2833 West Chestnut Street | Washington, PA 15301 | Toll Free: 800-245-4964 | www.westpenn-wpw.com

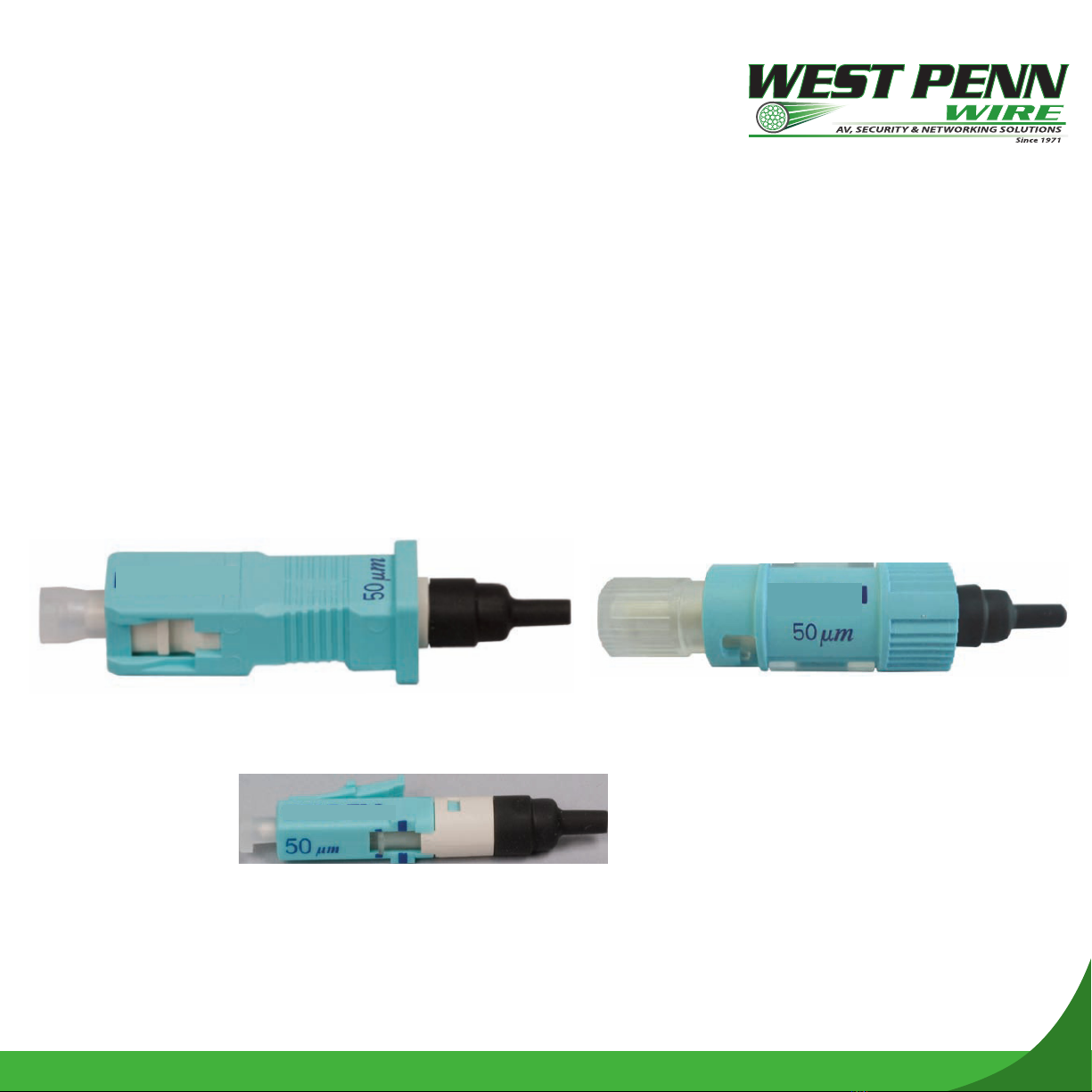

Boot

Closed Position

Section A - What’s New and What You Need to Know

is Guide Includes:

• Installation procedures for Brilliance LC, SC and ST connectors.

• A section describing components, features and accessories.

• Cleaning procedures.

• A troubleshooting guide and tips.

CAUTION:

• When installed on a live system, invisible laser radiation may be present.

• Do not stare into connector endface or view directly with optical instruments.

• Wear safety glasses when working with optical ber.

• Dispose of all scrap ber in the waste bottle to a void getting ber slivers.

• Do not touch cleaver blade.

Key Success Parameters

• Cleanliness:

- Keep exposed ber components clean as well as your environment.

- Keep dust caps on and avoid dust creating activities.

- Clean endface with alcohol wipes and then dry wipe as per cleaning procedures

• Cleave Quality:

- Field clea ver can produce inconsistant results, verify cleave quality with a microscope aer each cleave.

- Precision cleavers are recommended and will improve clea ve quality. However, it is important to

validate cleaver performance ever y 25 connectors or less.

• Installation Quality:

- Test connector performance at ever y 100 connector installations or less.

- Use VFL and Support Handle for best results during termination.

2833 West Chestnut Street | Washington, PA 15301 | Toll Free: 800-245-4964 | www.westpenn-wpw.com