SmartDHOME MyOT User manual

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

1

Thank you for choosing the interface/actuator for OpenTherm boilers, the latest generation device that allows you to

monitor the performance of the OpenTherm boilers on which it is installed. Z-Wave certified, it is compatible with any

gateway that communicates through this protocol such as MyVirtuoso Home.

www.myvirtuosohome.com

www.smartdhome.com

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

2

General Safety Rules

Before using this device, certain precautions must be taken to reduce any risk of fire and/or personal injury:

1. Read all instructions carefully and follow all precautions contained in this manual. All direct connections to the

mains conductors must be made by trained and authorized technical personnel.

2. Pay attention to any danger indications placed on the device or contained in this manual highlighted with the

symbol .

3. Disconnect the device from the power supply or battery charger before cleaning it. For cleaning, do not use

detergents but only a damp cloth.

4. Do not use the device in gas saturated environments.

5. Do not place the device near heat sources.

6. Use only the original EcoDHOME accessories supplied by SmartDHOME.

7. Do not place the connection and/or power cables under heavy objects, avoid paths near sharp or abrasive

objects, prevent people from walking on them.

8. Keep out of reach of children.

9. Do not carry out any maintenance on the device but always contact the assistance network.

10. Contact the service network if one or more of the following conditions occur on the product and/or an accessory

(supplied or optional):

a. If the product has come into contact with water or liquid substances.

b. If the product has suffered obvious damage to the container.

c. If the product does not provide performance conforming to its characteristics.

d. If the product has undergone a noticeable degradation in performance.

e. If the power cord is damaged.

Note: In one or more of these conditions, do not attempt to make any repairs or adjustments not described in this manual.

Improper interventions could damage the product and force additional work to regain the desired operation.

WARNING! Any type of intervention by our technicians, which will be caused by an incorrectly performed installation or

by a failure caused by the customer, will be quoted and will be charged to those who purchased the system.

Provision for Waste Electrical and Electronic Equipment. (Applicable in the European Union and in other European

countries with the separate collection system).

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

3

This symbol found on the product or its packaging indicates that this product must not be treated as common

household waste. All products marked with this symbol must be disposed of through appropriate collection

centers. Improper disposal could have negative consequences for the environment and for the safety of human

health. Recycling of materials helps to conserve natural resources. For more information, contact the Civic Office in your

area, the waste collection service or the center where you purchased the product.

Disclaimer

SmartDHOME Srl cannot guarantee that the information regarding the technical characteristics of the devices in this

document are correct. The product and its accessories are subject to constant checks aimed at improving them through

careful research and development analyses. We reserve the right to modify components, accessories, technical data

sheets and related product documentation at any time, without notice.

On the website www.myvirtuosohome.com the documentation will always be updated.

Intended use

This device has been designed for the monitoring of OpenTherm boiler. Should it be improperly used and/or modifications

not authorized by our technical department, the company reserves the right to cancel the two-year warranty and provide

assistance upon payment of the service.

Description

The MyOT interface/actuator for OpenTherm boilers is a fundamental tool for achieving the objectives of Predictive

Maintenance, Adaptive Energy Management, qualitative data analysis and remote programming of parameters for proper

operation of the systems. It has communication capabilities both through a Sigfox M2M network, through a gateway

equipped with a transceiver with Z-Wave protocol, and through Wi-Fi. Through these protocols it will be possible to send

the information received to a big data management cloud system to evaluate, through a Predictive Maintenance process,

the implementation of automatic customer support processes.

Features

•Code: 01335-2080-00

•Z-Wave protocol: Series 500

•Supported Protocol: OpenTherm

•Power Supply: 5 Vdc

•Radio signal power: 1mW

•Radio frequency: 868.4 MHz EU, 908.4 MHz US, 921.4 MHz ANZ, 869.2 MHz RU.

•Range: Up to 30 meters in open field.

