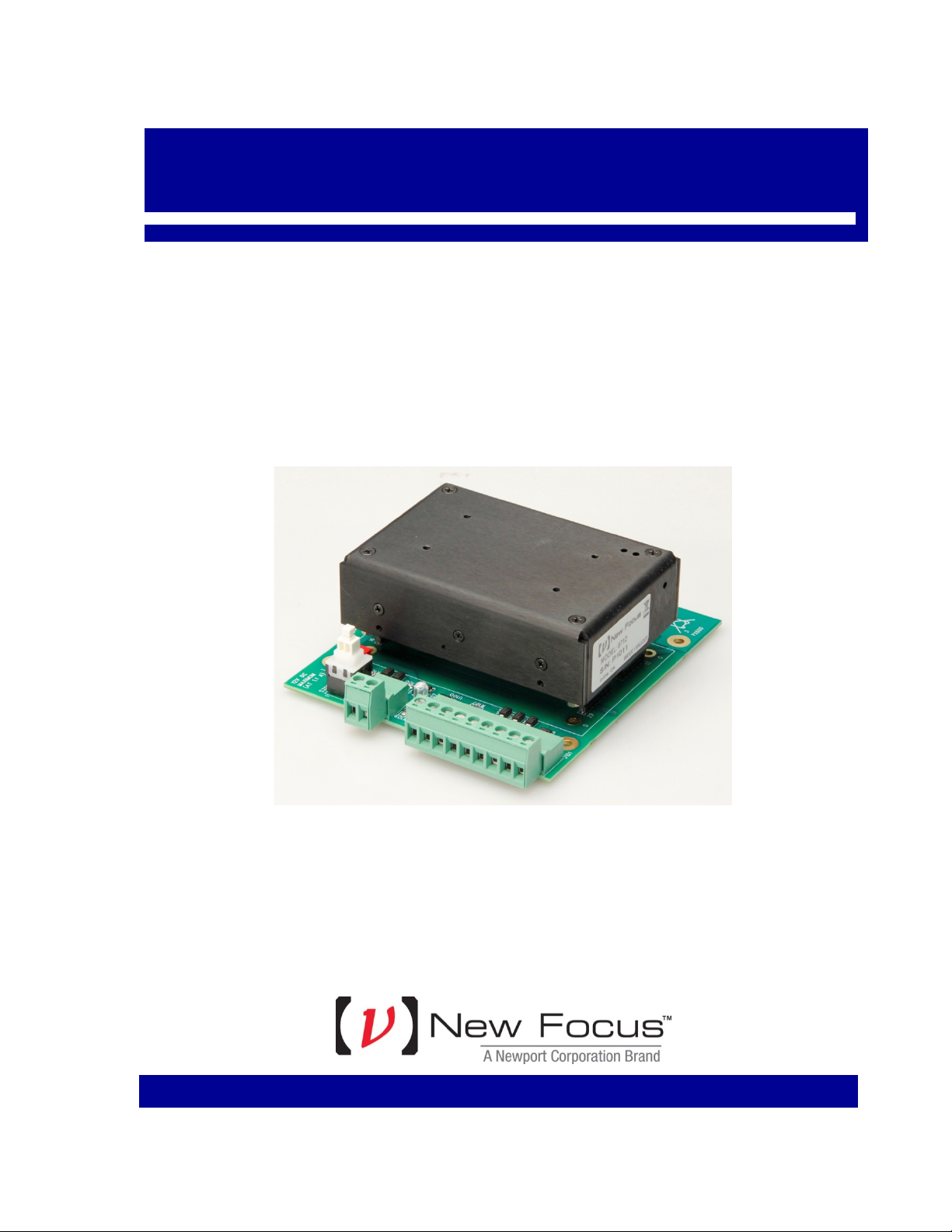

Newport New Focus 8712 User manual

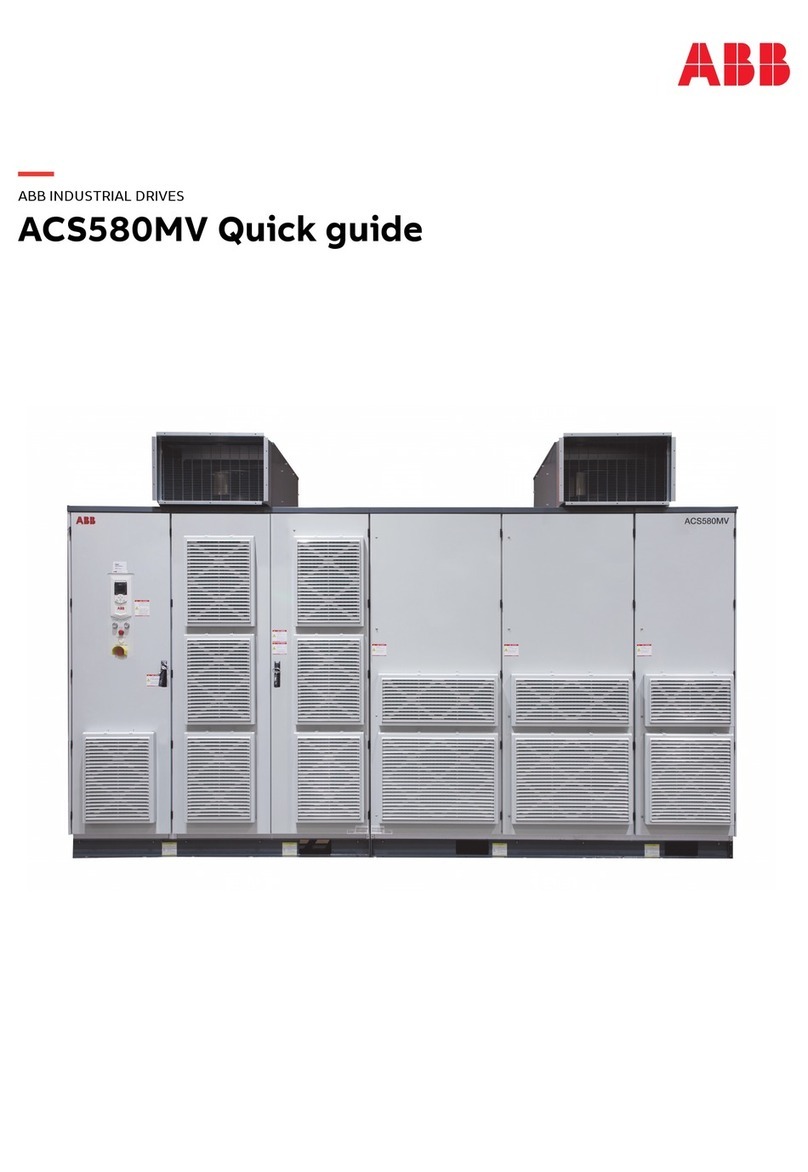

Model 8712 Picomotor Driver

Model 8703 System Driver

User’s Manual

Single-Axis Picomotor Driver

ii Preface

EU27 DECLARATION OF CONFORMITY

Application of Council Directive(s):

