8

Boiler Heat Exchanger Descaling/Cleaning

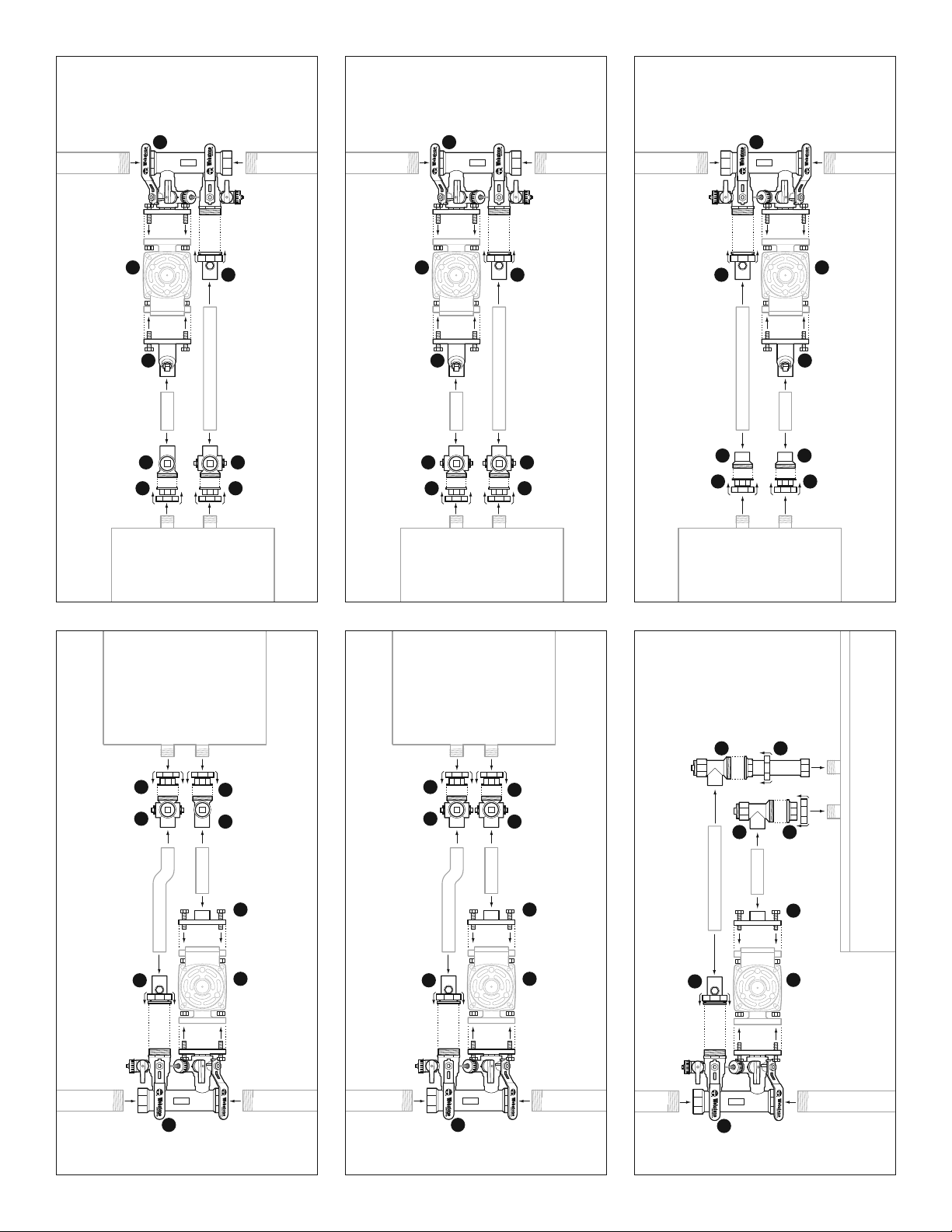

To Descale/Clean the boiler the following is needed:

• Boiler Manufacturer Maintenance Instructions

Should there be a discrepancy or conict with these instructions, follow the Boiler Manufacturer’s instructions.