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

4

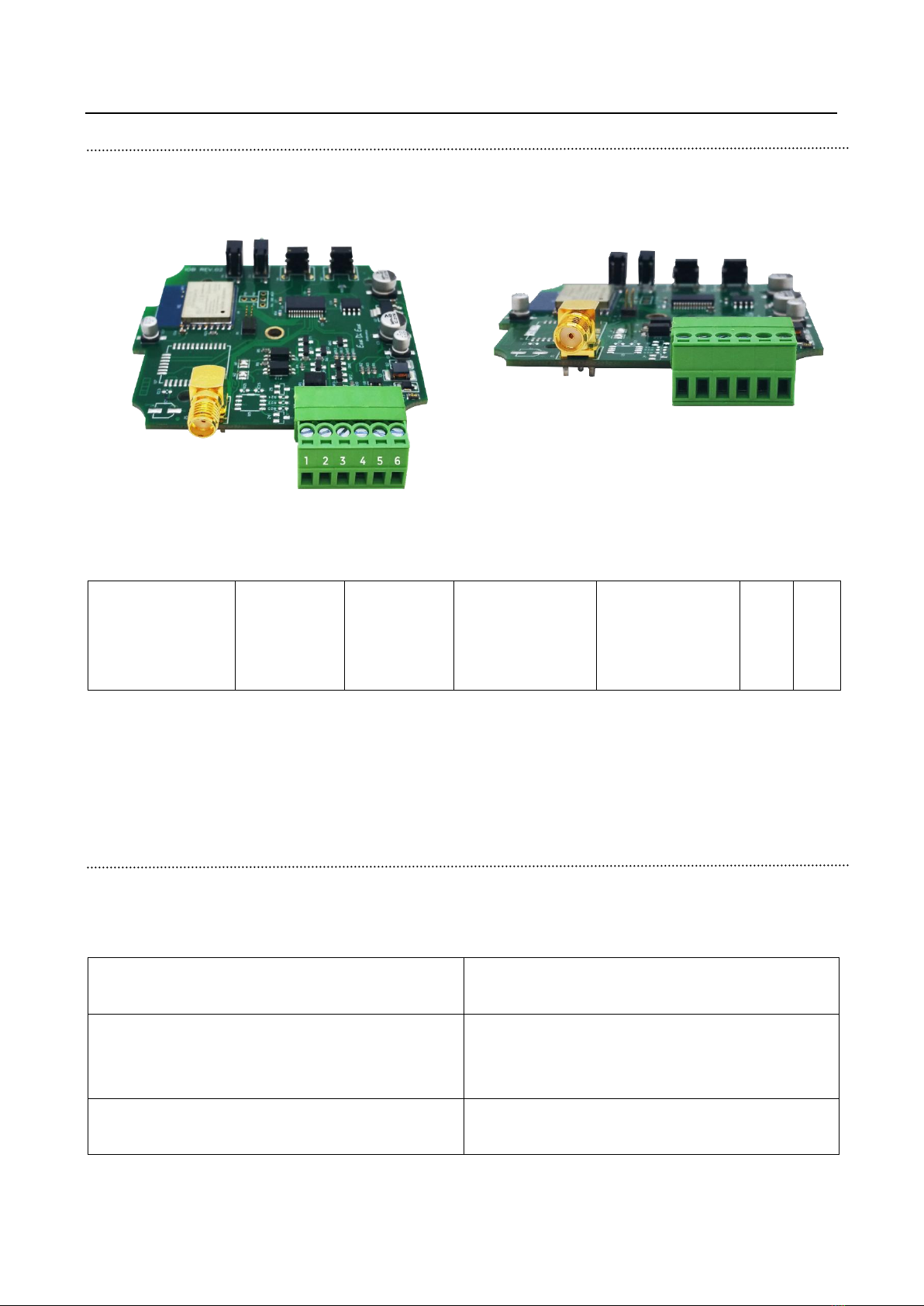

The parts of the MyOT interface/actuator for OpenTherm boilers

Figure 1: Buttons and LEDs

Functions Button: see Wi-Fi configuration and Z-Wave configuration sections.

Reset Button: reboot the device.

FUNCTIONS

RESET

GREEN

LED

RED

LED

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

5

Device Connections

To operate the device, you have to understand the utility of the green connector (see Tab. 1).

Figure 2: Aerial and green connector.

Tab. 1: green connector

Z-WAVE

AERIAL

1

OpenTherm

boiler

2

OpenTherm

boiler

3

OpenTherm

thermostat

4

OpenTherm

thermostat

5

GND

(-)

6

+5V

(+)

Here are some tips:

1. The OpenTherm connection for both the boiler and the chronothermostat has no polarization.

2. Pay close attention to the 5V power supply connection respecting the + and - as in table 1.

Warning LEDs

The IoB device has two signaling LEDs, one green and one red.

