Werner GRANUDOS S5 User manual

Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Language: EN

Operating Instructions

Control unit

Type GRANUDOS S5

without dosing unit

GRANUDOS

45/100-S5

Suitable for the operating

instructions for the dosing

unit:

GRANUDOS 45/100

No.: BA SW 003

GRANUDOS

Flex-S5

Suitable for the operating

instructions for the dosing

unit:

GRANUDOS Flex

No.: BA SW 022

GRANUDOS

15-S5

Suitable for the operating

instructions for the dosing

unit:

GRANUDOS 15

No.: BA SW 002

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 2 of 31

Table of contents

1About these instructions / general .......................................................................................................... 3

1.1 Scope of applicability ........................................................................................................................................3

1.2 Target group .................................................................................................................................................... 3

1.3 Symbols used ...................................................................................................................................................3

1.4 Warranty .........................................................................................................................................................4

1.5 Additional information .....................................................................................................................................4

1.6 Information regarding support queries.............................................................................................................5

2Safety ...................................................................................................................................................... 6

2.1 Intended use.....................................................................................................................................................6

2.2 Safety notices ................................................................................................................................................... 6

Handling of chemicals, risks to humans and the environment ........................................................................6

Protective measures and rules of conduct ..................................................................................................... 6

3Product description –scope of delivery .................................................................................................. 7

3.1 Scope of delivery / accessories.........................................................................................................................7

3.2 Product description .......................................................................................................................................... 7

3.3 Identification of the device/ Identification plate ................................................................................................7

3.4 Technical data .................................................................................................................................................. 8

4Installation ............................................................................................................................................... 8

5Commissioning ........................................................................................................................................ 8

6Operation / service of the control unit.................................................................................................... 9

6.1 General ............................................................................................................................................................9

6.2 Operation of the GRANUDOS S5 control unit ............................................................................................... 9

6.3 Start display (operation display) .......................................................................................................................9

start display –Automatic.............................................................................................................................10

Start display - Startup routine –Delay booster pump - Dosing delay...........................................................10

6.4 The Main Menu ..............................................................................................................................................10

Main menu Settings (overview)...............................................................................................................12

Main Menu Service .................................................................................................................................19

Main menu Event log (event and data logging)........................................................................................20

7Maintenance, care, fault removal........................................................................................................... 21

7.1 Device maintenance .......................................................................................................................................21

7.2 Fault removal .................................................................................................................................................22

8Decommissioning –Storage –Disposal................................................................................................. 24

9Documents............................................................................................................................................ 24

9.1 Declaration of conformity ..............................................................................................................................24

9.2 Wiring diagrams.............................................................................................................................................25

Wiring diagram network board GRANUDOS 45/ 100-S5.........................................................................25

Wiring diagram network board GRANUDOS Flex-S5 ...............................................................................26

Wiring diagram network board GRANUDOS 15-S5..................................................................................27

9.3 Commissioning protocol ................................................................................................................................28

9.4 Operation data sheet......................................................................................................................................28

9.5 Maintenance protocol.....................................................................................................................................30

9.6 Spare parts list, wear parts list, consumables..................................................................................................30

10 Appendices............................................................................................................................................ 30

10.1 Menu overview with abbreviations .........................................................................................................31

Imprint:

All rights reserved

© Copyright by WDT –Werner Dosiertechnik GmbH & Co KG

Edition: see footer

Reproduction of any kind and translation into other languages, even in excerpts, is only permitted with the express

authorisation of the company WDT - Werner Dosiertechnik GmbH & Co. KG.

These operating instructions are an English translation of the original German version by the company WDT.

Responsible for the content:

Co. WDT - Werner Dosiertechnik GmbH & Co. KG,

Hettlinger Str. 17, D-86637 Wertingen-Geratshofen

Phone: +49 (0) 82 72 / 9 86 97 –0, Fax: +49 (0) 82 72 / 9 86 97 –19

Email: info@werner-dosiertechnik.de

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 3 of 31

1About these instructions / general

1.1 Scope of applicability

This instruction describes the function, installation, commissioning and operation of the device. The Operating

Instructions must be read carefully before use and kept on the device for direct use!

These Operating Instructions are valid in conjunction with the Operating Instructions:

“GRANUDOS Flex Dosing Unit”, No.: BA SW 022

“GRANUDOS 45/100 Dosing unit”, No.: BA SW 003

“GRANUDOS 10 / 15 Dosing Unit”, No.: BA SW 002

1.2 Target group

Only our authorised partners and people who have been trained in the device functions are permitted to

work on the system, provided that they have read and understood these Operating Instructions.

Electrical connection work may only be carried out by appropriately trained specialists!

1.3 Symbols used

This document uses the following types of safety notices as well as general notices:

DANGER!

“DANGER” denotes a safety notice which, if disregarded, may lead to serious or life-threatening injuries,

serious material damage or death!

CAUTION!

"CAUTION" denotes a safety notice which, if disregarded, may lead to injuries, damage to health or

material damage!

ATTENTION!

