Page 1

Aviation

Phone: (860) 526-9504

Internet: www.flyWAT.com

Sales/Service e-mail: info@flyWAT.com

©2014 Whelen Aerospace Technologies

Form No. 14793D (032719)

STC Manual

Installation Guide/ICA

WARNING: This product can expose you to chemicals including Methylene Chloride which is known to the State of California to cause cancer, and

Bisphenol A, which is known to the State of California to cause birth defects or other reproductive harm. For more information go to

www.P65Warnings.ca.gov.

INSTALLATION PROCEDURES: The following information

provides guidelines for the installation of the WAT LED PAR

Lights listed above. Please refer to the OEM manual for

your aircraft for specific removal and installation

instructions.

1. Choose the appropriate replacement light assembly.

Note: It is not required to change all PAR lights or Taxi

lights to the new LED PAR lights.

2. Place the lighting switch in the OFF position.

3. Inspect the housing, attachment points and retainer for

any signs of abnormal wear or damage.

4. Loosen or remove the hardware holding the lamp in

place. Take steps to ensure the retainer doesn't fall

from the lamp assembly before it is ready to be

removed.

5. Place retainer screws in a safe place.

6. Remove the lamp from the holder.

7. Note there are two wires connected to the (existing)

lamp. Using a multi-meter, identify the negative wire by

measuring continuity to ground. Place a piece of black

electrical tape around the wire identified as ground.

This is your negative lead.

8. Identify the positive wire as the remaining wire lead.

The LED light assembly is polarity sensitive, however

you will not damage the unit by reversing the polarity.

9. While holding the lamp, loosen the screws holding the

attached wires. Remove each wire from the lamp.

MODEL LIST

Model Part # Style Application Weight* VDC* Input Current*

P36P1L 01-0771833-10 PAR36 Landing 0.52 lbs. 14VDC 1.36 Amps

P36P1T 01-0771833-15 PAR36 Taxi 0.52 lbs. 14VDC 1.36 Amps

P36P2L 01-0771833-20 PAR36 Landing 0.52 lbs. 28VDC 0.68 Amps

P36P2T 01-0771833-25 PAR36 Taxi 0.52 lbs. 28VDC 0.68 Amps

P46P1L 01-0790750-10 PAR46 Landing 1.00 lbs. 14VDC 2.60 Amps

P46P2L 01-0790750-20 PAR46 Landing 1.00 lbs. 28VDC 1.25 Amps

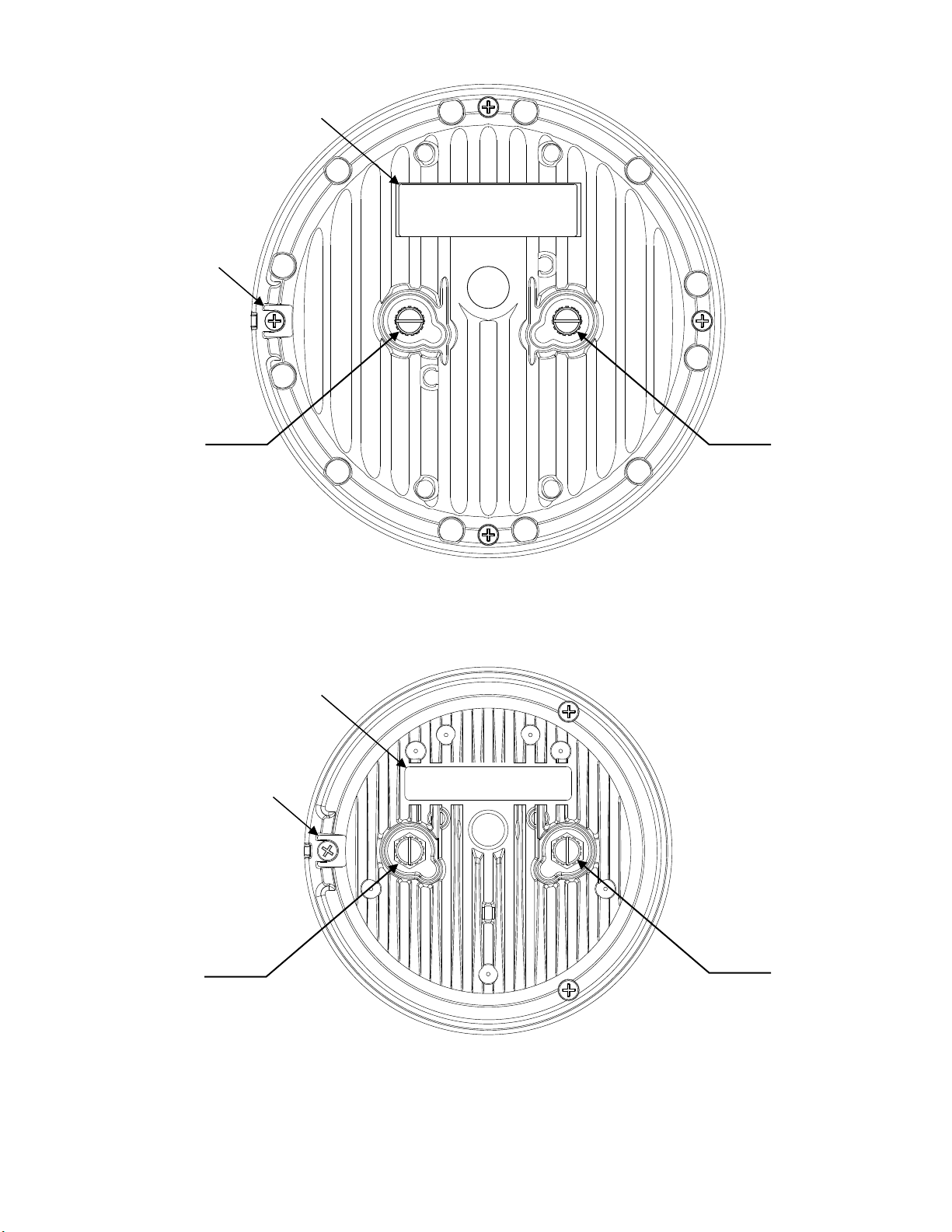

10. Secure the LED Light, note the terminal markings for

positive and negative, attach the negative marked wire

to the negative side terminal post of the LED Light.