The green LED signals the status of the OpenTherm connection to the chronothermostat:

1 flashing every 3 seconds

The MyOT device is connected with the OpenTherm

Thermostat.

2 flashing every 3 seconds

MyOT works as if it were connected to a

chronothermostat with ON/OFF contact (traditional

system).

LED on and with 2 shutdowns every 3 seconds

MyOT in ON/OFF chronothermostat mode with heating

request in progress.

The flashing red LED indicates anomalies:

SIGFOX/ZWAV

E AERIAL

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

6

2 flashes + pause

No communication on the OpenTherm bus.

5 flashes + pause

No Wi-Fi connection and/or Internet communication.

The error report on Wi-Fi can concern both a lack of connection to the local network and a failure to connect to the

SmartDHOME server (lack of Internet, server temporarily unreachable, etc.).

Wi-Fi Configuration

ATTENTION! Although the device has multiple communication modes, they cannot be configured at the same time. Before

configuring the device, it is advisable to carefully choose the type of communication desired.

ATTENTION! To use the application, it is necessary to purchase a paid package of the IoB portal. Please contact the sales

representative or the company by sending an email to [email protected].

WI-FI Configuration using application (recommended)

For correct device configuration, you need to download and install the IoB application on your smartphone. Then set the

MyOT in programming mode by turning on the device and pressing the function key for about 3 seconds. When the button

is released, the device will enter configuration, signaling the status with alternating

flashing of the LEDs (red and green). This will create the “IoB” Wi-Fi to which you

