Section BXB‐19A‐20A 030‐101713 Rev. B R

61406IARB

‐ KNOCK‐OUT REMOVAL NOTE ‐

Always remove knock‐outs (in the Boxer cabinet mounted

above the battery box) where holes are desired before mounting

the battery box or cabinet, regardless of the type of knock‐out and

regardless of the order of the mounting steps. All knock‐outs

should be knocked out from the inside of the cabinet, except for

the small 0.575” knock‐outs (which should be knocked out from

the outside of the cabinet) or the concentric knock‐outs.

3.5.1 Removing Knock‐outs in the Top Cabinet

Regardless of the mounting type, prior to mounting and joining

the cabinets together, remove knock‐outs where access holes

will be needed in the boxer cabinet which will be installed above

the battery box.

There are five 0.575” diameter knock‐outs in the floor of the

Boxer cabinet where the battery box attaches to the cabinet

(hole patterns of both units match). Remove these small

knock‐outs (see Paragraph 3.5.1 and the KNOCK‐OUT NOTE

therein)prior to joining and mounting the cabinets. Verify all

other needed knock‐outs are removed in the cabinet where

cable access holes will be desired, including the knock‐out for

the battery cable, if not already removed.

3.5.2 Joining the Boxer Cabinet and the Battery Box

Regardless of the mounting type, attach the Boxer cabinet to

the battery box prior to mounting or installing the conjoined

units. To join the units, follow the steps below:

