Part Number 550-110-639/0703

4

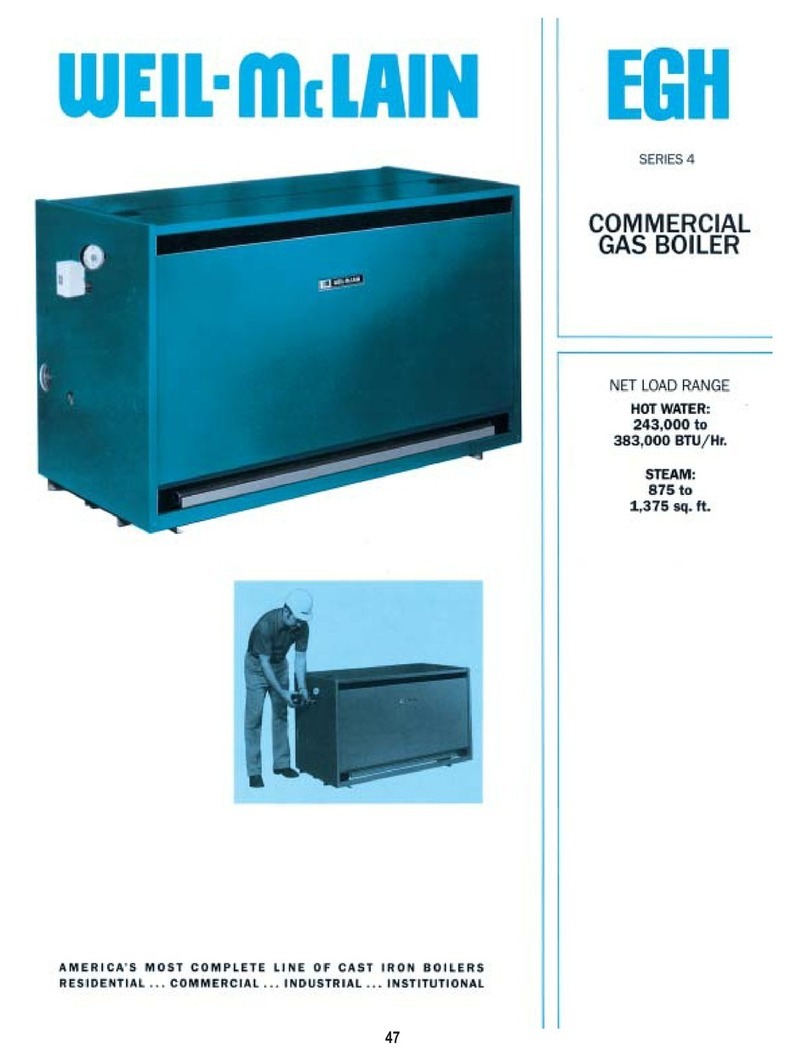

EG, PEG, EGH GAS-FIRED BOILERS — SERIES 4 — BOILER MANUAL

Chimney or vent requirements

(also refer to Breaching erection, Page 8)

VentingmustbeinstalledaccordingtoPart7,Ventingof

Equipment, of National Fuel Gas Code ANSI Z223.1-

latest edition and applicable building codes. Canadian

installationsmust comply withCAN/CSA B149.1 or.2

InstallationCodes.

Minimumchimneyorventsizesareonpage27ofthese

instructions. A chimney or vent without a listed cap

shouldextendatleast3feetabovethehighestpointwhere

it passes through a roof of a building and at least 2 feet

higherthananyportionofabuildingwithinahorizontal

distanceof 10feet. Achimney orvent must not extend

lessthanthosedistancesstatedabove.

A lined chimney is preferred and must be used when

requiredbyfederal,provincial,territorial,state,orlocal

building codes. Vitreous tile linings with joints that

prevent retention of moisture and linings made of

noncorrosive materials are best. Advice for flue

connectionsandchimneyliningscanbeobtainedfrom

localgasutility.Type“B”doublewallmetalventpipeor

singlewallventpipemaybeusedasaliner.