• Descaling/cleaning solution

• 2 hoses

• Bucket

• Ability to activate the NBP System Circulator

T

O

B

U

C

K

E

T

T

O

B

U

C

K

E

T

SUPPLYRETURN

F

L

O

W

F

L

O

W

SUPPLYRETURN

SUPPLYRETURN

C

O

N

N

E

C

T

T

O

W

A

T

E

R

S

O

U

R

C

E

T

O

B

U

C

K

E

T

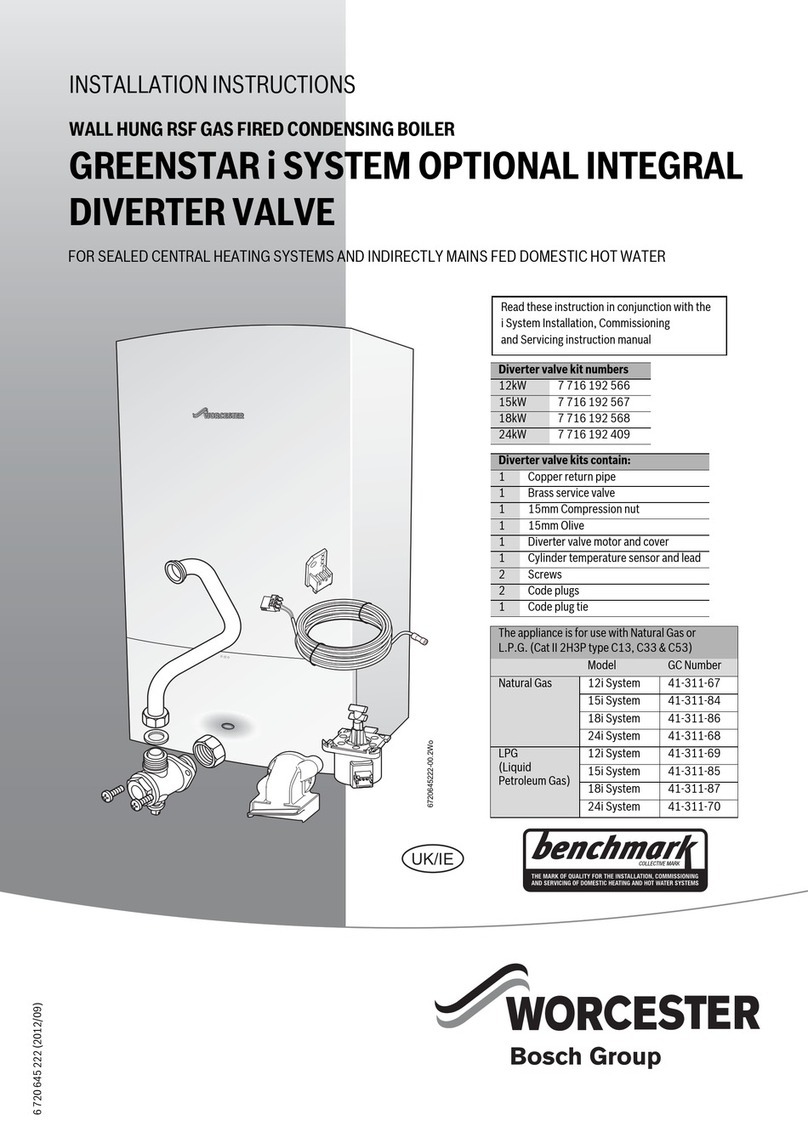

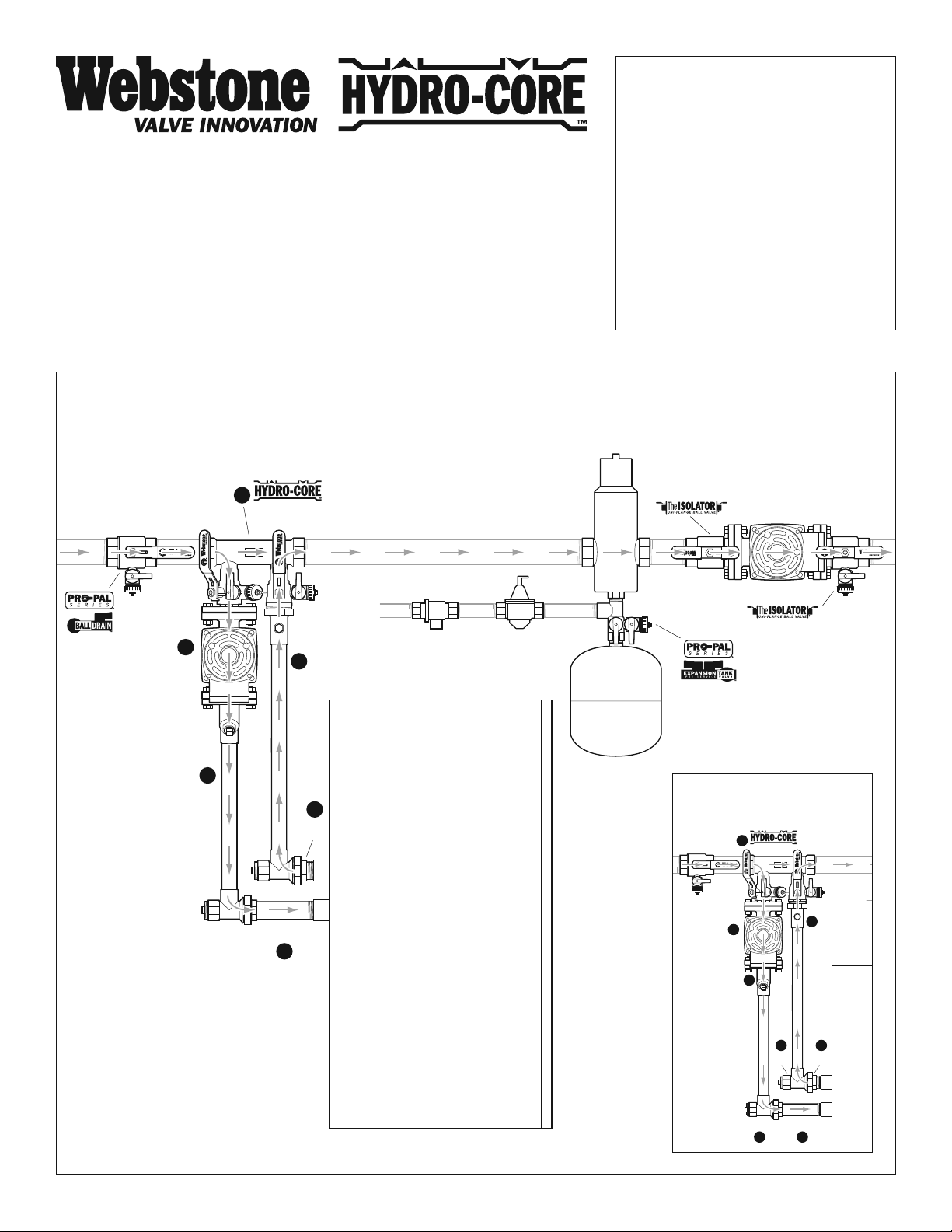

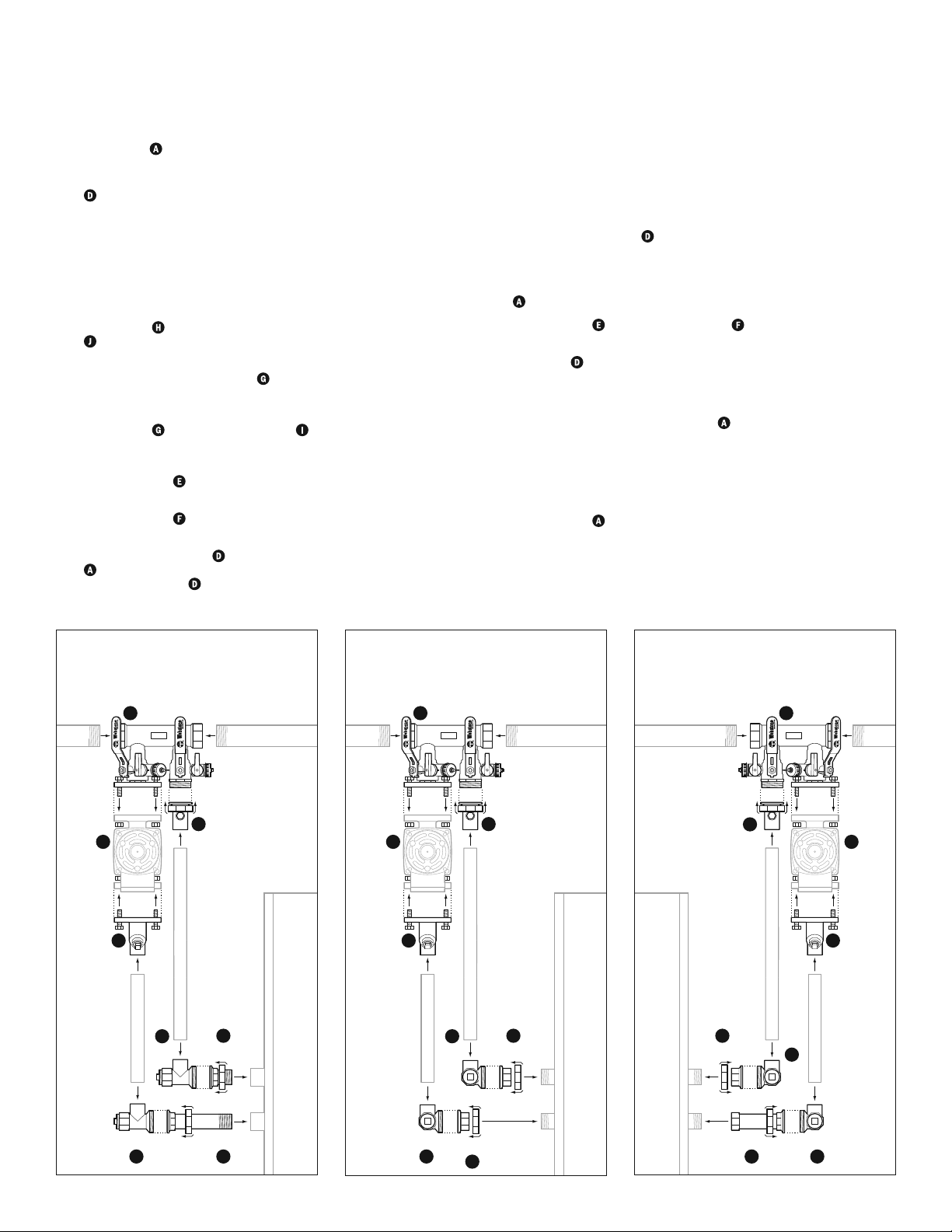

1. Turn the lever handles on both

Hydro-Core ball valves so that they

are parallel to the ange. The T-Flow

handle logo indicates the ow pattern

inside the valve. The logo should

indicate that ow can go through the

purging valve and both the supply

and return piped assemblies.