will need to connect to proceed with the configuration

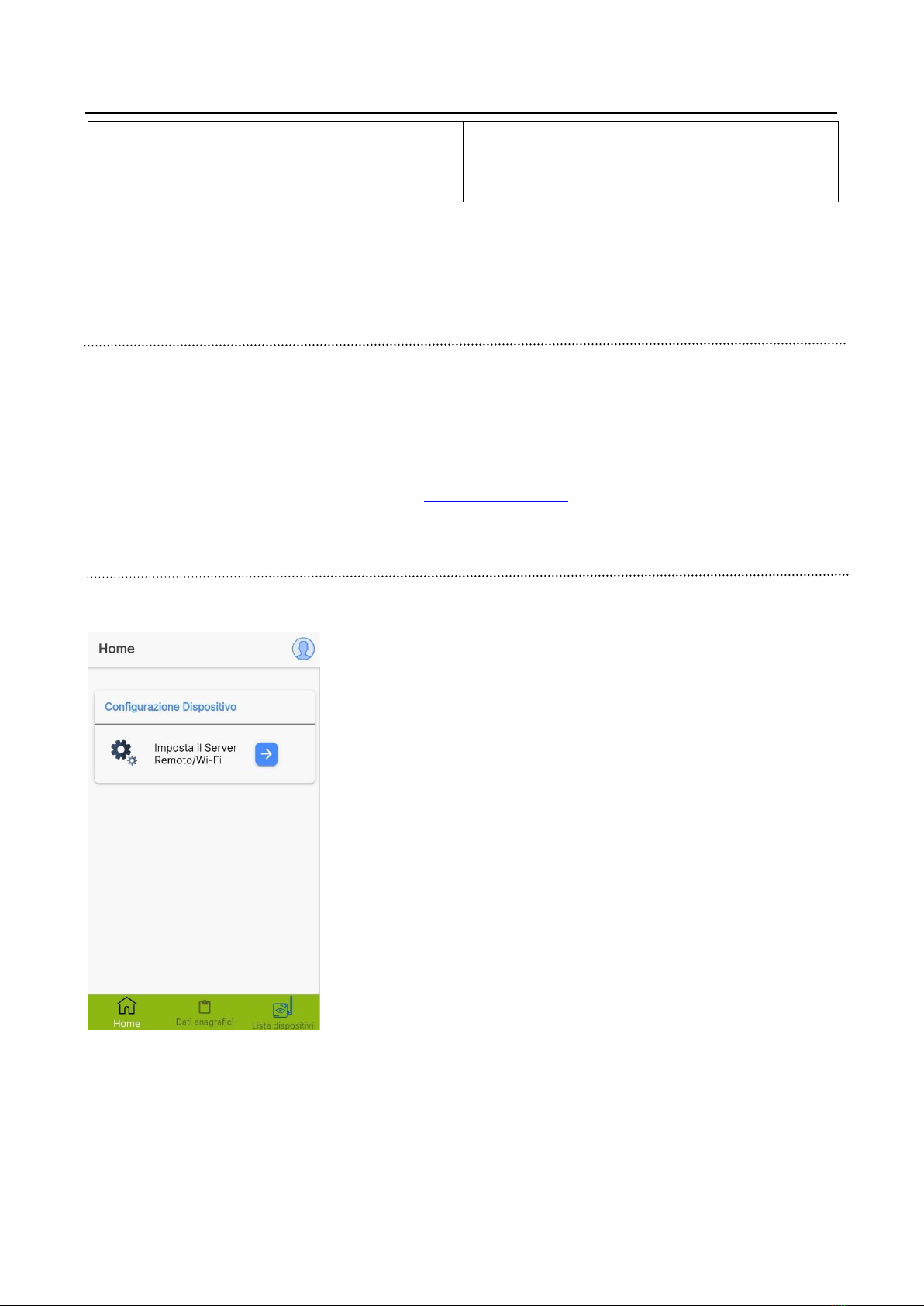

At this point it is necessary to open the application installed at the beginning. Once

entered, press Set the Remote Server/ Wi-FI on the Home screen (see image on

the left) and click on continue in the pop-up that will appear.

