Section A90-DCP10X10 030-101868 Rev A

________________________________________________________________________________

1. GENERAL DESCRIPTION

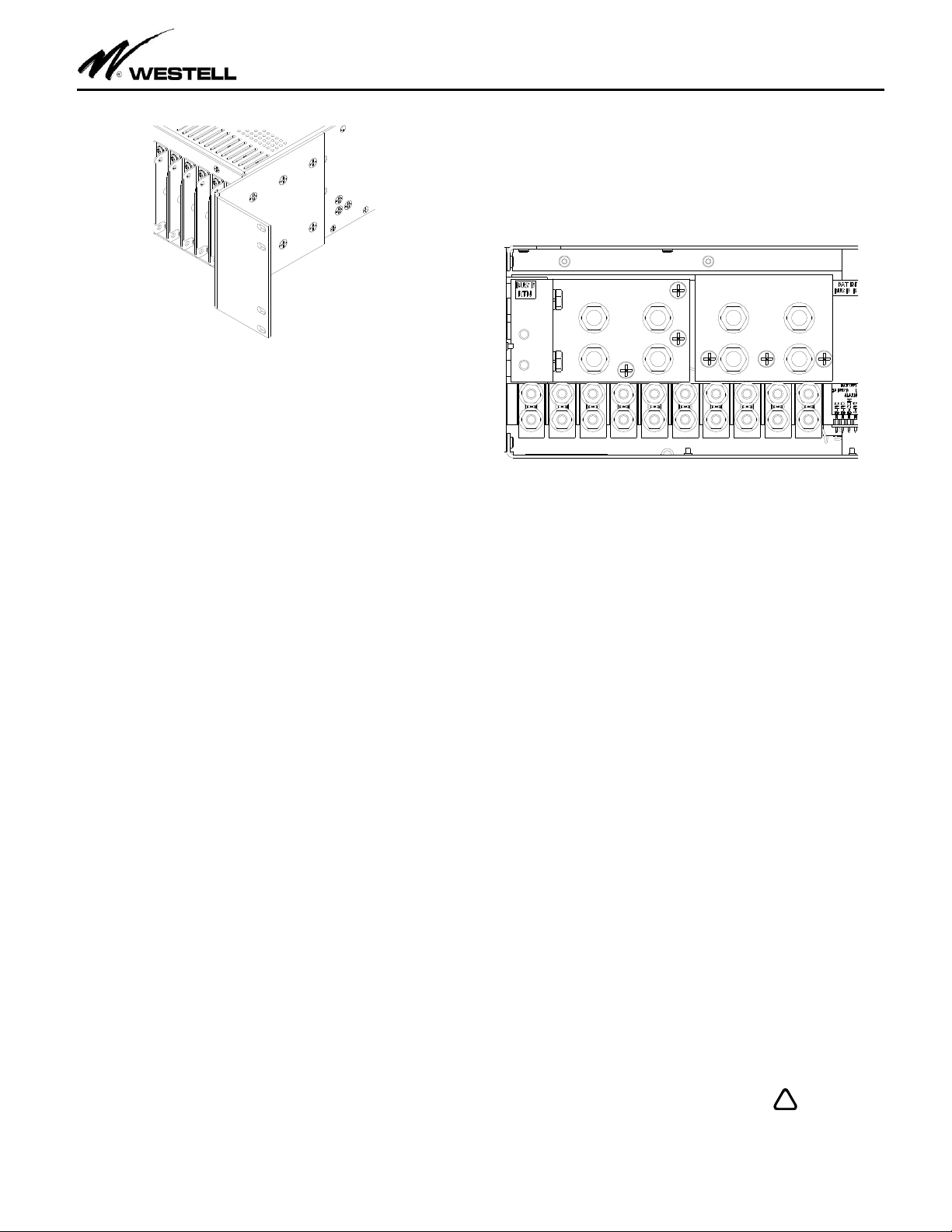

1.1. The Westell A90-DCP10X10 Breaker and Fuse Panel

provides distribution of DC power to equipment. The panel has 2

buses, each bus consisting of 10 pluggable fuse or breaker

positions. Alarm circuits are provided to indicate and extend

alarm conditions when faults occur.

