1

Westin Automotive Products, Inc.

320 W. Covina Blvd

San Dimas, Ca. 91773

Thank you for choosing Westin products

for additional installation assistance please call

Customer Service (800) 793-7846

www.westinautomotive.com

P.N.: 75-5653401-RevA ECO #: W17-0067 DATE: 11/2/17

INSTALLATION INSTRUCTIONS

AUTOMOTIVE PRODUCTS,

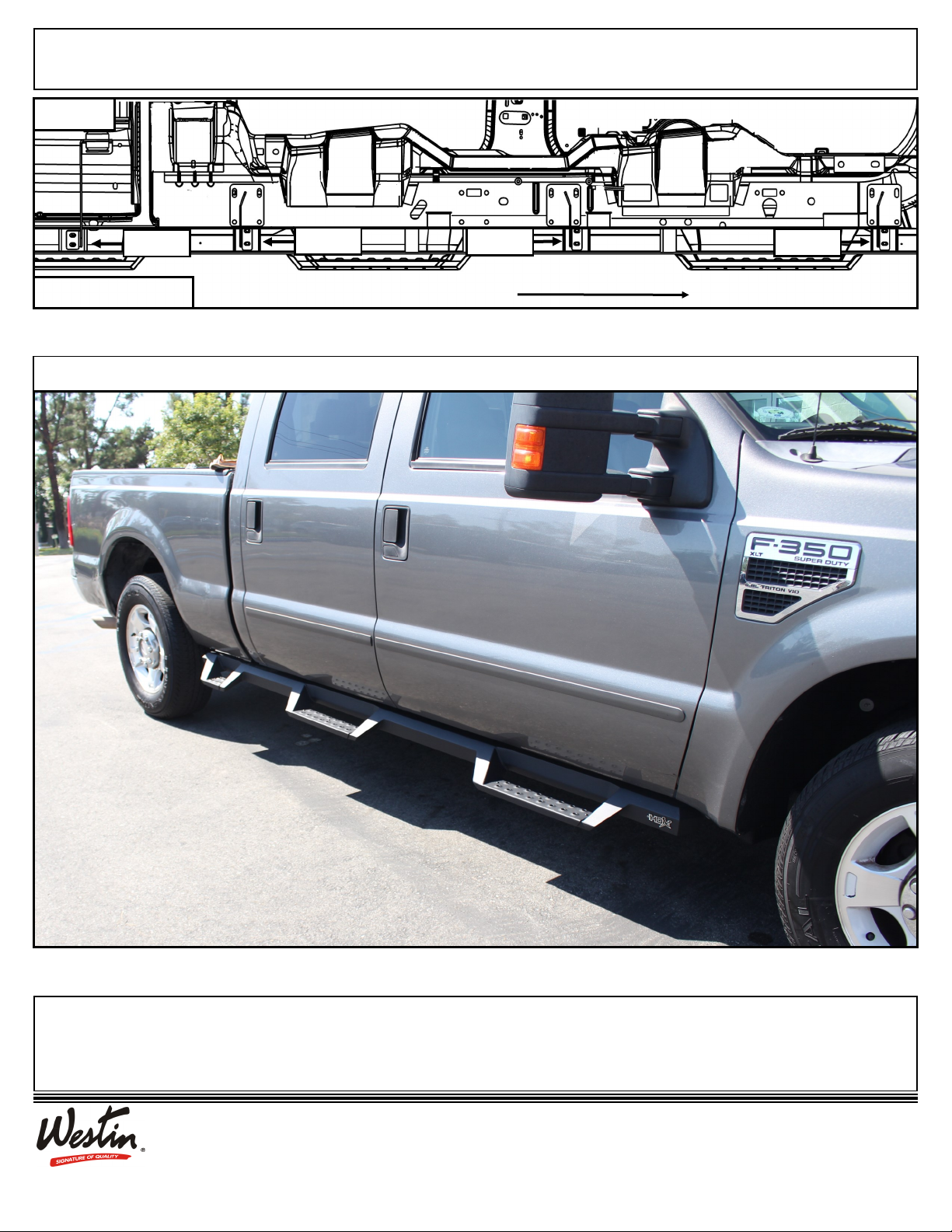

HDX DROP STEP WTW

APPLICATION:

1999-2016 Ford F250 / F350 / F450 / F550 - Super Crew 6 Ft Bed

PART NUMBER:

