Watt Drive V2500 Series User manual

FREQUENCY INVERTER

Series V2500

MANUAL

WATT DRIVE worldwide

WATT DRIVE ANTRIEBSTECHNIK GMBH

A-2753 Markt Piesting

Wöllersdorferstraße 68

Austria, EUROPE

Tel.: +43 / 2633 / 404-0

Fax: +43 / 2633 / 404-220

Web: www.wattdrive.com

BA.FBE.UR.024.001.07.03

V2500 Kurzanleitung dt/engl.

Watt Drive operates a policy of continuous development. Therefore, we reserve the right to make

changes and improvements to any of our products described in this manual without prior notice. Any

changes, improvements and typing errors justify no claims for compensation.

WATT DRIVE NORD GmbH

Eickelstraße 4

D-59759 Arnsberg

Germany, EUROPE

Tel.: +49 / 2932 / 96 81-0

Fax: +49 / 2932 / 96 81-81

Web: www.wattdrive.de

WATT DRIVE SÜD GmbH

Walkenmühleweg 49

D-72379 Hechingen

Germany, EUROPE

Tel.: +49 / 7471 / 9865-0

Fax: +49 / 7471 / 9865-29

Web: www.wattdrive-sued.de

WATT EURO-DRIVE (Far East) Pte Ltd

67B, Joo Koon Circle

Singapore 629082

Tel.: +65 / 686 22 220

Fax: +65 / 686 23 330

Web: www.wattdrive.com

WATT EURO-DRIVE (Malaysia) Sdn Bhd

No. 17 Jalan Bulan U5/8

Bandar Pinggiran Subang 2

40150 Shah Alam

Selangor Darul Ehsan

Malaysia

Tel.: +603 / 785 91626, 785 91613

Fax: +603 / 785 91623

Web: www.wattdrive.com

0

0-1

PREFACE

Thank you for choosing WATT DRIVE Antriebstechnik GmbH performance V2500 Series.

V2500 Series are manufactured by adopting high-quality components, material and

incorporating the latest microprocessor technology available.

! Getting Started

This manual will be helpful in the installation, parameter setting, troubleshooting, and

daily maintenance of the AC motor drives. To guarantee safe operation of the

equipment, read the following safety guidelines before connecting power to the AC

drives. Keep this operating manual handy and distribute to all users for reference.

!DANGER!

This message indicates a situation which may lead to serious injury or

even death if the instruction is not observed.

!CAUTION!

This message indicates a situation which may lead to minor or moderate

injury, or damage of product.

!HAZARDOUS HIGH VOLTAGE!

Motor control equipment or electronic controllers are connected to hazardous

line voltages.

When servicing drives and electronic controllers there might exist exposed

components with cases or protrusions at or above line potential.

Extreme care should be taken to protect against shock.

For these reasons, the following safety guidelines should be observed:

Stand on an insulating pad and make it a habit to use only one hand when

checking components. Disconnect power before checking controllers or

performing maintenance. Be sure that equipment is grounded properly. Wear

safety glasses whenever working on an electronic controller or rotating

electrical equipment.

!DANGER!

This equipment should be installed, adjusted and serviced only by qualified

electrical maintenace personel familiar with the construction and operation of the

equipment and the hazards involved. Failure to observe this precaution could result

in bodily injury.

!CAUTION!

These instructions should be read and clearly understood before working on V2500

series equipment.

!DANGER!

The user is responsible that all driven machinery, drive train mechanism not

supplied by WATT Drive Antriebstechnik and process line material are capable of safe

operation at an applied frequency of 150% of the maximum selected frequency range

to the AC motor. Failure to do so can result in destruction of equipment and injury to

personnel should a single point failure occur.

!DANGER!

HAZARD OF ELECTRICAL SHOCK. DISCONNECT INCOMING POWER BEFORE

WORKING ON THIS CONTROL.

Do not connect or disconnect wires and connectors while power is applied to

the circuit. Maintenance must be performed by qualified technicians.

CHAPTER 0: PREFACE

0-2

!DANGER!

A charge may still remain in the DC-link capacitor with hazardous voltages even if

the power has been turned off. To avoid personal injury, please ensure that power

has turned off before operating AC drive and wait ten minutes for capacitors to

discharge to safe voltage levels.

!CAUTION!

Proper grounds, disconnecting devices (e.g. fuses) and other safety devices and

their location are the responsibility of the user and are not provided by WATT

DRIVE Antriebstechnik GmbH.

!CAUTION!

Rotating shafts and electrical potentials above ground level can be hazardous.

Therefore it is strongly recommended that all electrical work conform to the national

electrical codes and local regulations. Installation, maintenance and alignment

should be performed by qualified personnel only.

Factory recommended test procedures included in this instruction manual should be

followed. Always disconnect electrical power before working on the unit.

!DANGER!

a) Any motor used must be of suitable rating.

b) Motors may have hazardous moving parts so that suitable protection must be

provided in order to avoid injury.

!CAUTION!

Alarm connections may have hazardous live voltages even when the inverter is

disconnected. In case of removing the front cover for maintenance or inspection,

confirm that incoming power for alarm connections is surely disconnected.

!CAUTION!

There are highly sensitive MOS components on the printed circuit boards. These

components are especially sensitive to static electricity. To avoid damage to these

components, do not touch these components or the circuit boards with metal

objects or your bare hands.

!CAUTION!

Ground the V2500 using the ground terminal. The grounding method must comply

with the laws of the country where the AC drive is to be installed. Refer to Basic

Wiring Diagram (Chapter 3).

!CAUTION!

