WELDMAN SEMI-AUTOMATIC LCD POWER MIG 210 MIG / MAG / MMA / TIG DC LIFT Page 3

carbon steel, alloy steel, stainless steel, cast iron and aluminum. Welding equipment has:

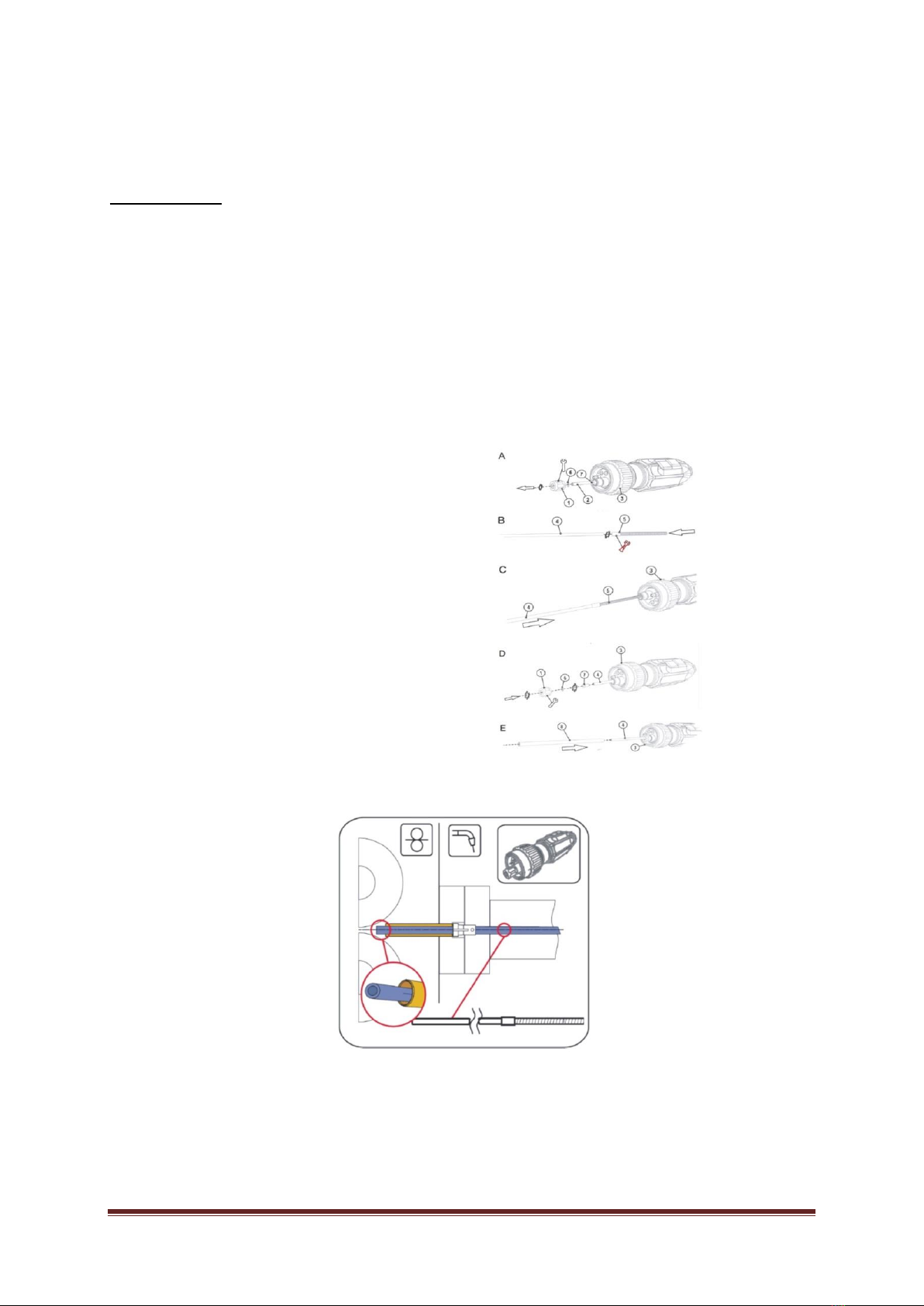

- 15 MB torch 3m

- ground terminal (DX25) with a 3 m 16 mm²

- connection cable 4 m to the gas cylinder

Inside the welder is placed wire feeder, which allows the spool to 5kg (200mm) setting all the device parameters is performed by means of a

control panel which is disposed a display and control knobs and buttons. This solution allows quick and easy set-up and read all the welding

parameters and the use of additional functions welder.

Welder is designed both for professional and semi-professional.