“ATTENTION” denotes a safety notice which, if disregarded, may lead to material damage or may impair

the function of the system

CORROSIVE!

“Corrosive” denotes a safety notice which, if disregarded when handling chemicals, may lead to injuries or

material damage.

ESD SENSITIVE!

"ESD SENSITIVE" denotes electronic components that may be damaged by electrostatic discharges. The

generally accepted safety precautions for electronic components must be observed when handling the devices!

NOTICE!

A “NOTICE” denotes information that is of particular importance for the smooth running of operations and

that can disrupt the operating process if not observed.

TIP!

A "Tip" denotes information that may result in improvements in the operating process.

Use face protection!

Wear approved face protection to prevent facial injuries due to contact with hot or chemical materials.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 4 of 31

Use hand protection!

Wear approved hand protection to prevent hand injuries due to contact with hot or chemical materials

(according to DIN EN 374: Protective gloves against dangerous chemicals and micro-organisms).

Use protective apron!

Wear an approved protective apron to prevent injuries to the front of your body due to contact with hot or

chemical materials.

Use foot protection!

Wear approved foot protection to prevent foot injuries due to contact with hot or chemical materials or

falling objects.

1.4 Warranty

All WDT devices and systems are manufactured using modern production methods and are subject to

comprehensive quality control. However, should there be a reason for complaint, any compensation claims

shall be directed to the company WDT in accordance with the general terms and conditions of warranty (see

below).

General terms and conditions of warranty

The company WDT assumes a 2-year warranty, starting with the commissioning, up to 27 months after

delivery; subject to correct installation and commissioning with a completed and signed commissioning

protocol.

Exempt from this are wear parts such as seals, hoses, diaphragms, dosing screws, electrodes, roller carriers

and other parts that are subject to mechanical or chemical wear and tear. For these we assume a warranty of

1/2 year.

Our enterprise resource planning system requires an invoice for each delivery (including warranty services).

When returning a defective component, upon review you will receive a corresponding credit, if applicable.

We request a return within 14 days.

The costs for subsequent damage and for the processing of warranty claims are excluded.

There are no warranty claims for damage caused by frost, water and electrical overvoltage or by improper

handling.

TIP!

In order to protect the warranty claims, please mail the completed commissioning

protocol, along with the defective component, to the company WDT. Without the

commissioning protocol, we reserve the right to assert a warranty regulation.

NOTICE!

It is not permitted to make any modifications to the device, as this may lead to

malfunctions. If this specification is not observed, the warranty obligation and product

liability will expire!

1.5 Additional information

Further information about special topics, e.g., design of the dosing performance or description of the

operating parameters, is available from your specialist dealer.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 5 of 31

1.6 Information regarding support queries

The control unit is subject to continued further development of both its software and hardware. We always

strive to preserve the compatibility of the components used, but we are unable to guarantee this over a period

of several years!

For spare part orders, we therefore always require the following data. You can find these on the identification

plate.

device designation

device serial number

year of manufacture

For technical support requests, we require the software data. You can find these under Main menu Service

Info.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 6 of 31

2Safety

2.1 Intended use

The GRANUDOS S5 control unit must only be used for the purposes described in the product description in

Chapter 3.2, Product description! Also pay attention to the locally applicable regulations concerning accident

prevention, occupational safety and drinking water protection!

2.2 Safety notices

Carefully read and comply with the operating instructions prior to installation, maintenance and use of the

device!

Work on the device and changes in the settings may only be carried out by properly instructed persons!

Handling of chemicals, risks to humans and the environment

Danger due to corrosive substances!

Formation of substances hazardous to health when handling and mixing chemicals!

In emergencies, contact the respective poison control centre.

Emergency number:

Munich Emergency Poison Centre (or any other Poison Centre)

Phone: +49 89 19240

Protective measures and rules of conduct

CORROSIVE!

The GRANUDOS Touch control unit controls devices that dose corrosive chemicals.

For this reason, it is essential that you pay attention to the safety information.

ESD SENSITIVE!

The electronic components in the device control units are sensitive to electrostatic

discharge. For this reason, the generally accepted safety precautions for electronic

components must be observed when handling the devices, including:

Discharge of personal static charge

Dissipative clothing

Disconnect the device from the voltage supply

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 7 of 31

3Product description –scope of delivery

3.1 Scope of delivery / accessories

The GRANUDOS S5 control unit is delivered as standard.

Customer-specific or order-related modifications are possible.