☒Electromagnetic Compatibility Directive (EMCD) – 2014/30/EU

☒Low Voltage Directive (LVD) – 2014/35/EU

☒Restriction of Hazardous Substances Directive (RoHS2) – 2011/65/EU (2)

☒Restriction of Hazardous Substances Directive (RoHS3) – (EU) 2015/863 (2)

☒Waste Electrical and Electronic Equipment – Directive 2012/19/EU

Standard(s) to which conformity is declared:

☒EN 61326-1:2013 – (EMC)

☒EN 61010-1:2010 + AMD 1:2016 (Ed 3) – (Safety)

Emissions:

☒CISPR 11:2015 Industrial, Scientific and Medical Equipment Radio-Frequency Disturbance Characteristics -

Limits and Methods of Measurement

☒IEC 61000-3-2:2018 EMC/Limits for Harmonic Current Emission (1)

☒IEC 61000-3-3:2013 + AMD1:2017 EMC/Limitations of Voltage Fluctuations and Flicker in Low-Voltage

Supply Systems (1)

Immunity:

☒IEC 61000-4-2:2008 EMC/Electrostatic Discharge Immunity Test

☒IEC 61000-4-3:2006+AMD1:2007+AMD2:2010 EMC/Radiated Radio - Frequency Electromagnetic Field

Immunity Test

☒IEC 61000-4-4:2012 EMC/Electrical Fast Transient/Burst Immunity Test

☒IEC 61000-4-5:2014 + AMD 1:2017 EMC/Surge Immunity Test (1)

☒IEC 61000-4-6:2013 EMC/Conducted Disturbances induced by Radio Frequency Fields Immunity Test

☒IEC 61000-4-8:2009 EMC/Power Frequency Magnetic Field Immunity Test

☒IEC 61000-4-11:2004 + AMD 1:2017 EMC/Voltage Dips, Short Interruptions and Variations Immunity Test (1)

Manufacturer’s Name: MKS Instruments, Inc., 2 Tech Drive, Andover, MA 01810 USA

Authorized Representative’s Name & Location: MICRO-CONTROLE Spectra-Physics S.A.S., Zone

Industrielle, 45340 Beaune la Rolande, France

Equipment Type/Description: Electrical equipment for measurement, control and laboratory use

Model Number(s) (1): 8712, 8703, 8745-PS

The object of the declaration described above is in conformity with the relevant Community harmonization

legislation. MKS product conforms to the above Directive(s) and Standard(s) only when installed in accordance with

manufacturer’s specifications. This declaration has been issued under the sole responsibility of the manufacturer.

Date: 2/3/2021 Signature:

Full Name: Le Cointe Hervé

Title: Quality director

==========================================================================================================================================

1) Compliance of the above model numbers requires the use of a braided shielded cable properly terminated at both ends – if so noted in the MKS

Instruction Manual.

2) RoHS Directive has to be checked for in scope products; cannot CE mark without compliance to RoHS. RoHS Directive can be unchecked

only for systems which MKS sells which qualify for “Large Scale Industrial Tool” exclusion.

Preface iii

iii

UK Declaration of Conformity

Application of Council Directive(s):

☒Electromagnetic Compatibility Directive (EMCD) – 2014/30/EU

☒Low Voltage Directive (LVD) – 2014/35/EU

☒Restriction of Hazardous Substances Directive (RoHS2) – 2011/65/EU (2)

☒Restriction of Hazardous Substances Directive (RoHS3) – (EU) 2015/863 (2)

☒Waste Electrical and Electronic Equipment – Directive 2012/19/EU

Standard(s) to which conformity is declared:

☒BS EN 61326-1:2013 – (EMC)

☒BS EN 61010-1:2010 + AMD 1:2016 (Ed 3) – (Safety)

Emissions:

☒CISPR 11:2015 Industrial, Scientific and Medical Equipment Radio-Frequency Disturbance Characteristics -

Limits and Methods of Measurement

☒IEC 61000-3-2:2018 EMC/Limits for Harmonic Current Emission (1)

☒IEC 61000-3-3:2013 + AMD1:2017 EMC/Limitations of Voltage Fluctuations and Flicker in Low-Voltage

Supply Systems (1)

Immunity:

☒IEC 61000-4-2:2008 EMC/Electrostatic Discharge Immunity Test

☒IEC 61000-4-3:2006+AMD1:2007+AMD2:2010 EMC/Radiated Radio - Frequency Electromagnetic Field

Immunity Test

☒IEC 61000-4-4:2012 EMC/Electrical Fast Transient/Burst Immunity Test

☒IEC 61000-4-5:2014 + AMD 1:2017 EMC/Surge Immunity Test (1)

☒IEC 61000-4-6:2013 EMC/Conducted Disturbances induced by Radio Frequency Fields Immunity Test

☒IEC 61000-4-8:2009 EMC/Power Frequency Magnetic Field Immunity Test

☒IEC 61000-4-11:2004 + AMD 1:2017 EMC/Voltage Dips, Short Interruptions and Variations Immunity Test (1)

Manufacturer’s Name: MKS Instruments, Inc., 2 Tech Drive, Andover, MA 01810 USA

Authorized Representative’s Name & Location: MICRO-CONTROLE Spectra-Physics S.A.S., Zone

Industrielle, 45340 Beaune la Rolande, France

Equipment Type/Description: Electrical equipment for measurement, control and laboratory use

Model Number(s) (1): 8712, 8703, 8745-PS

The object of the declaration described above is in conformity with the relevant Community harmonization

legislation. MKS product conforms to the above Directive(s) and Standard(s) only when installed in accordance with

manufacturer’s specifications. This declaration has been issued under the sole responsibility of the manufacturer.

Date: 2/3/2021 Signature:

Full Name: Le Cointe Hervé

Title: Quality director

==========================================================================================================================================

1) Compliance of the above model numbers requires the use of a braided shielded cable properly terminated at both ends – if so noted in the

MKS Instruction Manual.

