Section BXM‐161‐7HE‐20A

030‐101765 Rev. B

R

9

1311IARB

VProper lengths and types of communications cables

VProper lengths and types of power cables and fittings

VCable management supplies (ties, clips, markers, etc.)

VPower installation and testing equipment

VESD protection

3.5 Removing the Knock‐outs

Knock‐outs should be removed prior to mounting the cabinet.

See Figure 9 or Table 1 for knock‐out sizes, quantities, and loca

tions, and follow the steps below to remove the knock‐outs.

1. Open the cabinet door. If knock‐outs will need to be re

moved, using a 216 tool or can wrench or the provided

pin‐in‐hex wrench, open the large front door of the Box

er‐16 cabinet to access the knock‐outs.

2. Remove knock‐out(s). Prior to mounting the cabinet, per

company practice, remove as many appropriately‐sized

knock‐outs at the bottom of the cabinet as needed for the

specific application (consider ground, power, and com

munication cable access needs, venting, and whether

optionally mounting a battery box with the cabinet).

3. Install rubber grommets or conduit fittings. Install either

a heavy‐duty rubber grommet or the conduit fitting of

choice (liquid‐tight recommended) in each selected

knock‐out hole. If an optional vent is desired, the provided

vent cap can be installed in one of the smaller knock‐outs.

4. Close the cabinet door. Once the knock‐outs are removed,

lock the door using the 216 tool or can wrench, to minimize

possible product damage and personal injury.

3.6 Mounting the Cabinet

The Boxer‐16 cabinet is typically mounted outdoors, above

ground, on an H‐frame, a wall, post, a concrete pad, or a pole.

An optional mounting kit is available to support pole mounting

(from 8” to 20” in diameter). Concrete pad mounting is typically

used when used with an optional Boxer battery box or skirt. An

optional pad mount template kit is available for easy and conve

nient cement anchor placement. All mounting hardware (not

provided) must be capable of supporting the weight of the Box

er‐16 cabinet plus the weight of any equipment mounted in it.

For convenience, lift hooks or ears are provided for temporary

lifting purposes (do not use lift ears from which to hang the cabi

net in permanent installations). Run all cables to the mounting

location, perform any trenching, trench cable placements, and

backfilling prior to the cabinet mounting, and clear the installa

tion area of any debris, vegetation, and unneeded equipment or

obstacles.

‐ KNOCK‐OUT REMOVAL NOTE ‐

Always remove knock‐outs where holes are desired before

mounting cabinet or securing the battery box, regardless of the

knock‐out type and regardless of the order of the mounting steps.

All knock‐outs should be knocked out from the inside of the

cabinet, except for the small 0.575” knock‐outs (which are to be

knocked out from the outside of the cabinet) and except for the

concentric knock‐out (from either direction, per hole size).

‐ WEIGHT NOTE ‐

The Boxer‐16 cabinet weighs 80 pounds. The weight of the inter

nal equipment installed in the Boxer‐16 should not exceed 90

pounds. The mounting surface, structure, and hardware must be

able to support the combined weight (170 pounds).