3.2 Product description

The GRANUDOS S5 control unit is intended solely for control tasks associated with the treatment of

swimming pool water. It is used for the following dosing devices:

GRANUDOS 45/100-S5

GRANUDOS Flex-S5

GRANUDOS 15-S5

The control unit has the following main functions:

Chlorine dosing via dosing screw from the drum (GRANUDOS 45/100) or the dosing hopper

(GRANUDOS Flex, GRANUDOS 15)

Acid dosing with peristaltic pump directly from the supply canister

Backwash disinfection / shock chlorination

Fault indications, e.g., chlorine empty, acid empty, collective fault message potential free

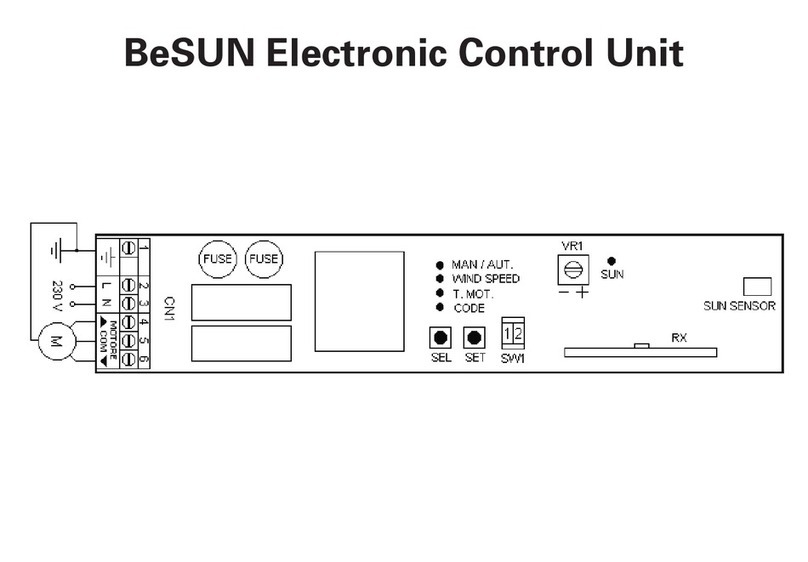

Device overview

The GRANUDOS S5 control unit is mounted on the respective dosing device.

Figure 1, GRANUDOS 45/100-S5, GRANUDOS Flex-S5 GRANUDOS 15-S5

GRANUDOS S5 control unit

The control unit is contained in a dust-proof housing. The start display, called “automatic” operation in the

display, shows the operation mode, the dosing performance and any pending actions or fault indications, if

applicable.

3.3 Identification of the device/ Identification plate

For spare part orders and troubleshooting, the device serial number and the software version must be

indicated. The device serial number is located on the identification plate on the right side of the control

housing. The software version can be found using the menu item Main menu Service Info.

Identification plate see OI Dosing unit

for GRANUDOS Flex-S5, No.: BA SW 022

for Granudos 45/100-S5, No.: BA SW 003

for Granudos 15-S5, No.: BA SW 002

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 8 of 31

3.4 Technical data

GRANUDOS 45/100-S5 control unit

GRANUDOS Flex-S5 control unit

Connection data

Electrical connection data

240 VAC/50-60 Hz ± 10%, 35 W, I max. 0.2 A, standby 22 VA, safety (Schuko)

plug 240 VAC

Protection class

Control housing IP54

Interface connection

---

Operating data:

Measuring range

pH-value: 2.00 to 12.00 pH-value: 2.00 to 12.00

Medium temperature

Ambient temperature

Humidity technical room

0 to 40°C

5 to 35°C

max. 70% (non-condensing)

Hypochlorous acid concentration

max. 0.35%

max. 0.2%

Room ventilation (in and out)

According to DIN 19643

Material of control housing

Housing: PS

Firmware version

--

Hardware version

---

Additional data, see the dosing unit of the respective dosing device.

4Installation

See operating instructions for the dosing unit of the respective dosing device.

for GRANUDOS Flex-S5, No.: BA SW 022

for Granudos 45/100-S5, No.: BA SW 003

for Granudos 15-S5, No.: BA SW 002

5Commissioning

For commissioning, see the operating instructions for the dosing unit of the respective dosing device.

for GRANUDOS Flex-S5, No.: BA SW 022

for Granudos 45/100-S5, No.: BA SW 003

for Granudos 15-S5, No.: BA SW 002

The device is delivered with defined factory settings. You can find the setting values in the operation data

sheet in Chapter 9.4. Adjust the parameters to your pool’s requirements.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 9 of 31

6Operation / service of the control unit

NOTICE!

The nationally applicable accident prevention provisions must be complied with. In

Germany: Operation of swimming pools DGUV 107-001.

6.1 General

Once all the preparations for commissioning have been completed, the settings can be adjusted on the

GRANUDOS Touch dosing system.

6.2 Operation of the GRANUDOS S5 control unit

The operation modes and faults are displayed directly on the start display (operation display): see 6.2, Figure

3.

In automatic operation, the current operation mode, the control, the set dosing performance, output for

chlorine or pH dosing and any potential delays or faults are displayed.

The device is operated by means of 3 operating keys next to the display.

Use the arrow keys to navigate up or down or to set numerical values.

Use the Enter key to navigate to the selected sub-menu and back.

For an overview of the menu structure and abbreviations, see Chapter 10.1, page

31.

Figure 2, Display with operating panel

TIP! - Shortcut!

Back to main menu: Simultaneously press the two arrow keys for 3

seconds.

Password

There are predefined menu areas that require a password to be entered. The password is automatically

queried in these areas. The password consists of four digits and has a factory default setting of 0123. It

protects defined menu areas against unauthorised access. We recommend that you change this password and

enter the new password in the operation data sheet.

