Watts SunStat Relay II User manual

• Wire all circuits as Class 1, Electric Light and Power Circuits.

• Wire all circuits with insulation rated 600V minimum.

• Mount this control only to a grounded metallic box or a nonmetallic box.

• Use power supply wires suitable for at least 90°C.

• High voltage – disconnect power supply before servicing.

•

The GFCI (ground-fault circuit interrupter) in this thermostat control does not

protect against shock if both bare conductors are touched at the same time.

•

Do not exceed 15 amps on this thermostat control. Doing so will cause risk

of fire hazard and damage.

• Make sure the house power supply voltage matches the voltage rating of

the floor heating system. Do not apply 240 VAC to a 120 VAC rated system.

Connecting the wrong voltage may cause overheating and damage to the

system, the control, floor coverings, etc.

Installation & Operation

Manual

SunStat® Relay II

Model 500810 (-BB, -HB)

Items included

Unpack the control and make sure everything is in good condition. Do not use

a damaged control or part. The package comes with these items:

(1) Relay II control

(5) Wire Nuts (Marettes®)

(2) Mounting Screws

(1) Screwdriver

InstallaƟon

Locating the Control

Find a suitable location for the control. Consider the following:

• It is designed for indoor dry location only.

• It may be placed on an insulated or uninsulated wall, preferably an interior

wall to avoid overheating from outside sun heat.

•

Keep it away from all water sources such as sinks, showers, and bathtubs

as well as heat sources such as hot-water piping, heat ducting, wall-mount

lighting, and direct sunlight.

•

Locate it at a suitable height, normally about 4-1/2’ to 5’ (1.4 m to 1.5 m)

from the floor.

Mounting the electrical box

•

When mounting on an existing wall, cut the opening for the electrical box for

the control. To make it easier to pull the wiring, wait to install the electrical

box until after all wiring is drawn into this opening.

• When mounting on an open wall, secure the electrical box for the control to

the wall stud. Conduit from the electrical box to the floor is recommended

(check local codes for requirements) for additional protection. Install one

conduit for the floor sensor. Install another conduit for the floor heating

system power leads.

• Refer to the Installation Instructions supplied with the floor heating system

for additional installation details.

The SunStat Relay II model 500810 is designed to operate either a 120 VAC or

240 VAC resistance floor heating system in conjunction with a thermostat Model

500750 or 500775. It comes with a GFCI inside to meet safety needs.

*A single-gang extra-deep box allows sufficient space to connect 1 or 2 heang

mats or cables. For 3 heang mats or cables, a 4-inch square extra-deep

electrical box with a single-gang “mud ring” is necessary. Alternately, a juncon

box may be installed to connect mulple heang mats or cables, then run

power supply wire from the juncon box to the control electrical box. See the

Installaon Instrucons provided with the floor heang system for more details.

For use only with Models 500750 and 500775

As with any electrical product, care should be taken to guard

against the potential risk of fire, electric shock, and injury to

persons. The following must be observed:

Read this Manual BEFORE using this equipment.

Failure to read and follow all safety and use

information can result in death, serious personal

injury, property damage, or damage to the

equipment.

Keep this Manual for future reference.

Installation must be performed by qualified personnel, in accordance with

local codes and standards. A licensed electrician is recommended.

Local building or electrical codes may require modifications to the information

provided. You are required to consult the local building and electrical codes

prior to installation. If this information is not consistent with local building or

electrical codes, the local codes should be followed.

Tools and supplies needed

• 18 AWG to 24 AWG 2-conductor shielded wire

• No. 2 Phillips screwdriver

• Hole saw (if installing in an existing wall)

• Wire strippers, wire cutters, and other electrical tools

• Electrical wall box (plastic or metal)*

To prevent the risk of personal injury and/or death, make sure

power is not applied to the product until it is fully installed

and ready for final testing. All work must be done with power

turned off to the circuit being worked on.

House Wiring

Pull power supply wiring to the control location. Consider the following:

• Leave about 6 to 8 inches (15 to 20 cm) of wire for connections later.

•

This wiring should be size 12 or 14 AWG following appropriate local code

requirements.

•

A qualified person should run a dedicated circuit from the main circuit

breaker panel to the control location. If a dedicated circuit is not possible, it

is acceptable to tap into an existing circuit. However, there must be enough

capacity to handle the load (amps) of the floor heating system being installed

and any possible appliance, such as a hair dryer or vacuum cleaner.

• Avoid circuits that have ballasted lighting, motors, exhaust fans, or hot tub

pumps due to possible interference.

•

The circuit breaker should be rated 20 amps for total circuit loads up to 15 amps.

A 15 amp circuit breaker may be used for total circuit loads up to 12 amps.

•

A GFCI (ground-fault circuit interrupter) or AFCI (arc-fault circuit interrupter)

type circuit breaker may be used if desired, but is not necessary.

Communication Wiring

Pull 18 AWG to 24 AWG 2-conductor shielded wire through the wall from the

SunStat Relay II location to this control location. This wire may be up to 100

feet (30 m) in length. Strip the wire ends 1/8" to 3/16" (3 mm to 4.5 mm) long.