11. Attach the positive wire to the positive side terminal

post. Remove tape or temporary placard which

identified the polarity of the wiring inside the housing.

12. If required, install the rubber gasket included with your

new LED Light around the LED Light assembly. A light

application of a common hand soap on the rubber may

aid in its fit into the light housing.

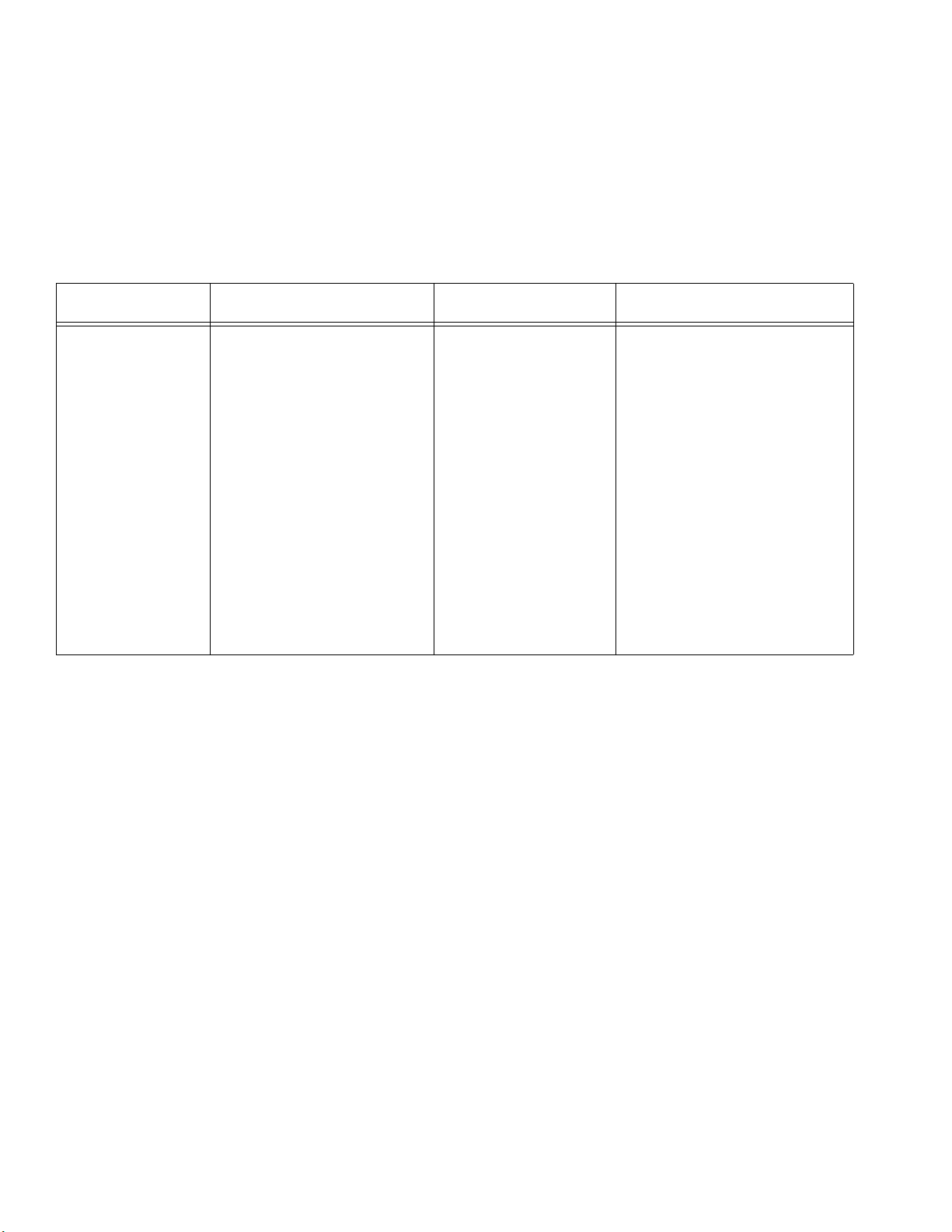

13. Place the LED light into the housing ensuring the key

(of the assembly) matches the key of the housing.

Proper orientation of the lamp is necessary for beam

orientation to be left and right of centerline while in

operation. For a Taxi light, the ‘lines’ of the inner optic

should be orientated vertically to produce a horizontal

light beam.

14. Secure the retainer. Care should be taken to tighten the

screw only to the point the retainer does not turn with

hand pressure. Over-tightening may stress the

polycarbonate lens of the LED Light.

15. Place the light switch in the ON position and verify

proper operation of the WAT LED lamp.

16. Determine that the Landing or Taxi light characteristics

have not been substantially affected, per 14CFR

23.1383.

17. If required, update aircraft records utilizing FAA Field

Approval (Form 337) or equivalent.

*NOMINAL