6.3 Start display (operation display)

After activating the device, you will see the start display (also called operation display).

01. Operation modes line

02. Input signal external chlorine control active

03. Input signal external pH control active

04. Status line / fault indication

05. Set chlorine dosing performance

06. Set acid dosing performance

07. Chlorine dosing active

08. pH dosing active –Example, chlorine and acid

cannot be active at the same time

The operation modes line (01) can show the following displays:

Automatic, Manual dosing, GRD OFF, Auto Dos OFF, Start delay b-pump, filter disinfection (shock

chlorination), CCT OFF

The status line (04) displays general notices and faults:

e.g., start-routine, dos delay XX sec., alarm fuse F2 - F14 as well as additional alarms and faults.

Depending on the operating state, the display shows different views. The following illustrates and describes

the main display views.

Figure 3, Start display - Explanation

01

02

04

03

05

07

08

06

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 10 of 31

start display –Automatic

The device is in the Automatic operation mode. The device doses upon request via an

external controller. The set dosing performance is displayed.

There is no fault.

NOTICE!

The dosing stops once you switch to the main menu by pressing “Enter” and only starts

again once you switch back to the start display. After 10 minutes without entry, the

system automatically switches back to the start display.

Start display - Startup routine –Delay booster pump - Dosing delay

The startup routine:

If the device is started via the CCT, the startup delay runs for the booster pump “Start

delay b-pump”. The startup delay is used to ensure that no air enters the booster pump

during the subsequent operation.

Setting the delay time under “Settings”“Start delay b-pump”

If the specified pump pressure is reached within 6 seconds after the start of the booster

pump, the dosing delay then runs (for a fixed 3 sec) and the dosing device switches to

the set operation mode. The remaining times are displayed at the bottom in each case.

Startup mode:

If the specified pump pressure or the minimum water level is not reached/undercut within 6 seconds after

the start of the booster pump or also during operation (fault “Pressure min”, “Level min”), a startup mode

of 120 sec. starts again up to 5x. In this case, the Boosterpump runs for 6 seconds, then pauses until 120 sec.

The remaining times are displayed at the bottom in each case. If the specified values for pressure/level are

not reached, the device enters the fault mode.

Software alarms are suppressed during this time.

6.4 The Main Menu

The main menu is reached by pressing “Enter”.

Automatic (PWM/Frequency) / Manual

Shows the set operation mode. Press “Enter” to switch to the start display that starts

the GRANUDOS. Setting the operation mode time under the “Settings Control”

menu item.

GRANUDOS ON/OFF

Press “Enter” to switch the display to “GRANUDOS OFF” (see 6.2); the device

switches to “Standby” operation.

The start display (operation display) displays “GRD OFF” in the status line (04).

Dosing ON/OFF

Press “Enter” to switch the display to “Dosing OFF”, e.g., for service tasks or to flush

the dissolving unit. The b-pump continues to run, the chlorine and acid dosing is switched

off.

The start display displays “Auto Dos OFF” in the status line (04).

Reset alarm

For acknowledging a pending fault indication (alarm relay).

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 11 of 31

Start display –Fault indication –Acknowledge alarm

If a fault occurs, this will be indicated by a red display and the fault indication in the

bottom line.

For a description of the fault indications, see Chapter 7.2, Fault removal.

Faults must be pending for 6 seconds before a notification or an alarm is triggered.

A distinction is made between alarms (software alarms, e.g., dosing time monitoring,

monitoring switch) and notifications (e.g., “Chlorine empty”).

Examples for fault indications / alarm

Dos-limit Cl = Dosing time limit for chlorine exceeded

pH empty = pH (= acid canister) empty

Cl empt = Chlorine tank empty

Fuse F2 = Fuse F2, for details, see Chapter 7.2,. Fault removal

NOTICE!

An alarm will automatically be deleted when its cause has been remedied. For example,

the empty chemical container has been exchanged with a full one.

Acknowledge alarm

Use the Enter key to switch to the main menu

Use the arrow keys to navigate to the “Reset alarm” menu item

Press the Enter key

The alarm relay is temporarily deactivated; this does not rectify the fault! If the fault subsequently recurs,

or if the fault is not rectified, the alarm relay will be reactivated.

Navigate back to the operation mode; this will restart the device.

Special cases

The two alarms for the dosing time monitoring “Dos-limit” cannot automatically be deleted and must

always be acknowledged manually!

In case of the faults “Pressure min” or “Level min” the startup mode starts 5 times for 120 seconds

each to check if the fault is still pending. (See Chapter 6.3.2)

oIf the fault is rectified during the 5 startup attempts, the device returns to the previous state, e.g.,

automatic operation.

oIf the fault still continues after this, the GRANUDOS switches off.

oIf the GRANUDOS has switched off, the fault must be acknowledged manually. To do so, the “Reset

alarm” command must be carried out twice: Once to reset the alarm, and once to reset the startup

delay. Now, the GRANUDOS will start up again and the cause of the fault can be investigated.