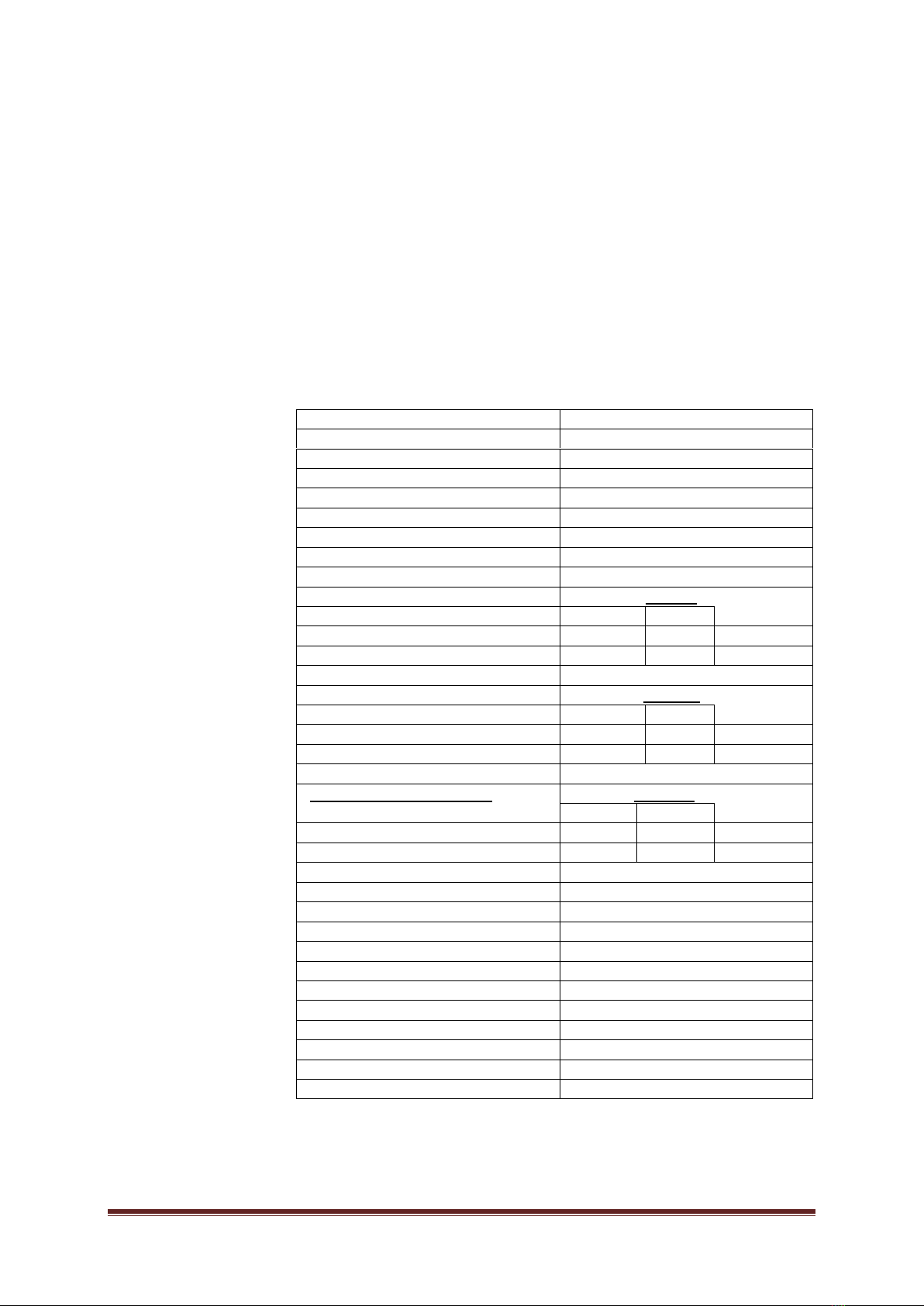

III. TECHNICAL DATA:

Duty cycle is based on the

percentage distribution of 10

minutes for the time in which the

machine can weld at rated current

welding without interruption. Duty

cycle of 30% means that, after 3

minutes of operation.

is required 7 minute break to cool

down. Time cooling device can

sometimes reach up to 15 minutes.

Duty cycle of 100% means that the

machine can operate continuously

without interruption.

MODEL POWER MIG 210 LCD

GENERAL

POWER SUPPLY VOLTAGE 230V / 50Hz

POWER PROTECTION 20 And

CURRENT INTENSITY POWER 36 And

CURRENT INTENSITY POWER EFF. 16 And

VOLTAGE POWER IDLE 69 V

MIG WELDING PARAMETERS 40 -200 / 16- 24V 40 -200 / 16- 24V 40 -200 / 16- 24V

EFFICIENCY (at 40 ° C) 20% 60% 100%

Welding current 200A 115A 89A

Welding voltage 24V 19,7V 18,5V

MMA WELDING PARAMETERS 10-1 80A / 20,4- 27,2V 10-1 80A / 20,4- 27,2V 10-1 80A / 20,4- 27,2V

EFFICIENCY (at 40 ° C) 20% 60% 100%

Welding current 180A 104A 80A

Welding voltage 27,2V 24,1V 23,2V

TIG WELDING PARAMETERS LIFT 10 -180 / 10,4- 17,2V10 -180 / 10,4- 17,2V10 -180 / 10,4- 17,2V

EFFICIENCY (at 40 ° C) 20% 60% 100%

Welding current 180A 104A 80A

Welding voltage 17,2V 14,1V 13,2V

WIRE DIAMETER FE: 0.6-1.0 AL. and FLUX: 0.8-1.0

SIZE SPOOL 5 kg (200mm)

TYPE WIRE FEED 2-roll

arc ignition TOUCH

MODE HANDLE 2T / 4T

ELECTRODE DIAMETER 1.6 - 4.0

COOLING FAN

INSULATION CLASS H

DEGREE OF PROTECTION IP 21S

DIMENSIONS 73x32x48 cm

WEIGHT 21.5 kg