2. Remove both purging valve caps.

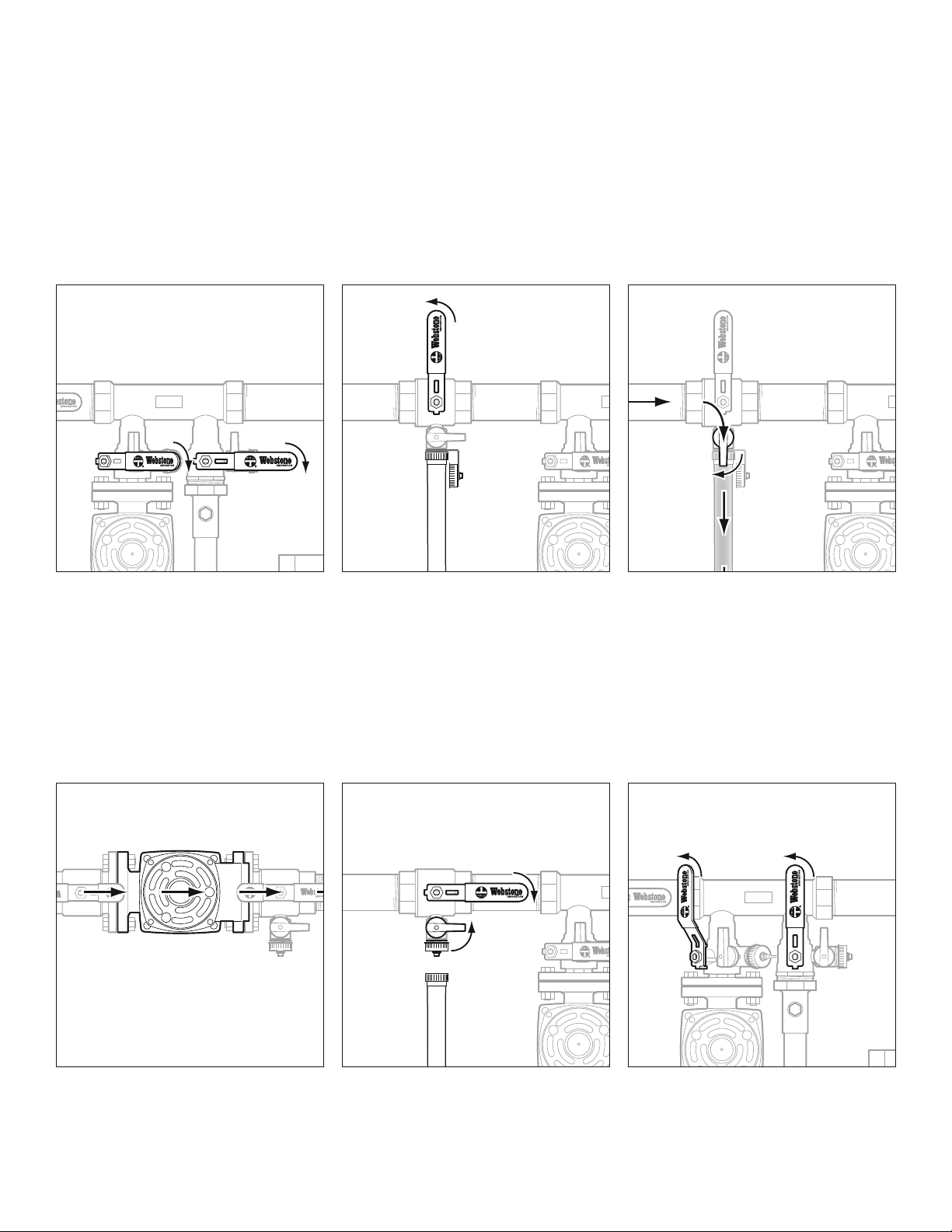

3. Connect one of the hoses to the

system return purging valve (located

above the ange connection).

4. Connect the other hose to the

system supply purging valve.

5. Fill a 5 gallon bucket with the boiler

manufacturer’s recommended

cleaning/descaling solution.

6. Place the ends of both hoses

into bucket of solution.

7. Turn the drain handles on both the

system return & system supply

purging valves into the open position

(drain handles parallel with the ange).

8. Turn on the circulator pump in the

NBP Loop and allow the solution to

ow into and out of the NBP System.

9. See boiler manufacturer maintenance

instructions to determine when

system is sufciently cleaned.