Settings –see Chapter 6.4.1

For adapting parameters and system settings:

Dos perform., Shock chlorination, System, Dust extraction, Delay b-pump, Config. Cl

(= rated dosing performance), Config. pH, Control, Teach Cl, Input inverse, return

Service –see Chapter 6.4.2

For input and output test and device information.

Event Log –see Chapter 6.4.3

Displays the past 25 fault indications

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 12 of 31

Main menu Settings (overview)

The Settings menu is used to implement the desired settings for the dosing device. Use the arrow keys to

navigate to the next menu item.

Dos perform.

Adjust dosing performances for chlorine and acid to the pool size. The dosing

performance is monitored.

Shock chlorination

Set dosing performance for the shock chlorination function for shock chlorination or

filter disinfection.

System

Set or implement language, contrast, password, reset

Dust extraction (option)

Set parameters for dust extraction

Delay b-pump

Set delay time for the start of the booster pump after an external switch-off

Config. Cl (with password entry)

Set device-specific dosing parameters for chlorine (set ex works)

Config. pH (with password entry)

Set device-specific dosing parameters for acid (set ex works)

Control (with password entry)

Control type PWM (= pulse width modulation, also impulse length control), set

Frequency or Manual

Teach Cl full (optional)

Calibrate the Chlorine empty switch

Input inverse (with password entry)

Invert the input signals

return

back to main menu

Main menu Settings Dosing performance/Dosing time monitoring/dosing process

The Dosing performance menu is used to adjust the dosing performance to the expected consumption of

chemicals in the pool.

The required dosing performance depends on several factors, e.g., the pool volume, location, type of use and,

of course, the pool’s frequency of use.

Explanation regarding the dosing process

Chlorine and acid are dosed at intervals with pauses between the dosing cycles.

The dosing performance is determined by the set cycle time, the set dosing times (running time of the dosing

motors for chlorine and acid) with the intermittent pauses.

A dosing cycle proceeds as follows:

1. Chlorine dosing: 1-15 sec.

2. Pause: 3.5 sec. fixed

3. Acid dosing: 1-8 sec.

4. Pause until end of cycle –etc.

With “Manual dosing”, this cycle runs continuously.

In “Automatic” operation, this cycle also runs; however, the dosing is only activated if the control command

for the dosing (chlorine or acid) is pending. It the control command encounters a pause, the respective dosing

is activated in the following cycle.

Chlorine and acid dosing are independent; dosing occurs when the external controller requests chlorine or

acid –but always in the cycle, so that chlorine and acid can never be mixed in the open flushing tub.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 13 of 31

Explanation of the setting parameters

Chlorine: Dosing time for chlorine granulate in seconds per cycle, can be set from

1-15 sec. The dosing performance set in this way can be seen on the start display. It

is best to use the “shortcut”, see Chapter 6.2.

pH (acid): Dosing time for acid in seconds / cycle, can be set from 1-8 sec.

Cycle: Length of entire dosing cycle in seconds, can be set from 30-360 sec.

The cycle time must be set first. If the cycle time is changed, the dosing performance

for chlorine and acid changes at an equal ratio.

Dos-limit Cl: Dosing time monitoring for the chlorine dosing with external control,

can be set in minutes from 0-100 min. This prevents overdosing in case of a fault in

the control: For an explanation, see 6.4.1.8.

Dos-limit pH: Dosing time monitoring for the acid dosing with external control in

minutes from 0-100 min. –see dosing time limit for chlorine.

Explanation of dosing time monitoring “Dos-limit Cl/pH”

If the GRANUDOS is controlled by a measuring and control device, the dosing performance must be set

sufficiently high so that even large loads can be regulated without significant deviations from the target value.

In case of a pulse width modulation (PWM), this means that the pause times must always be greater than the

dosing times, since the actual values should approach the target values. However, if the dosing times are

longer than the pause times, then either the dosing performance is too low (set too weakly, or motor or

screw are defective), or there is a malfunction in the measuring and control device (control relay stuck, contact

defective) or a fault in the GRANUDOS control board.

The dosing time monitoring totals the dosing times against the pause times, and if the set dosing time limit is

exceeded, dosing is deactivated and indicated as a fault.

Both the chlorine and pH control respectively dosing are monitored.

Example for calculating the realisable dosing performance required according to DIN 19643

In accordance with DIN 19643, in indoor pools 2 g of chlorine must be added per each 1 m³/h circulation

capacity. In outdoor pools, a dosing capacity of 10 g/m³h is required as a possible dosing performance.

Calculation: Thus, for an indoor pool with 600 m³ and a circulation capacity of 200 m³/h, a dosing

performance of 200 m³/h x 2g chlorine = 400g/hour must be possible.