The final enclosures of the AC drive must comply with EN50178. (Live parts shall be

arranged in enclosures or located behind barriers that meet at least the

requirements of the Protective Type IP20 Main terminals or other hazardous

terminals for any interconnection (terminals for connecting the motor, contact

breaker, filter etc.) must be inaccessible after installation.. The top surface of the

enclosures or barrier that is easily accessible shall meet at least the requirements of

the Protective Type IP40). (V2500 series corresponds with this regulation.)

!CAUTION!

The rated voltage of power system that is installed on AC drive must be equal to or

less than 240 Volts (400 / 460V model is 480 Volts) and the current must be equal

to or less than 5000A RMS.

0

0-3

!DANGER!

The AC drive may be destroyed beyond repair if incorrect cables are connected to

the input/output terminals. Never connect the AC drive output terminals U/T1,

V/T2, and W/T3 directly to the AC main circuit power supply.

!CAUTION!

Turn power on only when the DC-link capacitors are fully discharged.

CAUTION!

Heat sink may heat up over 70°C, during the operation. Do not touch the heat sink.

All of the above instructions, together with any other requirements,

recommendations, and safety messages highlighted in this manual must be strictly

complied with.

TABLE OF CONTENTS

• Chapter 1 – receiving and inspection

• Chapter 2 – storage and installation

• Chapter 3 – wiring

• Chapter 4 – digital keypad operation

• Chapter 5 – parameters

• Chapter 6 – maintenance and inspections

• Chapter 7 – troubleshooting and fault information

• Chapter 8 – summary of parameter settings

• Appendix A – specifications

• Appendix B – accessories

• Appendix C – dimensions

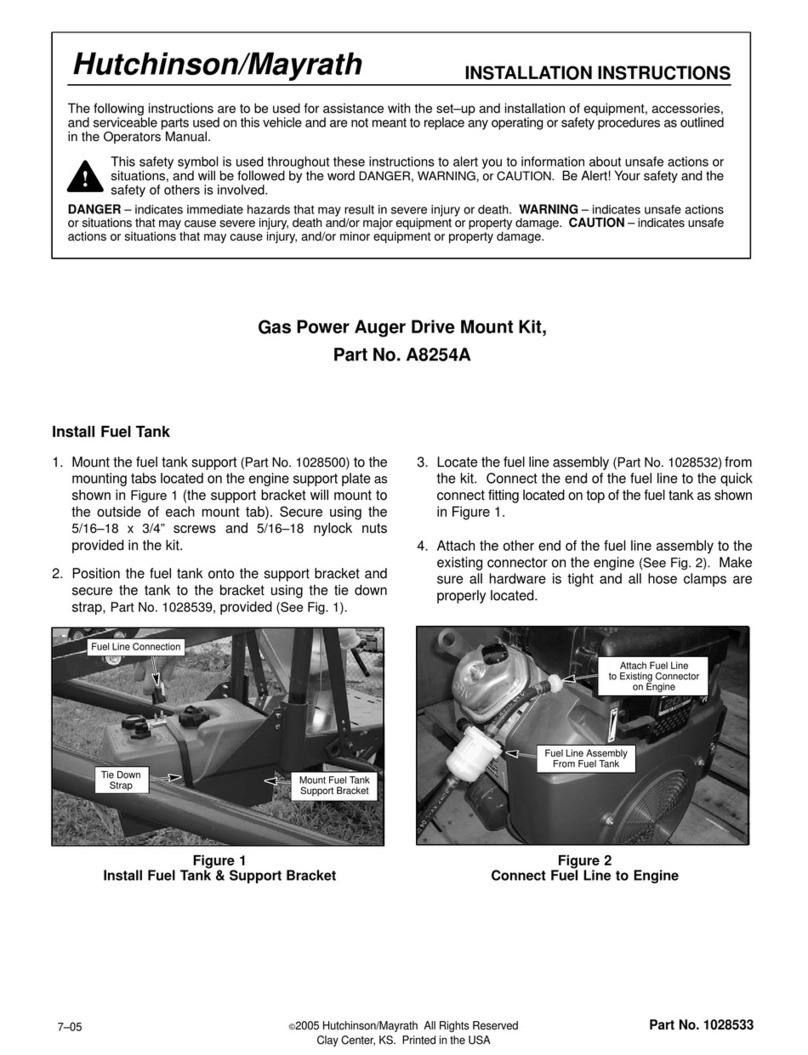

CHAPTER 1: RECEIVING AND INSPECTION

1-1

CHAPTER 1 RECEIVING AND INSPECTION

This V2500 AC drive has gone through rigorous quality control tests at the factory before

shipment. After receiving the AC drive, please check for the following:

Receiving

! Check to make sure that the package includes an AC drive, the User Manual, dust

covers and rubber bushings.

! Inspect the unit to insure it was not damaged during shipment.

! Make sure that the part number indicated on the nameplate corresponds with the

part number of your order.

1.1 Nameplate Information: Example for 0.75 kW/1HP 1/3-phase 230V AC drive

1.2 Model Explanation:

1.3 Series Number Explanation:

If there is any nameplate information not

corresponding to your purchase order or any

problem, please contact your distributor.

Inverter Model

Input Specification: phases, voltage, frequency,

current

Output Specification: phases, voltage range,

rated current andpower

Output Frequency Range

Serial Number and Bar Code

2

2-1

CHAPTER 2 STORAGE AND INSTALLATION

2.1 Storage

The AC drive should be kept in the shipping carton before installation. In order to retain the

warranty coverage, the AC drive should be stored properly when it is not to be used for an

extended period of time.

Ambient Conditions:

Operation Air Temperature: -10oC to +40oC

+50oC without dust cover.