1.2. Input wiring is connected to high current, 2-hole lug input

terminals located at the rear of the panel. Each bus has its own

completely isolated inputs, allowing the distribution of two battery

voltages through the same panel.

1.3. The power is distributed to the load side equipment

through breakers, TLS, TPS or TPC style fuses. There are 10

positions per group and two groups per panel. Each position is

available for installer connection at the rear of the panel. A

designation card is provided for keeping records of which position

is connected to which equipment and what amperage is to be

used.

1.4. Alarm circuits are provided to alert service personnel of

fault conditions. A fuse alarm is generated when a fuse is blown

or a breaker has toggled into an alarm state. That is, a mid-trip

breaker alarms only in the tripped position and not in the off

position. However, a non mid-trip breaker will alarm when it is in

the off position. A red alarm LED

on the faceplate will

illuminate when a fuse or breaker alarm condition is present. As

well, the green Normal Operation LED will extinguish to signal

a fuse/breaker alarm or input power failure and the appropriate

relay contacts will change states. These fuse/breaker panels

have common (C), normally open (NO) and normally closed (NC)

terminals for alarms. Note: the use of the alarm contacts is

optional. If you do not wish to extend the alarms, you don’t have

to do anything with the alarm pins. The “Normal” condition of the

relay exists when the panel is powered up without any fuse or

breaker alarms. The local alarm LEDs are located on the front of

the panel as shown in Figure 1.4.1.

BLOWN FUSE

or TRIPPED

BREAKER

Figure 1.4.1

1.5. The panels are shipped with universal brackets (1” & 1-

1/4” hole spacing) that will fit both 19" and 23" wide racks and use

three 1.75" panel spaces. The panel has two clear plastic shields

to protect the wiring connections on the back of the panel. When

cabling out the top of the panel, use the rear shield. When cabling

out of the back of the panel, use the top shield.

2. APPLICATION

2.1. The A90-DCP10X10 Power Distrirbution Panel is

designed to be used in the rack level distribution of DC power.

They are rack mount panels that provide DC power through two

busses; each bus has 10 positions.

2.2. The A90-DCP10X10 is suitable for installation as part of

a Common Bonding Network (CBN). As well, this product is

intended for restricted access locations in Network

Telecommunications Facilities and OSP.

