DO NOT OPERATE THE COOLER UNIT

WITH THE COVER REMOVED.

ELECTRICAL SHOCK CAN KILL,

MOVING PARTS CAN CAUSE

SERIOUS INJURY.

TEC WELDING PRODUCTS, INC.

P.O. Box 1870 •San Marcos, CA 92079 •Phone 760-747-3700

www.tectorch.com www.weldtec.com

If the cooler will be used in freezing

conditions a non-automotive anti-freeze

should be added. Follow the anti-freeze

directions for proper mixture based on the

lowest expected temperatures. Automotive

anti-freeze contains additives which will harm

the pump, lines and equipment causing

permanent damage. Use of automotive

anti-freeze voids the cooler warranty.

Propylene glycol type anti-freeze is

recommended for safety reasons.

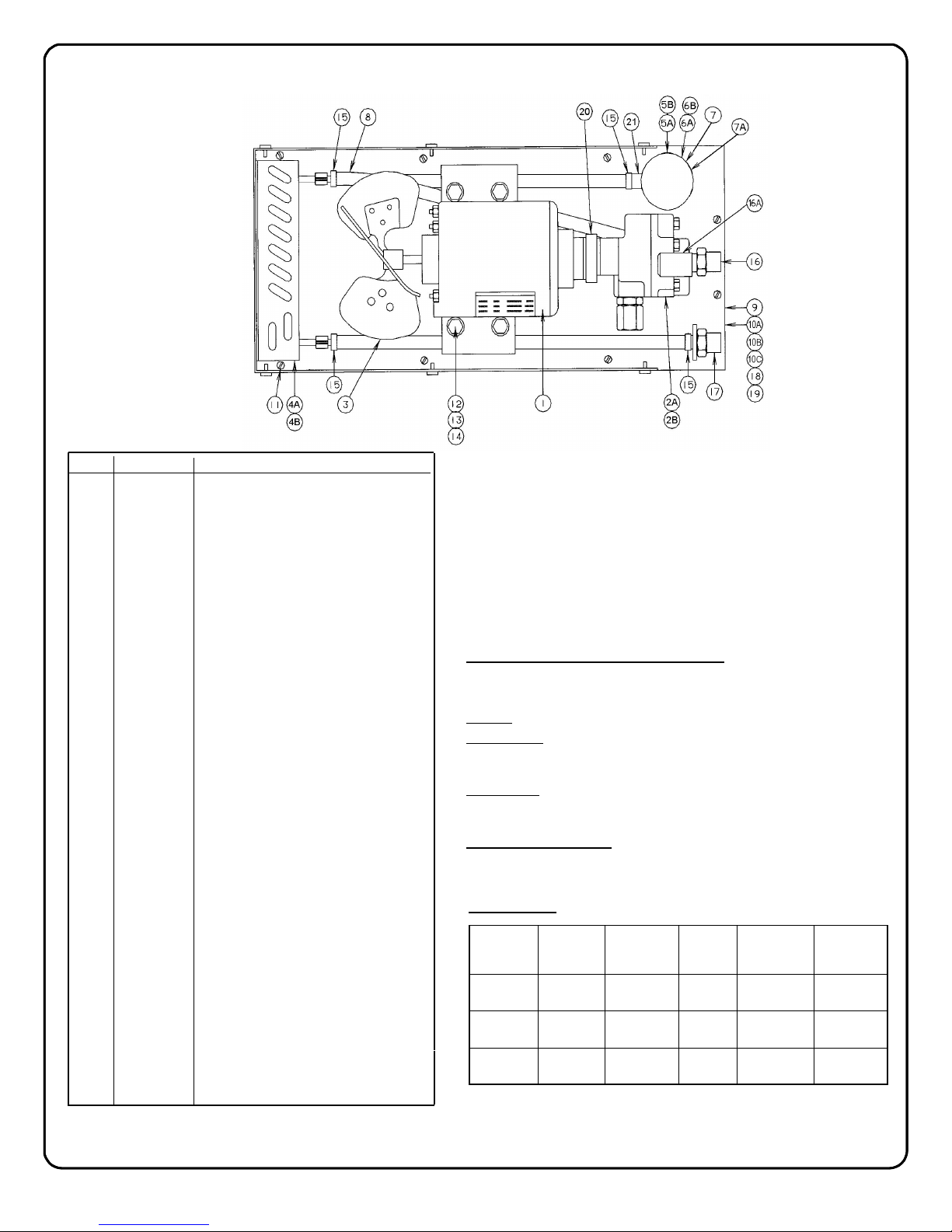

3) OPERATION

ADJUSTABLE PUMP PRESSURE

The pump is equipped with an adjustable

pressure screw. The factory setting is 50 psi

which will yield 1.7 gpm of flow. Some

equipment may require higher pressure

settings. Consult the manufacturers guidelines

for maximum pressure ratings. To adjust

the pressure setting unplug the cooler, locate

the adjusting screw on the side of the pump.

Turning the adjusting screw clockwise will

increase the output pressure and counter

clockwise will decrease the output pressure.

A pressure test gauge should be used to

accurately set the output pressure. Do not

exceed the maximum pressure rating for the

equipment being cooled. CAUTION -most

welding equipment requires flow volume, not

high pressure for proper cooling. Check the

flow requirements of the equipment being

cooled for the proper fluid flow needs.

4) MAINTENANCE

CAUTION -Do not attempt any repairs or

maintenance while the unit is connected

to the input power supply. Unplug the unit

before making any adjustments or repairs.

Consult the equipment manuals for

maintenance instructions for that specific

equipment.

Keep the unit clean and free from accumulated

dust and debris. Blow off the unit and radiator

fins with compressed air every six months or

more frequently if needed. If the unit is fitted

with a dust filter, blow off and wash the filter

in soapy water, rinse, dry and replace.

To replace the coolant, pump all coolant from

tank and flush with clean water. Flush out the

torch lines at the same time. Replace the

coolant, distilled, or deionize water and fill

with the exact gallons required for the tank

size. Replace coolant yearly. Check all lines

and hose clamps and adjust or replace as

needed.

The gear type pump will give long trouble free

service. Pump wear is noticeable by a decrease

in output pressure or flow rate. The wear will

usually take place over a lengthy period

allowing time to make repairs or replace the

pump before complete failure occurs. A repair

kit is available for field repair that contains

internal pump gears, seals, etc. The entire

pump can be quickly changed by means of

the clamp connection.

The vane type pump will fail if the internal

vanes are chipped or broken by debris in

the lines, usually without warning. It is not

field repairable, so a spare pump will save

down time and can be quickly changed if

unexpected failure occurs.

When ordering spare or replacement parts be

sure to give the cooler model, item part number

and complete description of the parts required.