2M-Z21001 Rev- Owner's Manual for IRCS4 Impingement/Radiant Split-Belt Conveyor Toaster

5

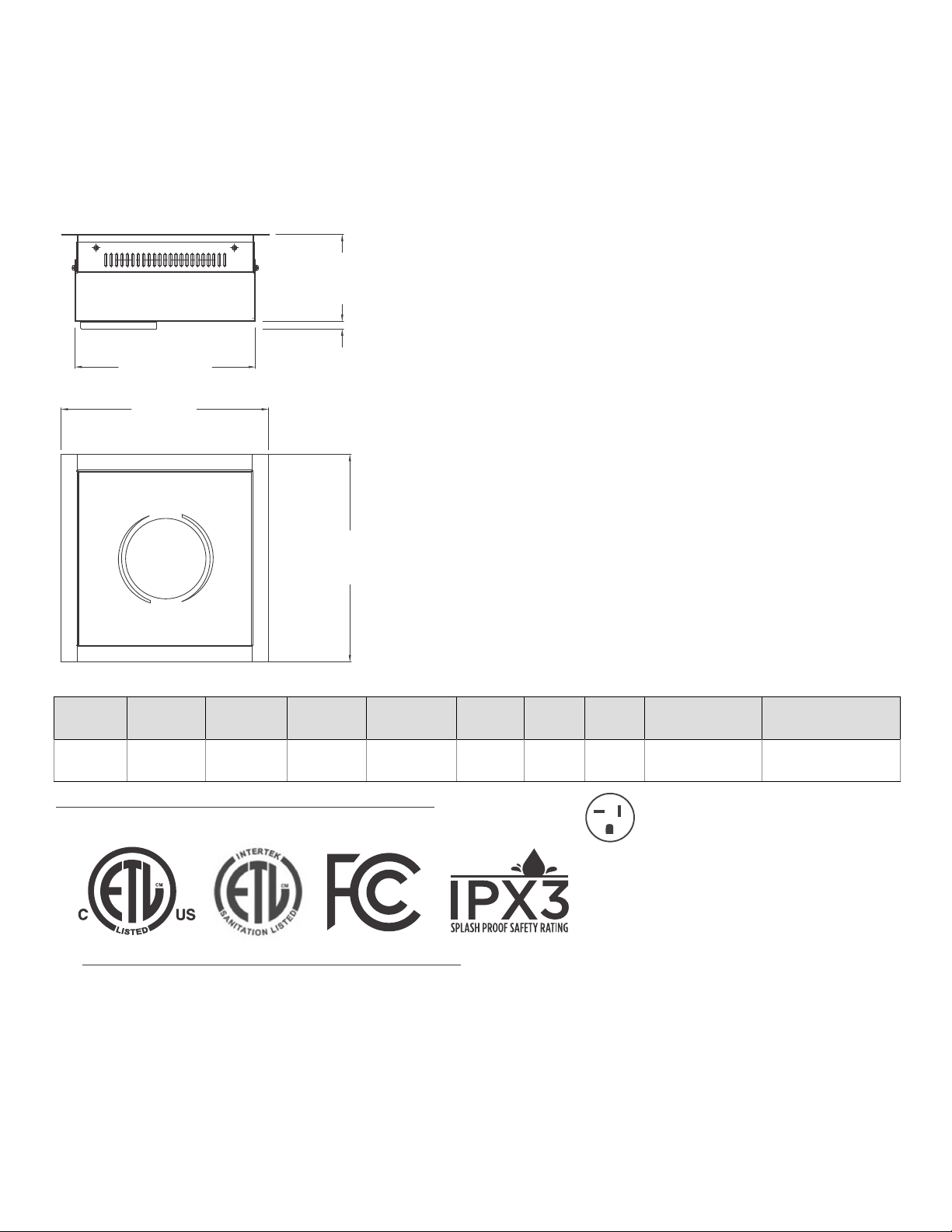

2M-Z21951 Rev- Owner’s Manual for ISDIxx Drop-In Induction Range

OPERATION

CERTAIN SURFACES ARE EXTREMELY HOT DURING

OPERATION AND CARE SHOULD BE TAKEN WHILE

USING THIS UNIT.

DO NOT LEAVE THE UNIT IN OPERATION WITHOUT

AN ATTENDANT.

DO NOT LEAVE THE UNIT ON DURING IDLE PERIODS.

DO NOT CYCLE THE POWER QUICKLY ON AND OFF

AS THIS MAY CAUSE DAMAGE TO THE UNIT OVER

TIME.

MAKE CERTAIN TO READ ALL INSTRUCTIONS AND

WARNINGS CONTAINED WITHIN THIS MANUAL

IN FULL, PRIOR TO USE.

KEEP PAPER AND OTHER MATERIALS THAT CAN

BLOCK THE FAN AWAY FROM THE BOTTOM OF

THE UNIT.