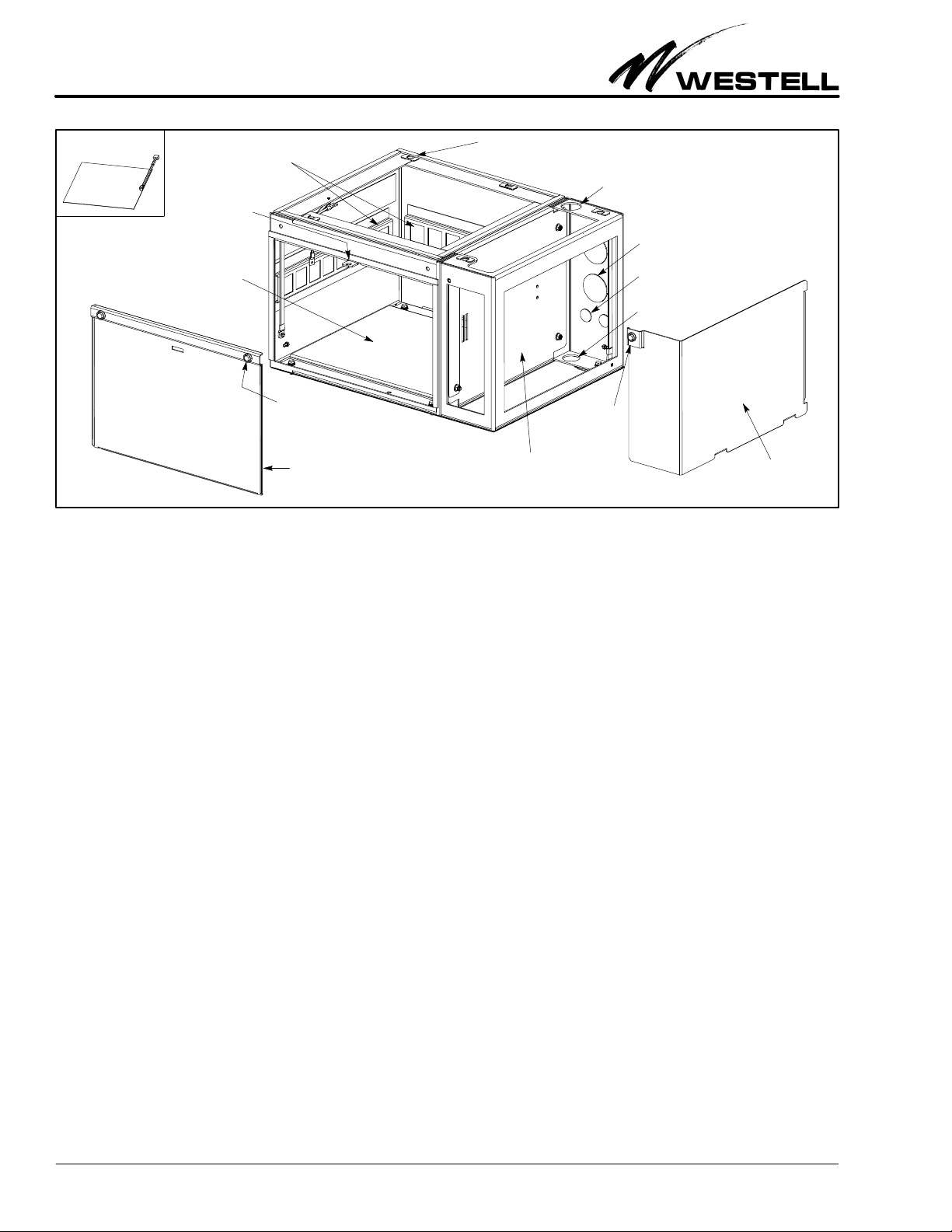

1. Open and prepare both Boxer units. Open the door of the

main Boxer cabinet and remove both access panels of the

battery box for easier handling and mounting hole access.

2. Locate and open parts/hardware kit. Find the bag of hard

ware and parts located inside the battery box. Open the

bag and spread out the parts for easy access.

3. Remove knock‐outs in the Boxer cabinet. If not already

done, remove any required knock‐outs in the cabinet (see

Paragraph 3.5.1 and the KNOCK‐OUT NOTE at this time).

4. Install stiffener bar. Install the L‐shaped stiffener bar to

the rear bottom surface of the cabinet. To do this, loosen

the AC outlet box in the lower rear right corner, orient the

bar so the mounting holes face down, slip the bar (length

wise) behind the outlet box, and place it in the back of the

cabinet where the rear wall meets the bottom surface.

Align the holes in the bar with the holes in the cabinet, and

secure the bracket to the bottom of the cabinet with the

provided hardware. Retighten the AC outlet box.

