WELDMAN POWER PULSE DC TIG 200 HF / LIFT 2

1. You should properly use gas cylinders.

2. Using our recommended by us or gas reducers.

3. Please refer to the instructions for use reducers and properly apply it.

4. Attach the cylinder by means of a suitable belt or chain located in the delivery device.

5. Keep the bottle away from heat sources and protect from direct sunlight.

6. When opening the valve closer to the gas outlet face. Cut off the gas supply when the welder is not used.

7. Do not lean on the welding torch cylinder and do not touch the electrode to the cylinder

ATTENTION:

Welding works are a source of potential danger to life and health:

• Arc can cause damage to the eyes and skin.

• Chips and welding fumes can cause eye damage or burns.

• Noise can cause hearing loss.

In order to avoid injury to yourself and others nearby, it is necessary that the appropriate means of protection:

1. Wear safety glasses (the welding helmet) with appropriate lenses tinted with UV 1. Wear safety glasses (the welding helmet) with appropriate lenses tinted with UV

2. Wear appropriate protective clothing, 2. Wear appropriate protective clothing,

3. Protection should be extended to other persons in the vicinity of the weld using screens or curtains 3. Protection should be extended to other persons in the vicinity of the weld using screens or curtains

non-reflective.

ATTENTION:

Welding fumes threaten the health:

1. Protection measures should be used to avoid the risk of soot or gases 1. Protection measures should be used to avoid the risk of soot or gases

2. Avoid breathing dust 2. Avoid breathing dust

3. Make sure that the welding work is adequate ventilation and that there are appropriate measures to 3. Make sure that the welding work is adequate ventilation and that there are appropriate measures to

removal of welding fumes.

4. It should be kept in mind when working on materials, primary gases that arise as a result of the evaporation are 4. It should be kept in mind when working on materials, primary gases that arise as a result of the evaporation are

harmful to health.

5. Welder should work in the presence of another person in case of poisoning. 5. Welder should work in the presence of another person in case of poisoning.