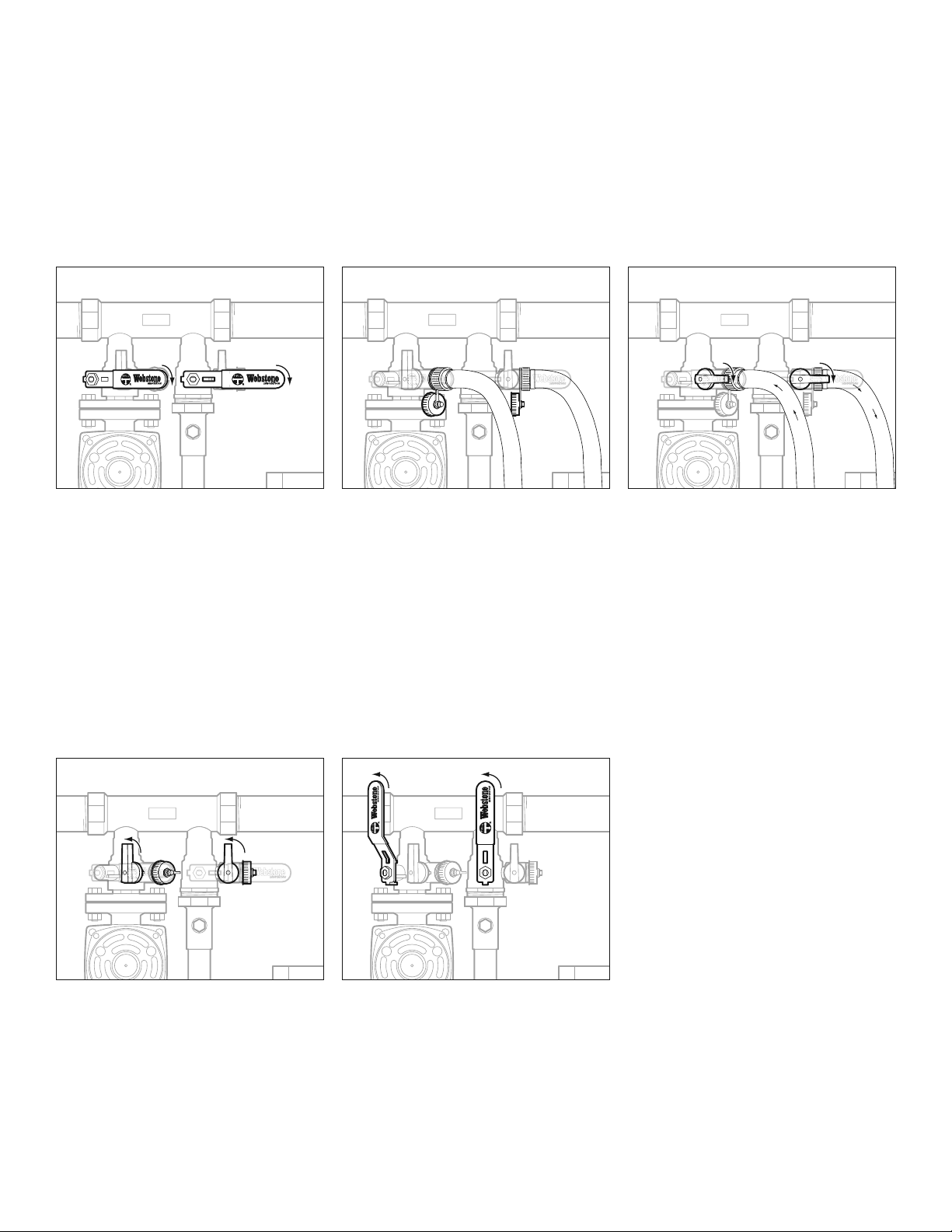

10. When boiler is sufciently cleaned,

remove the hose connected to the

system return’s purging valve from

the bucket (system return is the

side with the ange connection).

11. Connect system return purging

valve hose to a water source.

12. Turn on the water source and allow

water to ow into the circulator to

purge the entire loop with fresh water.

If needed, turn on the circulator pump

to force water through the system.

13. Once the solution has been

purged out in the bucket and the

drainage from the hose on the

system supply purging valve runs

clear, turn off the circulator.

14. Close the two purging valves, remove

the hoses, and replace the caps.

15. The boiler and NBP loop will now

be lled with clean fresh water.