2) RoHS Directive has to be checked for in scope products; cannot UKCA mark without compliance to RoHS. RoHS Directive can be

unchecked only for systems which MKS sells which qualify for “Large Scale Industrial Tool” exclusion.

iv Preface

Warranty

New Focus warrants that this product will be free from defects in material

and workmanship and will comply with Newport’s published specifications

at the time of sale for a period of one year from date of shipment. If found to

be defective during the warranty period, the product will either be repaired or

replaced at Newport's option.

To exercise this warranty, write or call your local Newport office or

representative, or contact Newport headquarters in Irvine, California. You

will be given prompt assistance and return instructions. Send the product,

freight prepaid, to the indicated service facility. Repairs will be made and the

instrument returned freight prepaid. Repaired products are warranted for the

remainder of the original warranty period or 90 days, whichever first occurs.

Limitation of Warranty

The above warranties do not apply to products which have been repaired or

modified without Newport’s written approval, or products subjected to

unusual physical, thermal or electrical stress, improper installation, misuse,

abuse, accident or negligence in use, storage, transportation or handling. This

warranty also does not apply to fuses, batteries, or damage from battery

leakage.

THIS WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES,

EXPRESSED OR IMPLIED, INCLUDING ANY IMPLIED WARRANTY

OF MERCHANTABILITY OR FITNESS FOR A PARTICULAR USE.

NEW FOCUS SHALL NOT BE LIABLE FOR ANY INDIRECT, SPECIAL,

OR CONSEQUENTIAL DAMAGES RESULTING FROM THE

PURCHASE OR USE OF ITS PRODUCTS.

First printing 2021

© 2021 by New Focus, Santa Clara, CA. All rights reserved. No part of this

manual may be reproduced or copied without the prior written approval of

New Focus.

This manual has been provided for information only and product

specifications are subject to change without notice. Any change will be

reflected in future printings.

New Focus

3635 Peterson Way

Santa Clara, CA, 95054

USA

Part No. 90051552 Rev G

Preface v

v

Confidentiality & Proprietary Rights

Reservation of Title

The New Focus programs and all materials furnished or produced in

connection with them ("Related Materials") contain trade secrets of New

Focus and are for use only in the manner expressly permitted. New Focus

claims and reserves all rights and benefits afforded under law in the Programs

provided by New Focus.

New Focus shall retain full ownership of Intellectual Property Rights in and

to all development, process, align or assembly technologies developed and

other derivative work that may be developed by New Focus. Customer shall

not challenge, or cause any third party to challenge the rights of New Focus.

Preservation of Secrecy and Confidentiality and Restrictions to Access

Customer shall protect the New Focus Programs and Related Materials as

trade secrets of New Focus, and shall devote its best efforts to ensure that all

its personnel protect the New Focus Programs as trade secrets of New Focus.

Customer shall not at any time disclose New Focus's trade secrets to any

other person, firm, organization, or employee that does not need (consistent

with Customer's right of use hereunder) to obtain access to the New Focus

Programs and Related Materials. These restrictions shall not apply to

information (1) generally known to the public or obtainable from public

sources; (2) readily apparent from the keyboard operations, visual display, or

output reports of the Programs; 3) previously in the possession of Customer

or subsequently developed or acquired without reliance on the New Focus

Programs; or (4) approved by New Focus for release without restriction.

Trademarks

The New Focus logo and name are registered trademarks of Newport

Corporation in Mexico, Israel, Singapore, European Union, Taiwan, Hong

Kong, China, Japan, Korea, Canada, Australia, and the United States.

Service Information

This section contains information regarding factory service for the source.

The user should not attempt any maintenance or service of the system or

optional equipment beyond the procedures outlined in this manual. Any

problem that cannot be resolved should be referred to New Focus.

vi Preface

Technical Support Contacts

North America Europe

New Focus

3635 Peterson Way, Santa Clara, CA

95054

Telephone: (866) 683-6287

Telephone: (408) 919-1500

Newport/MICRO-CONTROLE S.A.

Zone Industrielle

45340 Beaune la Rolande,

FRANCE

Telephone: (33) 02 38 40 51 56

Asia

Newport Opto-Electronics Technologies

中国 上海市 爱都路 253号 第3号楼 3层

C部位, 邮编 200131

253 Aidu Road, Bld #3, Flr 3, Sec C,

Shanghai 200131, China

Telephone: +86-21-5046 2300

Fax: +86-21-5046 2323

Newport Corporation Calling Procedure

If there are any defects in material or workmanship or a failure to meet

specifications, promptly notify Newport's Returns Department by calling 1-800-222-

6440 or by visiting our website at www.newport.com/returns within the warranty

period to obtain a Return Material Authorization Number (RMA#). Return the

product to Newport Corporation, freight prepaid, clearly marked with the RMA# and

we will either repair or replace it at our discretion. Newport is not responsible for

damage occurring in transit and is not obligated to accept products returned without

an RMA#.

E-mail: rma.service@newport.com

When calling Newport Corporation, please provide the customer care representative

with the following information:

•Your Contact Information

•Serial number or original order number

•Description of problem (i.e., hardware or software)

To help our Technical Support Representatives diagnose your problem, please note

the following conditions:

•Is the system used for manufacturing or research and development?

•What was the state of the system right before the problem?

•Have you seen this problem before? If so, how often?

•Can the system continue to operate with this problem? Or is the system non-

operational?

•Can you identify anything that was different before this problem occurred?