In the delivery state, the maximum dosing performance of the GRANUDOS is displayed in the start display

according to the installed dosing technology. (see also Chapter 6.4.1.6/6.4.1.7 Config. Cl / pH)

Example for setting the dosing performance

1.Chlorine dosing

In an indoor pool, the usual chlorine requirement is around 200-300 g/100 m3 water content per day. For

a 600 m3pool, this equals 250 x 6 = 1500 g/day or 150 g/hour with 10 hours of circulation time. If the

GRANUDOS is designed with a dosing technology of 1600 g/h –see “Config. Cl”, about 150 g/h should be

set with continuous dosing without measuring and control technology. To do so, the cycle could be reduced

to 60 seconds and the dosing time could be reduced so that the start display (see above) displays approx. 150

g/h

If a measuring and control technology is present, the dosing performance must be set about 2-3x as high

to be able to control demand peaks. In this case, a dosing performance of 300-400 g/h would be required.

Set the cycle to 30 seconds here and reduce the dosing time until about 350 g/h is displayed.

In an outdoor pool, with fair weather the chlorine consumption is about 5x as high, i.e., in the above pool,

a dosing performance of approx. 700-800 g/h should be provided. With the assumed incorporated dosing

performance of 1600 g/h, the cycle should therefore be set to 30 seconds, and the dosing performance

should be set to the desired value.

After a few days, a readjustment may be necessary, according to the obtained measuring results –

measuring value deviations from the target value!

2. Acid dosing

No exact prediction can be made for acid consumption. The actual demand for chemicals depends on the

concentration of the acid, frequency of use by pool visitors and the specific local conditions (fresh water pH,

hardness, temperature) and must be readjusted according to the measuring values:

At the start, the acid dosing is adjusted to approximately half of the chlorine dosing; e.g., if chlorine is 600g/h,

then set acid to approx. 300ml/h. (With 37% sulphuric acid).

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 14 of 31

ATTENTION!

The use of sulphuric acid is generally possible up to a concentration of 50%. With

higher concentrations or when using other acids (e.g., hydrochloric acid, dissolved

sodium hydrogen sulphate, etc.), pay attention to a change in dosing performance

and/or increased corrosiveness! We recommend consultation with the manufacturer!

NOTICE!

When refilling the pool, the pH value must be manually brought to the desired value,

since a relatively large amount of acid is required to reach the desired value with a high

pH-value and extreme hardness. This would take too long if only using the

GRANUDOS’s acid pump. The result would be a poor disinfection performance at a

high pH-value, or possibly a fault indication because the target value has not been

reached.

Main menu Settings Shock chlorination

With this menu, you can adjust the dosing performance for chlorine and pH for a shock

chlorination. Please select a dosing performance that ensures the availability of the

desired concentration during the shock chlorination.

This dosing performance is used when a filter disinfection is requested by the CCT.

For monitoring purposes, the chlorine concentration should be checked several times

during shock chlorination.

Main menu Settings System

Here, you can adjust the system settings for language, contrast, password and reset.

Language

Select the desired user language

Contrast

Adjust the display’s contrast

Password

Change the password:

The password consists of four digits and has a factory default setting of 0123. It protects

defined menu areas against unauthorised changes. We recommend that you change this

password and enter the new password in the operation data sheet.

In order to change the password, you must first enter the old password.

Use the arrow keys to select the appropriate number.

Use the Enter key to jump to the next number and select it.

Finally, confirm with the Enter key.

The display jumps to the entry field for the new password. Enter the new password,

confirm with Enter, and make a note of the new password in the operation data

sheet.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 15 of 31

If a wrong password is entered, the display colour changes to red, and the password must be re-entered.

Only certain predefined menu areas require a password to be entered. The password is automatically queried

in these areas. The respective areas are:

Reset

Dust extraction

Delay booster pump

Config. Cl

Config. pH

Control

Input inverse

Once the password has been entered, all other password-protected menu areas are also activated. The

activation ends once the user switches back to the start menu.

NOTICE!

Please store the individually chosen passwords safely in the operation data sheet. Lost

passwords can only be reset by the factory customer service!

Reset

This process can only be performed by entering the password.

All of the set parameters are reset here to the factory settings.

The factory settings are listed in the operation data sheet in Chapter 9.4

TIP!

Note down the operating settings in the operation data sheet before

resetting! This makes it easier to set new values.

Main menu Settings Dust extraction (option), (password entry)

This process can only be performed by entering the password.

The dust extraction parameters are set here. The extraction begins with the start of the

chlorine dosing and runs until the end of the run-on time.

Set Delay time, 0-60 sec, 0 = dust extraction deactivated; after completion of the

chlorine dosing, the dust extraction continues to run for the set amount of time.

Set Flushing time 1-5 sec. for the suction injector and the dissolving pipe (option);

the flushing valve opens for the set amount of time and both items are cleaned.

Set Flushing interval 0 - 48 hrs (option); the flushing interval is the time between

two flushing cycles.

Main menu Settings Delay Booster pump (password entry)

This value can only be set by entering the password.

This function is only active when the GRANUDOS is switched off externally for filter

flushing via the CCT. Once the GRANUDOS has been switched on again, the booster

pump is started with the set delay time. This ensures that no air remains in the supply

line to the GRANUDOS, which could lead to faults in the b-pump.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 16 of 31

Main menu Settings Config. Cl (chlorine dosing performance) (password entry)

This setting can only be executed by entering the password.

