Section VEU-E30-20A 030-101705 Rev. C R

40908IARC

11. Insert all Network cables (or pigtails) into their proper cou-

plers on the Network side of the compartment divider wall.

12. If no Customer connections are to be made at this time, secure

the divider wall by tightening the two locking screws.

13. After all connections are made, secure/lock the large exterior

Network door.

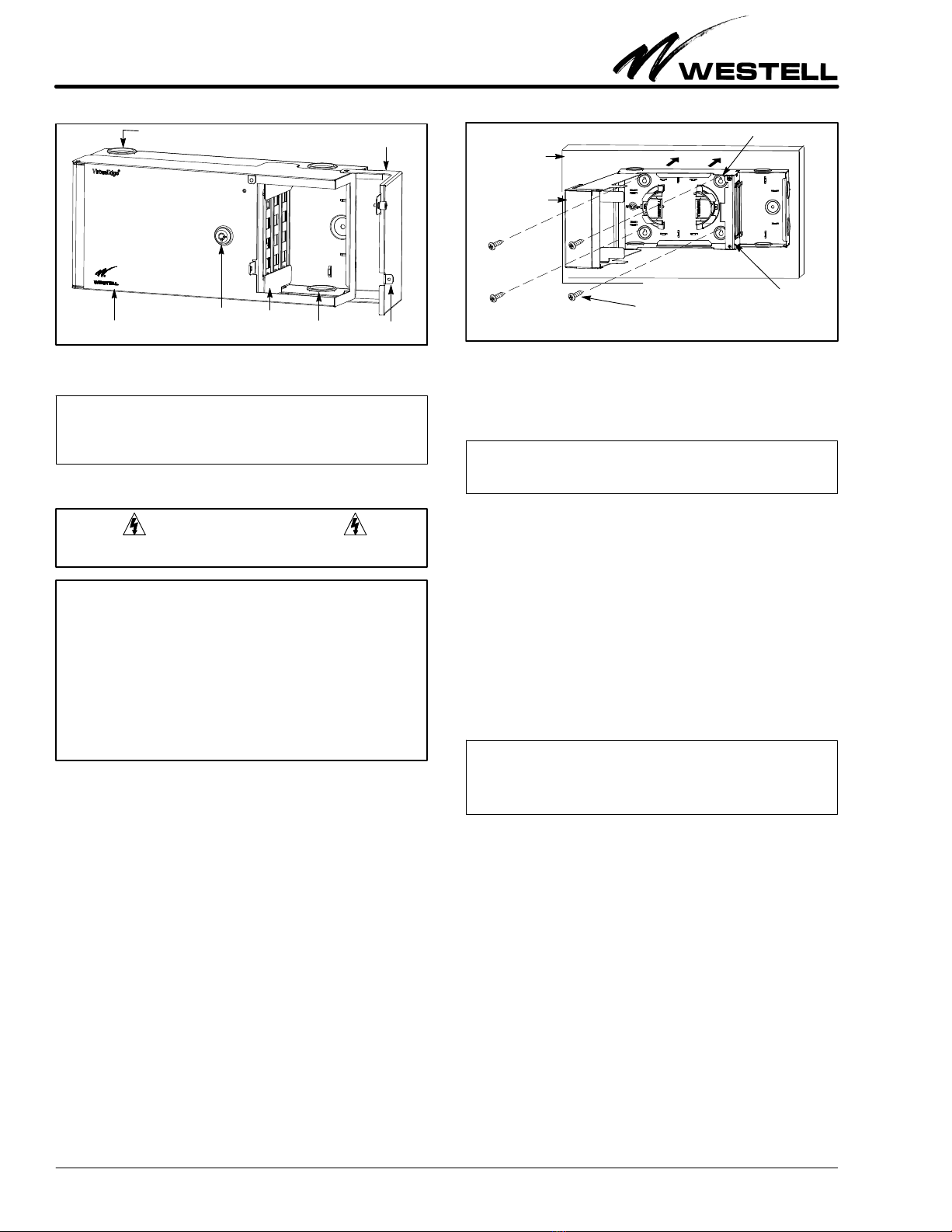

2.4.2 Making Customer Interface Connections

The Customer wiring and termination connections are made in

the right-side compartment of the enclosure.

1. Open the Customer-side door (see Figure 2) by unscrewing

the two screws and removing any optional padlock.