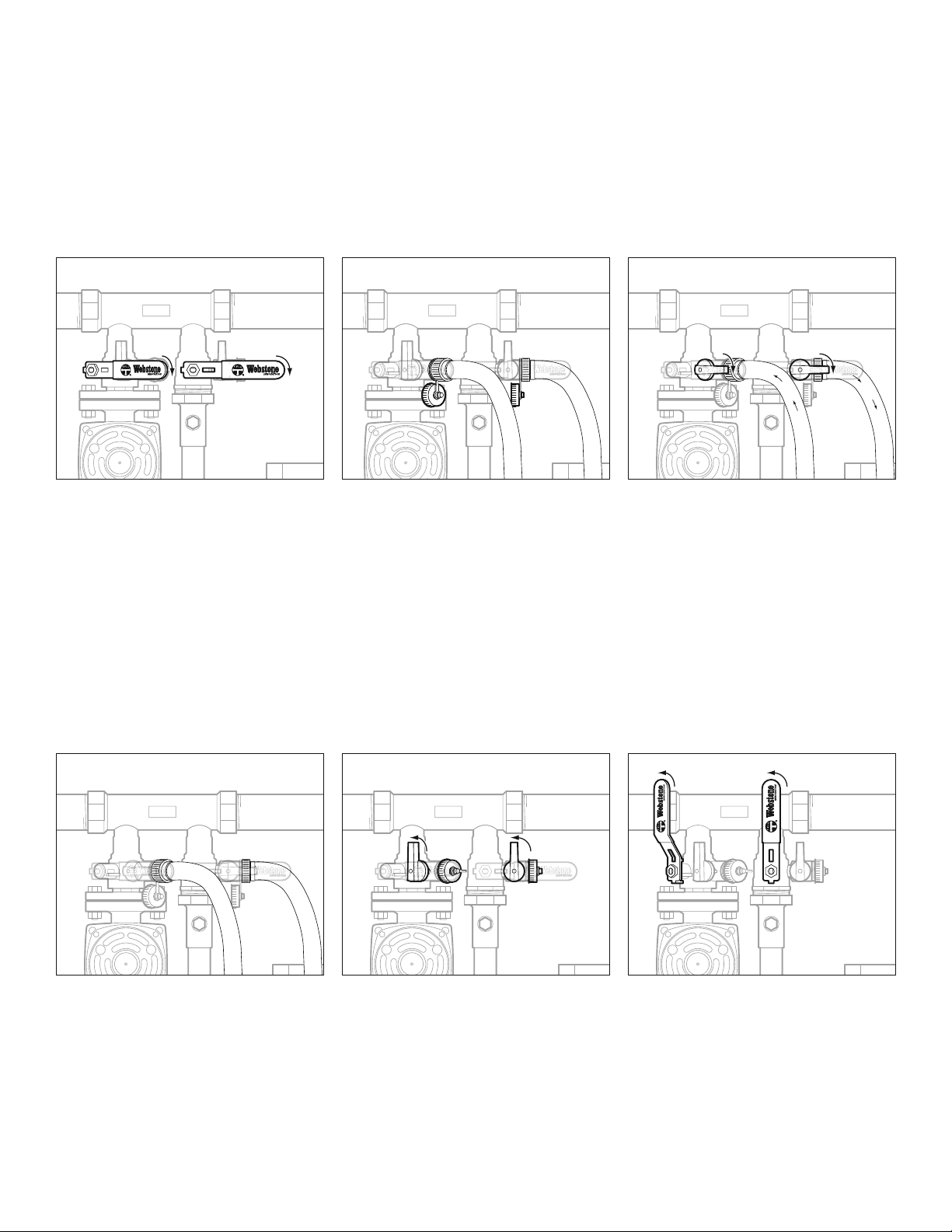

If a glycol solution is preferred,

repeat steps 2–14 above with glycol

rather than a descaling solution.

16. Return the lever handled ball valves

to their normal operating position

(handles perpendicular to the ange).

The Isolator®and Pro-Pal®are registered trademarks of Webstone Company, Inc.

© 2011 Webstone Company

HCM-0112