Preface vii

vii

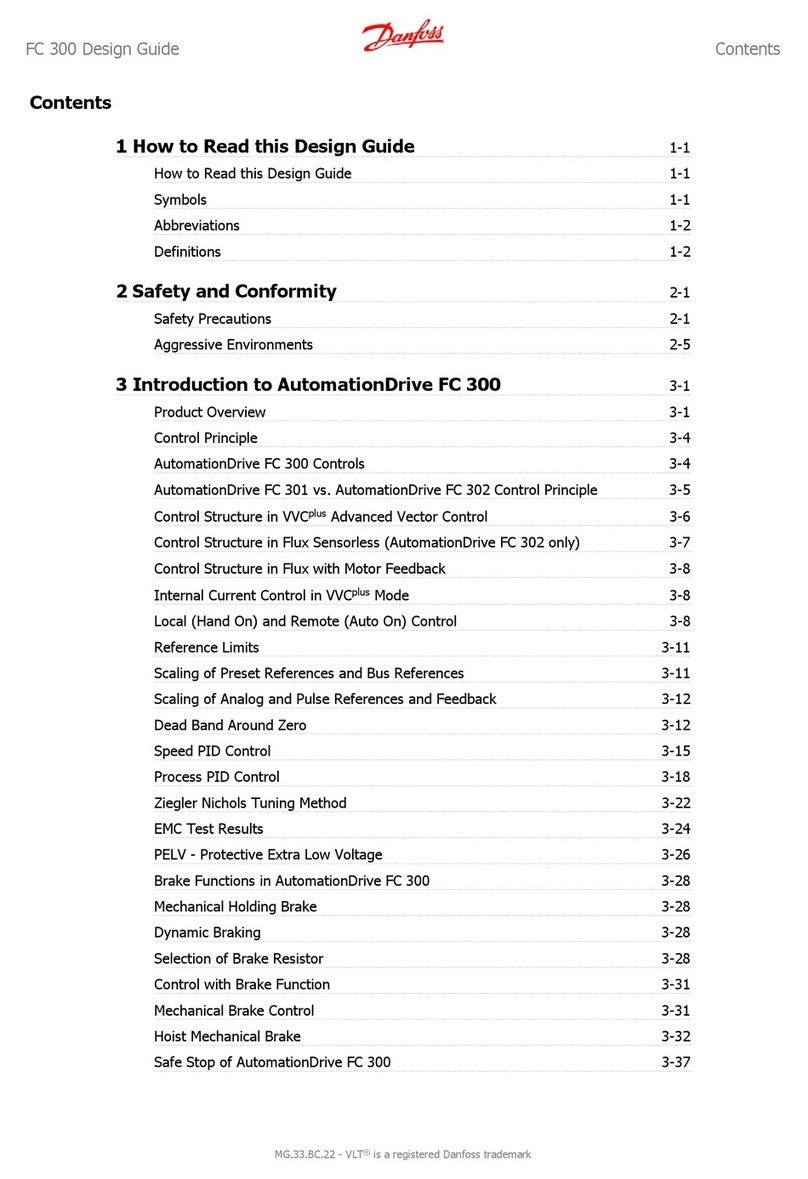

Table Of Contents

EU27 DECLARATION OF CONFORMITY ....................................... ii

UK Declaration of Conformity .............................................................iii

Warranty................................................................................................ iv

Technical Support Contacts .................................................................. vi

Table Of Contents................................................................................ vii

List of Figures....................................................................................... ix

1Introduction 1

1.1 Introduction ...................................................................................1

1.2 Safety.............................................................................................1

1.3 Operating Limits*..........................................................................2

2Specifications 3

2.1 Electrical Specifications................................................................3

2.2 Model 8712 pin Descriptions ........................................................4

2.3 Typical Characteristics..................................................................7

2.4 MODEL 8712 DRAWINGS .........................................................8

3Theory of Operation 9

3.1 Block Diagram...............................................................................9

3.2 Input Mode Control Bits..............................................................10

3.2.1 Step/Direction Mode .......................................................10

3.2.2 Quadrature Mode.............................................................10

3.2.3 Linear Voltage Input........................................................11

3.2.4 Bang-Bang Voltage Input................................................12

3.3 Status Indicators ..........................................................................12

3.4 Power Supply...............................................................................13

3.4.1 Fault Protection ...............................................................13

3.4.2 Power Connections..........................................................14

3.5 Control Interface..........................................................................15

3.6 Output Connections.....................................................................16

3.7 Sockets.........................................................................................16

3.8 EMC Considerations ...................................................................17

viii Preface

4MODEL 8703 SYSTEM 18

4.1 Model 8703 System Hook Up.....................................................18

4.1.1 I/O Connector Descriptions.............................................18

4.1.2 I/O Connector Terminal Functions (Connectors J100 &

J101)................................................................................19

4.1.3 Setting the Control Mode ................................................19

4.1.4 Power Input .....................................................................20

4.1.5 Analog Control................................................................20

4.1.6 Digital Control.................................................................20

4.1.7 LIDLE..............................................................................21

4.1.8 LFAULT..........................................................................21

4.1.9 Temperature Sensor.........................................................22

4.2 Picomotor Connections ...............................................................22

4.2.1 Isolation...........................................................................23

4.3 Model 8703 System Board Layout..............................................24

5Safety Precautions 26

5.1 Definitions and Symbols .............................................................26

5.1.1 General Warning or Caution ...........................................26

5.1.2 Electric Shock..................................................................26

5.1.3 European Union CE Mark...............................................26

5.1.4 UKCA Mark....................................................................27

5.1.5 Waste Electrical and Electronic Equipment (WEEE).....27

5.1.6 Control of Hazardous Substances....................................27

5.2 Warnings and Cautions................................................................28

5.2.1 General Warnings............................................................28

5.2.2 General Cautions.............................................................29

5.2.3 Summary of Warnings and Cautions...............................29

Preface ix

ix

List of Figures

Printed Circuit Board Mounting Pattern (Top View)..................... 8

Dimensions of the 8712 Module ([mm] inches)............................. 8

Block Diagram................................................................................ 9

Quadrature-Mode Operation......................................................... 11

Pulse Rate vs. Input Voltage for Linear Voltage Input Mode ...... 11

Detailed View of Pulse Rate vs. Input Voltage around the dead-

band for Linear Voltage Input Mode .......................................... 12

Status Indicators position.............................................................. 13

Heatsink mounting holes............................................................... 14

Schematic of Model 8703 System Board...................................... 21

System Board (Upper Layer, Top View)...................................... 24

System Board (Bottom Layer, Top View).................................... 25

Dimensions of Model 8703........................................................... 25

General Warning or Caution Symbol ........................................... 26

Electrical Shock Symbol............................................................... 26

CE Mark........................................................................................ 26

UKCA Mark.................................................................................. 27

WEEE Directive Symbol.............................................................. 27

RoHS Compliant Symbol ............................................................. 27

1 Introduction

1.1 Introduction

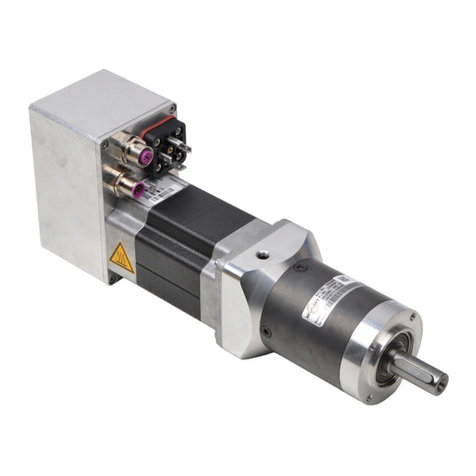

The Model 8712 & Model 8703 Picomotor drive modules are ideal drivers

for OEM Picomotor systems. Model 8712 is designed to be mounted on a

printed circuit board (PCB). Model 8703 incorporates the Model 8712 with a

PCB for quick and easy integration into your system. Key features and

specifications are:

•12V nominal power supply.

