

to ensure there is sufcient air ow through the Hydroxzone ozone generator.

4. TROUBLESHOOTING GUIDE

NOTE: Cloudy water may occur when the Hydroxzone ozone generator is

started. Filter and backwash as necessary.

i

PROBLEM PROBLEM CAUSE REMEDY

No light from Hydroxzone

Loose wiring Check all wiring

connections

No power to unit Check voltage compatibility

Check power source

Defective ; amp or other

internal component Return unit to dealer

No bubbles from injector

or no evidence of ozone in

pool

Excessive back pressure Check for kinks or clogs in

hose or pluming

Leak in tting Replace tting

Filter not working Check lter

Water in Hydroxzone Check valve failure Verify check valve in Venturi

is operating properly

Cloudy water; foamy water;

scum

Water chemistry out of

balance

Check readings and

balance accordingly

Total dissolved solids (TDS)

level is too high

Refer to dealer for proper

water testing

Filter not working Clean or replace lter

5. TECHNICAL SPECIFICATIONS

6. SPARE PARTS LIST

7. WARRANTY

Power Input (volts) 120 - 277

Frequency (Hz) 50/60

Degree of Protection IPX4

Max. Current (A) 8

Temperature Operating Range (°C) -32 to 60

Dimension (mm) 425 x 160 x 90

PART NUMBER DESCRIPTION

60137201 CHECK VALVE 1/4”

60137203 1/4” HOSE BARB TEE

60137204 PLASTIC CLIP

60137205 ¼” POLYBRAIDED HOSE

132308 DYNAMIC VENTURI INJECTOR

Component Warranty

Hydroxzone 24 months

(commercial application 12 month)

Venturi Injector 12 months

Labour 12 months

Please refer to Waterco’s Warranty terms and conditions.

I pg 11

Hydroxzone Ozone Generator

Waterco Limited ABN 62 002 070 733

(ZZB1460) 11/2014

Offices - AustrAliA

NSW - SYDNEY

(HEAD OFFICE)

