1

Contents

1. MEMORY SWITCH ..................................................................................................................... 1

1-1

S

TARTAND

C

HANGE

..................................................................................................................... 1

1-2

F

UNCTION

L

IST

.............................................................................................................................. 3

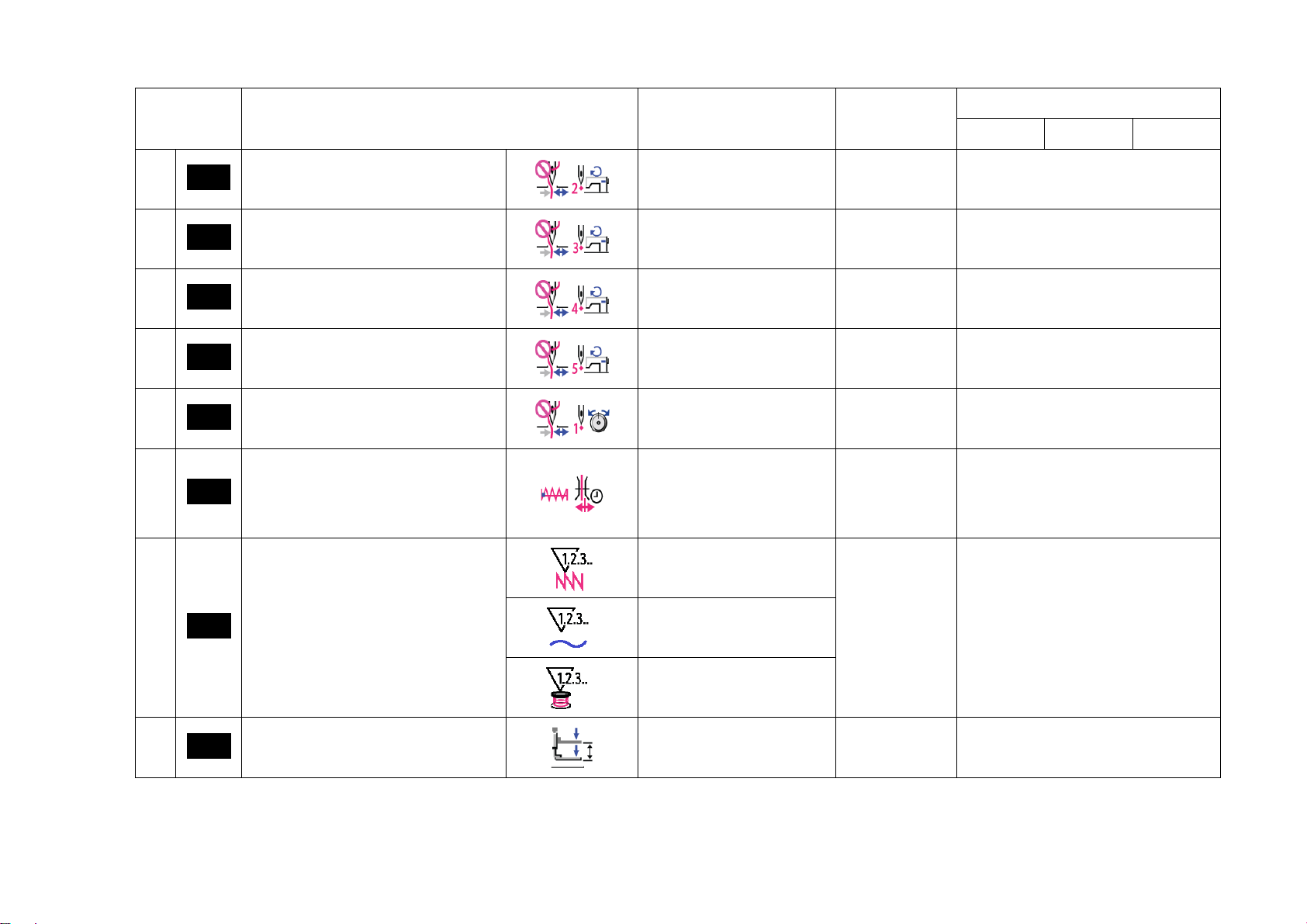

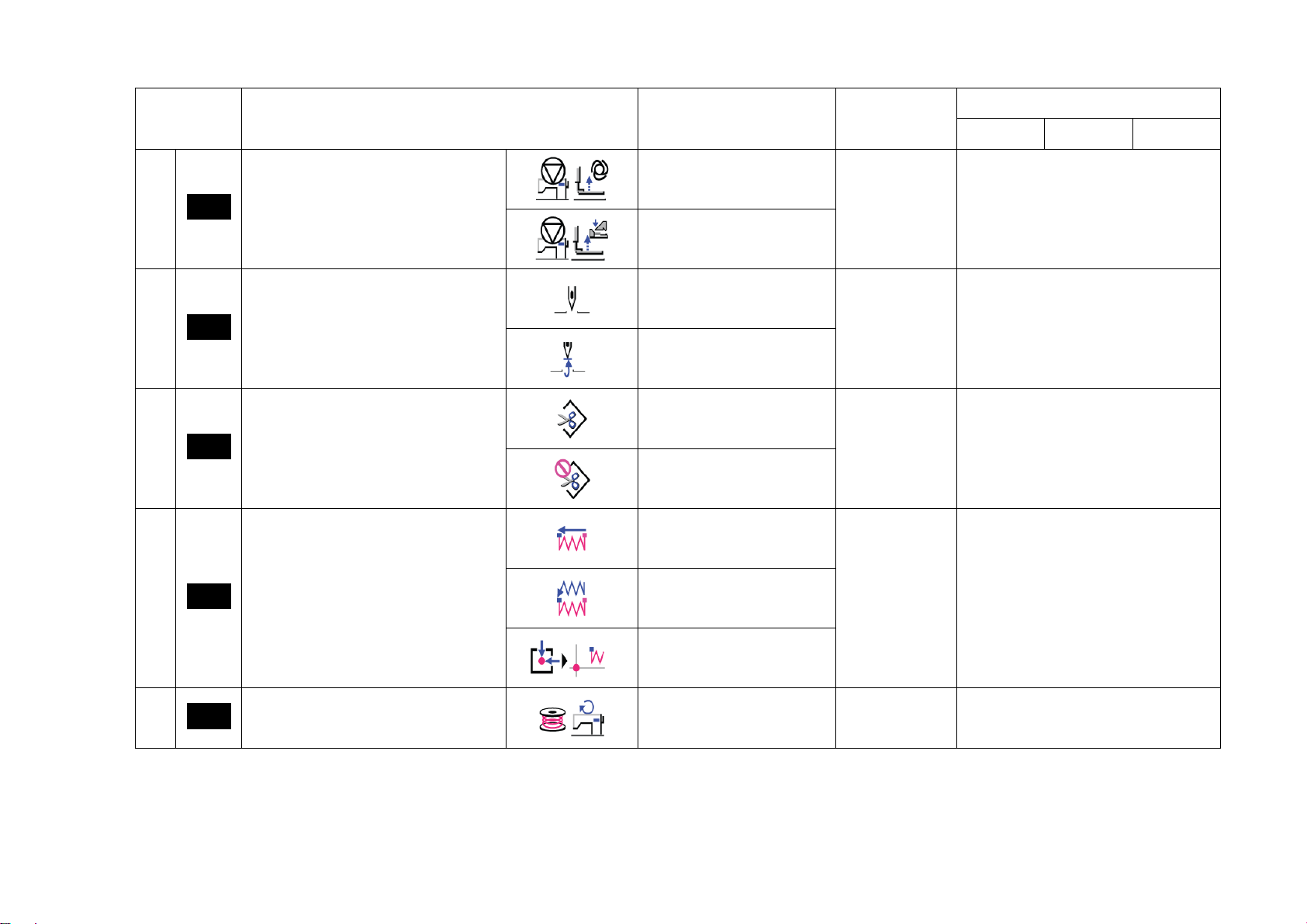

1-2-1 Level 1 ................................................................................................................................. 3