•Choice of 4 industry-standard analog and optically coupled digital

motion-control interfaces.

•Idle control input for reduced power consumption and interlock.

•No motion caused by turn on/off transients.

•Instantaneous direction reversal.

•Continuous operation at up to 1 kHz in a still-air 55 ºC environment.

•2 kHz maximum pulse rate at 25 ºC, intermittent operation at higher

temperatures.

•Over-temperature auto protection

•Threaded holes on top and lateral sides for easy mounting

Step/direction, quadrature, and ±10V linear or bang-bang voltage control

interfaces set the velocity and direction of a Picomotor connected to the drive

module. Two mode inputs are used to select one of the four control interfaces

when power is applied to the module. An optically isolated LIDLE input

turns off the high-power circuits to reduce power consumption to 0.8 W

(typical). The LIDLE input also disables Picomotor pulse generation.

1.2 Safety

Voltages of up to 130 V are accessible inside the driver chassis, mounts,

Picomotors, and the interface board. DO NOT operate the units with the

driver or mount covers removed. If the wire of a mount or Picomotor is

damaged, discontinue use and return it for repair. If the device is used in a

manner not specified by New Focus, the protection provided by the device

may be impaired.

2 Introduction

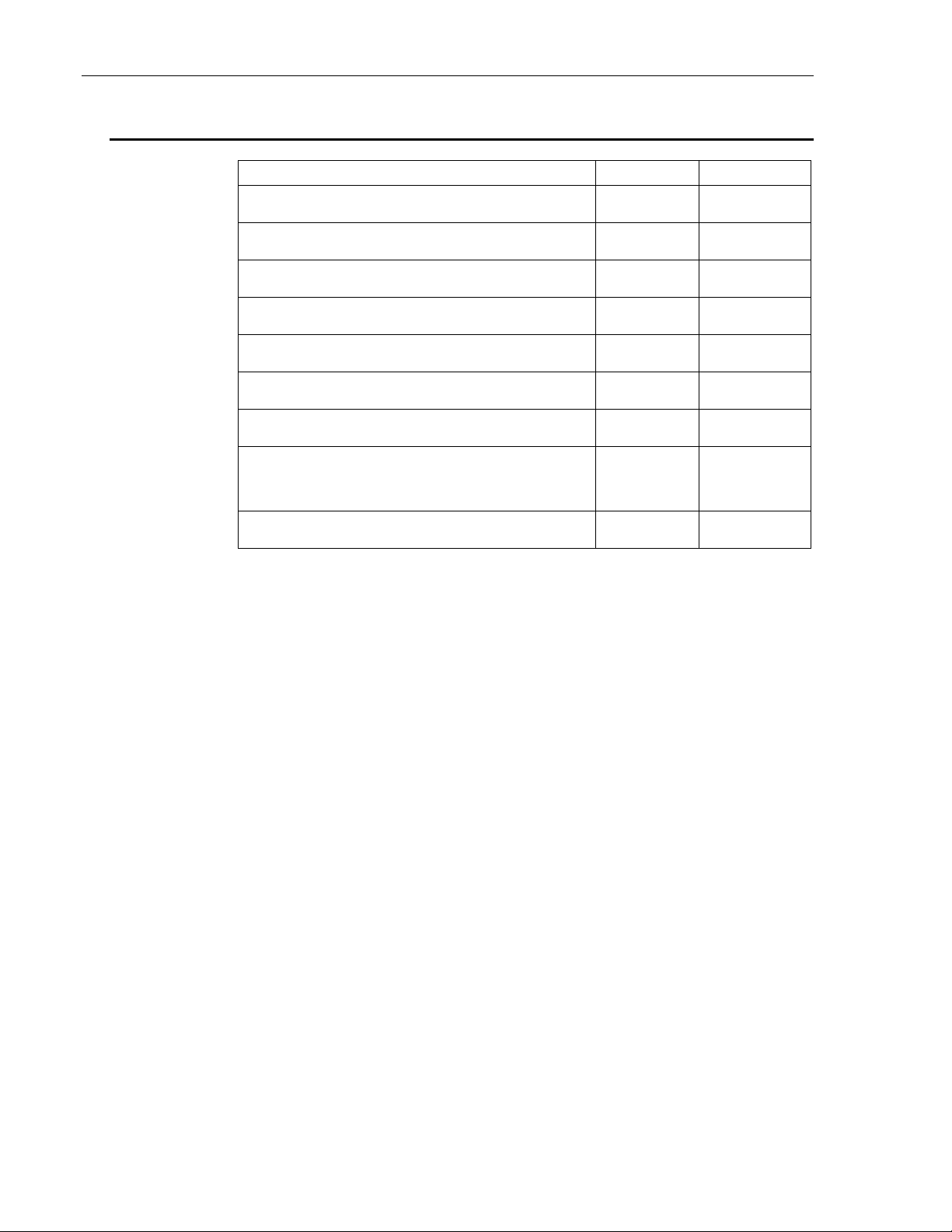

1.3 Operating Limits*

PARAMETER

MIN.

MAX.

Model 8712 Power input voltage (+V IN) 10 V 16 V

Model 8703 Power input voltage (+V IN) 10 V 12 V

Continuous pulse rate in 55 ºC still air 9.5 Hz 1 kHz

Ambient still-air operating temperature 0 °C 65 °C

Storage temperature (non-operating) -40 °C 95 °C

Voltage on optically coupled output 0 V 5 V

Input voltage on optically isolated inputs 0 V 6.0V

Analog input voltage**

(ANALOG IN–, ANALOG IN+) -10 V +10 V

Current into optically coupled input 10 mA

*Operating outside the operating limits may damage the unit.

**The magnitude of the analog input voltage must be less than the power supply input

voltage.