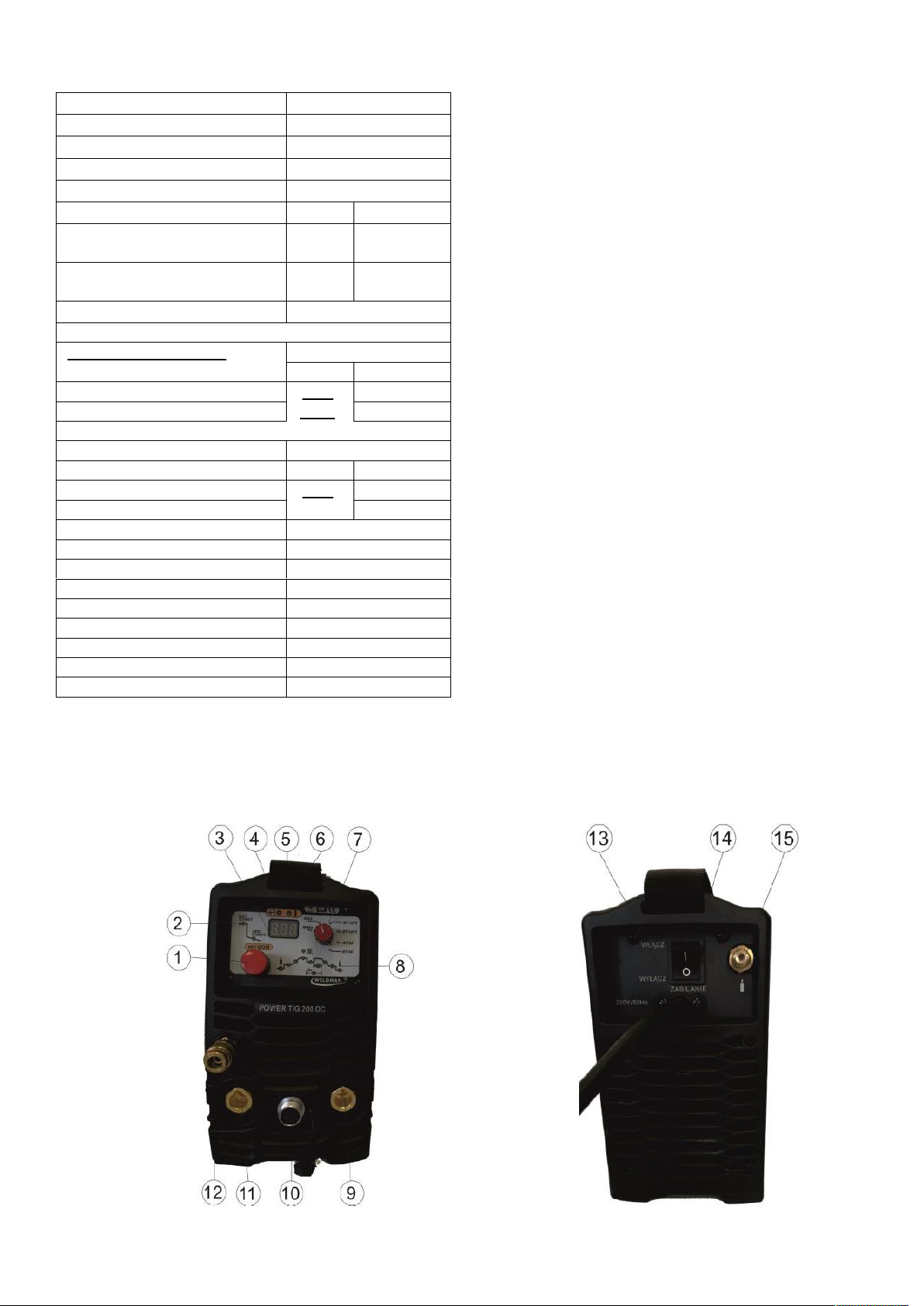

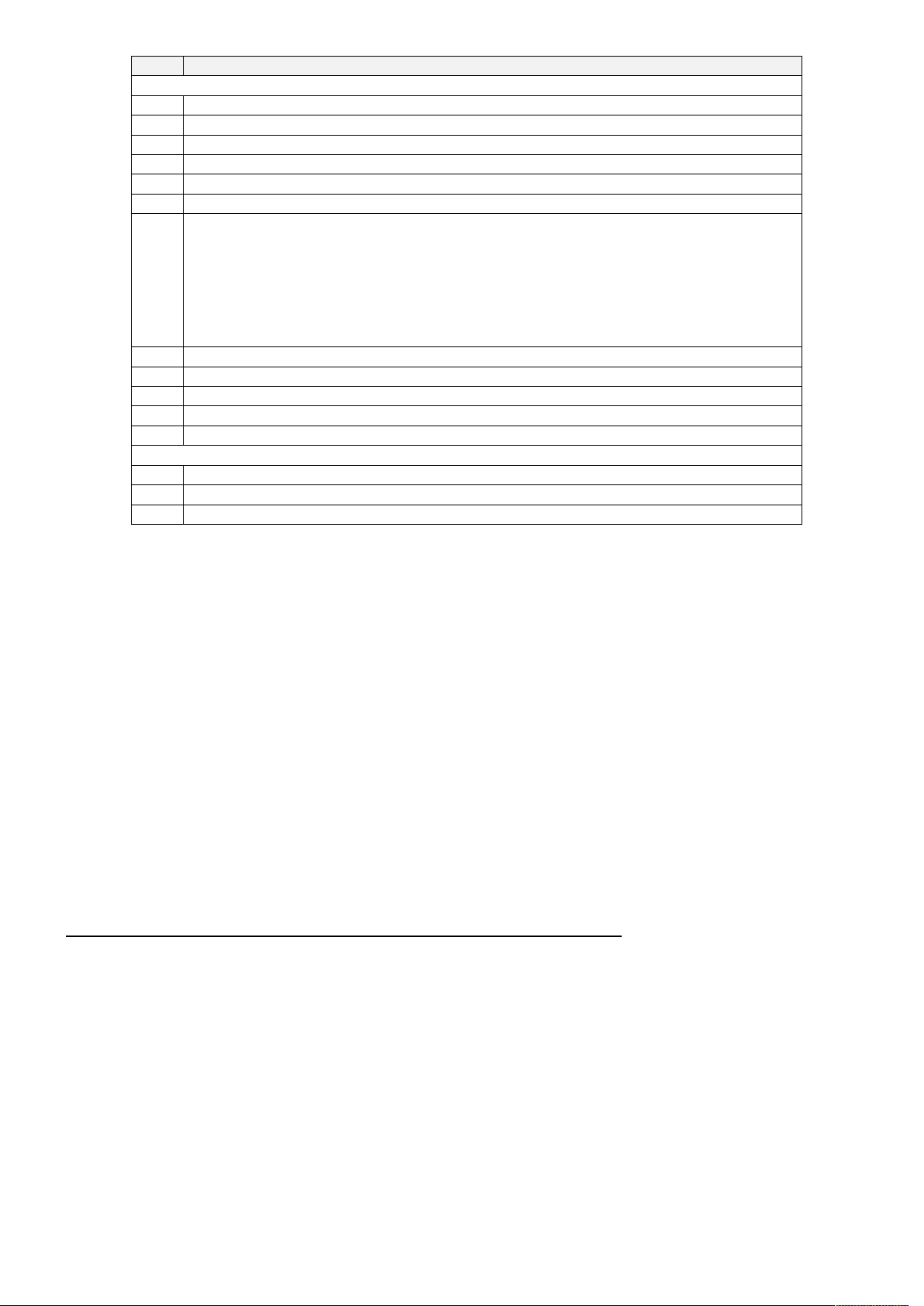

II. GENERAL FEATURES II. GENERAL FEATURES

This device POWER TIG series (from now on referred to as welder) was made on the basis of inverter technology, using IGBT and PWM components and MCU.

