5

2 Safety

This section includes general safety notes for handling the

product. Specic warnings for specic tasks and situations

are given at the appropriate places in the documentation.

Failure to observe the safety notes and warnings can result

in physical injury and property damage.

2.1 General safety note

– Before carrying out any work on the product, it must be

switched o and free of dangerous voltage (see section

2.2). This reduces the risk of electric shocks or arcing.

– The product is not suitable for use in potential-

ly explosive atmospheres. Work on the PV Next

String Combiner Box can produce sparks that can ignite

a potentially explosive air mixture.

– The approved environmental conditions for the installa-

tion site must be observed.

– The operator must ensure that the product is not acces-

sible to unauthorised persons.

– No combustible or electrically conductive materials may

be stored inside the enclosure.

– The PV Next String Combiner Box must not be operated

with damaged cables or connectors, as they may cause

electric shock, short circuit or re. Do not touch dam-

aged areas and ensure the system is not live. Have the

system checked and repaired by a specialist.

– Fuse links must not be removed or inserted under load

as this may result in life-threatening arcing.

– Suitable personal protective equipment must be worn

during all work on the product.

– During installation and maintenance work, make sure

that no moisture can penetrate into the enclosure.

– The PV system must be designed in such a way that all

components are operated exclusively within their per-

missible operating range.

– Local installation regulations must be observed.

– If a fault in the product cannot be remedied by the meas-

ures described in these instructions, you must return the

product to Weidmüller. Weidmüller does not provide a

guarantee if the product has been tampered with.

– The outputs of the PV Next String Combiner Box must

never be connected to the inverter (load) while it is live.

Even when the inverter is switched o, charging the in-

ternal capacitors can lead to dangerous arcing.

– Never touch exposed live parts or cables.

– Do not disconnect PV connectors under load.

– Disconnect the inverter before carrying out any main-

tenance work. Inverters contain capacitors that store

life-threatening voltages. Wait until the capacitors are

discharged.

– Follow the operating instructions of the inverter you are

using. Contact the manufacturer for more information

and advice.

2.2 Switching off and on safely

DANGER

Risk of fatal electric shock when touch-

ing live DC cables and live parts in the

opened product!

PV systems can generate dangerous voltag-

es. Before starting work, ensure that the PV

system and devices are disconnected from the

mains and from the PV generators.

►Before carrying out any work on the prod-

uct, it must be disconnected from the power

supply and secured against being switched

on again.

Switching off safely

►Make sure there is no voltage before you open the

PV Next String Combiner Box. Proceed exactly in this

order:

1. Switch o the inverter.

2. Switch the switch-disconnector of the PV Next

String Combiner Box or of the inverter to the o-position.

3. Disconnect all string cables to the inputs of the PV Next

String Combiner Box. Both the positive and negative

connections must be disconnected.

You can now open the PV Next String Combiner Box.

Switch on once all work has been completed:

►Close the PV Next String Combiner Box with the cover.

►Check the voltage, polarity and absence of earth faults

of the string cables.

►Reconnect the string cables to the connectors on the

underside of the PV Next String Combiner Box.

– Pay attention to the correct polarity and assignment

of the string cables.

– Only connect string cables with identical open-circuit

voltages.

►Switch the inverter on again using the switch-disconnec-

tor on the output side.

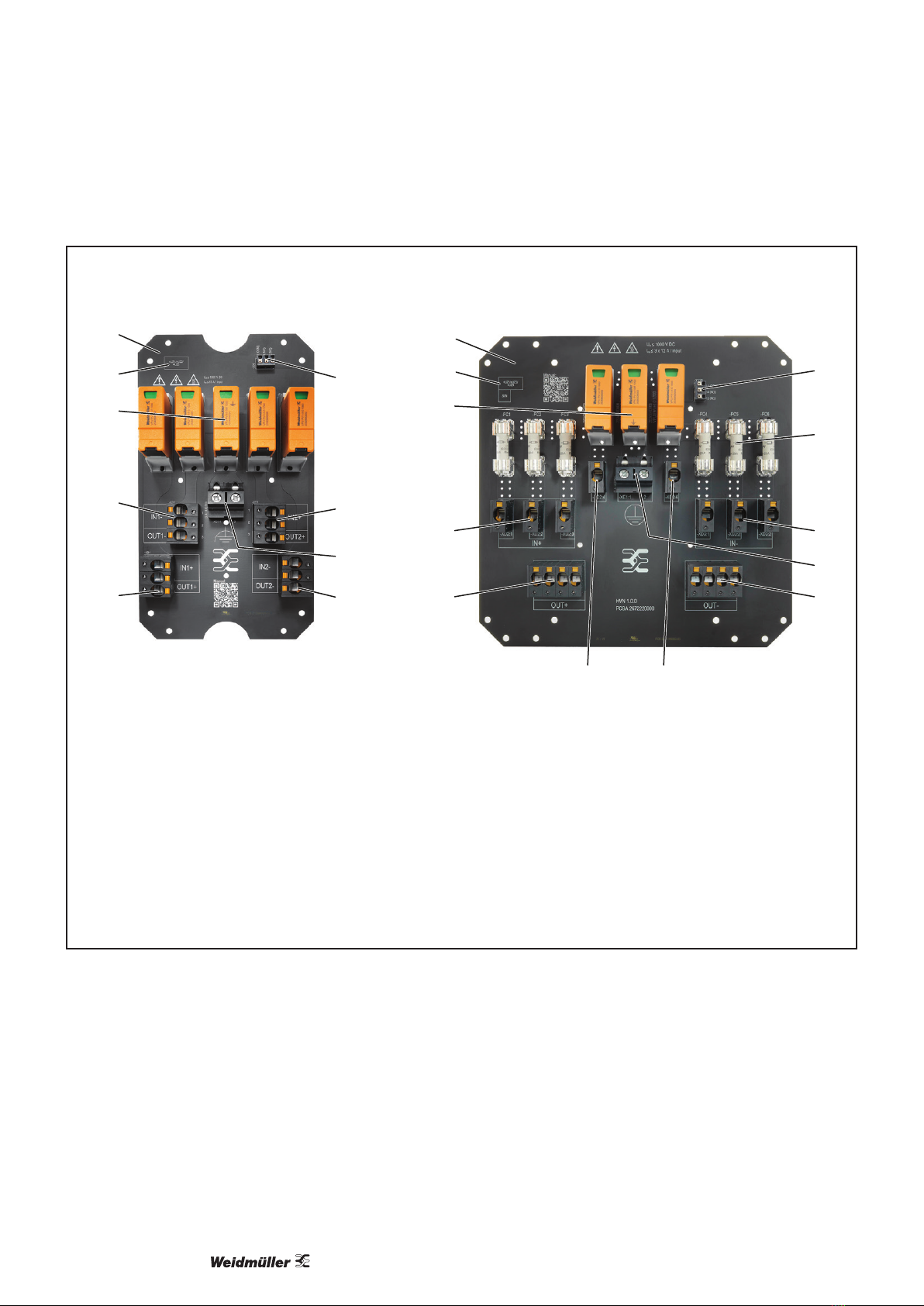

2.3 Intended use

The PV Next String Combiner Box is intended to be in-

stalled in the DC connection between photovoltaic modules

and inverters. Any other use is considered improper. Mod-

ications to the product and the installation of further com-

ponents are only permitted if recommended by Weidmüller.

Observance of the documentation is also part of the intend-

ed use.

7770019215/15.10.2021