Tel: +61 2 9898 8600

QLD - BRISBANE

Tel: +61 7 3299 9900

VIC/TAS - MELBOURNE

Tel: +61 3 9764 1211

WA - PERTH

Tel: +61 8 9273 1900

SA/NT - ADELAIDE

Tel: +61 8 8244 6000

ACT DISTRIBUTION

Tel: +61 2 6280 6476

Offices - OVerseAs

WATERCO (EUROPE) LIMITED

Sittingbourne, Kent, UK

Tel: +44 (0) 1795 521 733

WATERCO FRANCE

Saint Priest, France

Tel: +33 4 72 79 33 30

WATERCO (USA) INC

Augusta, Georgia, USA

Tel: +1 706 793 7291

WATERCO CANADA

Longueuil, Quebec, Canada

Tel: +1 450 748 1421

WATERCO (NZ) LIMITED

Auckland, New Zealand

Tel: +64 9 525 7570

WATERCO © LIMITED

Guangzhou, China

Tel: +86 20 3222 2180

WATERCO (FAR EAST) SDN BHD

Selangor, Malaysia

Tel: +60 3 6145 6000

PT WATERCO INDONESIA

Jakarta, Indonesia

Tel: +62 21 4585 1481

WATERCO SINGAPORE INTL PTE LTD

Nehsons Building, Singapore

Tel: +65 6344 2378

Table of contents

Other Waterco Lighting Equipment manuals

Popular Lighting Equipment manuals by other brands

Laserworld

Laserworld ES-400 RGY manual

Shadow-Caster

Shadow-Caster SCM-ZC-KIT Installation & operation manual

Philips

Philips Selecon user manual

Xoop Lighting

Xoop Lighting EL100 USER MANUAL & DATASHEET

MOB

MOB MO8940 user manual

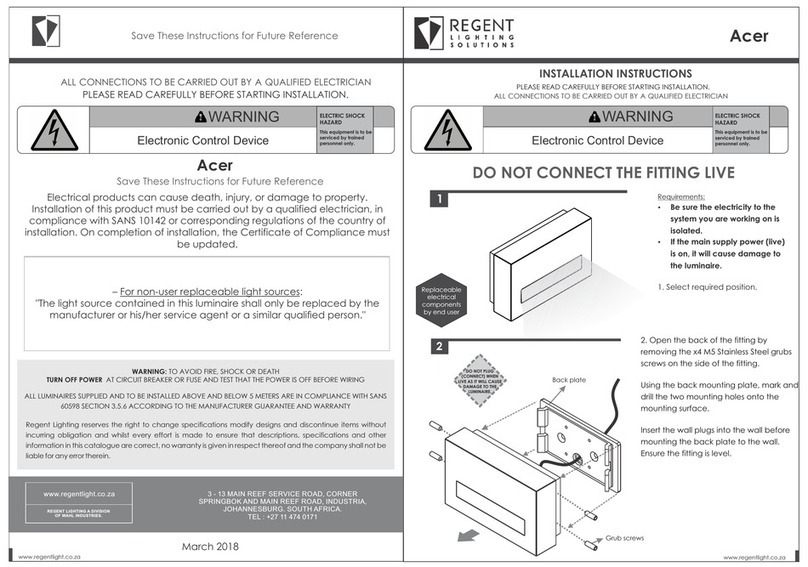

Regent Lighting Solutions

Regent Lighting Solutions Acer installation instructions

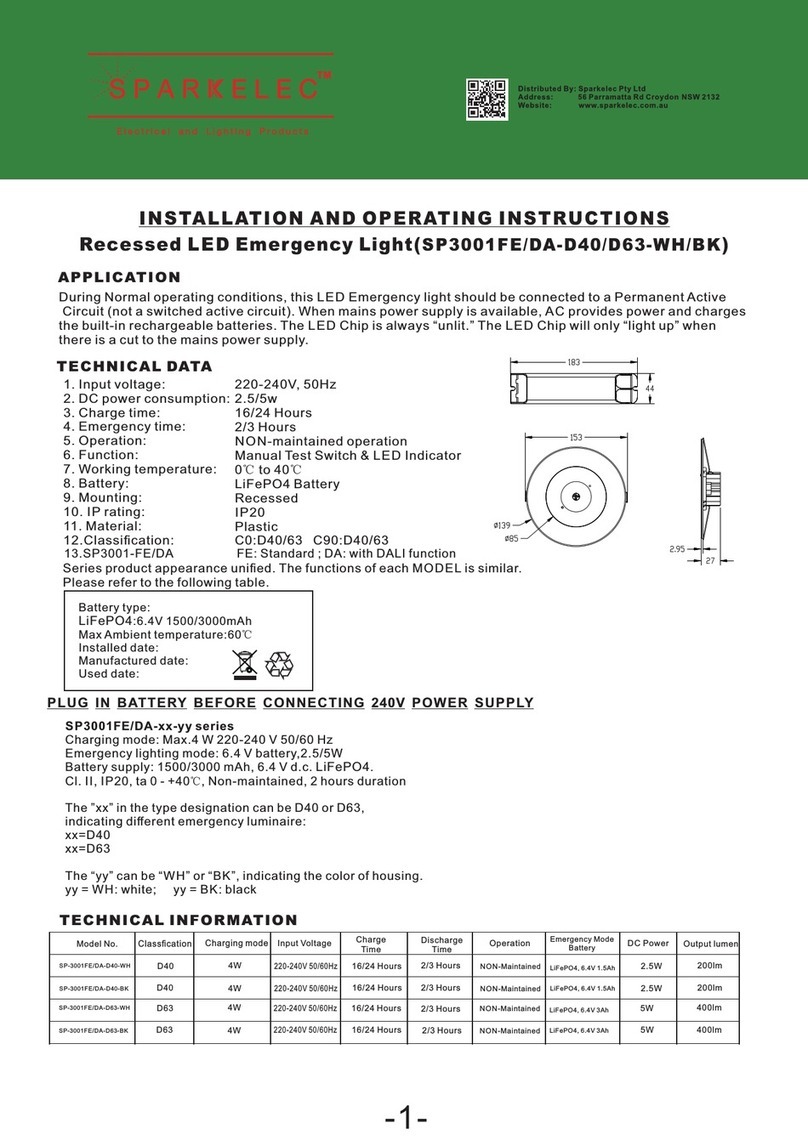

SPARKELEC

SPARKELEC SP-3001FE/DA-D40-WH Installation and operating instructions

Equinox Systems

Equinox Systems MaxiPar Tri user manual

LumX

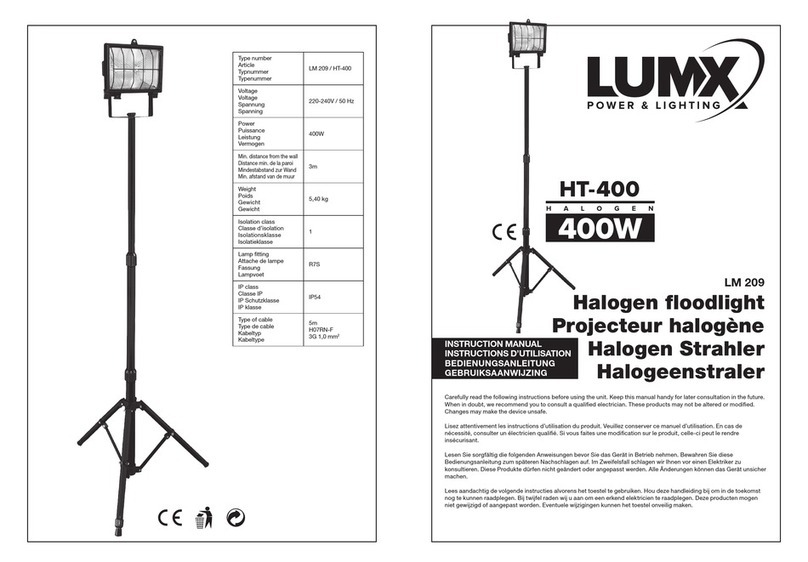

LumX LM 209 instruction manual

EuroLite

EuroLite LED ML-56 QCL RGBW/RGBA 18x8W user manual

thomann

thomann Ignition LED Mini Studio PAR One 40 user manual

superbrightleds

superbrightleds STN-2-COB user manual