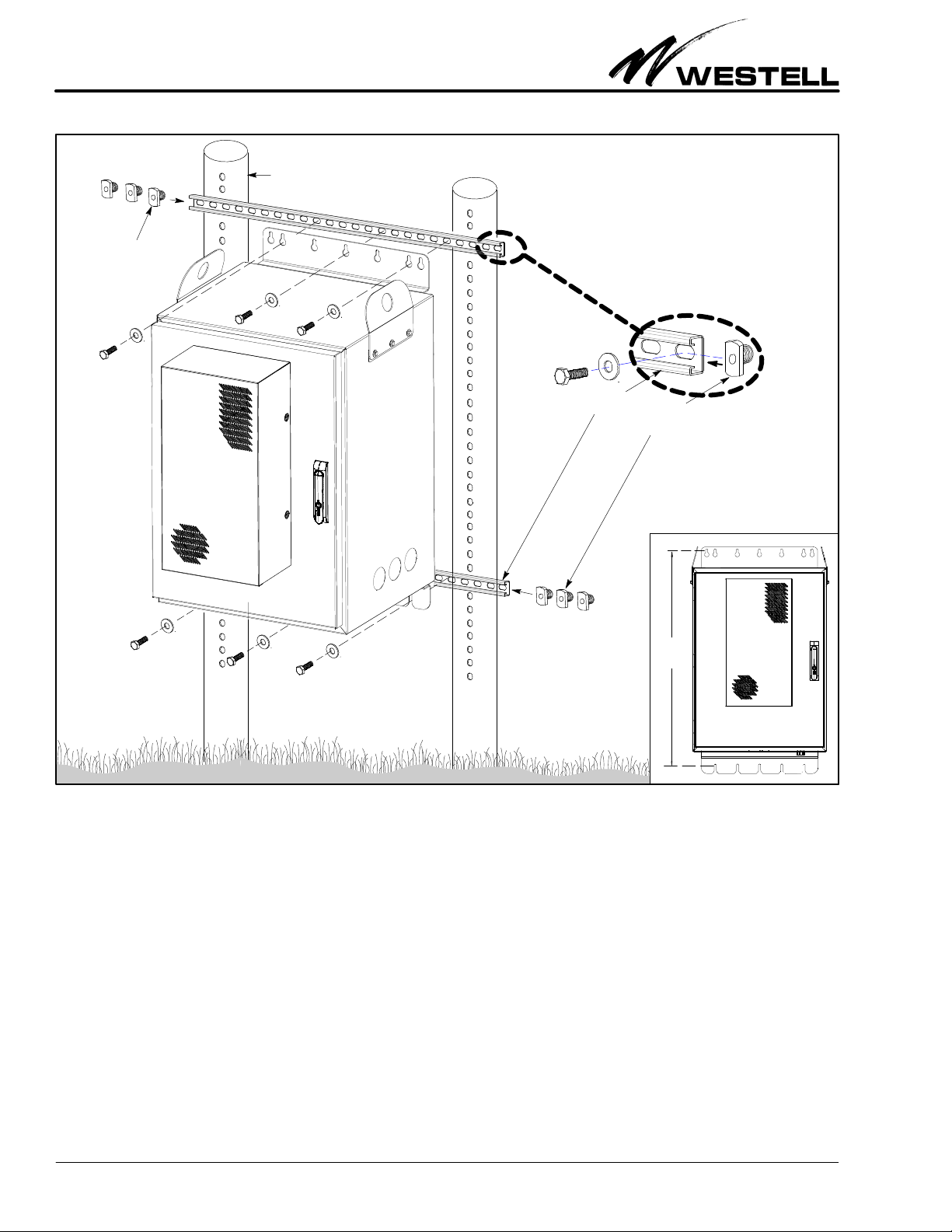

3.6.1 Mounting on an H‐Frame

To mount the Boxer‐16 on an H‐frame, the top and bottom

mounting brackets are used. Follow company practice or the

steps below to mount the Boxer‐16 cabinet on an H‐frame. See

Figure 15 for an H‐frame mounting drawing. If the installation

includes the battery box, attach the battery box to the cabinet

prior to mounting the conjoined units to the H‐Frame.

1. Determine exact mounting location in H‐frame. Select and

mark the exact horizontal and vertical final mounting loca

tion within the H‐frame. The spacing between the top and

bottom horizontal‐rail mounting holes should be 39” (on

centers). Westell recommends a height of 30” from the

ground. In addition to leaving a comfortable installer

working height, leave adequate space under Boxer‐16 for

cable access, as well as in front of the cabinet to allow the

door to open, and at the sides in the event of any multiple

installations.

2. Remove knock‐outs. See the steps in Paragraph 3.5 (Re

moving the Knock‐outs) to remove the knock‐outs where

any cable access holes (or holes for mounting the optional

battery box) are desired.

3. Prepare the H‐frame mounting hardware. Bring the ap

propriate rail nuts (to secure the cabinet to the H‐frame)

to the installation site. The mounting hardware must be

able to support the weight of the cabinet plus the weight of

the added internal equipment. Insert at least three rail

nuts into each rail (compress the spring on the nuts as

needed) and place them at the desired mounting location.

4. Lift cabinet. Lift the cabinet to the mounting height. If us

ing lift equipment, use two cables or straps of equal length,

one connected to each lift ear, for a balanced symmetrical

lift. The lift ears are provided at the top of the cabinet, one

at each side wall, and each lift ear has a 2” hole in it.

5. Attach cabinet to H‐frame rails. Align the holes in the cabi

net's top mounting bracket with the holes in the inserted

rail nuts in the H‐frame rails, then insert and install an ap

propriate bolt through each set of aligned holes. Westell

recommends a minimum of 3 mounting bolts per mount

ing flange (top and bottom). Tighten hardware appro‐

priately. Repeat for the bottom mounting bracket and H‐

frame rail. Verify the cabinet is in the proper horizontal

position, make any needed adjustments, then securely

tighten all mounting hardware.

6. Test installation firmness. Test the installation by attempt

ing to move the cabinet. Correct any looseness, if

detected. Tighten all bolts again.

7. Determine next step. If ground, power, and communica

tions cables and internal equipment will not be connected

and mounted at this time, proceed to the next step to final

ize the cabinet installation. If ground, power, and

communications cables and internal equipment will be