Atmosphere pressure: 86 to 106 kPa (0,86 to 1,06 bar)

Installation Site Altitude: below 1.000m

Power de-rating at high Site Altitude:

above 1.000m -1% per 100m (max. 3.000m)

Vibration: Maximum 9.80 m/s2(1G) at less than 20Hz

Maximum 5.88 m/s2(0.6G) at 20Hz to 50Hz

Storage Temperature: -20oC to +60oC

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere pressure: 86 to 106 kPa (0,86 to 1,06 bar)

Transportation Temperature: -20oC to +60oC

Relative Humidity: Less than 90%, no condensation allowed

Atmosphere pressure: 86 to 106 kPa (0,86 to 1,06 bar)

Vibration: Maximum 9.80 m/s2(1G) at less than 20Hz, Maximum

5.88 m/s2(0.6G) at 20Hz to 50Hz

Pollution Degree 2: good for a factory type environment.

CHAPTER 2: STORAGE AND INSTALLATION

2-2

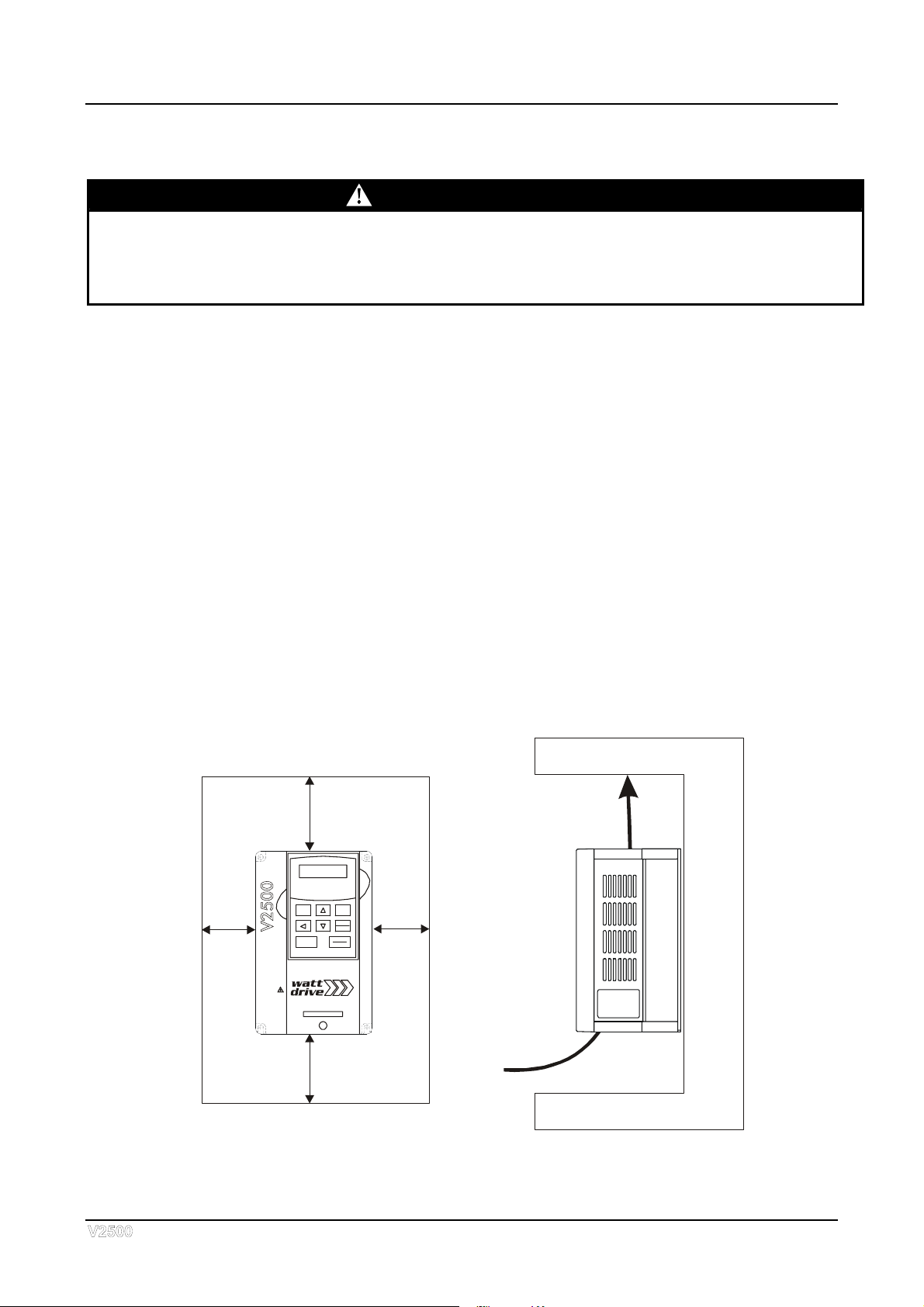

2.2 Installation:

CAUTION

The control, power supply and motor leads must be laid separately. They must not be

fed through the same cable conduit / trunking.

High voltage insulation test equipment must not be used on cables connected to the

drive.

Improper installation of the AC drive will greatly reduce its life. Be sure to observe the

following precautions when selecting a mounting location.

Failure to observe these precautions may void the warranty!

! Do not mount the AC drive near heat-radiating elements or in direct sunlight.

! Do not install the AC drive in a place subjected to high temperature, high humidity,

excessive vibration, corrosive gases or liquids, or airborne dust or metallic particles.

! Mount the AC drive vertically and do not restrict the air flow to the heat sink fins.

! The AC drive generates heat. Allow sufficient space around the unit for heat

dissipation.

ACHTU NG

HOCHSPANNUNG:VOR

DEM ÖFF NE N DES

UM RI C HTE RS MIN DE STE N S

5 MINUTENWARTEN.

BETRIEBSANLEITUNG

BEACHTEN

WARNING- HIGH VOLTAGE:

WAI T AT LEAS T 5 MIN UTES

BEFOREOPENING.