“dos-screw”denotes the dosing screw

Here, the dosing components: dosing motors, dosing screws that can be used are

displayed. The values are preset ex works and are used as the basis for determining the

defined maximum dosing performance that is shown when the display is switched on.

The maximum dosing performance defined from the Config. Cl is displayed here. To

change the desired dosing performance, the cycle time and the chlorine dosing time

(Settings Dosing performance menu) can be changed.

CAUTION!

These values may only be changed if the appropriate components have been installed

in the dosing device. Otherwise, the dosing performance will be displayed incorrectly!

Maximum achievable dosing performance depending on the dosing motor’s rotation speed and the

diameter of the dosing screw.

Rotation speed of the dosing motor

Diameter of the dosing screw

maximum dosing performance* - default

12 rpm

19 mm

600 g/h

35 rpm

19 mm

1600 g/h

60 rpm

19 mm

2200 g/h

12 rpm

26 mm

1000 g/h

35 rpm

26 mm

3300 g/h

60 rpm

26 mm

4800 g/h

* The specified values are the maximum dosing performance of the GRANUDOS. This represents 50% of

the permanent dosing performance. These are approximate values +/- 20% - depending on the condition of

the granulate and dosing screw.

Main menu Settings Config. pH (acid dosing performance) (password entry)

This Input can only be performed by entering the password.

The hose length of the installed peristaltic pump for acid is set here. The values are

preset ex works and are used as the basis for the dosing performance display.

If an external acid pump is used, the menu item "External" must be selected and the

external pump's dosing performance must be entered.

The maximum possible dosing performance is displayed here –see below. To change

the dosing performance, the cycle time and the pH dosing time can be changed (Menu

Settings Dosing performance).

If the cycle time is changed, the chlorine dosing performance and the pH dosing

performance change at an equal ratio.

CAUTION!

These configuration values may only be changed if the appropriate components have

been installed in the dosing device. Otherwise, the dosing performance will be

displayed incorrectly!

2400

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 17 of 31

Maximum achievable dosing performance, depending on the dosing pump’s hose diameter.

Hose kit - hose diameter

maximum dosing performance*

0.8 mm

100 ml/h

1.6 mm

400 ml/h

3.2 mm

1200 ml/h

4.8 mm

2400 ml/h

* The specified values are the maximum dosing performance of the GRANUDOS; this represents 25% of the

pump’s permanent dosing performance. These are approximate values +/- 10% - depending on the condition

of the peristaltic pump.

Main menu Settings Control (password entry)

Control via external measuring and control technology

CORROSIVE!

The measuring and control technology must not switch the GRANUDOS device on or

off under any circumstances, but only the dosing unit –see wiring diagram. Any

necessary shutdown of the GRANUDOS must not take place during cycle. The dosing

cycle must always be able to run unimpeded. Otherwise, a chemical back-up could

occur when flushing the chlorine granulate, resulting in chlorine gas formation!

This setting determines the control mode of the chlorine and acid dosing and can only

be executed by entering the password.

a) Control PWM = Pulse width modulation (standard)

The controller output is organised in cycles. The control signals come with 230 VAC or potential-free. After

capturing the input signal, the GRANUDOS doses for chlorine or acid using the set performance. If the input

signal is pending for a longer time than the set cycle duration, another dosing is carried out in the following

cycle.

NOTICE!

The shortest signal duration should be at least 2 seconds long to ensure accurate

dosing.

Explanation about the operation with an external acid dosing pump for regulating the pH-

value; only possible with PWM control

If an (existing) external dosing pump is to be operated for regulating the pH-value, it must be considered that

the acid dosing in the GRANUDOS must also always be active in order to avoid deposits in the dissolving

system.

For this purpose, the acid control can be clamped parallel on the chlorine control (electric wire bridge).

With 230 V control: on SL3 terminal 1+3, plus bypass 2+4.

With potential-free control: on SL8 terminal 1+3, plus bypass 2+4.

Thus, during each chlorine dosing the acid dosing is activated as well. For the required cleaning function, the

dosing performance for acid dosing must be set to a low value. However, it must be checked if the set dosing

performance is sufficient for the cleaning; the mixing cyclone must not get cloudy. See also Chapter 6.4.1.1,

page 12, Example for setting the dosing performance.

CAUTION!

It is urgently recommended in this case to also connect the pH-control at the

GRANUDOS in parallel to avoid acid overdosing in the event of a fault in the chlorine

dosing.

TIP!

As a rule, the pH-value in the pool is set with the acid dosing at the GRANUDOS.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 18 of 31

b) Frequency control pH external, Cl external

The maximum number of impulses (frequency) of the external control technology is set

on the GRANUDOS up to max. 200 impulses/minute. The GRANUDOS now always

counts the incoming impulses per minute, calculates the requested dosing performance

on this basis and doses the respective amount in the following cycle.