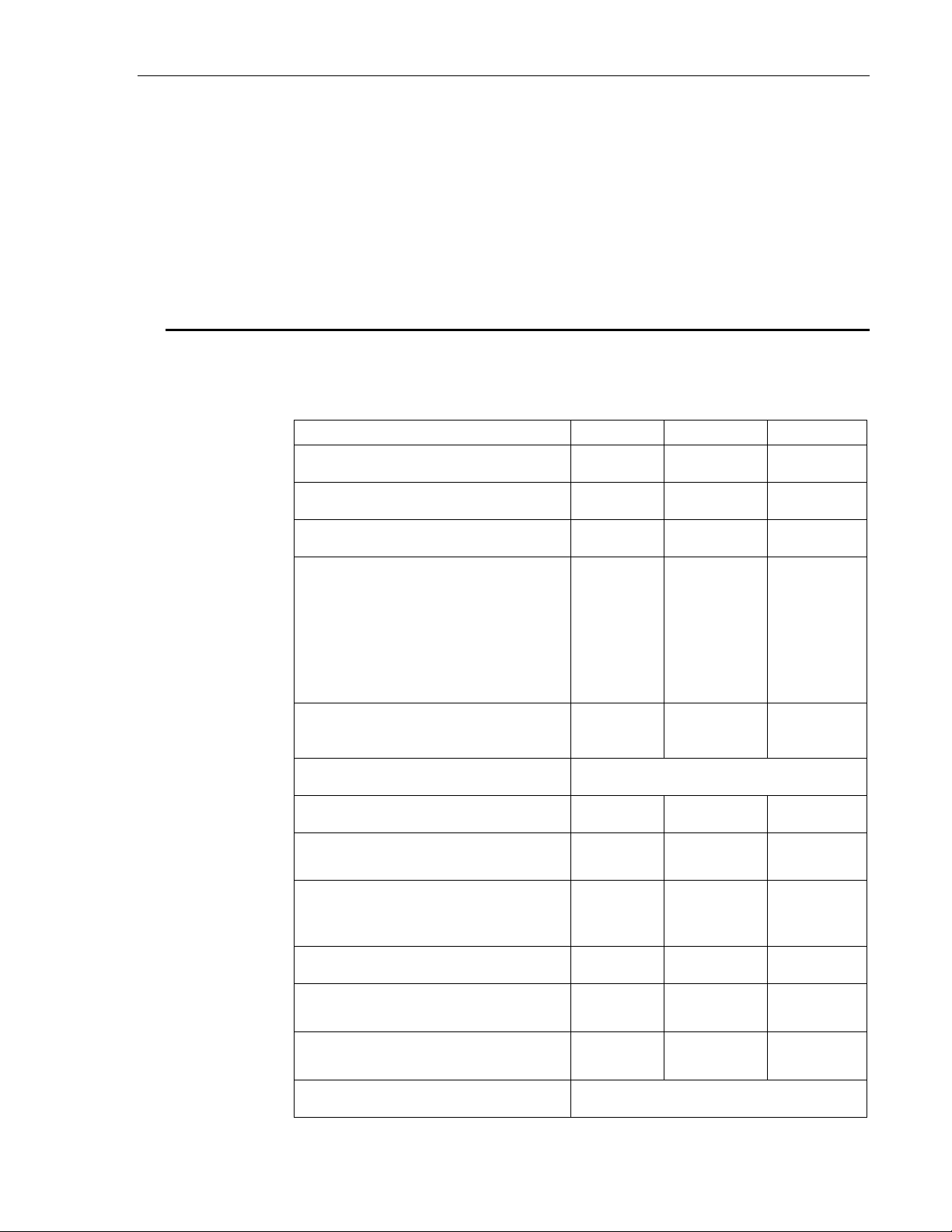

2 Specifications

2.1 Electrical Specifications

All specifications assume a 1 kHz pulse rate, 12 V power input, 25° C still-air

ambient, and TTL step/direction input, unless otherwise indicated.

PARAMETER

MINMUM

TYPICAL

MAXIMUM

Power Supply Voltage 10 V 16 V

Inrush Current at Power On 600 mA

Idle Current Draw 75 mA

Pulse Rates

Step/Direction Mode

Quadrature Mode

Linear Voltage Mode

Bang-Bang Voltage Mode

0

0

0

0

2 kHz

2 kHz

2 kHz

2 kHz

Minimum Non-Zero Pulse Rate in

Linear Voltage Mode 9.5 Hz

Linear Voltage Mode Step Size refer to Figure 11 and Figure 12

Analog Threshold ±1 V

ANALOG IN Input Impedance 14.1 kΩ

Optically Coupled Input Series

Resistance 470Ω

/0.06W

Package Thermal Time Constant 7 minutes

Over-temperature LFAULT Trip Point at

Temperature Monitor Output 4.00 V

Over-temperature Shut-Down Trip at

Temperature Monitor Output Point 4.12 V

Weight 5.76 oz (163 g)

4 Specifications

Dimensions

(L x W x H including standoffs)