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

7

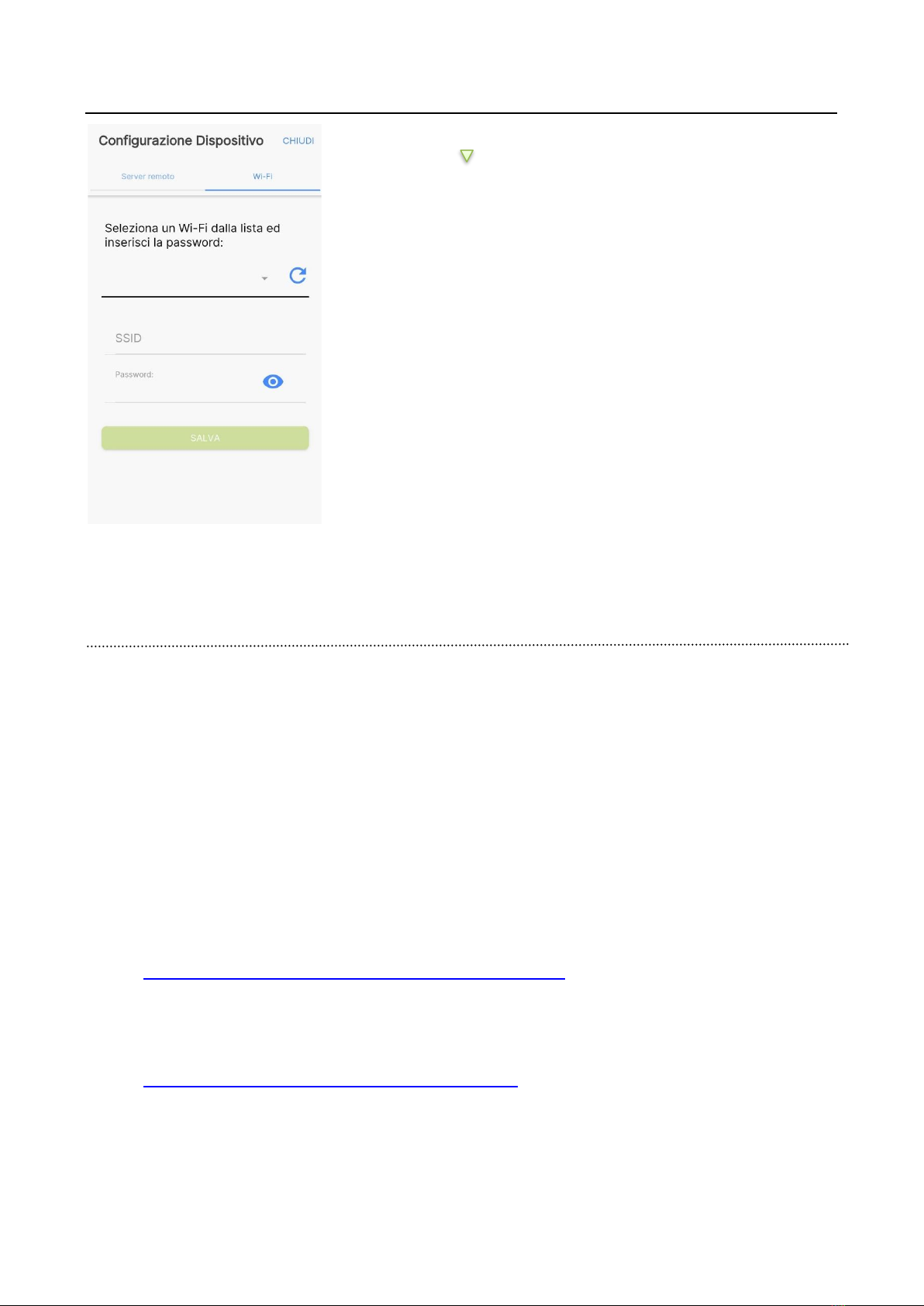

On the page that opens, move to the Wi-Fi section (see image).

Then press the key to view the list of Wi-Fi detected by the device. Select the

correct one, enter the password and press SAVE. If the Wi-Fi is not present or

visible, press the reload button in the list.

The operation was successful, a successful configuration message will be visible

at the bottom of the screen.

To end the process press the Close button at the top right. The LEDs on the MyOT

device will stop flashing alternately.

At the end of the programming procedure, the device will be operational again with the new configuration. In case of missing

programming, or to cancel it, press the RESET key and the device will restart.

Wi-Fi configuration without application (not recommended)

WARNING! Any type of intervention by our technicians, which will be caused by an incorrectly performed installation or

by a failure caused by the customer, will be quoted and will be charged to those who purchased the system.

If you have good experience with this type of device, you can configure MyOT without using the application:

1. Switch on the device.

2. Press the FUNCTIONS button for 3 seconds.

3. Release the button and verify that the device is in configuration mode. The LEDs will flash alternately (red and

green).

4. Connect your smartphone at the Wi-Fi network with SSID IoB (no password).

5. Once the connection has been established, open the navigation application and enter the following link and

press enter:

http://192.168.4.1/sethost?host=iobgw.contactproready.it&port=9577

A white screen with the inscription OK will be displayed.

6. Open the browser and enter the following second link:

http://192.168.4.1/setwifi?ssid=nomerete&pwd=passwordwifi

Insert instead of nomerete the SSID of the network you want to connect to. Enter instead of passwordwifi the

Key of the Wi-Fi chosen.

A white screen with the inscription OK will be displayed.

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

8

7. Open the browser and enter the following third link:

http://192.168.4.1/exit

A white screen with the inscription EXIT will be displayed.

Z-Wave Configuration

WARNING! Although the device has multiple communication modes, they cannot be configured at the same time. Before

configuring the device, it is advisable to carefully choose the type of communication desired.

Inclusion/Exclusion in a Z-Wave network

If you have the Z-Wave version, you can include or exclude the MyOT device in a Z-Wave network. To do this, first of all

consult the manual of your gateway to learn how to include and exclude devices. After that it is possible to include/exclude

the MyOT device by pressing the function button for 8 seconds.

Data Mapping

MyOT device supports the following command class:

•COMMAND_CLASS_ASSOCIATION

•COMMAND_CLASS_ASSOCIATION_GRP_INFO

•COMMAND_CLASS_BASIC

•COMMAND_CLASS_SWITCH_BINARY

•COMMAND_CLASS_THERMOSTAT_SETPOINT

•COMMAND_CLASS_SENSOR_MULTILEVEL

•COMMAND_CLASS_METER

•COMMAND_CLASS_FIRMWARE_UPDATE_MD_V2

•COMMAND_CLASS_SECURITY

These are described in the following sections.

COMMAND_CLASS_BASIC

This class can be used to switch the boiler on/off (or to know its current status). However, it must be specified that the self-

report of this CC has not been implemented. It is therefore recommended to use the CC

COMMAND_CLASS_SWITCH_BINARY.