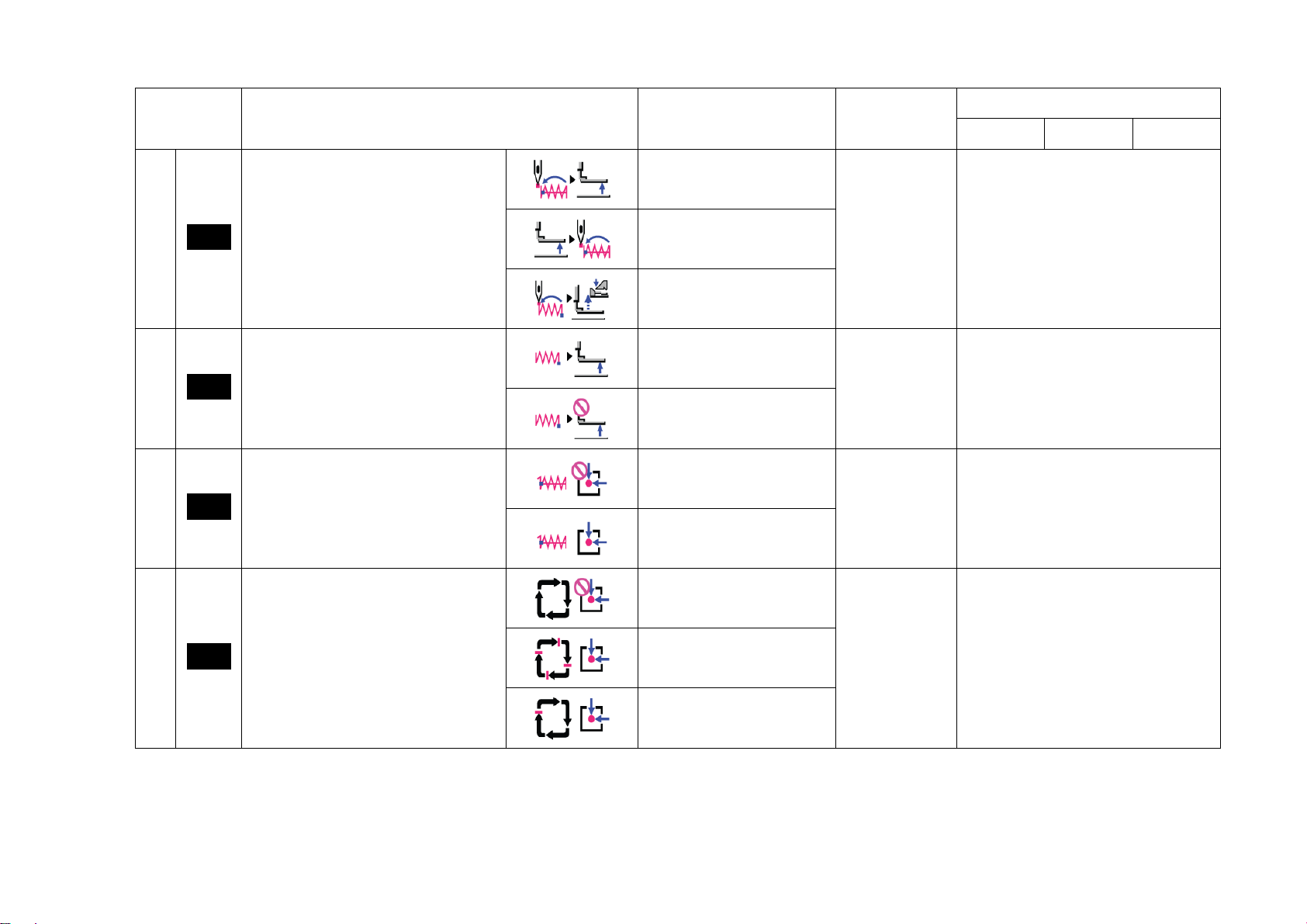

1-2-2 LEVEL 2 ............................................................................................................................ 16

2. WIRE DIAGRAM ....................................................................................................................... 27

2-1

E

LECTRIC

C

ONTROL

B

OX

........................................................................................................... 27

2-2

C

IRCUIT DIAGRAMS OF DIGITAL PEDAL INPUTAND CYLINDER OUTPUT

....................................... 28

2-2-1 Solid Presser .................................................................................................................... 29

2-2-2 Left/right separated pressers ......................................................................................... 29

2-3

M

AIN

C

ONTROL

B

OARD

(CB) ..................................................................................................... 30

2-4

D

RIVING OF

S

TEP

M

OTOR

B

OARD

(SB) ..................................................................................... 31

2-5

T

RANSFER BOARD OF MACHINE HEAD

(TB) ................................................................................ 32

3. TEST MODE .............................................................................................................................. 33

3-1

S

CREEN TO DISPLAY A PROCEDURAL TEST

................................................................................. 33

3-2

A

DJUST THE SENSOR BLOCK PIECE OF

X/Y

AXIS ORIGIN

............................................................ 33

4. ERROR CODES LIST ............................................................................................................... 35

5. MESSAGES LIST ..................................................................................................................... 43