Introduction

To ensure proper installation, the following steps and notes must be complied with under all circum- stances.

Only this way can it be ensured that the product will work to complete satisfaction.

Read all instructions before starting installation. Our sales department will be happy to answer any

questions you may have.

Hint

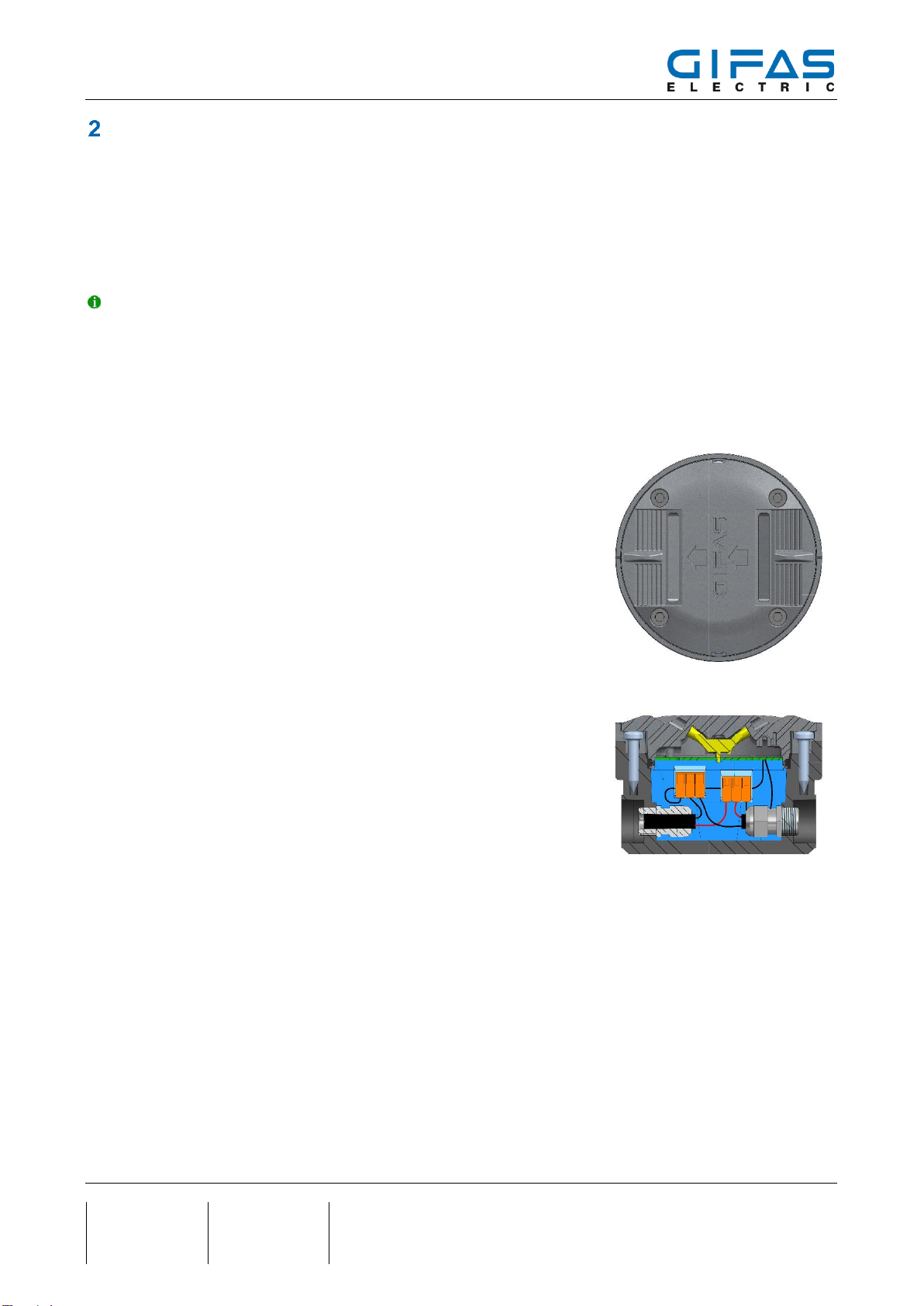

The content of the installation instructions predominantly refers to TrafficLED, but is also valid for CircLED as

well. This applies for pictures correspondingly and is valid for both applications. TrafficLED is fitted with a metal

ring for the alignment of the plastic mounting socket. This is not used in the CircLED. There are two different

installation gauges for TrafficLED and CircLED. It is imperative that the corresponding installation gauges are

used for installation. Without the correct installation gauge, the lights cannot be fitted flush with the roadway.

2.1 Installation conditions TrafficLED / CircLED

-The road surface must have the necessary depth and stability so

that the TrafficLED can withstand the traffic load.