FOL LO W US ER M ANU A L

ECO -li ne

OPTI-line

JOG MODE

PROG

DATA

STOP

RESET

RUN

V2500-0220TDA1

F

H

U

RUN STOP JOG FWD REV

120mm

4.72inch

50mm

1.97inch

A

ir Flow

50mm

1.97inch

120mm

4.72inch

3

3-1

CHAPTER 3 WIRING

DANGER

Hazardous Voltage

Before accessing the AC drive:

Disconnect all power to the AC drive.

Wait five minutes for DC bus capacitors discharge.

Any electrical or mechanical modification to this equipment without prior written

consent of WATT Drive Antriebstechnik GmbH will void all warranties and may

result in a safety hazard in addition to voiding the UL listing or CE conformity.

Short Circuit Withstand:

The rated voltage must be equal to or less than 240V (400/460V model is 480Volts) and

the current must be equal to or less than 5000A RMS. (the model of 30 kW or above is

10000A RMS)

General Wiring Information

For installation in compliance with CE standards you must follow the instructions provided

in the section “Notes on EMC” in this chapter.

All V2500 AC drives except Underwriters Laboratories, Inc. (UL) and Canadian

Underwriters Laboratories (CUL) listed, and therefore comply with the requirements of

the National Electrical Code (NEC) and the Canadian Electrical Code (CEC) and CE

conformity.

Installation intended to meet the UL and cUL requirements must follow the instructions

provided in “Wiring Notes” as a minimum standard. Follow all local codes that exceed UL

and cUL requirements. Refer to the technical data label affixed to the AC drive and the

motor nameplate for electrical data.

The "Line Fuse Specification" in Appendix B, lists the recommended fuse part number for

each V2500 part number. These fuses (or equivalent) must be used on all installations

where compliance with U.L. standards is a required.

CHAPTER 3: WIRING

3-2

NOTES ON EMC (ELECTRO MAGNETICAL COMPATIBILITY)

WARNING

This equipment should be installed, adjusted and serviced by qualified

personnel familiar with construction and operation of the equipment and the

hazards involved. Failure to observe this precaution could result in bodily

injury.

When using V2500 series inverters in EU countries, the EMC directive 89/336/EEC

must be observed. To satisfy the EMC directive and to comply with the standard, the

following provisions should be obeyed:

A)Environmental conditions for the inverter:

• Ambient temperature: -10°C to 40°C.

• Relative Humidity: 20% to 90% (no dew condensation)

• Vibrations: max. 5,9m/s2(0.6 g) at 10–55Hz.

• Location: 1000 meter or less altitude, indoors (no corrosive gas or dust).

B) The power supply to the V2500 inverter must conform to the conditions stated

below. If one of the conditions mentioned is not satisfied then an appropriate

V2500 AC reactor will have to be installed.

• Voltage fluctuation +/-10% or less

• Voltage unbalance +/-3% or less

• Frequency variation +/-4% or less

C) Wiring

• Shielded wiring (screened cable) is required for motor wiring, and total

length has to be kept to less than 50m. When using motor cables longer

than 50m, V2500 motor filters should be installed. Directions for installing

filters can be found in the V2500 installation manual.

• Seperate the mains circuit wiring from the wiring used for signals or process

circuit. Please refer to the V2500 installation manual.

D) Installation

• For V2500 series inverters, the filters described hereafter have to be used

and the installation notes have to be observed.

If installed according to the following directions, the frequency inverters comply

with the following standards:

Emmissions: EN 61800-3 (EN 55011 group 1, class B)

Immunity: EN 61800-3, (industrial environments)

For the best possible damping of interference, special line filters have been

developed which guarantee you easy assembly and installation along with the

necessary electrical reliability. However, effective EMC is only ensured if the

suitable filter is selected for the particular drive and installed in accordance with

these EMC recommendations.

The amount of line-conducted interference also increases as motor cable length

increases. Adherence to the interference limits for line-conducted interference is

guaranteed on following way:

• If maximum motor cable length is 35 m (200/240V-inverters) and 15 or 20 m

(400/460V inverters) – details see Appendix A: Class „B“

• If maximum motor cable length is between 25 and 80 m (depending on

inverter size) – details see Appendix A: Class „A“

3

3-3

Observe the following provisions for an electromagnetically compatible setup of

your drive system:

1.As user you must ensure that the HF impedance between frequency inverter,

filter and ground is as small as possible.

• Take care it that the connections are metallic and have the largest possible

areas (zink-plated mounting plates)

2.Conductor loops act like antennas, especially when they encompass large

areas. Consequently:

• Avoid unnecessary conductor loops

• Avoid parallel arrangement of „clean“ and interference-prone conductors

3.Lay the motor cable and all analog and digital control lines shielded.

• You should allow the effective shield area of these lines to remain as large as

possible; i.e., do not move the shield further away than absolutely

necessary.

• With compact systems, if for example the frequency inverter is

communicating with the steering unit, in the same control cabinet connected

at the same PE-potential, the screen of control lines should be put on, on

both sides with PE. With branch systems, if for example the communicating

steering unit is not in the same control cabinet and there is a distance

between the systems, we recommend to put on the screen of control lines

only on the side of the frequency inverter. If it is possible, direct in the cable

entry section of the steering unit. The screen of Motor cabels always must be

put on, on both sides with PE.

• The large area contact between shield and PE-potential you can realise with

a metal PG screw connection or a metallic mounting clip.