COMMAND_CLASS_SWITCH_BINARY

This CC can be used to switch the boiler on/off (or to know its current status). Furthermore, if, due to an external cause,

the boiler switches on/off independently, an auto-report is activated at node 1 of the network.

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

9

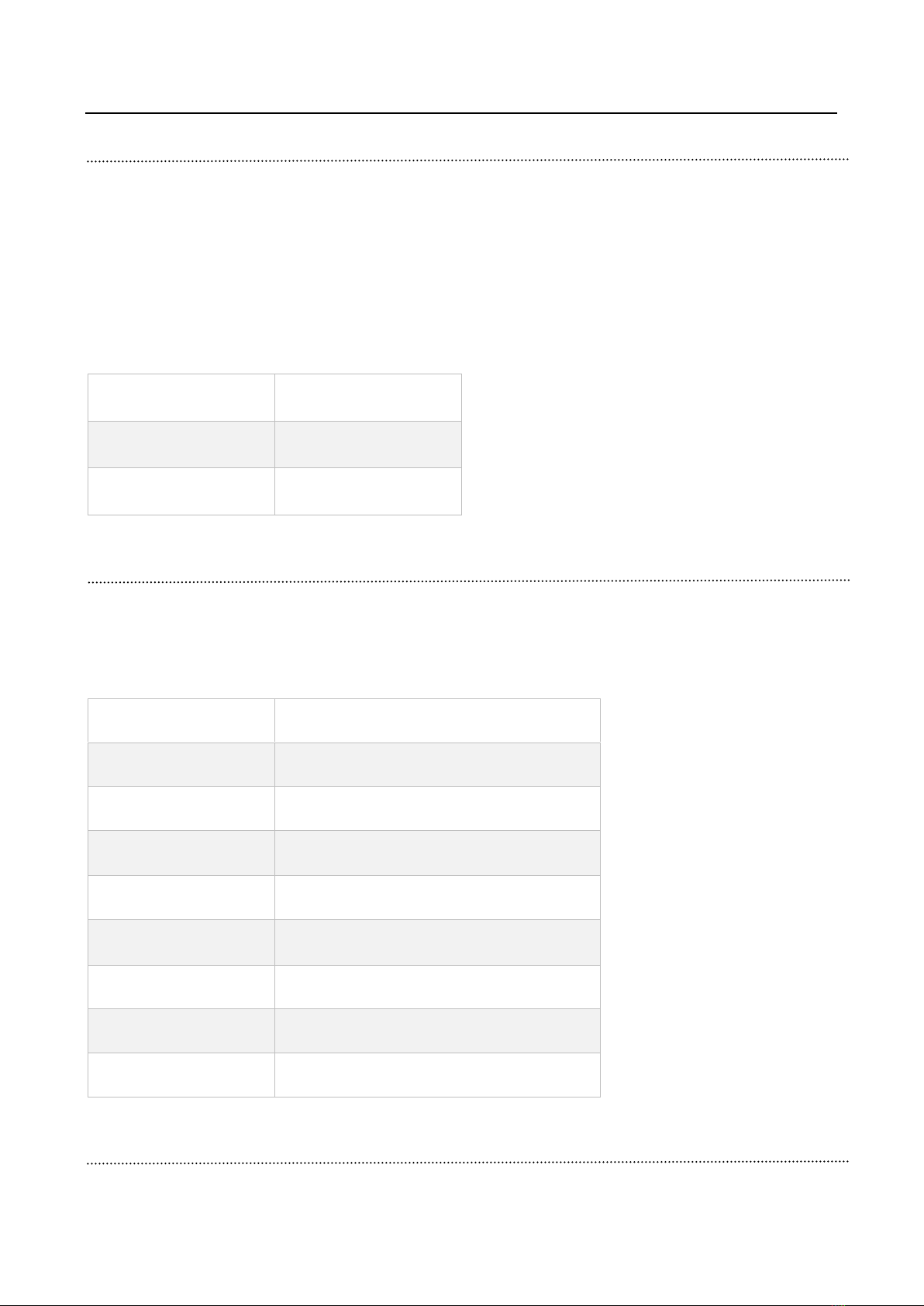

COMMAND_CLASS_THERMOSTAT_SETPOINT

This CC can be used to manage the boiler setpoints.

N.B. The maximum and minimum value of the setpoints are displayed with the COMMAND_CLASS_CONFIGURATION.