In this case, an input signal of 200 impulses/minute results in 100% dosing

performance.

An input signal of 100 impulses/minute results in 50% of the set dosing

performance.

The setting must be made separately for the pH and chlorine control.

c) Manual control = Manual dosing

It is possible to change over to continuous dosing. This may be required in the event of

a fault in the external measuring technology, e.g., electrode failure, that cannot be

rectified at short notice.

“Manual dosing” can only be selected for both chlorine and acid dosing together.

Upon activation of Manual dosing, the status line on the start display changes from

Automatic to Manual dosing.

CAUTION!

In the “Manual dosing” operation mode, the water quality must be checked

continuously and the dosing performance must be adjusted to the current

consumption. Non-compliance with this may result in considerable incorrect dosing!

Main menu Settings Teach Cl full (optional)

TIP!

This function is not available in the standard design; it only works in combination with

a special sensor.

The switch for the Chlorine empty notification in the device is a capacitive proximity

switch. This switch must be recalibrated, if necessary. The justage is carried out as

follows.

Full adjustment (justage):

Full adjustment can only be carried out if the dosing hopper contains granulate!

Fill chlorine granulate into the dosing hopper (for GRANUDOS Flex +

GRANUDOS 15), or attach the chlorine drum (for GRANUDOS 45/100) and

pivot into the dosing position.

Carry out the full adjustment in the menu via “Teach Cl full” Full adjustment. The

process is started by pressing the Enter key; it runs for 12 seconds. The full

adjustment has now been carried out.

For the standard design, the justage is described in the Operating Instructions

for the respective dosing device.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 19 of 31

Main menu Settings Input inverse (password entry)

With an activation via an external control (e.g., central control technology CCT) it may

be necessary to invert the input signals “CCT OFF” and “Dosing CCT OFF”. Here, you

can switch between NC and NO.

NO (normally open) indicates that the is switch open in the operating state and closed

when deactivated (for switching off).

NC (normally closed) indicates that the switch is closed in the operating state and open

when deactivated (for switching off).

Main Menu Service

Input test

A test programme for the switch inputs (electrical signals).

Output test

A test programme for the actuators and relay outputs.

Info

Information about the software version.

Main menu Service Input test

The input test is used to check (via manual actuation) the connected monitoring switches and external inputs.

The position of the switch inputs is indicated by symbols.

The symbol “ ” indicates Switch open

The symbol “ ” indicates Switch closed

Use the arrow keys to scroll through the pages.

List of input tests:

1. pH ext 24 V, potential-free signal for pH dosing via external control

2. Cl ext 24 V, potential-free signal for chlorine dosing via external control

3. CCT OFF, The GRANUDOS is deactivated via the central control technology

(CCT). No dosing, no alarm message issued (b-pump OFF).

4. Filter dis., A filter disinfection is running (the dosing performance is set in the

“Shock chlorination” menu)

5. Cl empty, no chlorine in the dosing hopper chlorine empty switch active

6. Level min, The level in the GRANUDOS flushing tub is too low. The booster

pump is stopped

7. DosCCT OFF, The dosing is deactivated externally.

8. pH empty, no chlorine in the dosing canister Acid empty switch active

9. Pres. min, The pressure at the GRANUDOS booster pump is too low. The

booster pump and the dosing are stopped

10. pH ext 230 V, 230 V signal for pH dosing via external control

11. Cl ext 230 V, 230 V-free signal for chlorine dosing via external control

12. Suct. pipe, The flow in the GRANUDOS’s suction pipe is too low. The dosing of

chlorine and acid is stopped.

13. Level max, The level in the GRANUDOS flushing tub is too high. The dosing of

chlorine and acid is stopped.

Control Unit, GRANUDOS S5

Index: 03 Change date: 09/01/2024 OI No.: BA SW 014-03 Granudos S5-Steuereinheit EN.docx Page 20 of 31

Main menu Service Output test

The output test is used to check the connected outputs (actuators and relays). The selected output is activated

for 20 seconds. The activation can be cancelled at any time using “Enter”.

For safety reasons (chlorine gas formation), the output test for the chemical-dosing outputs is only released if

no fault exists that could prevent the dosing, e.g., flow in the suction pipe too low.

An output test can be performed for the following actuators:

1. pH (=acid) dosing

2. Chlorine dosing

3. Knocker - 4x active

4. Heater / Heating

5. Actutator Dust extraction (option)

6. Dust extraction flushing valve (option)

7. Fault indication with relay output

8. pH (=acid) empty = output test for indication with relay output

9. Chlorine empty = output test = indication with relay output

Main Menu Service Info

The software version used can be viewed using the Info button.

This is required for support queries.

Main menu Event log (event and data logging)

The Event log displays the past 25 fault indications. Use the arrow keys to scroll up and

down. The last fault indication received is in the no. 1 position.

At the end of the list, the “Delete log?” command is shown under no. 26. Use “Yes“ to

delete the entire list.

Back to the main menu using the “Shortcut” (Chapter 6.2)

Actuat dust

ext

This manual suits for next models

3

Table of contents