If the ends are stripped longer than this they may short-circuit.

Power Leads from Heating Mat or Cable

Pull the power lead wires from the floor heating system into the control location.

Excess power lead wire may be cut off, but leave about 6 to 8 inches (15 to 20

cm) of wire for connections.

Screw

Cover

Cover Screw

Front

Module

Load 1

Line 2

Load 2

BUS A & B

Terminals

Power

Module

Line 1

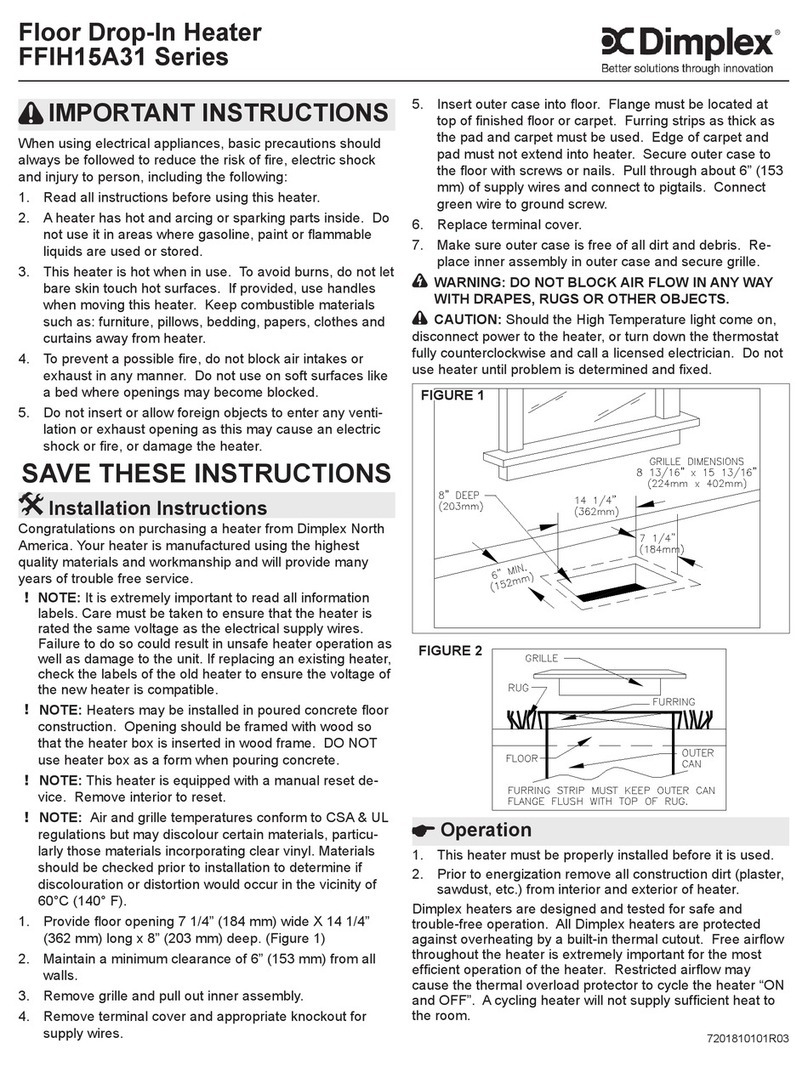

Wiring Connections (see Figure 1 and 2)

Connect the wires as shown in the diagram. Consider the following:

• Gently tug on the wires to make sure they are secure. For added security,

overwrap the Wire Nut connecons with electrical tape.

• If the electrical box is metal, a short length of wire must be secured to the

electrical box from the ground connecon.

• When connecng the Communicaon Wires to the Bus A and B terminals,

observe polarity. Make sure the wire in the Bus A terminal is connected to

the thermostat Bus A terminal.

Figure 1

Wiring

Removing the Relay Front Module

1. Remove the Screw Cover at the bottom and loosen the screw.

2. Lift the Front Module away from the Power Module.

Power (green)

Heating (amber)

Operation

Overview

Mounting the Control

1. Make sure the power supply to the circuit is turned off at the circuit breaker.

2. Carefully press the wires back into the electrical box.

•

DO NOT use the control to push wires in, as this may cause connections to

loosen and possible failure.

3. Use the Mounting Screws provided to secure to the electrical box and tighten

by hand.

•

DO NOT over-tighten the screws causing the plastic to distort, as this may

cause improper function of the control.

4. Press the Front Module onto the Power Module. Make sure both tabs at the

top are completely engaged.

• DO NOT install the Front Module with power applied on the Power Module,

as this may cause improper function of the control.

5. Secure the screw at the bottom and replace the Screw Cover.

• DO NOT over-tighten the screw causing it to strip. Turn it until snug.

On/Off and Reset

Pressing will turn the thermostat on or off. This also resets the thermostat to

clear an error or GFCI fault. See “GFCI Testing” and “Troubleshooting”.

Heating

The Heating light will show amber when the control is sending power to the

floor heating system. There may be a delay of up to 3 minutes from any changes

at the thermostat.