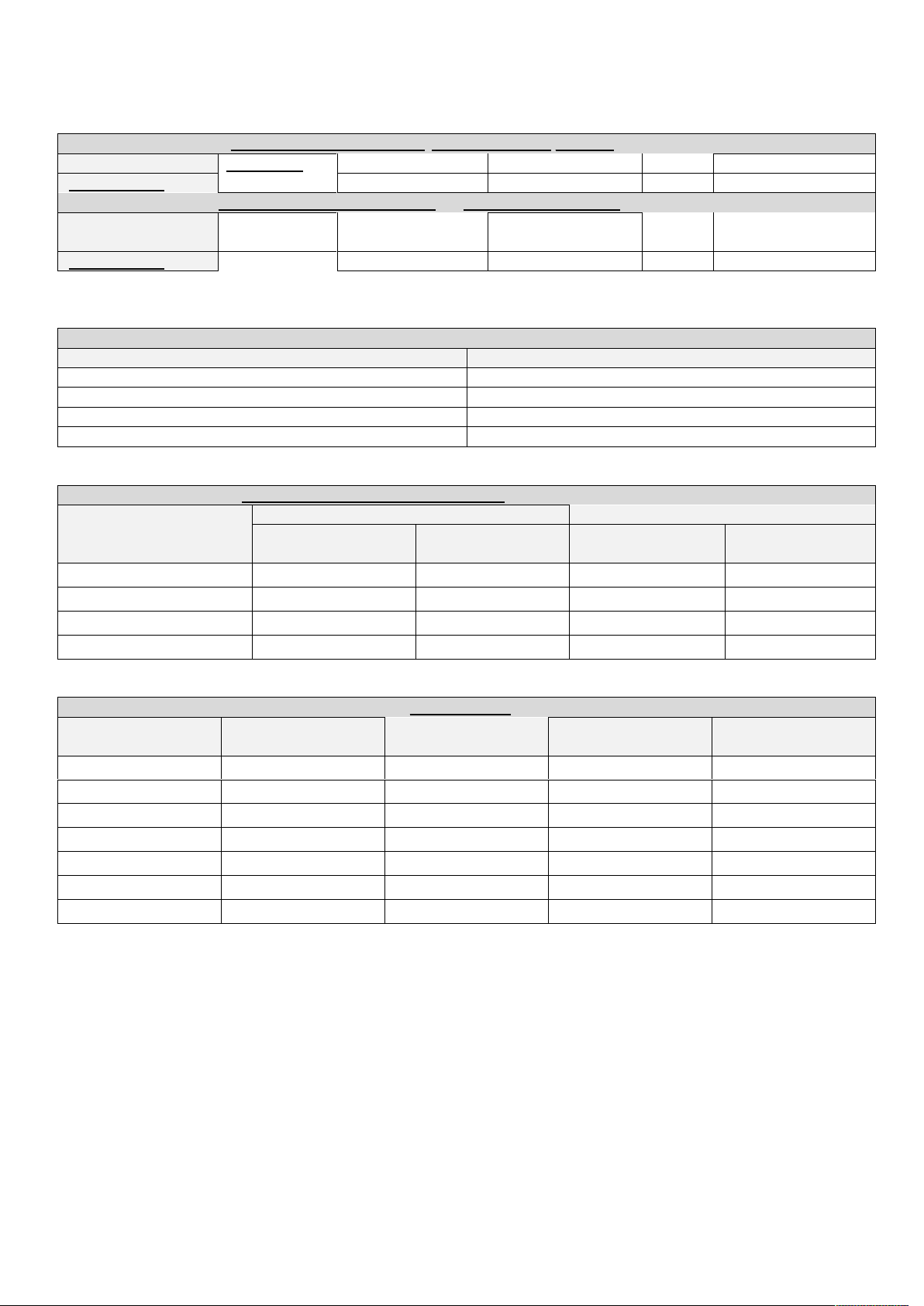

Welder is designed for welding methods:

1) MMA

2) The DC TIG

3) The DC TIG PULSE

carbon steel, alloy steel, stainless steel, cast iron and copper.