Cold masonry chimneys, also known as outside

chimneys, typically have one or more walls exposed to

outsideair.

Whenanyatmosphericgas-firedboilerwithautomatic

ventdamperisventedthroughthistypeofchimney,the

potentialexistsforcondensationtooccur.Condensation

candamageamasonrychimney.

Weil-McLain recommends the following to prevent

possibledamage:

1. Line chimney with corrosion-resistant metal liner

such as AL29-4C® single wall stainless steel or B-vent.

SizelinerperNationalFuelGasCodeANSIZ223.1-latest

edition.

2. Providedraintraptoremoveanycondensate.

Inspect existing chimney or vent before

installingboiler.Failuretocleanorreplace

perforated pipe or tile lining will cause

severeinjuryordeath.

Donotalterboilerdrafthoodorplaceany

obstruction or non-approved damper in

the breeching of vent system. CSA

certificationbecomesvoid.Fluegasspillage

andcarbonmonoxideemissionswilloccur

causingseverepersonalinjuryordeath.

Wheretwoormoregasappliancesventintoacommon

chimneyorvent,equivalentareashouldbeatleastequal

totheareaoftheventoutletonthelargestapplianceplus

50percentoftheareaoftheventoutletontheadditional

appliance.

When removing boiler from common venting

system Failure to follow all instructions listed below can cause flue gas

spillage and carbon monoxide emissions, resulting in severe

personal injury, death or substantial property damage.

At the time of removal of an existing boiler, the following steps shall be

followedwitheachapplianceremainingconnectedtothecommonventing

systemplacedinoperation,whiletheotherappliancesremainingconnected

tothecommonventingsystemarenotinoperation.

a. Seal any unused openings in the common venting system.

b. Visuallyinspecttheventingsystemforproper size andhorizontalpitchand

determine there is no blockage or restriction, leakage, corrosion and other

deficiencieswhich could cause anunsafe condition.

c. Insofar as is practical, close all building doors and windows and all doors

between the space in which the appliances remaining connected to the

common venting system are located and other spaces of the building.Turn

onclothes dryers and any appliance not connected to the common venting

system.Turnonanyexhaustfans,suchasrangehoodsandbathroomexhausts,

so they will operate at maximum speed. Do not operate a summer exhaust

fan.Close fireplacedampers.

d. Place in operation the appliance being inspected. Follow the lighting

instructions.Adjustthermostatsoappliancewilloperatecontinuously.

e. Test for spillage at the draft hood relief opening after 5 minutes of main

burner operation. Use the flame of a match or candle, or smoke from a

cigarette,cigarorpipe.

f. After it has been determined that each appliance remaining connected to

the common venting system properly vents when tested as outlined above,

returndoors, windows, exhaustfans, fireplace dampers, andany other gas-

burningappliancetotheirpreviousconditionsofuse.

g. Anyimproperoperationofthecommonventingsystemshouldbecorrected

sotheinstallationconformswiththeNationalFuelGasCode,ANSIZ223.1-

latest edition. When resizing any portion of the common venting system,

the common venting system should be resized to approach the minimum

size as determined using the appropriate tables in Part 11 in the National

Fuel Gas Code, ANSI Z223.1-latest edition.

CanadianinstallationsmustcomplywithCAN/CSAB149.1or.2Installation

Code.

Select the boiler location

• Considerallconnectionstoboilerbeforeselectingalocation.

• Boilermustbeinstalledsogascontrolsystemcomponentsareprotected

fromdippingorsprayingwaterorrainduringoperationorservice.

• Non-combustiblefloorONLY.See“Boilerfoundation”,Page5.

Toavoidpersonalinjury,deathorpropertydamage,keepboiler

area clear and free from combustible materials, gasoline and

otherflammablevaporsandliquids.

Installation

(continued)

1