3.75 in x 2.53 in x 1.26 in

95 mm x 64 mm x 32 mm

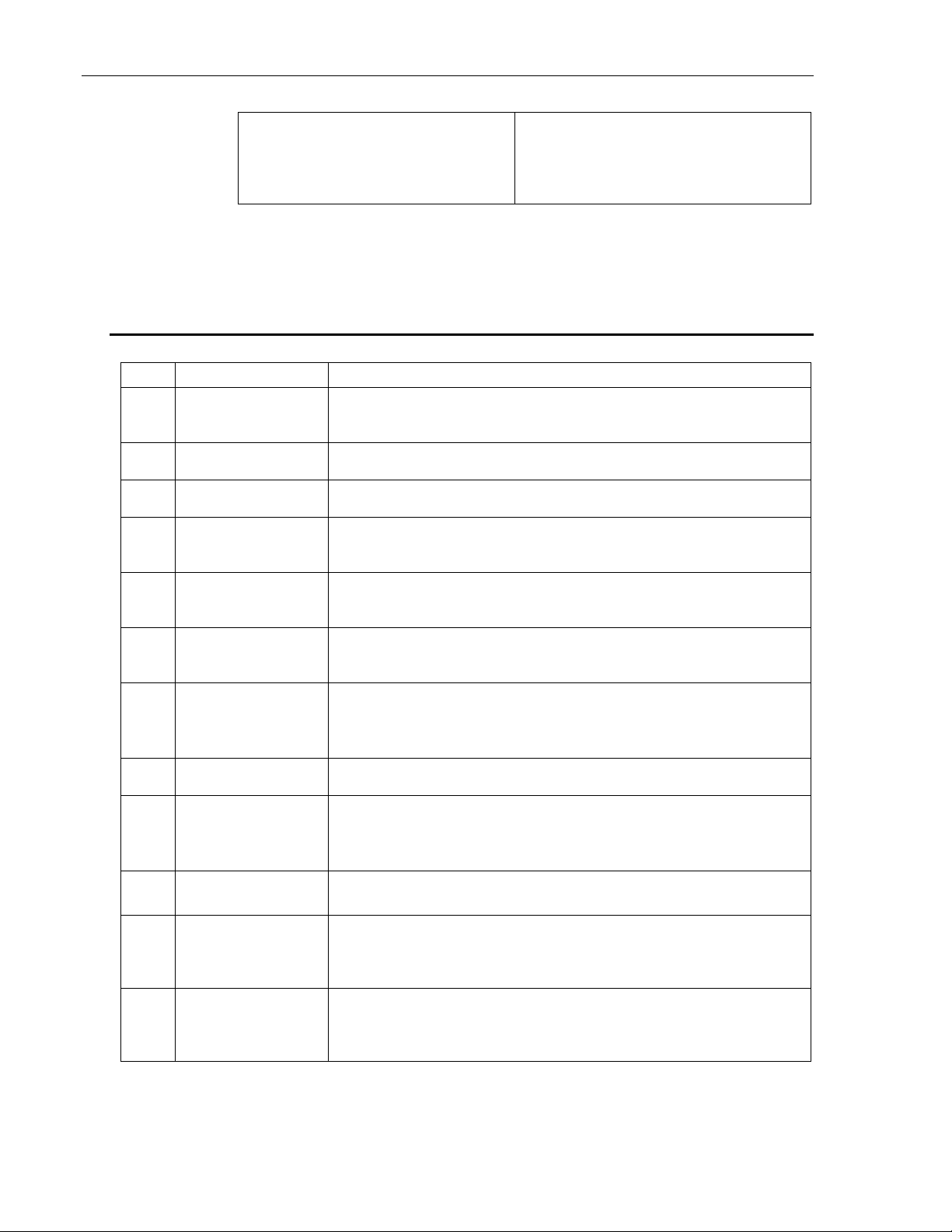

2.2 Model 8712 pin Descriptions

Pin

Name

Description

1 SYSTEM

GROUND Power return

2 +V IN Input power, 10–16 V

3 +V IN Input power, 10–16 V (same as pin 2)

4 SYSTEM

GROUND Power return (same as pin 1)

5 SYSTEM

GROUND Power return (same as pin 1)

6 SYSTEM

GROUND Power return (same as pin 1)

7 +5V OUT Logic-supply output connected to a 1-kΩresistor. Used for

manufacturing test and mode configuration. Typical output voltage

range is 4.8 to 5.2Volts DC (no load).

8 ANALOG IN– Voltage-controlled rate input. Connect to analog common.

9 ANALOG IN+ Voltage-controlled rate input. Connecting to analog voltage ±10 V

gives full-scale rate of 2 kHz. The input impedance is 14.1 kΩto

ground. Enabled by MODE 0,1 or 1,1 inputs.

10 DGROUND Opto-coupler return. Connect to digital ground close to control logic.

11 DIR+/A Opto-coupled TTL control input enabled by MODE 0,0 or 1,0 inputs.

In Step/Direction mode, controls direction: high=clockwise,

low=counterclockwise. In Quadrature mode, acts as quadrature A.

12 PULSE+/B Opto-coupled TTL control input enabled by MODE 0,0 or 1,0 inputs.

In Step/Direction mode, each falling edge initiates a step. In

Quadrature mode, acts as quadrature B.

Specifications 5

13

14

MODE0

MODE1

The MODE0 and MODE1 pins control the mode of the unit as

follows:

MODE0 MODE1 Description

0 0 Step/Direction Mode: Digital mode

where DIR+/A controls direction

(high=clockwise, low=counterclockwise)

and the falling edge of PULSE/B initiates

each step.

1 0 Quadrature Mode: Digital mode where

pulses are generated from edge

transitions of both the A-phase (DIR+/A)

and B-phase (PULSE/B) inputs.

0 1 Linear Voltage Input Mode: Analog

mode where ANALOG IN+ controls pulse

direction and rate. Negative voltage

results in counter-clockwise motion:

positive results in clockwise. See Figure

11 for the frequency-to-voltage

correlation.

1 1 Bang-Bang Voltage Input Mode:

Analog mode where voltage on ANALOG

IN+ above the threshold results in

maximum analog pulse rate. Polarity

controls direction.

Mode bits are only read when power is turned on. They are not

optically isolated. Tie them to +5V OUT or SYS GROUND.

15 LIDLE Opto-coupled TTL input. Low input disables pulse generation and

reduces power consumption. Can also be used as system interlock.

16 LFAULT Open-collector opto-coupler output pulled low when output amplifier

temperature limit is exceeded. On start-up, firmware version

number is present on this pin in the form of on/off pulses.

17 N/C Not connected pin.

18 +5V REF Reserved. Test point for manufacturing reference only.

19 LV PULSE Reserved. Test point for manufacturing reference only.

20 -15V Reserved. Test point for manufacturing reference only.

21 TEMP MONITOR Voltage proportional to the output-amplifier case temperature. If it

goes above 4 V pulls LFAULT low.

6 Specifications

22 GROUND Ground reference for pin 21. Do not tie to SYS GROUND (pins 1, 4,

5 & 6).

23 +130V Reserved. Test point for manufacturing reference only. Typical

output voltage range is 120 to 138 Volts DC (no load).

24 PULSE RETURN

Drive pulse return

.

Note: PULSE RETURN and PULSE OUTPUT should be routed in

close proximity. Other signal traces should be kept away from

PULSE RETURN and PULSE OUTPUT.

25 PULSE OUTPUT

Drive pulse.

Note: PULSE RETURN and PULSE OUTPUT should be routed in

close proximity. Other signal traces should be kept away from

PULSE RETURN and PULSE OUTPUT.

26 PULSE RETURN Drive pulse return. (same as pins 24)

27 FRAME GROUND Return for EMI T-filter on PULSE RETURN and PULSE OUTPUT.

28 FRAME GROUND Return for EMI T-filter on PULSE RETURN and PULSE OUTPUT.

29 FRAME GROUND Return for EMI T-filter on PULSE RETURN and PULSE OUTPUT.

Specifications 7

2.3 Typical Characteristics

Operating Current vs. Pulse Rate

Idle Current as a Function of Input Voltage

Temperature Rise vs. Pulse Rate

Temperature Sensor Output vs. Case

Temperature

Quadrature Mode, Counter-Clockwise

Motion

Quadrature Mode, Clockwise Motion

8 Specifications

2.4 MODEL 8712 DRAWINGS

Printed Circuit Board Mounting Pattern (Top View)

Dimensions of the 8712 Module ([mm] inches)