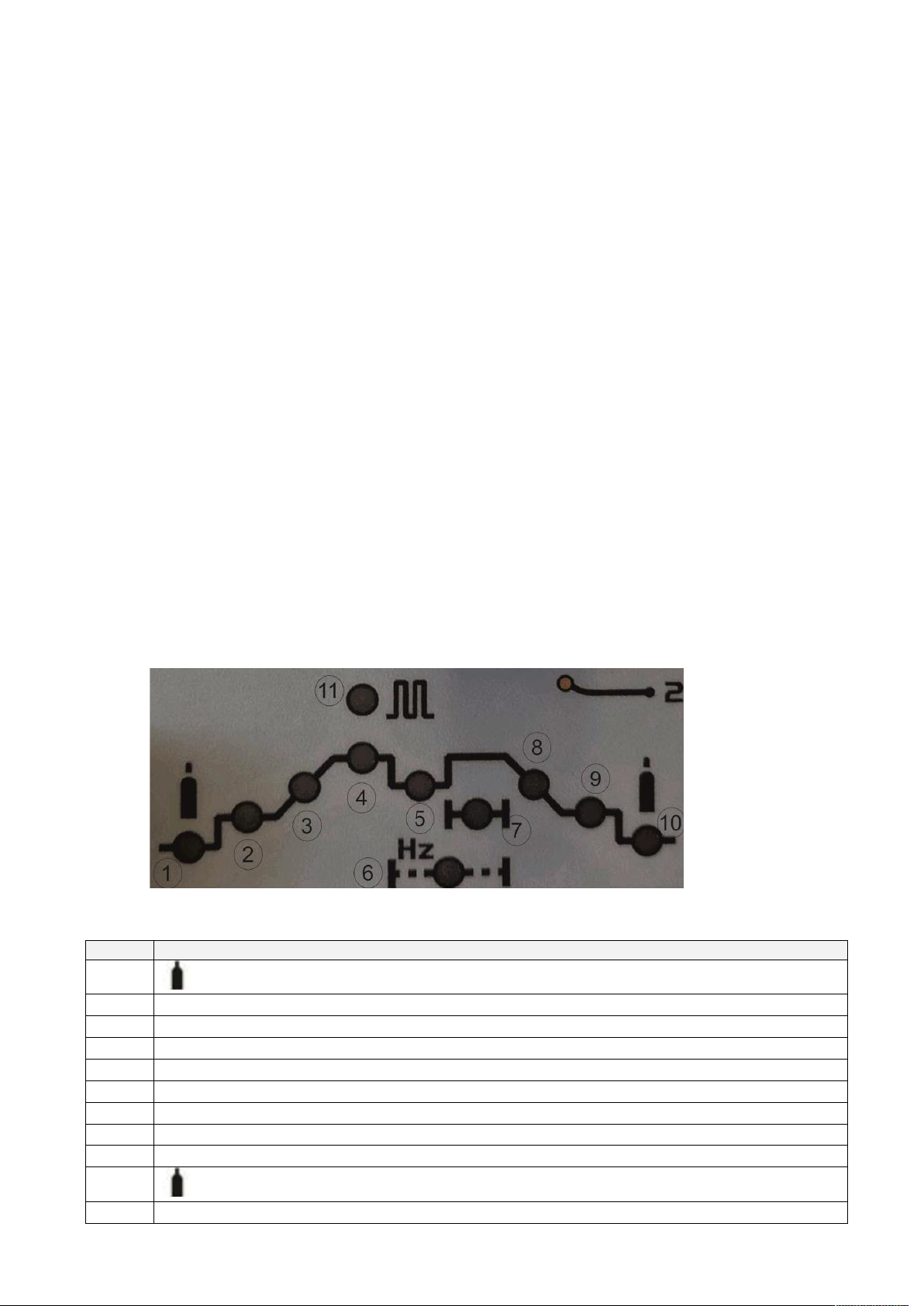

Welding machine can work in a mode 2T / 4T with a contactless (HF) or pin (LIFT), the arc is struck. It has an adjustable ARC FORCE (hold

pressure) and HOT START (hot start).

Welder has intelligent thermal protection, overload, undervoltage, overvoltage. Setting the parameters of any device is on the control panel, which is placed on the

multi-function knob and LCD display. This solution enables easy and fast positioning and reading of all the welding parameters. Welder is designed for both home

users and professionals.

Welding equipment has:

• TIG torch 17 WP (DX50) 4 m

• 3m of the ground wire terminal 200A (DX50)

• 3 m cord plug 230

• a gas conduit for connection PU 3.5 m quick coupling type 21 and two clamps

• carrying case made of plastic

gas regulator absent standard equipment. gas regulator absent standard equipment. gas regulator absent standard equipment.