2. Using any of cable access holes, with a sharp object or knife

carefully cut one or two slits through the rubber grommet pro-

vided in the cable access hole. Make the slit just large enough

to allow the wires and cables to fit through the grommet.

3. Route all Customer wires or cables through the grommet.

4. Attach or secure each Customer’s cable plug or connector to

the appropriate customer-side coupler on the LGX-type pan-

el mounted on the compartment divider wall.

5. Per company practice, use the tie-downs located on the wall

near each cable access hole to secure the cable(s) as it enters

the enclosure.

6. After all Customer connections are made, secure and lock all

doors.

3. CUSTOMER & TECHNICAL SERVICES

3.1 Customer Assistance. For technical or customer assistance

is required, contact Westell by calling or using one of the follow-

ing options:

Voice: (800) 377-8766

For additional information about Westell, visit the Westell

World Wide Website at http://www.Westell.com.

3.2 Part Numbers. This equipment is identified by a part num-

ber (A90-VEUE30), which consists of an issue letter of the

equipment (A), the assembly type (90), and the specific model

number (VEUE30). When a change is made to the product

which changes the form, fit, or function of the product, the issue

letter is incremented by one. Please indicate the issue level and

model number when making inquiries about the equipment.

3.3 Part Numbers

4. WARRANTY & REPAIRS

4.1 Warranty. Westell warrants this product to be defect free

at shipment time, and warrants the product to be fully func-

tional for the time period specified by the terms and conditions

governing the product sale. Equipment repairs/modifications

by unauthorized persons will void the warranty.

4.2 Repair and Return. Westell will repair or replace this unit

without cost during the warranty period if the unit is defective

for any reason other than abuse, improper use, or improper

installation. To return defective equipment, first request a Re-

turn Material Authorization (RMA) number from Westell by

calling or using one of the options shown below. Once an RMA

number is obtained, return the defective unit (freight prepaid),

along with a brief problem description, to the address we will

provide to you when you contact us.

Voice: (630) 375-4457

Replacements will be shipped in the fastest manner consistent

with the urgency of the situation. Westell will continue to repair

or replace faulty equipment beyond the warranty period for a

nominal charge. Contact Westell for details.

5. SPECIFICATIONS

To order units, call the telephone number shown in Paragraph

3.1 and please specify the part number shown in Table 2. The

physical specifications are shown in Table 1.

Physical Feature U.S. Metric

Height 7.25 inches 18.4 cm

Width (closed) 18 inches 45.7 cm

Depth (including locks) 5.5 inches 14 cm

Weight (approx.) 7.5 pounds 3.4 Kilograms

Operating Temp. -40°to +167°F-40°to +75°C

Humidity 5 to 95% (non-condensing)

Table 1. Physical Specifications

Part # Description

A90-VEUE30 VirtualEdger12-port wall-mount universal enclosure

with interior 2-piece fiber spool, 3 LGXr-type panels (4

ports each), full-size Network door and smaller

customer door.

A90-VECE30 VirtualEdger12-port wall-mount universal enclosure

with interior 12-splice fiber tray, 2-piece fiber spool, 3

LGX-type panels (4 ports each), 4 SC couplers, fiber

pigtail, fiber cable compression fitting, and full-size

door.

Other Panels, and Panel Accessories and Options*

A90-VE118BNC6 LGX-type panel with 6 BNC couplers

A90-VE118SCU6 LGX-type panel with 6 SC/UPC couplers

A90-VE118SCA6 LGX-type panel with 6 SC/APC couplers

A90-VE118SCA8 LGX-type panel with 8 SC/APC couplers

A90-VECMSPTY00 Fiber splice tray with holders for 12 splices

A90-VECMSPTY01 Same as above tray (12 splices)

but with a mounting bracket.

023-700200 Fiber cable, 4 SC male connector to stub (2 meters)

A90-VECPL5E10 CAT 5e RJ48 Keystone

style coupler (Qty = 10)

A90-VECPLBNC10 BNC COAX coupler

(Qty = 10)

A90-VECPLSC1 Fiber coupler with SC

connectors (Qty = 1)

A90-VECPLLC1 Fiber coupler with LC

connectors (Qty = 1)

A90-VECPL5EIDC10 CAT 5e coupler with IDC termination on Network side

(Qty = 10)

*A variety of cables and fiber jumpers also are available. Call Westell for details.

Table 2. Ordering and Option Information