• Use only copper mesh cable (CY) with 85% coverage

• The shielding should not be interrupted at any point in the cable. If the use of

reactors, contactors, terminals or safety switches in the motor output is

necessary, the unshielded section should be kept as small as possible.

• Some motors have a rubber gasket between terminal box and motor housing.

Very often, the terminal boxes, and particularly the threads for the metal PG

screw connections, are painted. Make sure there is always a good metallic

connection between the shielding of the motor cable, the metal PG screw

connection, the terminal box and the motor housing, and carefully remove

this paint if necessary.

4.Very frequently, interference is coupled in through installation cables. This

influence you can minimize:

• Lay interfering cables separately, a minimum of 0.25 m from cables

susceptible to interference.

• A particularly critical point is laying cables parallel over larger distances. If

two cables intersect, the interference is smallest if they intersect at an angle

of 90°. Cables susceptible to interference should therefore only intersect

motor cables, intermediate circuit cables, or the wiring of a rheostat at right

angles and never be laid parallel to them over larger distances.

5.The distance between an interference source and an interference sink

(interference-threatened device) essentially determines the effects of the

emitted interference on the interference sink.

• You should use only interference-free devices and maintain a minimum

distance of 0.25 m from the drive.

CHAPTER 3: WIRING

3-4

6.Safety measures

• Ensure that the protective conductor terminal (PE) of the filter is properly

connected with the protective conductor terminal of the frequency inverter.

An HF ground connection via metal contact between the housings of the

filter and the frequency inverter, or solely via cable shield, is not permitted as

protective conductor connection. The filter must be solidly and permanently

connected with the ground potential so as to preclude the danger of electric

shock upon touching the filter if a fault occurs. You can achieve this by

connecting it with a grounding conductor of at least 10 mm² or connecting a

second grounding conductor, connected with a separate grounding terminal,

parallel to the protective conductor (the cross section of each single

protective conductor terminal must be designed for the required nominal

load).

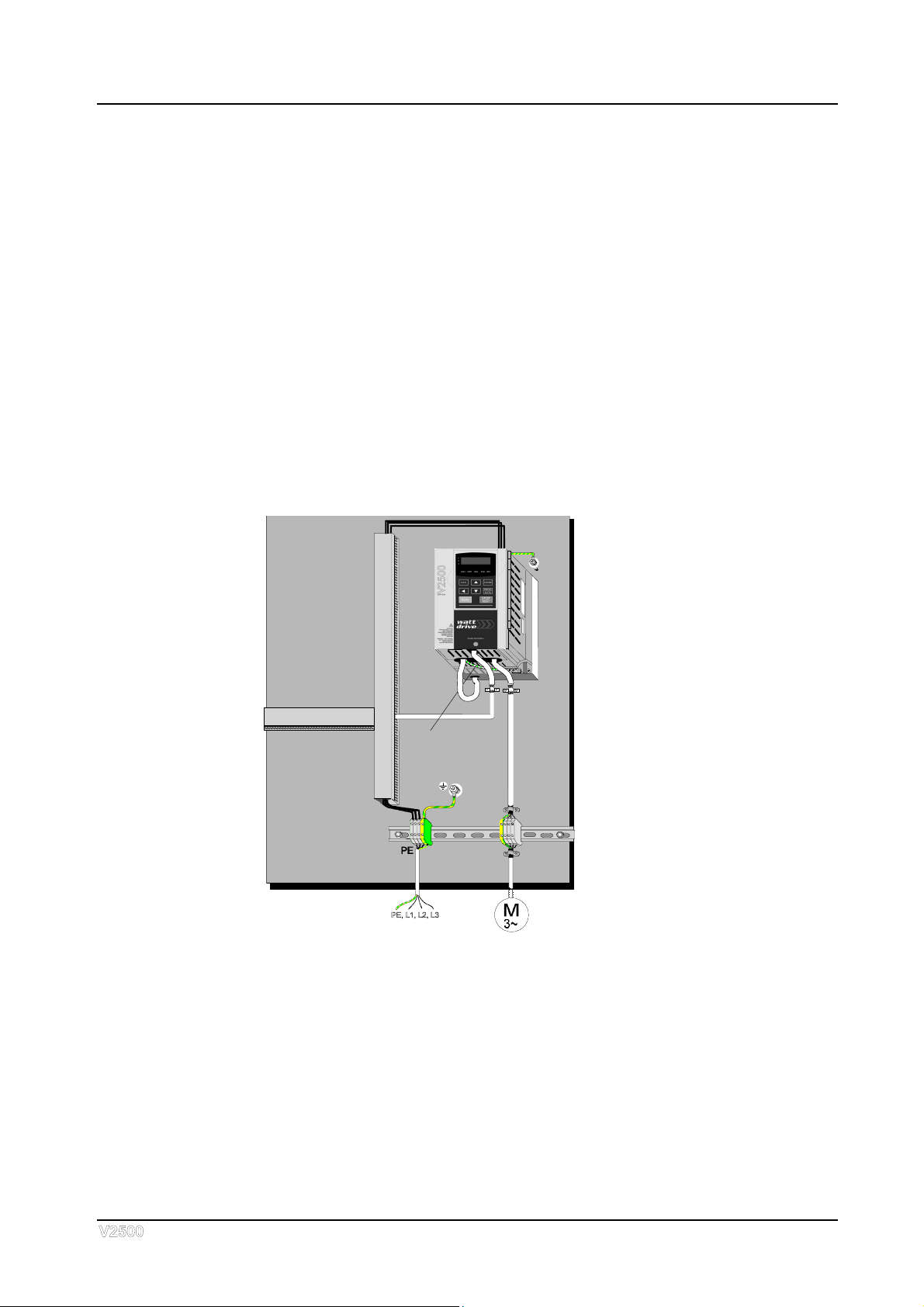

Cabinet installation of V2500 foot print filter:

PE-connection

3

3-5

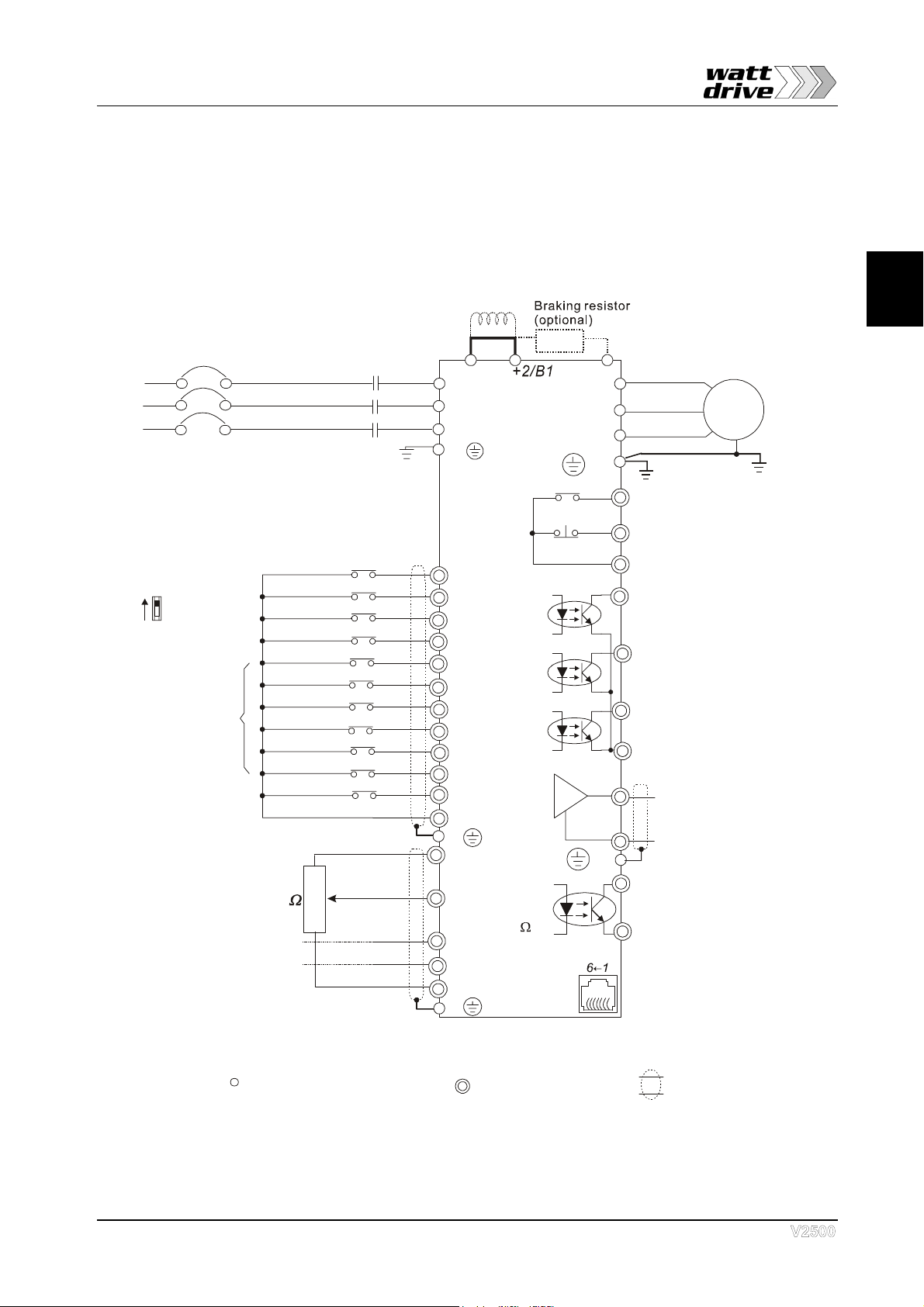

3.1 Basic Wiring Diagram

Users must connect wires according to the following circuit diagram shown below. Do not

plug a Modem or telephone line to the RS-485 communication port, permanent damage

may result. Terminals 1 & 2 are the power sources for the optional copy keypad and

should not be used while using RS-485 communication.

AVI

ACI

AUI

ASC

B2

4~20mA

-10~+10V

5K

3

2

1

Fi

g

ure 1 for models of V2500 Series

1~0.75/1.5; 3~0.75-2.2kW

Jumper

Master Frequency

0 to 10V 47K

Analog Signal Common

DC choke

(optional)

E

Main circuit (power) terminals Control circuit terminals Shielded leads & Cable

FWD

REV

JOG

EF

DI1

DI2

DI3

DI4

DI6

TRG

DI5

DIC

+24V

Sw1

Sink

Source

Factory Default:

SINK Mode

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Counter

Digital Signal Common

Factory

default

* Don't apply the mains voltage directly

to above terminals.

E

Please refer to Figure 4

for wiring of SINK

mode and SOURCE

mode.

R(L1)

S(L2)

T(L3)

Fuse/NFB(None Fuse Breaker)

+1

R(L1)

S(L2)

T(L3)

E

Analog Multi-function Output

Te r m i n a l

Factory default: Analog freq.

