I pg 07

Heat Pump Swimming Pool Heaters

INSTALLATION INSTRUCTIONS

Location

The location of the pool heater is very important in keeping installation costs to a minimum, while providing for

maximum efciency of operation as well as allowing adequate service and maintenance access.

The unit is designed for outdoor installation and should not be installed in a totally enclosed area such as a shed,

garage, etc. unless ventilation is provided to ensure adequate air exchange for proper operation. Re-circulation of

cold discharged air back into the evaporator coil will greatly reduce unit heating capacity and efciency.

The unit should be located as close as possible (3.0m is ideal) to the existing pool pump and lter to minimize

water piping. The use of 90 degree bends and short radius elbows in the water piping should be kept to a

minimum.

Mount the unit on a sturdy base, preferably a concrete slab or blocks. The base should be completely isolated

from the building foundation or wall to prevent the possibility of sound or vibration transmission into the building.

The size of the base should not be less than the base of the pool heater.

Contact your dealer to learn about our patio tile which ensures stability and reduces vibration.

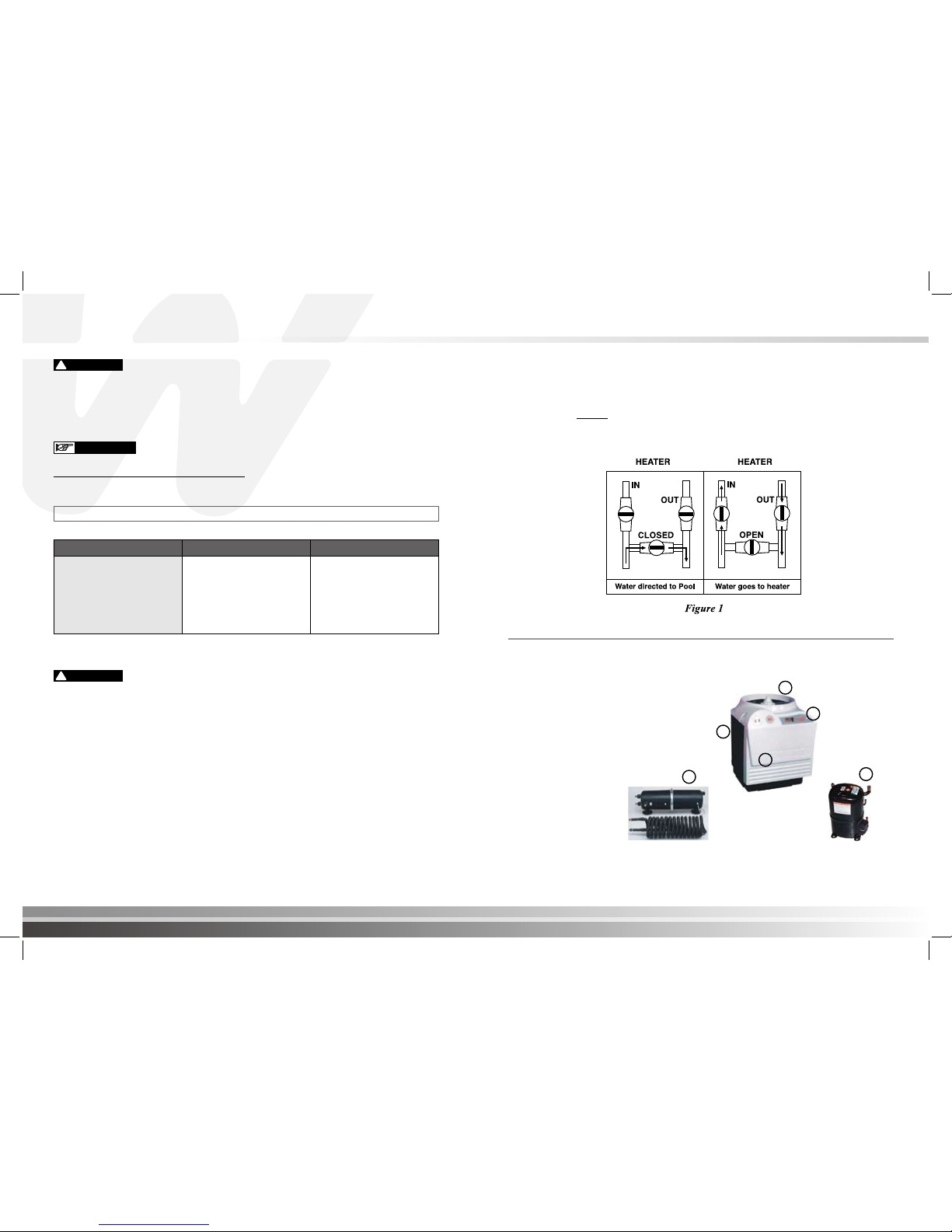

Waterco models discharges air either from the top of the unit. Air is pulled through the evaporator coil and

discharge through the grille. Clearance should be allowed in front and around the unit for unrestricted air

discharge and service access. See Figure 1.

IMPORTANT

Water Piping

The piping sequence: pool pump / lter / heater / pool (inline chlorinators, if used, must be downstream (after

the heater) to minimise harm to the pool equipment). See “Caring for your Pool Heater” section for more details

on chlorination and chemical feeding. Rigid PVC piping is recommended, all joints should be glued with PVC

glue. If rigid PVC is not available, you can use soft or exible piping with stainless steel clamps. When the piping

installation is complete, operate the pool pump and check the system for leaks. Then check the lter pressure

gauge to see that excessive head pressure is not indicated.

NOTE: The installation of a bypass which isolate the heater from the water circuit is highly recommended. Make sure the

heat exchanger is not deprived of water circulation for several days, high chlorine gas could cause excessive

corrosion. If the disconnect switch is turned off, be sure the pool water is allowed to circulate through the unit, or

is drained out of it.

Plumbing Diagram

1. Any kind of Automatic Chlorination System MUST be installed after (downstream) of the Heat Pump.

2. Filter MUST be connected before (upstream) the Heat Pump.

3. A bypass should be installed on all systems for water ow adjustment and ease of service.

!

VITAL

When connecting the heater,

tighten the connections by hand

only. Too much pressure may

damage the water in or water

out of the heat exchanger.

IMPORTANT

Piping

The piping and plumbing between the heat pump and other equipment should be minimised. During colder

months, signicant heat loss will occur through the piping.