4

EN

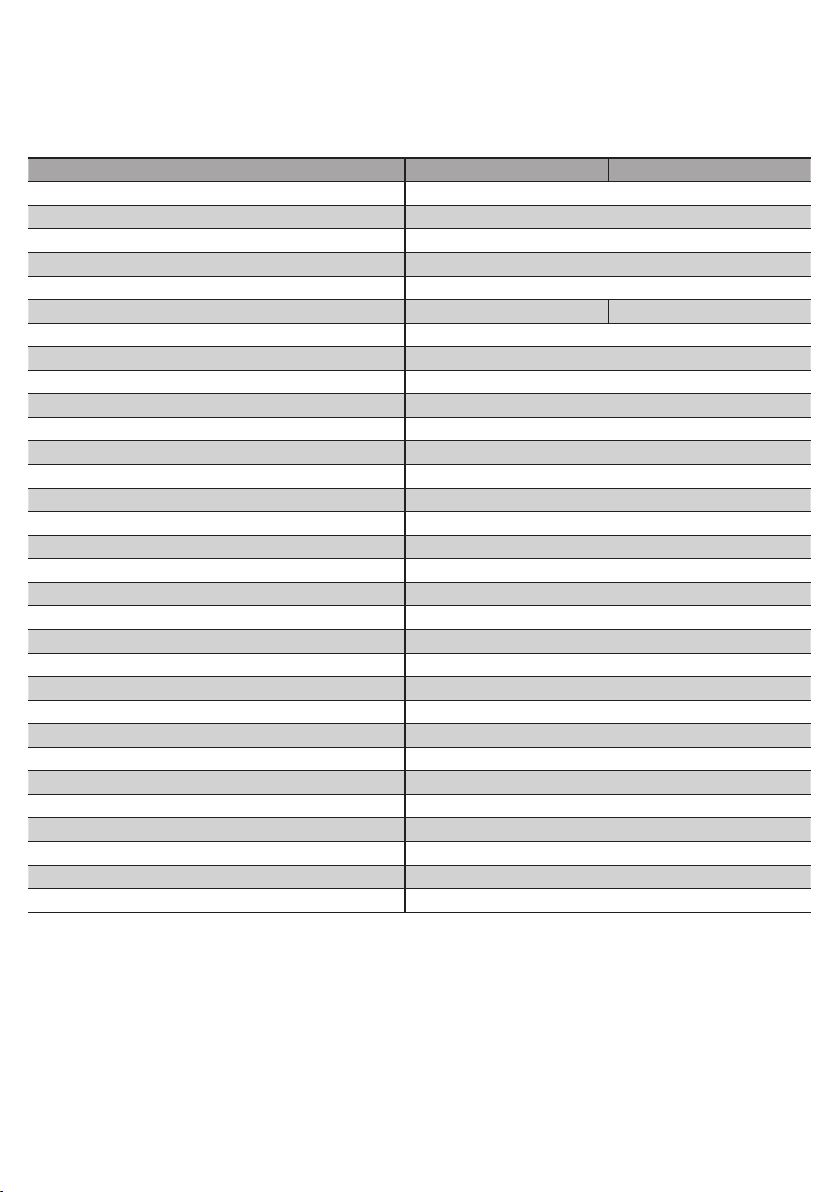

4. Technical Data

Order number ZAI02PN01 ZAI02PN02

Supply voltage 18...32 V DC

Power consumption of device max. * 0.1 A

Power consumption of system max. ** 1.8 A

Temperature range –25...60 °C

Voltage drop switching outputs < 2,5 V

Max. Switching current switching outputs 0.6 A 2 A

Max. total current of the I/O ports 9 A

Sensor Supply Voltage (Pin 1) 200 mA

Inputs according to DIN EN 61131-2:2003 Type 2

Digital I/O ports short-circuit protected yes