/ current meter

0~10VDC/2mA

U(T1)

V(T2)

W(T3)

IM

3~

DO1

DO2

DO3

AFO

ASC

RA

RB

RC

DOC

RS-485

Motor

Factory default:

indicates during operation

48V50mA

Factory default:

Freq. Setting Indication

Factory default:

Low-voltage Indication

Multi-function

Photocoulper Output

Analog Signal common

Serial interface

1: EV 2: GND

5:NC

6: for communication

3: SG-

4: SG+

DFO

DIC

Digital Frequency Output

Te r m in a l

Factory default: 1:1

Duty=50%

Digital Signal Common

48V50mA

48V50mA

E

E

Please refer to “Control

Terminal Explanation”

see page 3-10

1 /2 Accel/Decel

st nd

+10V/20mA

CHAPTER 3: WIRING

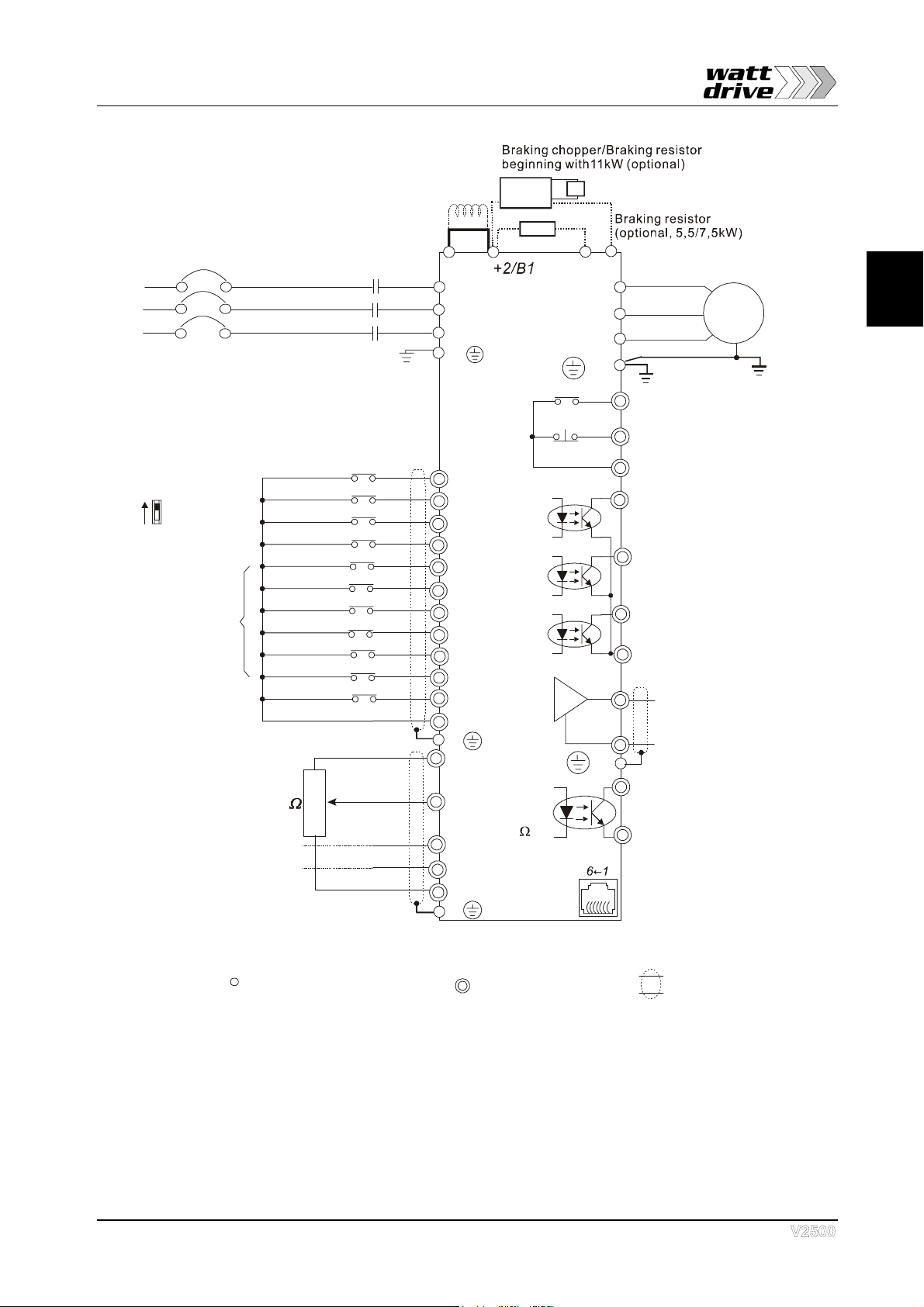

3-6

1 /2 Accel/Decel

st nd

AVI

ACI

AUI

ASC

4~20mA

-10~+10V

5K

3

2

1

Fi

g

ure 2 for models of V2500 Series

1~2.2; 3~4.0kW

Master Frequency

0 to 10V 47K

Analog Signal Common

E

Main circuit (power) terminals Control circuit terminals Shielded leads & Cable

FWD

REV

JOG

EF

DI1

DI2

DI3

DI4

DI6

TRG

DI5

DIC

+24V

Sw1

Sink

Source

Factory Default:

SINK Mode

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Counter

Digital Signal Common

Factory

default

* Don't apply the mains voltage directly

to above terminals.

E

Please refer to Figure 4

for wiring of SINK

mode and SOURCE

mode.

R(L1)

S(L2)

T(L3)

Fuse/NFB(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

E

Analog Multi-function Output

Te r m i n a l

Factory default: Analog freq.

/ current meter

0~10VDC/2mA

U(T1)

V(T2)

W(T3)

IM

3~

DO1

DO2

DO3

AFO

ASC

RA

RB

RC

DOC

RS-485

Motor

Factory default:

indicates during operation

48V50mA

Factory default:

Freq. Setting Indication

Factory default:

Low-voltage Indication

Multi-function

Photocoulper Output

Analog Signal common

Serial interface

1: EV 2: GND

5:NC(EV2 for 300T~750T)

6: for communication

3: SG-

4: SG+

DFO

DIC

Digital Frequency Output

Te r m in a l

Factory default: 1:1

Duty=50%

Digital Signal Common

48V50mA

48V50mA

E

E

* For the single phase application, the AC input line can

be connected to any two of the three input terminals R,S,T

* Three phase input power may apply to single phase drives.