56-534015, 56-5340152

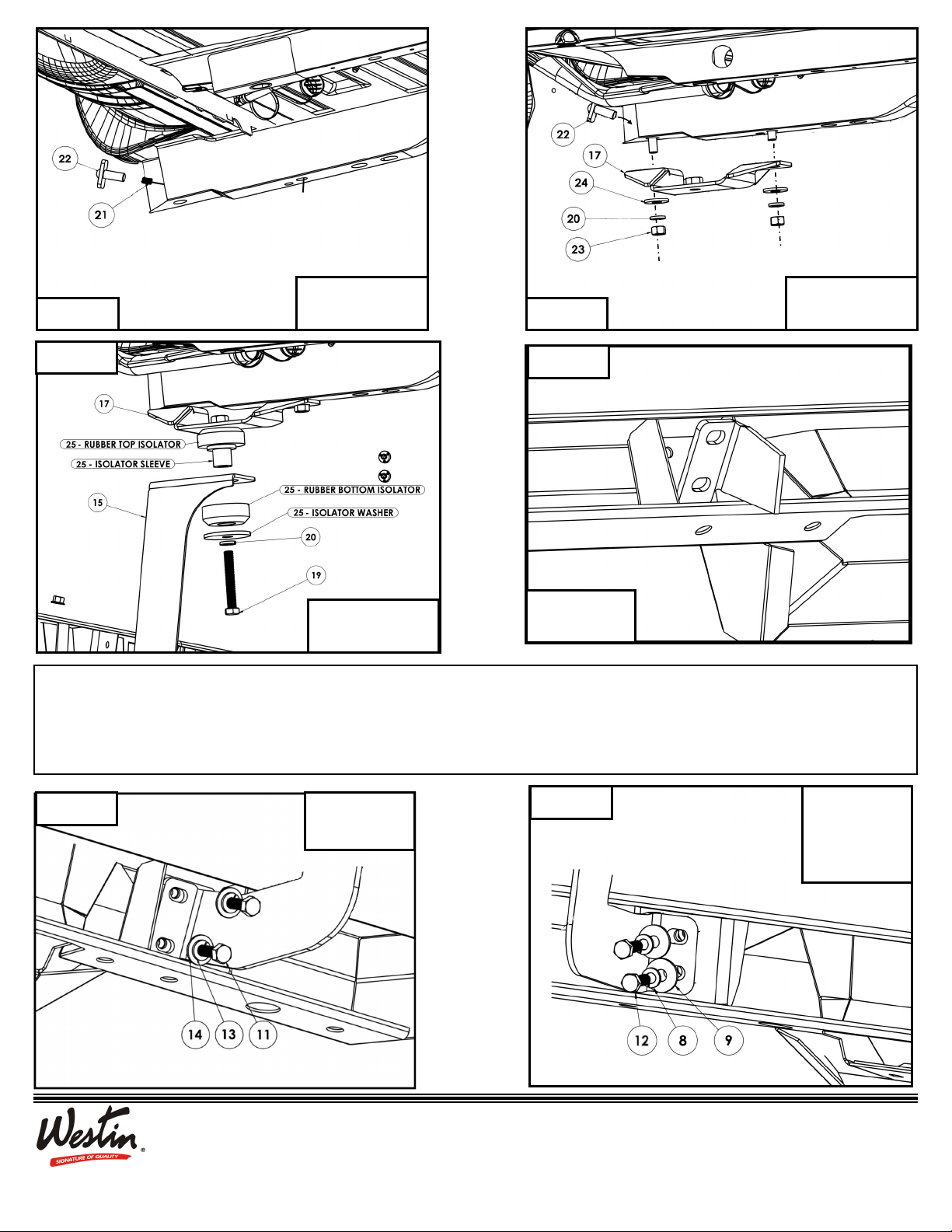

ITEM QUANTITY DESCRIPTION TOOLS NEEDED

12STEP BAR ASSEMBLY 3/8” DRIVE RATCHET

24MOUNTING BRACKET 1/2” DRIVE RATCHET

31DRIVER SIDE CENTER MOUNTING BRACKET TORQUE WRENCH

41PASSENGER SIDE CENTER MOUNTING BRACKET 13MM SOCKET

52FRONT SPACER PLATE ALLEN WRENCH

610 M8 EXTRUDED U-NUT (ZINC PLATED) SOCKET EXT.

712 M8 HEX NUT (BLACK ZINC) 13MM WRENCH

812 M8 BUTTON HEAD CAP SCREW (BLACK ZINC) 18MM SOCKET

912 M8 SPLIT LOCK WASHER (BLACK ZINC) 19MM SOCKET

10 24 M8 FLAT WASHER (BLACK ZINC) 18MM WRENCH

11 12 SHORT M8 HEX HEAD CAP SCREW (YELLOW ZINC) 19MM WRENCH

12 14 LONG M8 HEX HEAD CAP SCREW (YELLOW ZINC)

13 26 M8 SPLIT LOCK WASHER (YELLOW ZINC)

14 26 M8 FLAT WASHER (YELLOW ZINC)

15,16 2ISOLATOR BRACKET, DRIVER (15) AND PASSENGER (16)

17, 18 2TOP ISOLATOR MOUNT BRACKET, DRIVER (17) AND PASSENGER (18)

19 2M12 HEX HEAD CAP SCREW (YELLOW ZINC)

20 6M12 SPLIT LOCK WASHER (YELLOW ZINC)

21 2M12 FISH WIRE

22 4M12 BOLT PLATE

23 4M12 HEX NUT (YELLOW ZINC)

24 4M12 FLAT WASHER (YELLOW ZINC)

25 2ISOLATOR KIT

ANTI-SEIZE LUBRICANT MUST BE USED ON ALL STAINLESS STEEL FASTENERS TO PREVENT THREAD DAMAGE AND GALLING

CONTENT

ITEM 2 ITEM 3 ITEM 4 ITEM 5ITEM 1