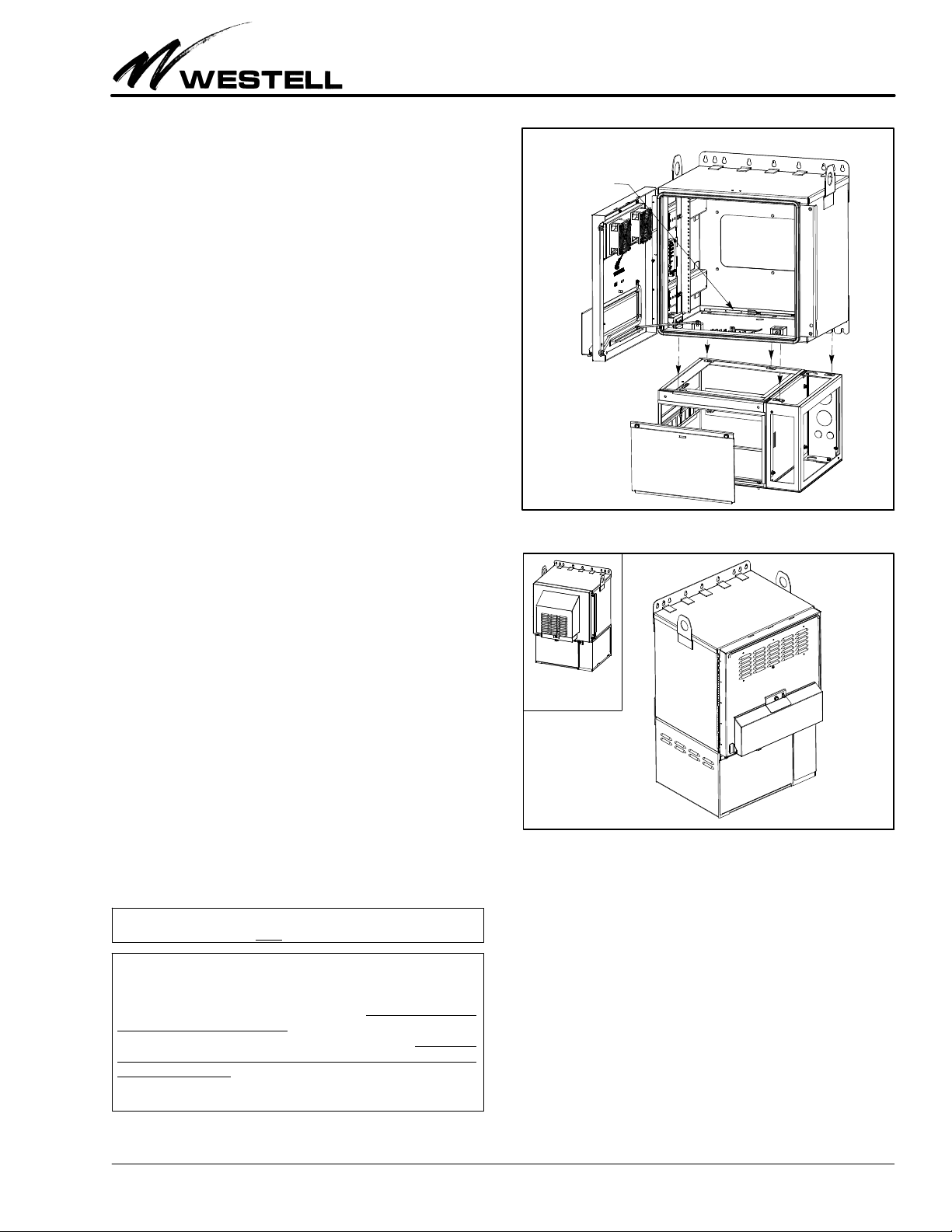

5. Set cabinet on battery box. Lift the Boxer cabinet and place

it on top of the battery box. Slide the cabinet to align the

five holes in the top surface of the battery box with the

matching holes in the bottom of the Boxer cabinet.

6. Attach cabinet to battery box. After aligning all holes, se

cure the units together by inserting, threading and

tightening a bolt (plus a washer) through each set of

aligned holes.

3.5.3 Mounting on a Concrete Pad

Follow the steps below to mount the Boxer battery box on a

concrete pad. The battery box (or an optional skirt) is required

when mounting the main Boxer cabinet on a concrete pad. Or

der and use the optional A90‐BXA19‐PT1 Pad Mount Template

Kit for mounting on a concrete pad. Use the numbered steps be

low and the instructions in Figure 7 to mount the conjoined

Boxer cabinet and battery box on a concrete pad. These instruc

tions are guidelines; you must design, dig, mix, pour, and install the

concrete pad per local building codes and practices. Note the fol

lowing additional concerns for concrete pad installations:

SVerify all required cabinet knock‐outs have been removed

(see the KNOCK‐OUT NOTE and Paragraph 3.5.1).

SSelect a mounting location that is dry, grade level or high

er, and will support a 48” X 42” wide concrete pad (min).

SIf placing the concrete pad next to an adjacent structure,

Westell suggests a 24” distance between the cable access

door panel and any structure to allow for easy cable access.

‐ CONCRETE PAD MOUNT NOTE ‐

For concrete pad mounting, prepare and pour the concrete pad

(and install the accompanying conduit or ductwork) per local

codes and company practices, insert anchors in the wet concrete

where holes at the bottom of the battery box are located (holes

are 0.344” in diameter), and allow the concrete to dry, prior to

mounting the Boxer units.

‐ CONCRETE PAD HEIGHT NOTE ‐

The pad location must be grade‐level or above ‐ it must not be be

low grade‐level. The location must be able to support the com

bined weight of both Boxer cabinets and all internal equipment.

Always follow local installation codes, procedures, and practices.

Concrete Pad Mounting Steps

1. Determine exact concrete pad location. Determine, select,

and prepare the location for the concrete pad, per compa

ny practice and local codes. When determining the size of

the pad, allow for 12” of concrete to extend out from each

side of the battery box (so the pad is a total of 2 feet wider

and 2 feet longer than the battery box).

2. Prepare template. Perform Steps 1‐3 of Figure 7.

3. Prepare the pad for conduit or ductwork. Dig and frame

the pad location per company practice. Once the pad is

framed for concrete, but before pouring gravel or con

crete, install any cable conduit or ductwork that is desired

to be routed through the concrete and which will enter the

battery box from the bottom.

4. Prepare the pad for concrete (add gravel). Fill and com

pact the pad site with gravel, per company practice.

5. Prepare and join both Boxer units. If not already done,

perform the steps in Paragraph 3.5.2 to open both Boxer

units, to locate the bag of hardware in the battery box, to

remove knock‐outs, and to join the units.

6. Pour concrete, place the template, then set insulator pad

and battery box on dry concrete. Perform Steps 4‐7 of