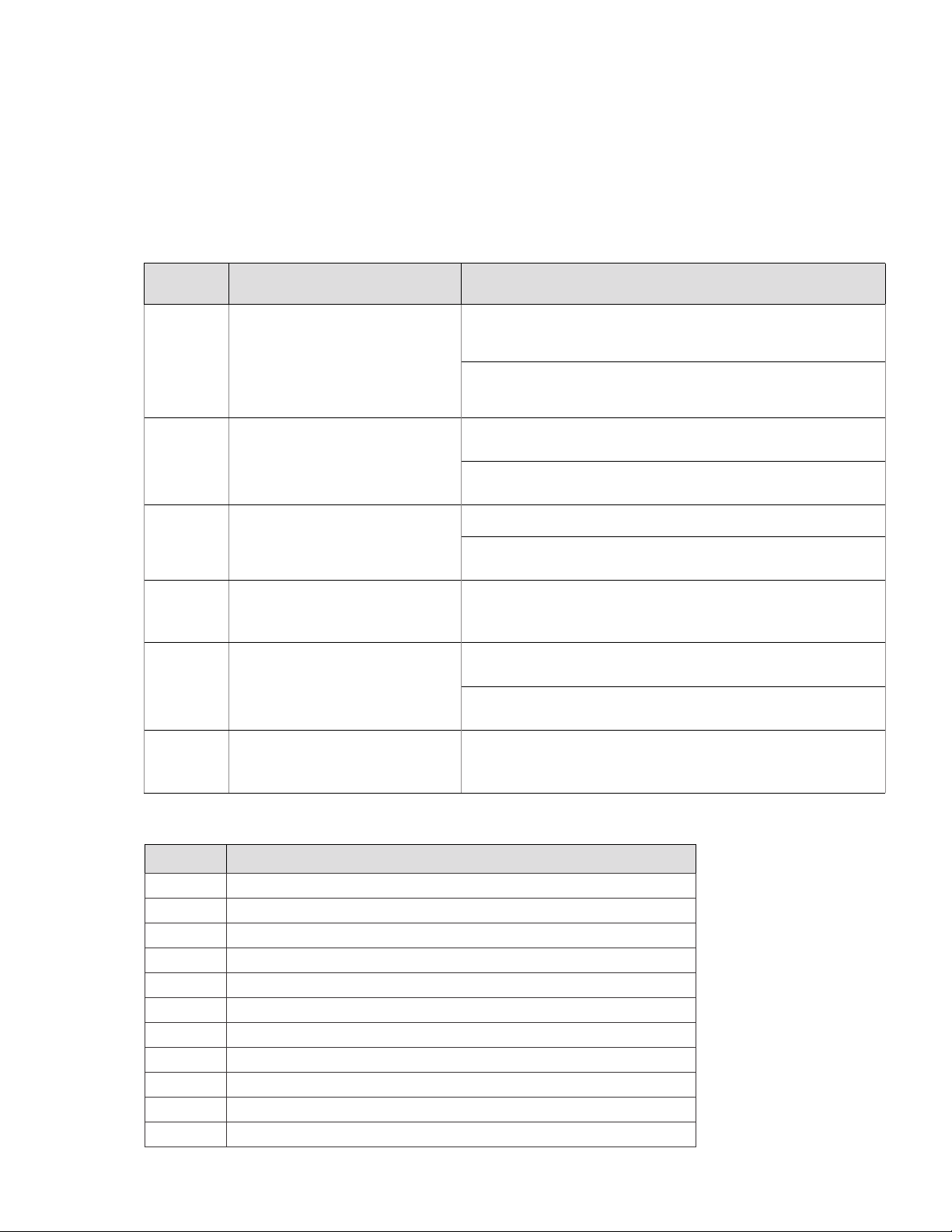

DAILY USE

i. Make sure the dial indicator is at the o position

[pointing straight up] and plug the unit into an

appropriate power outlet.

ii. Place an appropriate pot or pan onto the cooking

zone. [an error code will appear if there is no pan

or an incorrect type of pan placed on the unit]

iii. Adjust the knob slowly to the desired heat setting

while making certain that there are no error codes

present. If there are any error codes, record the

code[s], immediately turn the unit to the o position

and remove power to the unit, and consult the

troubleshooting section of the manual before

proceeding.

iv. Once done cooking, turn the knob back to the o

position and at the end of day, remove power from

the unit.

MAINTENANCE

The unit should be inspected by an authorized

agent at least once per year. Anything other than

standard cleaning procedures should be performed

by authorized service agents only. The inside of this

unit has no user-serviceable parts.

CLEANING & MAINTENANCE

CLEANING PROCEDURE

Preventive maintenance consists of the following

recommended cleaning procedures. To keep your

unit in its best operating condition, these steps

should be performed on a daily basis as required.

The cooking area must be kept clean for the unit

to function properly.

i. Turn the unit o, unplug it from the power source,

and allow it to cool completely.

ii. Once cool, begin by using a soft, slightly damp

sponge to wipe away and spilled food and debris.

If there is any hardened residue, use a scraper

or cleaning pad made specifically for glass/ceramic

surfaces and an appropriate glass/ceramic cooktop

cleaning solution.

iii. Wipe down the surface with glass/ceramic cooktop

cleaner and a soft cloth. A small amount of vinegar

can be used to clean away water spots and light

stains.

iv. Use a soft, dry cloth to wipe down the surface and

remove any remaining cleaner/liquid.

v. While cleaning the unit, make certain to examine

the screen on the fresh air intake located on the bottom

of the unit and clean as needed. This must stay clear

of blockages in order for the unit to function properly.

vi. Once the unit is clean and has dried, it is ready to plug

back in and begin using.

DO NOT USE COARSE SPONGES/PADS

WHICH WILL SCRATCH THE FINISH.

DO NOT USE CAUSTIC CLEANERS,

DEGREASERS, FLAMMABLE CLEANERS,

OR ANY OTHER CLEANER WHICH CAN

DAMAGE THE COOKING AREA SURFACE.

DO NOT IMMERSE THE UNIT IN WATER.

DO NOT ALLOW ANY CLEANER OR

LIQUID TO COLLECT ON THE TOP OF

THE UNIT.

DO NOT HOSE DOWN THE UNIT OR

THE TABLE/COUNTER THE UNIT IS

MOUNTED IN.

front