fW'/

_.4

mE

NEW

FOR

1991

-

WESTERBEKE'S

MODEL

82B

FOUR

DIESEL

ENGINE

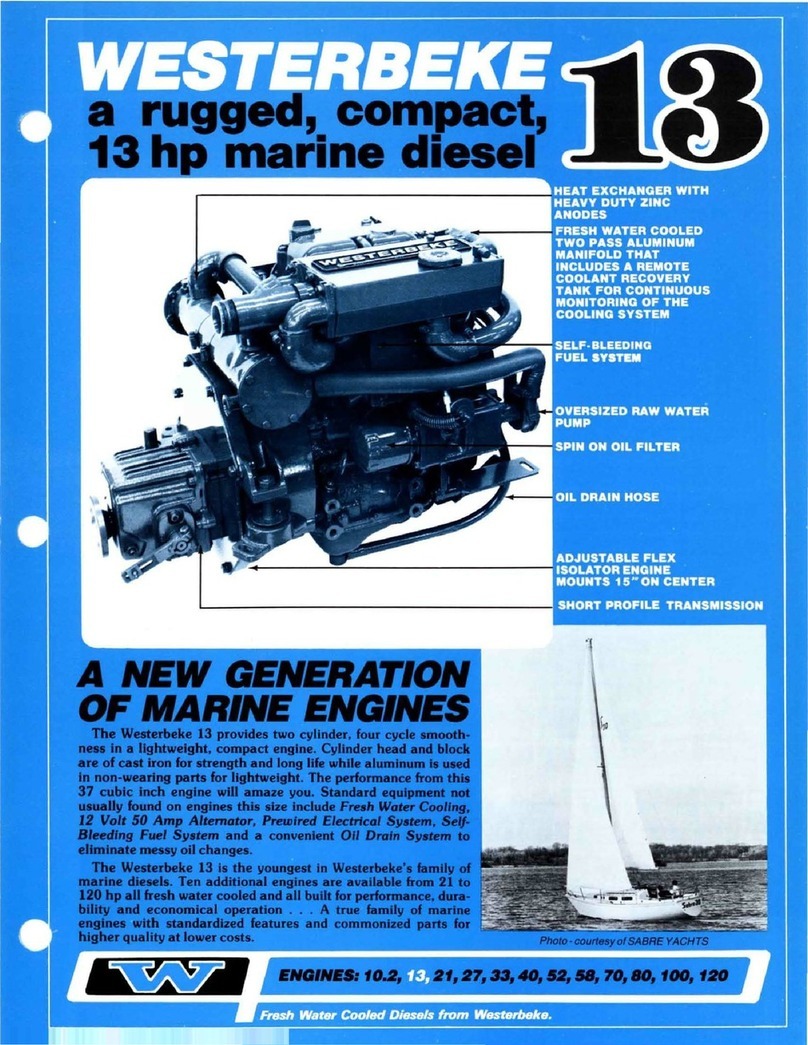

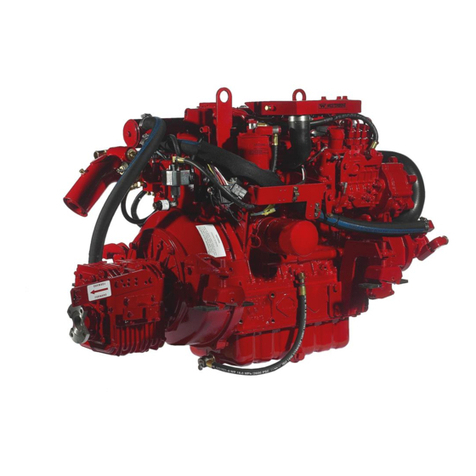

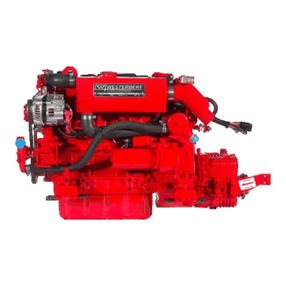

Having introduced the first small diesel engine for use in Auxiliary Sailboats in the late Fifties,

Westerbeke's goal has been to design dependable products with the important standard and

optional features needed by the customers. The

new

Model 82B Four

is

representative

of

that

effort. Here's why: • OVERSIZED COMPONENTS •

The transmission, heat exchanger and engine vibration mounts are all oversized for high

reliability. '

• SUPERIOR ENGINEERING •

The engine mounts are

of

the fail-safe type with the engine mounting bolt held captive so it

cannot pull apart. Because

of

the heavier loads, a

two

belt system provides the power for the

optional alternators and refrigeration compressor minimizing the chance

of

slippage and

premature belt failure.

• OUTSTANDING STANDARD FEATURES •

The 182 cubic inch engine

is

naturally aspirated which provides extra low end horsepower,

makes it simpler and easier to install and adds to its reliability. The engine

is

more tolerant

of

exhaust back pressure and a smaller two inch exhaust hose can be used saving cost, space and

the need for a large hole through the hull. Convenient domestic hot water heater connections

are part

of

the cooling system and are provided

on

the engine. Aselfbleeding fuel system

saves the owner the hassle of purging air from the engine fuel system

when

changing filters

or

when the engine

is

inadvertently run out

of

fuel. The engine oil cooler

is

built into the

engine block for reliability and long life. Other features such

as

high coolant and low oil

pressure alarms, reliable glow plug starting aide, electric engine shut-off, transmission oil

cooler and much more are

all

included

as

standard. Most important

is

the "One

Side

Service"

feature for ease in performing daily service checks and routine maintenance.

• UNIQUE, FACTORY INSTALLED OPTIONS •

Achoice

of

anyone

of

four optional high output battery charging alternators are available in

place

of

the standard

51

ampere alternator. A90 ampere single output

is

one choice. The

other three choices are a 135, a 165

or

a 190 ampere alternator. These latter three alternators

all feature dual outputs, capable

of

charging

two

banks

of

batteries without using a battery

splitter. This means fewer connections and more efficient charging. Another important option

is

provisions for a rotary refrigeration compressor. Engine mounted, it adds

less

than three

inches to the installed height. Factory engineered and factory installed, the owner and builder

benefit from a complete and properly designed compressor drive.

• INSTALLER

FRIENDLY.

With the builder/installer

in

mind, Westerbeke has designed the mounting system to provide

common bed widths and heights. The engine beds are in line with the propeller shaft allowing

fore and aft engine positioning while still maintaining shaft alignment. The narrow profile

(only 23.3 inches wide, above the beds) minimizes installation space. Exhaust and water

connections for standard size hose are provided eliminating the need for additional fittings.

Flexible fuel connections ending in standard pipe threads are also supplied. The smaller two

inch exhaust hose permitted by the naturally aspirated engine

is

easy to install and saves space

as

well

as

cost. Important options are factory designed and installed and the engine comes

as

a complete package, ready to drop

on

the beds. The self bleeding fuel system saves time

during testing and commissioning.