This was done to support a non-exclusion/inclusion boiler hot swap. It is also important to know that setting the heating

setpoint to 0 is equivalent to setting it to the maximum reported by the boiler. Otherwise, setting the DHW setpoint to 0 is

equivalent to setting it to 40 ° C. The map between the 'mode' and the setpoint is as follows, while the unit of each

measurement is correctly communicated in the command class report message.

Mode (dec)

Measure

1

Heating setpoint

13

DHW setpoint

COMMAND_CLASS_SENSOR_MULTILEVEL

This CC provides a series of measurements which are obtained from the boiler.

Below is the mapping between the "sensor type" and the "supplied measurement". The unit of each measure is

communicated as specified in the CC report message.

Sensor type (dec)

Measure

9

Heating circuit pressure

19

Total DHW

23

Return water temperature

56

DHW Flow

61

Boiler heating modulation

62

Boiler water temperature

63

DHW Temperature

65

Exhaust fumes temperature

COMMAND_CLASS_CONFIGURATION

This CC provides a series of measurements which are obtained from the boiler.

Below is the mapping between the “Parameter number” and the supplied “Parameter”.

MyOT interface/actuator for OpenTherm Boilers

User manual and data sheet

10

Parameter

number (dec)

Parameter

Bytes

Mode (Read/

Write)

Sign

90

ID LSB

4

L

No

91

Version

2

L

No

94

ID HSB

4

L

No

95

Report rate (minutes, 0: continuous)

4

L

No

1

Max setpoint of the boiler

2

L

No

2

Min boiler setpoint

2

L

No

3

Setpoint Max DHW

2

L

No

4

Setpoint Min DHW

2

L

No

30

Summer mode (0: no 1: yes)

1

L/S

No

31

Enabling DHW (0: no 1: yes)

1

L/S

No

10

Error flag if present (0 otherwise)

2

L

No

11

Error code if present (0 otherwise)

2

L

No

COMMAND_CLASS_SECURITY

MyOT device supports unauthenticated S0 and S2 security.

Warranty and customer support

Visit our website at the link:http://www.ecodhome.com/acquista/garanzia-eriparazioni.html

If you encounter technical problems or malfunctions, visit the site:

http://helpdesk.smartdhome.com/users/register.aspx

After a short registration you can open a ticket online, also attaching images. One of our technicians will answer you as

soon as possible.