Jumper

DC chock

(optional)

Please refer to “Control

Terminal Explanation”

see page 3-10

+10V/20mA

+1 B2

BR

3

3-7

1 /2 Accel/Decel

st nd

AVI

ACI

AUI

ASC

4~20mA

-10~+10V

5K

3

2

1

Fi

g

ure 3 for models of V2500 Series

5.5kW - 75kW

Master Frequency

0 to 10V 47K

Analog Signal Common

E

Main circuit (power) terminals Control circuit terminals Shielded leads & Cable

FWD

REV

JOG

EF

DI1

DI2

DI3

DI4

DI6

TRG

DI5

DIC

+24V

Sw1

Sink

Source

Factory Default:

SINK Mode

FWD/STOP

REV/STOP

JOG

E.F.

Multi-step 1

Multi-step 2

Multi-step 3

Multi-step 4

RESET

Counter

Digital Signal Common

Factory

default

* Don't apply the mains voltage directly

to above terminals.

E

Please refer to Figure 4

for wiring of SINK

mode and SOURCE

mode.

R(L1)

S(L2)

T(L3)

Fuse/NFB(None Fuse Breaker)

R(L1)

S(L2)

T(L3)

E

Analog Multi-function Output

Te r m i n a l

Factory default: Analog freq.

/ current meter

0~10VDC/2mA

U(T1)

V(T2)

W(T3)

IM

3~

DO1

DO2

DO3

AFO

ASC

RA

RB

RC

DOC

RS-485

Motor

Factory default:

indicates during operation

48V50mA

Factory default:

Freq. Setting Indication

Factory default:

Low-voltage Indication

Multi-function

Photocoulper Output

Analog Signal common

Serial interface

1: EV 2: GND

5:NC

6: for communication

3: SG-

4: SG+

DFO

DIC

Digital Frequency Output

Te r m in a l

Factory default: 1:1

Duty=50%

Digital Signal Common

48V50mA

48V50mA

E

E

Jumper

DC chock

(optional)

Please refer to “Control

Terminal Explanation”

see page 3-10

+10V/20mA

+1 B2

VFDB

BR

BR

CHAPTER 3: WIRING

3-8

Figure 4 for all models V2500

SINK Mode and SOURCE Mode

Sw1

Sink

Source

1 /2 Accel/Decel

st nd

1 /2 Accel/Decel

st nd

DIC

DIC

3

3-9

3.2 Terminal Explanations

Terminal Symbol Explanation of Terminal Function

R/L1, S/L2, T/L3 AC line input terminals

U/T1, V/T2, W/T3 AC drive output terminals motor connections

+1,+2 Connections for DC Link Reactor (optional)

+2/B1-B2 Connections for Braking Resistor (optional)

+2 - -(minus sign)

+2/B1- -(minus sign) Connections for External Braking Unit (V2500 series)

Earth Ground

3.3 Control Terminals Explanations

Terminal Symbols Terminal Functions Factory Settings

FWD Forward-Stop command

REV Reverse-Stop command

JOG Jog command

EF External fault

TRG External counter input

DI1 Multi-function Input 1

DI2 Multi-function Input 2

DI3 Multi-function Input 3

DI4 Multi-function Input 4

DI5 Multi-function Input 5

DI6 Multi-function Input 6

Refer to Pr.04-04 to Pr.04-09

Multi-function Input Terminals

DFO Digital Frequency Meter

(Open Collector Output)

Factory setting 1:1

(Maximum 48VDC, 50mA)

+24V DC Voltage Source (+24V, 20mA), used for source

mode.

DIC Digital Signal Common Used as common for digital

inputs and used for sink mode.

CHAPTER 3: WIRING

3-10

Terminal Symbols Terminal Functions Factory Settings

RA Multi-function Relay output

(N.O.) a

RB Multi-function Relay output

(N.C.) b

RC Multi-function Relay common

Resistor Load

5A(N.O.)/3A(N.C.) 240VAC

5A(N.O.)/3A(N.C.) 24VDC

Inductive Load

1.5A(N.O.)/0.5A(N.C.) 240VAC

1.5A(N.O.)/0.5A(N.C.) 24VDC

Refer to Pr.03-01 to Pr.03-03

DO1 Multi-function output 1

(Photocoupler)

DO2 Multi-function output 2

(Photocoupler)

DO3 Multi-function output 3

(Photocoupler)

Maximum 48VDC, 50mA

Refer to Pr.03-01 to Pr.03-03

DOC Multi-function output common Maximum 48VDC, 50mA

+10V Potentiometer output

power source +10V 20mA

AVI Analog voltage Input 0 to +10V

ACI Analog current Input 4 to 20mA

AUI Auxiliary analog voltage input -10 to +10V

AFO Analog output meter 0 to 10V, 2mA

ASC Analog control signal

(common)

* Control signal wiring size: 18 AWG (0.75 mm2).

This manual suits for next models

18

Table of contents

Popular DC Drive manuals by other brands

Siemens

Siemens Micromaster Eco Reference manual

Danfoss

Danfoss VLT FC 103 Design guide

Danfoss

Danfoss VLT FC 103 operating guide

American Control Electronics

American Control Electronics Minarik MDVF03-D230-PCM quick start guide

Leadshine Technology

Leadshine Technology M415B user manual

Newport

Newport New Focus 8712 user manual