DGSL

Festo AG & Co. KG

Ruiter Straße 82

73734 Esslingen

Germany

+49 711 347-0

www.festo.com

Operating instructions

(Original instructions)

8067708

2017-01g

[8067710]

Mini slide DGSL English...............................................

Note

Installation and commissioning are to be carried out only by qualified personnel

in accordance with the operating instructions.

1 Further applicable documents

For all available product documentation èwww.festo.com/pk

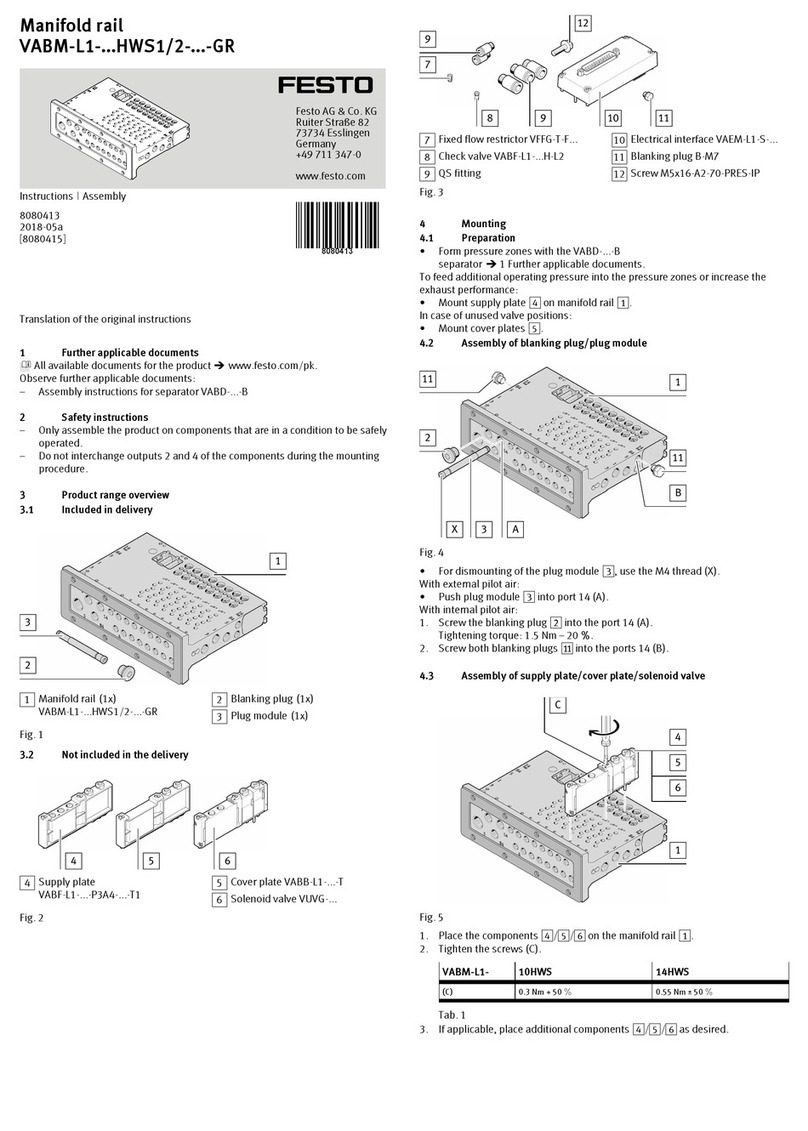

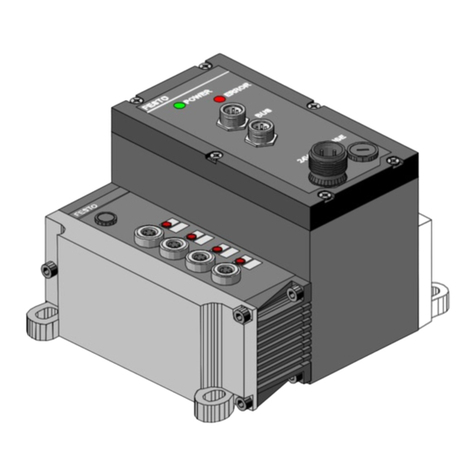

2 Operating elements and ports

1 5

8

6

739

aJ

2 3 4

aAaBaC

1Cushioning component:

– Elastic (DGSL-…-E/-P/-P1

– Hydraulic (DGSL-…-Y3/-Y11)

– None (DGSL-…-N)

2Drill hole for mounting the mini

slide (lies concealed)

3Thread with centring recess for

mounting the effective load

(centring sleeves included in scope

of delivery)

4Slide/bearing guide

5Yoke plate

6Fixed stop

7Thread with centring recess for

mounting the mini slide

8Piston rod

9Slots for proximity sensor

aJ Compressed air supply port

(retracting)

aA Compressed air supply port

(extending)

aB Compressed air supply port

(extending) with blanking screw1)

aC Compressed air supply port

(retracting) with blanking screw1)

1) In condition on delivery

Fig. 1

3 Function and application

The DGSL mini slide is a non-rotating single-piston drive with roller bearing guide.

When the compressed air supply ports are pressurized reciprocally, the slide

moves back and forth. The slide is braked by elastic cushioning components in the

case of DGSL-…-E/-P/-P1 and by hydraulic shock absorbers in the case of

DGSL-…-Y3/-Y11. In the case of DGSL-…-N, cushioning elements must be attached

for both end positions (è6.2 DGSL-…-N without cushioning components).

The DGSL mini slide is intended for the space-saving transport of masses. A high

degree of positioning accuracy is achieved.

4 Transport and storage

Take into account the weight of the DGSL.

Depending on the version, the DGSL can weigh up to 7 kg.

Ensure storage conditions as follows:

– Short storage times and

– Cool, dry, well-shaded, corrosion-resistant locations.

5 Requirements for product use

Note

Malfunctions will occur if the device is incorrectly used.

Make sure that the specifications contained in this chapter are adhered to at

all times.

Observe the warnings and notes on the product and in the relevant operating

instructions.

Compare the limit values in these operating instructions with those of your

application (e.g. forces, torques, temperatures, loads, speeds).

Operation of the product in compliance with the relevant safety regulations is

contingent on adherence to the load limits.

Take into consideration the ambient conditions at the location of use.

Corrosive environments will reduce the service life of the product (e.g., ozone).

Comply with the regulations of the workers’ compensation trade association,

the German Technical Control Board (TÜV), of the VDE or relevant national

regulations.

Use the product in its original status, without any unauthorised product

modifications.

Remove all transport packaging, such as foils, caps, cardboard.

Exception:

– possibly covers in the pneumatic connections.

The material used in the packaging has been specifically chosen for its

recyclability (exception: oiled paper = residual waste).

Make sure there is a supply of correctly prepared compressed air

(è13 Technical data).

Maintain the selected medium for the total service life of the product. Example:

Always use non-lubricated compressed air.

Pressurize your entire system slowly. There will then be no uncontrolled

movements.

For slow start-up pressurisation, use on-off valve HEL.

Take the tolerance of the tightening torques into account. Unless otherwise

specified, the tolerance is ± 20 %.

6 Installation

Note

For vertical installation:

Make sure that the slide has reached a stable position when it comes to

astop (e.g., the lowest point or secured with external stops).

6.1 Installation, mechanical

Handle the DGSL with care so that the slide guide is not damaged.

This could impair the roller bearing function.

Leave all screws and threaded bolts in their original states, unless you are

requested to modify them in these instructions.

For safety reasons, they are fixed with a screw locking agent.

Make sure there is sufficient space

for the pneumatic connections, the

control sections and for possible

replacement of the cushioning

component and proximity switches.

Fig. 2

Make sure that the device is installed

free of distortion and deflection.

Fig. 3

Installing the effective load

Note

If pins strike against the yoke plate, the

mechanical connector can be destroyed.

Push a metal plate between the yoke plate and

the housing as a counterholder.

Then press the required pins into the yoke

plate. Fig. 4