This manual suits for next models

1

Table of contents

Popular Boiler Supplies manuals by other brands

TriangleTube

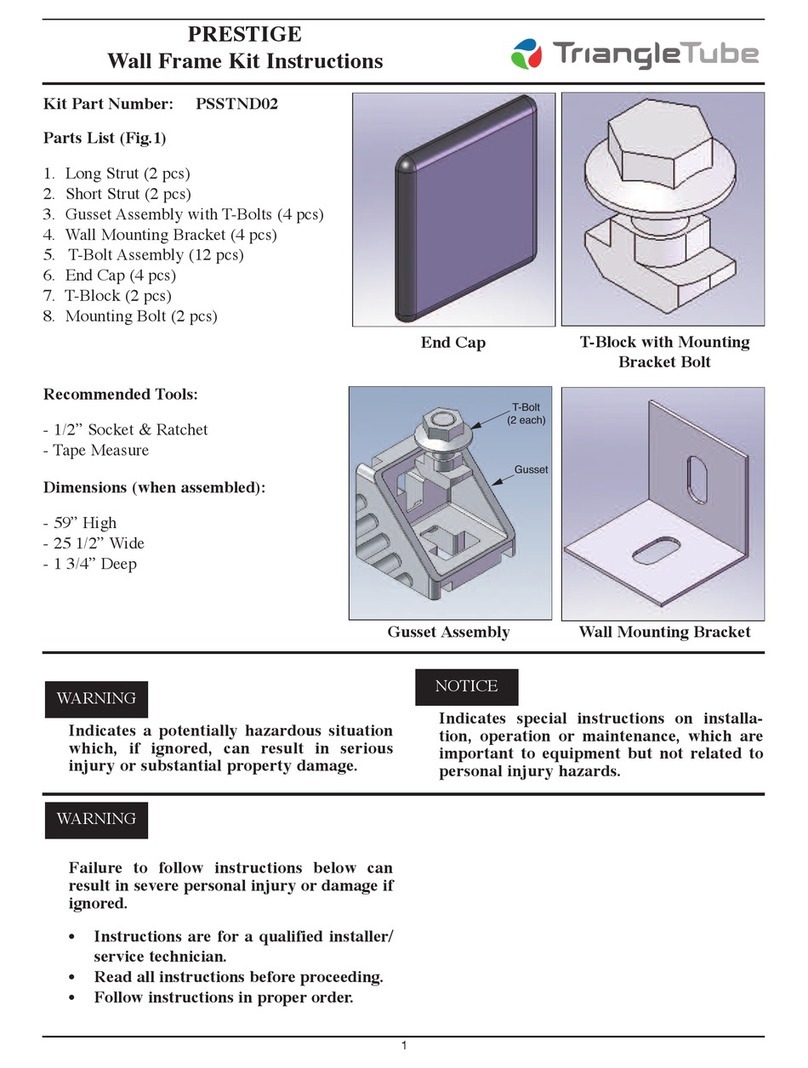

TriangleTube PSSTND02 instructions

Regulus

Regulus 13899 Installation and operation instructions

TriangleTube

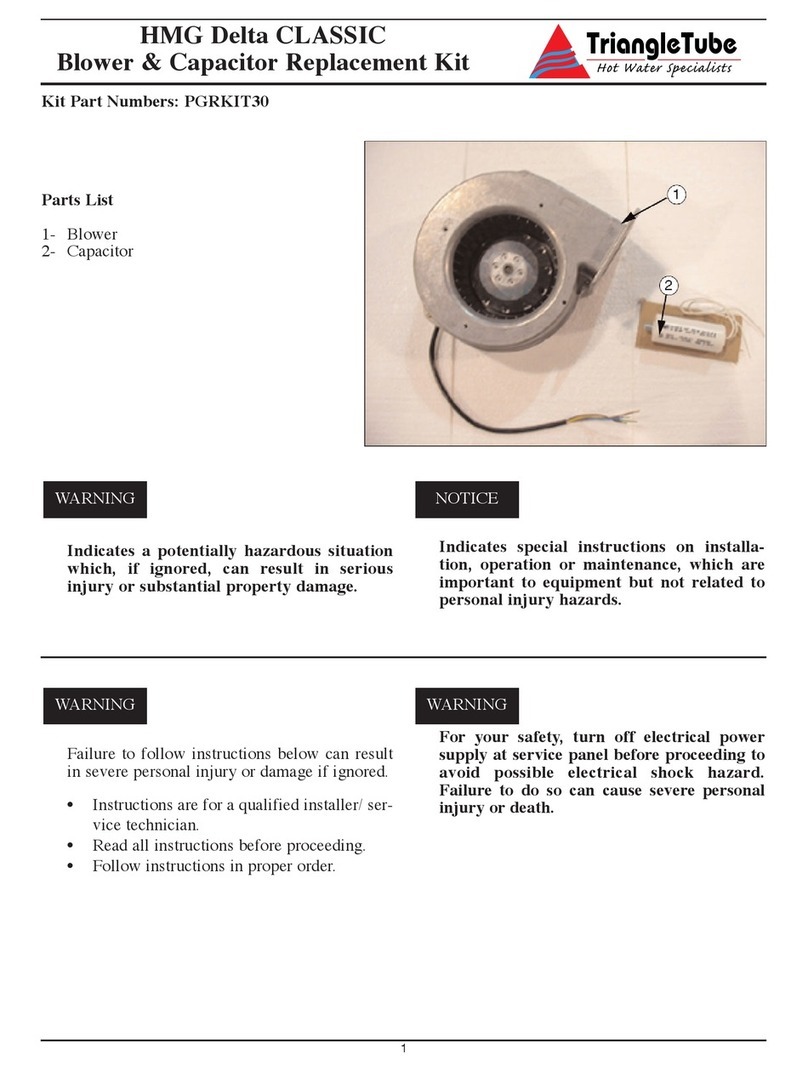

TriangleTube PGRKIT30 Assembly instructions

Immergas

Immergas 3.015266 quick start guide

Miura

Miura CMU-324HE Installation and operation manual

Watts

Watts tekmar 294EXP Installation, operation and maintenance manual