Digital I/O ports overload protected yes

Digital I/O ports reverse polarity protected yes

Number of standard I/O pins 16

Housing material Aluminum

Weight 1100 g

Protection class IP67

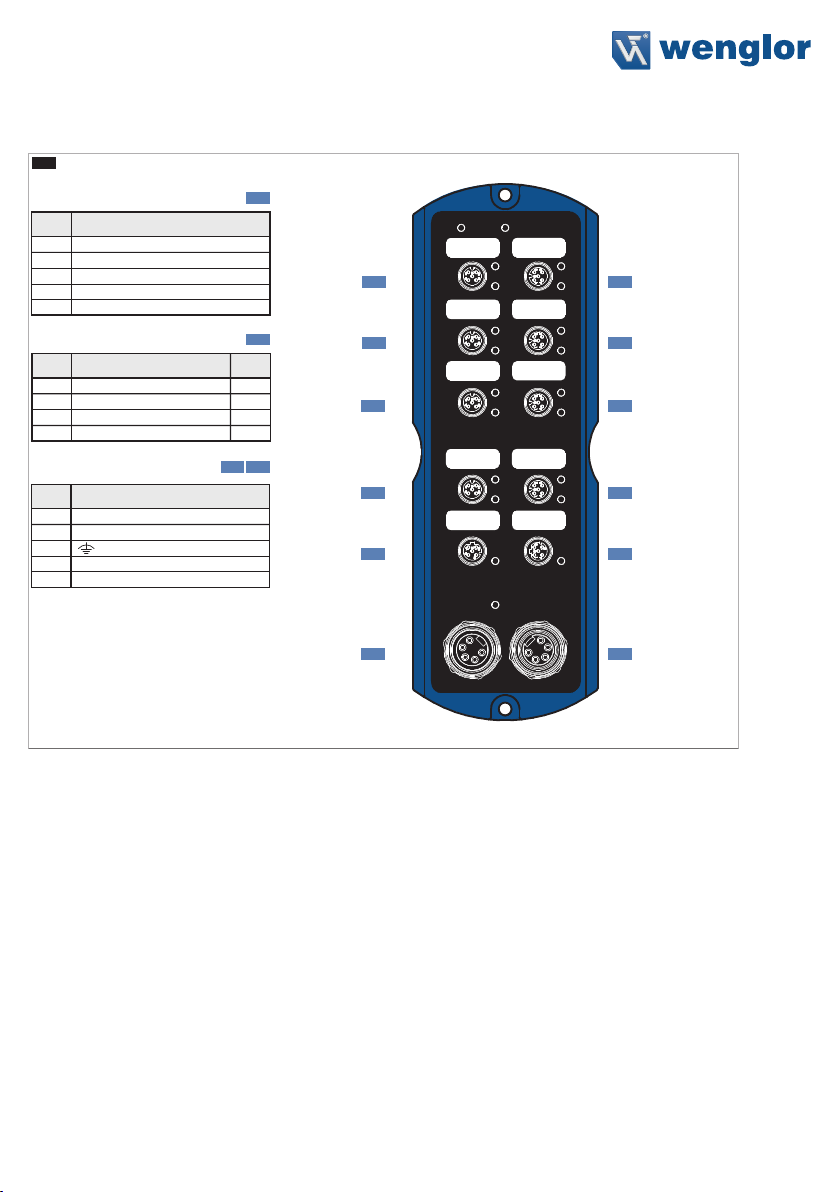

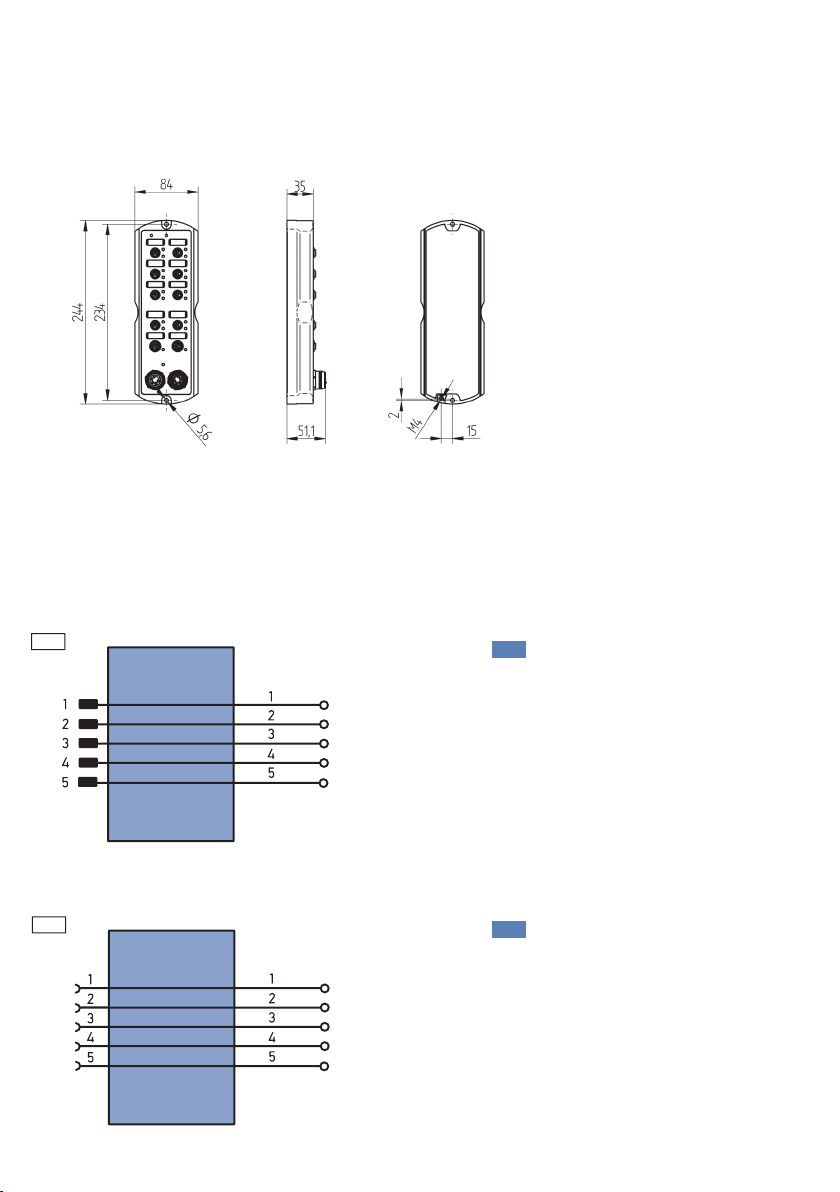

Type of connection power 7/8", 5-pin

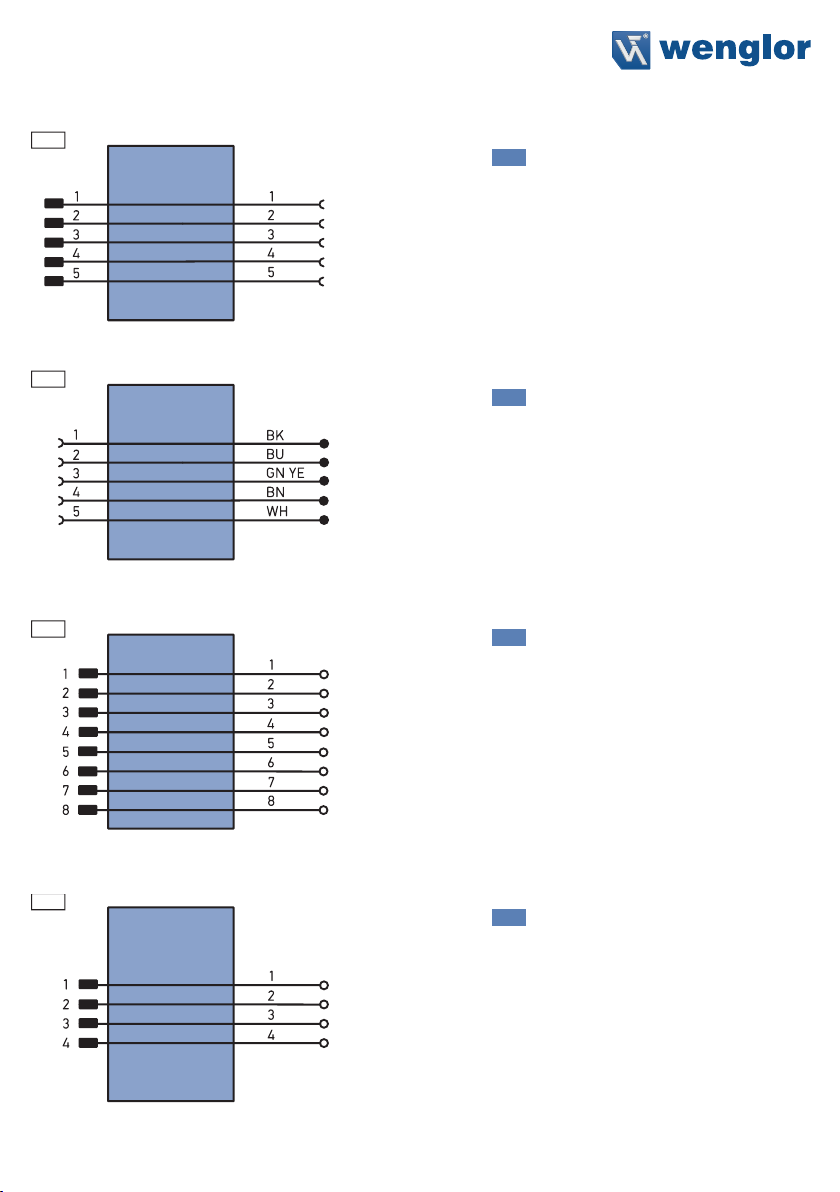

Type of Connection Industrial Ethernet ports M12×1, 4-pin, D-coding

Type of Connection Digital I/O ports M12×1, 4-pin, A-coding

Number of Industrial Ethernet ports 2

Number of Digital I/O ports 8

Baud Rate 10 Mbit/s / 100 Mbit/s

Transmission Mode Full / Half Duplex

Webserver yes

Switch Mode Store & Forward

VLAN Prioritization ja

Default IP 192.168.100.1

Auto-Crossover yes

Auto-Negotiating yes

Auto-Polarity yes

Protection class III

* Maximum own power consumption of the product without additional loads

** Maximum own power consumption of the product with additional loads

Full assignment of all digital I/O ports with sensor supply (without outputs)