GFCI Testing

The GFCI (Ground Fault Circuit Interrupter) in this control must be tested when

installation is finished and once each month.

1. Make sure the control shows it is Heating. This may require temporarily

increasing the Setpoint temperature on the Thermostat.

2. Press the

GFCI TEST

button. GFCI TRIP should be indicated on the control by

a constant red light. There will also be a click sound, indicating power has

been removed from the floor heating system. If either of these indications

fail, turn off the control and replace it. Do not continue to use.

3. To reset the GFCI TRIP, press the button off and back on.

Figure 2

SpecificaƟons

Power Supply 120 / 240 VAC, 50/60 Hz

Maximum Load 15 A, resisve

Maximum Power 1800 W at 120 VAC / 3600 W at 240 VAC

GFCI Class A (5 mA trip nominal)

Environment Indoor dry locaon only

Storage Temperature 0ᵒF to 120ᵒF (-17ᵒC to 49ᵒC)

ETL Lisng Control No. 3037530. Conforms to UL 873, UL 943,

CSA C22.2 No. 24, CSA/CAN C22.2 No. 144.

Problem Display Soluon

The following are common issues and solutions. A more complete list and

more solutions are on the manufacturer website.

No heat

GFCI TRIP

Light

Reset by turning control off/on.

Reset by turning circuit breaker off/on.

Electrician: Check for loose wire connections at

breaker and junctions. Check for short-circuit to

ground on heating system.

No heat HEATING

Light

Allow sufficient time. Verify floor is insulated.

Electrician: Check for correct resistance between

heating system power lead wires. Check for correct

voltage supplied to heating system. Check for correct

amps drawn by heating system.

No lights

showing None

Reset circuit breaker.

Check contacts between Power Module and Front

Module and clean with alcohol wipe.

Electrician: Check for loose wire connections at

circuit breaker and junctions. Check for correct

voltage between LINE1 and LINE2.

Error Codes: An error code may display due to a power glitch or other false

issue. Always:

1. Try clearing the Error code once by turning the control off, resetting the

circuit breaker, and then turning the control back on.

2. Check the contacts between Power Base and Front Module for dirt or

damage. Turn the circuit breaker off and remove the Front Module. Are

the contacts bent or dirty? Try gently cleaning them with a rubbing alcohol

wipe. Dirt or oil may have contaminated them during installation. In most

locations this step may be performed without an electrician since there

is no power available.

3. Check that the Mounting Screws are not too tight causing distortion. Turn

the circuit breaker off and remove the Front Module. Back the screws out

until the Power Base is just snug to the wall.

4. Check that both clips at the top are engaged and that the screw at the

bottom is snug.

If these actions and the following do not resolve the issue, turn off the

circuit breaker and contact the manufacturer for direction. Do not continue

using the system to prevent further risk of damage, fire, or electrical shock.

No heat

Power Light

blinking

No signal or incorrect signal from thermostat.

Electrician: Check Communication Wire connections

and polarity of wires (A to A, B to B).

No heat

Power and

Heating

lights

blinking

Contacts or internal connections may be faulty.

Check connections and mounting screws as stated

above.

Limited Warranty

Watts Radiant warrants this control (the product) to be free from defect in

material and workmanship for a period of (3) years from the date of original

purchase from authorized dealers. During this period, Watts Radiant will replace

the product or refund the original cost of the product at Watts Radiant’s option,

without charge, if the product is proven defective in normal use. Please return

the control to your distributor to begin the warranty process.

This limited warranty does not cover shipping costs. Nor does it cover a product

subjected to misuse or accidental damage. This warranty does not cover the

cost of installation, diagnosis, removal or reinstallation, or any material costs

or loss of use.

This limited warranty is in lieu of all other warranties, obligations, or liabilities

expressed or implied by the company. In no event shall Watts Radiant be liable for

consequential or incidental damages resulting from installation of this product.

Some states or provinces do not allow limitations on how long an implied

warranty lasts, or the exclusion or limitation of incidental or consequential

damages, so the above exclusions or limitations may not apply to you. This

warranty gives you specific legal rights and you may also have other rights that

vary from state to state.

Troubleshooting

If problems arise with the thermostat, please consult this troubleshooting guide.

If not qualified to perform electrical work, it is highly recommended a qualified,

licensed electrician be hired. Any electrical troubleshooting work should

be performed with the power removed from the circuit, unless otherwise

noted. Although this troubleshooting guide is provided to assist with problems

experienced with a system, results are never guaranteed. Watts Radiant does

not assume any liability or responsibility for damage or injury that may occur

from using this guide. If problems with the system persist, call the manufacturer.

A Watts Water Technologies Company USA: Springeld, MO • Tel. (800) 276-2419 •

Fax: (417) 864-8161 • www.wattsradiant.com

IOM-WR-SS-Relay2 1408 © 2014 Watts Radiant

WARNING: This product contains chemicals known to the State of California to cause cancer

and birth defects or other reproductive harm. For more information: www.watts.com/prop65

This manual suits for next models

3

Other Watts Heater manuals