3 Theory of Operation

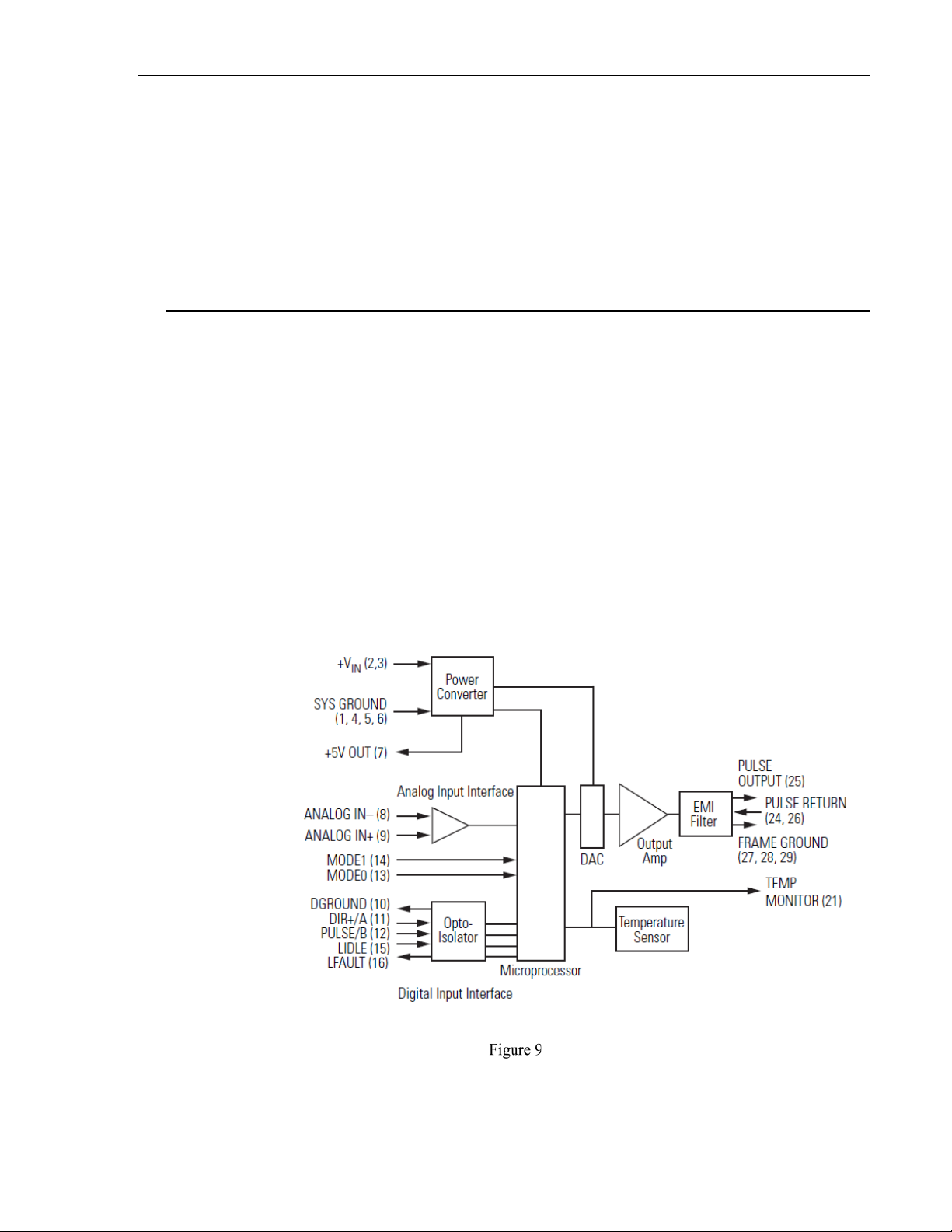

3.1 Block Diagram

The block diagram shows the basic design of the 8712. The microprocessor

reads the input mode bits when power is turned on and selects the input

interface. It also flashes the firmware version number on the internal red

LFAULT indicator. To check the firmware version, one has to count the

number of led flashes. There is a longer pause between the significant

number and the decimal number. For example, version 1.5 will flash the

LED once, followed by a pause, then will flash the LED five times.

Pulse and direction inputs (voltage or logic edge) from the selected interface

cause the microprocessor to generate low voltage Picomotor drive

waveforms. The output amplifier increases the amplitude of the drive

waveform sufficiently to drive the Picomotor. An internal power supply

generates the high voltage power for the output amplifier as well as other

supply voltages.

Block Diagram

10 Theory of Operation

When LIDLE is pulled low, the microprocessor shuts down the power supply

and stops generating Picomotor drive pulses. The response to this input is

rapid enough to prevent the generation of more than one pico pulse after

LIDLE goes low. Normal operation resumes after LIDLE is brought high.

3.2 Input Mode Control Bits

MODE0 and MODE1 are decoded when the power is applied. The interface

mode can only be changed by removing power to the 8712, then changing the

mode bits and applying power again. MODE0 and MODE1 define the control

interface as follows:

3.2.1 Step/Direction Mode

In this mode, DIR+/A is the direction input. PULSE+/B is the pulse

command input. TTL inputs to the control interface determine pulse

generation and the direction of motion. One Picomotor pulse is generated for

each falling edge of PULSE+/B. PULSE+/B can be left in either a high or

low state because it is edge sensitive. The low state is preferred because the

opto-coupler input diode will be off.

DIR+/A causes clockwise motion when high, and counter-clockwise motion

when low. It is checked before each pulse is made to allow instantaneous

direction reversal. DIR+/A is level sensitive, so it must be in the desired state

when PULSE+/B goes low and remain in that state for a minimum of 100 μs

after PULSE+/B goes low. The pulse rate can be between 0 and 2 kHz. Faster

pulse rates will not result in increased response.

3.2.2 Quadrature Mode

In this mode, DIR+/A is the A-phase input and the PULSE+/B is the B-phase

input. Like the step/direction mode, quadrature mode uses the digital control

interface. In this mode a pulse is generated for every edge transition of both

the A-phase and B-phase control inputs. The direction of motion is

determined by the phase of A with respect to B:

MODE0 MODE1 Description

0 0 Step/Direction Mode

1 0 Quadrature Mode

0 1 Line Voltage Input

1 1 Bang-Bang Voltage Input

This manual suits for next models

1

Table of contents

Other Newport DC Drive manuals

Popular DC Drive manuals by other brands

Danfoss

Danfoss VLT CDS 803 Design guide

Raymarine

Raymarine Mk II installation guide

KSB

KSB PumpDrive 2 Eco Application guide

SEW-Eurodrive

SEW-Eurodrive MOVIMOT MM D Series Compact operating instructions

Siemens

Siemens simovert masterdrives operating instructions

TR-Electronic

TR-Electronic MP-200 user manual