3. CIRCUIT DESCRIPTION

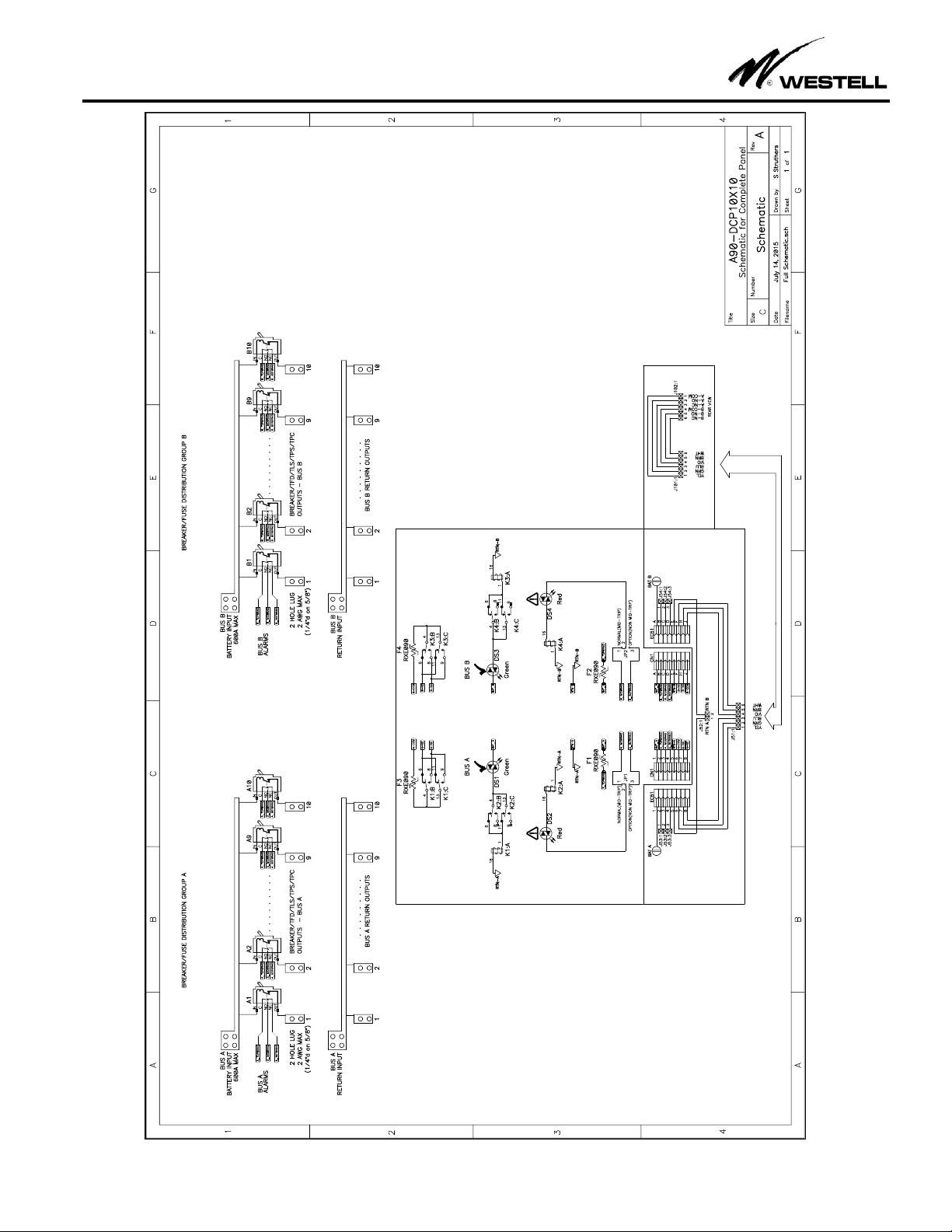

3.1. Power is connected to the panel through 3/8” stud inputs

(see fig 4.4.1). There are two sets of input terminations for each

bus. These inputs are high current terminations for providing up

to 600A per bus. There is a Return (RTN) and Battery (BAT) input

for each bus.

3.2. Distribution of current from each bus is provided by

either breakers, TLS, TPS or TPC style fuses. Each bus has 10

pluggable positions. Each position is made available at the rear

of the panel via ¼” on 5/8” stud terminals.

3.3. Fuse/breaker alarm circuitry provides 1 set of form “C”

contacts (C, NO and NC) for each bus (Bus A, and Bus B). In the

event of a tripped breaker, blown fuse or loss of input power, the

proper relay will change states, providing a connection between

the Normally Open “NO” and Common “C” terminals for that bus.

The normally closed “NC” terminal will open to high impedance.

4. INSTALLATION

Please read completely before beginning.

WARNING: Installation should only be performed by an

experienced Installer familiar with DC power distribution systems.

This product must be installed within a RESTRICTED

ACCESS LOCATION where access is through the use of a

tool, lock and key or other means of security, and is

controlled by the authority responsible for the location. This

product must be installed and maintained by TRAINED

SERVICE PERSONNEL ONLY.

4.1. Unpack and inspect the Panel for possible damage

incurred during shipping. If damage is found, file a claim

immediately with the carrier, and notify Customer Service.

4.2. Once thepanelisunpacked,verifythat therearetwo sets of

mounting brackets. One set is for 19” racks, and the other for 23”

racks. Thebracketswillfitboth1” and 1-1/4” hole spacing applications.

The brackets can be mounted so the panel can be installed for a flush

mounting or offset positions. Adjust the position and orientation of the

correctmountingbracketsonthefusepanel,suchthatitwillfittherack

you wish to mount the panel in.