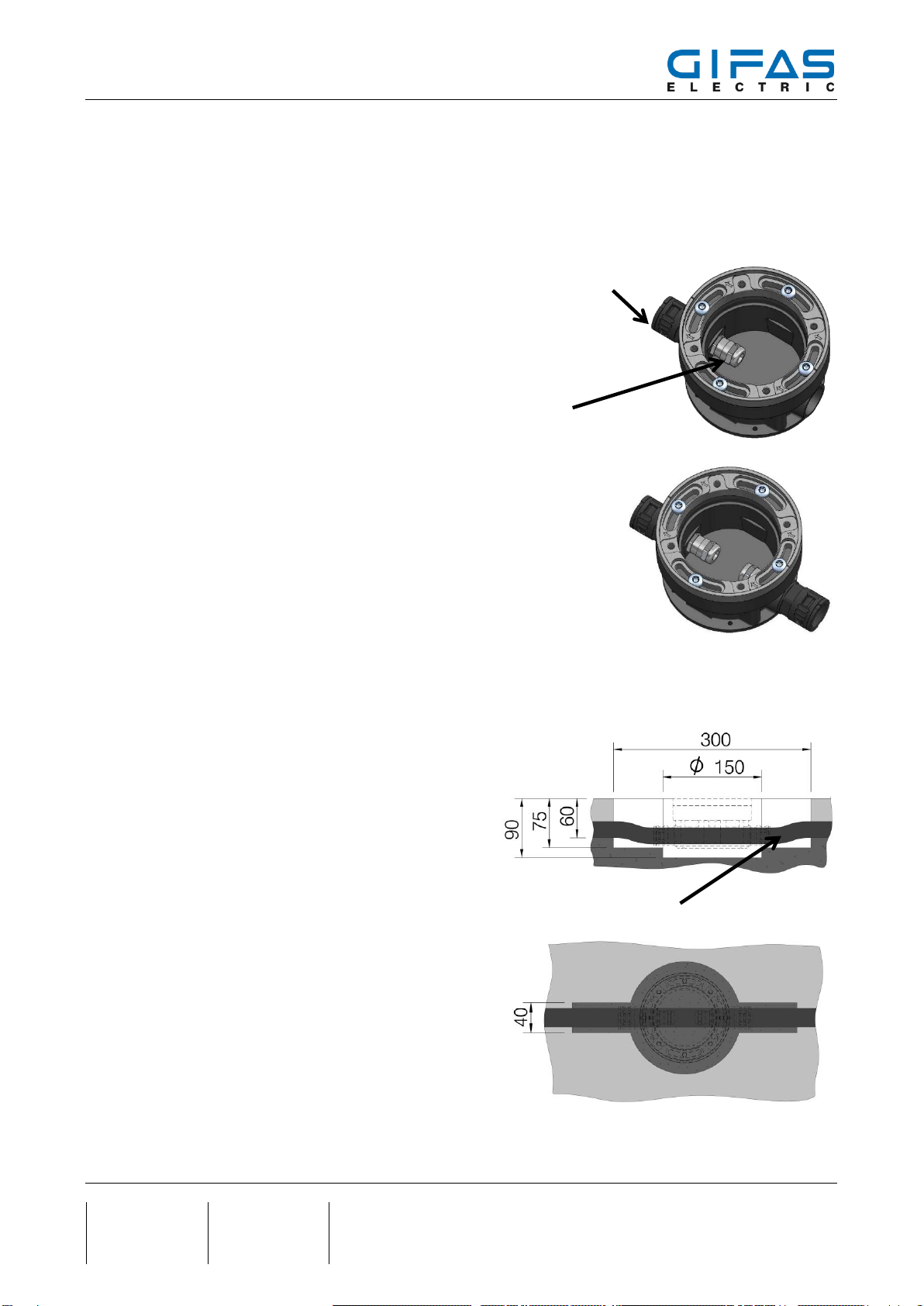

-The mounting socket must be installed firmly in the roadway. If the

asphalt moves, the socket may have to be placed again.

-The surface around the light must be flat; the socket installed must

not protrude. The upper part of TrafficLED only protrudes 4 mm

(CircLED 3.5 mm) above the roadway.

-In order to increase the service life, the lights should be installed

between or next to the lanes.

-In order to increase the service life, the lights should be installed

between or next to the lanes.

-Only use mortar which withstands the load correspondingly. Note

in the process that small cracks may occur between surface and

TrafficLED / CircLED.

-In order to comply with the necessary operating voltage, the cable

cross-section must be adjusted to the cable length.

-Install only in dry weather or under a covered installation site.

-Installation work must not be carried out at roadway temperatures

of below 5°C or above 30°C as well as in wet conditions / rainfall.

The drying time of mortar may take several hours in case of low temperatures!

-TrafficLED has been designed in such a way that it can be mounted opposite to the driving direction

as well.